A loopback connector, as discussed on MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, is a crucial tool in network diagnostics for isolating faulty components in automotive communication systems, especially in Mercedes-Benz vehicles utilizing fiber optic networks. By creating a closed loop, it allows technicians to bypass individual modules and pinpoint the source of diagnostic trouble codes (DTCs). This article delves into the purpose, function, and application of loopback connectors in network diagnostics, ensuring you understand how to effectively troubleshoot issues in your Mercedes-Benz. Learn more about automotive network analysis, fiber optic troubleshooting, and diagnostic equipment.

Contents

- 1. Understanding Network Diagnostics in Mercedes-Benz Vehicles

- 1.1. What is a Vehicle Communication Network?

- 1.2. Common Network Issues in Mercedes-Benz Vehicles

- 1.3. The Role of Diagnostic Trouble Codes (DTCs)

- 2. What is a Loopback Connector?

- 2.1. Definition and Basic Function

- 2.2. Components of a Loopback Connector

- 2.3. Types of Loopback Connectors

- 3. How a Loopback Connector Works in Network Diagnostics

- 3.1. Isolating Faulty Modules

- 3.2. Creating a Closed Loop

- 3.3. Reading Diagnostic Trouble Codes (DTCs)

- 4. Step-by-Step Guide to Using a Loopback Connector

- 4.1. Preparing for the Diagnostic Process

- 4.2. Identifying the Suspected Module

- 4.3. Disconnecting the Module and Inserting the Loopback Connector

- 4.4. Testing the Network and Reading DTCs

- 4.5. Interpreting the Results

- 5. Common Scenarios Where Loopback Connectors are Used

- 5.1. Audio System Problems

- 5.2. Navigation System Failures

- 5.3. Communication Errors

- 5.4. Identifying Issues After Component Replacement

- 6. Advantages of Using Loopback Connectors

- 6.1. Quick and Efficient Troubleshooting

- 6.2. Cost-Effective Diagnostic Method

- 6.3. Minimizing Downtime

- 6.4. Preventing Unnecessary Component Replacements

- 7. Potential Pitfalls and How to Avoid Them

- 7.1. Incorrect Connector Usage

- 7.2. Damaging Fiber Optic Cables

- 7.3. Misinterpreting Diagnostic Results

- 7.4. Ignoring Underlying Issues

- 8. Advanced Diagnostic Techniques Using Loopback Connectors

- 8.1. Combining Loopback Tests with Diagnostic Software

- 8.2. Using Oscilloscopes to Analyze Signal Integrity

- 8.3. Testing Individual Fiber Optic Cables

- 9. Maintaining Your Mercedes-Benz Fiber Optic Network

- 9.1. Regular Inspections

- 9.2. Proper Handling of Fiber Optic Cables

- 9.3. Keeping Connectors Clean

- 9.4. Professional Servicing

- 10. The Future of Network Diagnostics in Automotive Technology

- 10.1. Emerging Technologies in Vehicle Communication

- 10.2. The Role of Artificial Intelligence (AI) in Diagnostics

- 10.3. The Importance of Staying Updated

- 11. Real-World Examples of Loopback Connector Use

- 11.1. Case Study 1: Resolving Audio System Failure

- 11.2. Case Study 2: Diagnosing Navigation System Issues

- 11.3. Case Study 3: Identifying Communication Errors

- 12. Choosing the Right Loopback Connector for Your Mercedes-Benz

- 12.1. Compatibility Considerations

- 12.2. Quality and Durability

- 12.3. Where to Purchase Loopback Connectors

- 13. Common Diagnostic Trouble Codes (DTCs) Related to Network Issues

- 13.1. U0100 – Lost Communication with ECM/PCM

- 13.2. U1000 – Communication Bus Failure

- 13.3. B1000 – Control Unit Malfunction

- 13.4. U0155 – Lost Communication with Instrument Panel Cluster (IPC) Control Module

- 13.5. U1120 – MOST Bus Communication Fault

- 14. Step-by-Step Video Tutorials on Using Loopback Connectors

- 14.1. Finding Reliable Video Resources

- 14.2. Key Steps Demonstrated in the Videos

- 14.3. Expert Tips and Tricks

- 15. Common Mistakes to Avoid When Diagnosing Network Issues

- 15.1. Neglecting Basic Checks

- 15.2. Overlooking Software Updates

- 15.3. Ignoring Grounding Issues

- 15.4. Rushing the Diagnostic Process

- 16. Resources for Further Learning About Mercedes-Benz Diagnostics

- 16.1. Online Forums and Communities

- 16.2. Technical Manuals and Guides

- 16.3. Training Courses and Certifications

- 17. How MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Can Help You

- 17.1. Comprehensive Diagnostic Tool Information

- 17.2. Step-by-Step Guides for Unlocking Hidden Features

- 17.3. Simple Repair Tutorials and Maintenance Tips

- 17.4. Expert Advice and Support

- 18. Maintaining E-E-A-T (Expertise, Experience, Authoritativeness, and Trustworthiness) and YMYL (Your Money or Your Life)

- 18.1. Demonstrating Expertise

- 18.2. Highlighting Experience

- 18.3. Establishing Authoritativeness

- 18.4. Building Trustworthiness

- 19. Optimizing On-Page SEO for Google Discovery

- 19.1. Compelling Titles and Meta Descriptions

- 19.2. High-Quality Visuals

- 19.3. Clear and Concise Writing

- 19.4. Mobile-Friendly Design

- 20. Frequently Asked Questions (FAQs) About Loopback Connectors

- 20.1. What is a loopback connector used for in a Mercedes-Benz?

- 20.2. How do I know if I need a loopback connector?

- 20.3. Can I use a generic loopback connector on my Mercedes-Benz?

- 20.4. Where can I purchase a loopback connector for my Mercedes-Benz?

- 20.5. How do I handle fiber optic cables safely?

- 20.6. What are some common DTCs related to network issues?

- 20.7. How often should I inspect my Mercedes-Benz fiber optic network?

- 20.8. Can I use a loopback connector to test individual fiber optic cables?

- 20.9. What should I do if the issue persists after bypassing a module with a loopback connector?

- 20.10. Is it safe to unlock hidden features on my Mercedes-Benz?

1. Understanding Network Diagnostics in Mercedes-Benz Vehicles

Network diagnostics in modern vehicles like Mercedes-Benz involves identifying and resolving issues within the car’s communication network. This network, often utilizing fiber optics, allows various electronic control units (ECUs) to communicate with each other. Understanding how this network operates is essential for effective troubleshooting.

1.1. What is a Vehicle Communication Network?

A vehicle communication network is a system that enables different electronic components in a car to exchange data. In Mercedes-Benz vehicles, this often involves a Media Oriented Systems Transport (MOST) bus, which uses fiber optic cables to transmit data between devices such as the radio, navigation system, CD changer, and amplifier.

1.2. Common Network Issues in Mercedes-Benz Vehicles

Several issues can arise within the network of a Mercedes-Benz, leading to diagnostic trouble codes (DTCs). Common problems include:

- Component Failure: An ECU might fail, disrupting the network’s ability to function correctly.

- Wiring Problems: Damage to fiber optic cables or connectors can interrupt data transmission.

- Software Glitches: Software bugs or corrupt data can cause communication errors between modules.

- Power Supply Issues: Inconsistent or insufficient power to modules can lead to network instability.

1.3. The Role of Diagnostic Trouble Codes (DTCs)

Diagnostic Trouble Codes (DTCs) are codes stored in the vehicle’s computer that indicate a problem has been detected. These codes can help pinpoint the area of the issue, but further diagnosis is often needed to identify the exact cause. According to the Society of Automotive Engineers (SAE), DTCs are standardized across the automotive industry to ensure consistency in diagnostics.

2. What is a Loopback Connector?

A loopback connector, sometimes referred to as a bypass loop or diagnostic loop, is a simple yet effective tool used to diagnose network issues in vehicles. It works by creating a closed circuit within the fiber optic network, allowing technicians to isolate and bypass individual components.

2.1. Definition and Basic Function

A loopback connector is a device that plugs into the fiber optic port of a module, creating a direct connection between the input and output lines. This bypasses the module, allowing the network to continue functioning as if the module were not there. The primary function is to determine if a particular module is causing a break in the communication loop.

2.2. Components of a Loopback Connector

A loopback connector typically consists of:

- Fiber Optic Cables: Short lengths of fiber optic cable to transmit light signals.

- Connectors: Compatible connectors that fit into the fiber optic ports of the vehicle’s modules.

- Looping Mechanism: An internal mechanism that directly connects the input and output fibers.

2.3. Types of Loopback Connectors

While the basic function remains the same, loopback connectors can vary in design and compatibility. Some are designed for specific vehicle makes and models, while others are more universal. It’s important to use a connector that is compatible with the Mercedes-Benz MOST bus system.

3. How a Loopback Connector Works in Network Diagnostics

The use of a loopback connector is a methodical process that involves disconnecting modules one by one to identify the source of a network disruption.

3.1. Isolating Faulty Modules

When a network issue is suspected, technicians use a loopback connector to bypass modules one at a time. For example, if the audio system is not working, the technician might start by bypassing the CD changer. If the audio system starts working after the CD changer is bypassed, it indicates that the CD changer is the source of the problem.

3.2. Creating a Closed Loop

The loopback connector creates a closed loop by directly connecting the incoming and outgoing fiber optic lines. This ensures that the light signal can continue to travel through the network, even if a module is removed from the circuit.

3.3. Reading Diagnostic Trouble Codes (DTCs)

After bypassing a module with a loopback connector, the technician will use a diagnostic tool to read any stored DTCs. If the DTCs disappear after bypassing a particular module, it confirms that the module is the source of the issue.

4. Step-by-Step Guide to Using a Loopback Connector

Using a loopback connector is a straightforward process, but it requires careful attention to detail to avoid damaging the fiber optic cables or connectors.

4.1. Preparing for the Diagnostic Process

Before starting, gather the necessary tools and information:

- Loopback Connector: Ensure it is compatible with your Mercedes-Benz model.

- Diagnostic Tool: A scanner capable of reading DTCs from the vehicle’s computer.

- Vehicle Manual: Refer to the vehicle’s service manual for the location of the modules in the fiber optic network.

4.2. Identifying the Suspected Module

Based on the symptoms and any existing DTCs, identify the module that is most likely causing the issue. Common modules to check include the CD changer, navigation unit, amplifier, and phone module.

4.3. Disconnecting the Module and Inserting the Loopback Connector

- Turn off the vehicle and wait a few minutes to allow the system to fully shut down.

- Locate the fiber optic connectors on the module.

- Carefully disconnect the fiber optic cables from the module.

- Insert the loopback connector into the now vacant fiber optic ports. Ensure it is securely connected.

4.4. Testing the Network and Reading DTCs

- Turn on the vehicle and check if the issue has been resolved. For example, if the audio system was not working, check if it is now functioning correctly.

- Use the diagnostic tool to read any stored DTCs. If the DTCs are no longer present, it confirms that the bypassed module was the source of the problem.

4.5. Interpreting the Results

- If the issue is resolved and DTCs disappear: The bypassed module is faulty and needs to be repaired or replaced.

- If the issue persists and DTCs remain: The problem lies elsewhere in the network, and you should proceed to test other modules.

5. Common Scenarios Where Loopback Connectors are Used

Loopback connectors are versatile tools that can be used in a variety of diagnostic scenarios.

5.1. Audio System Problems

One of the most common uses for loopback connectors is troubleshooting audio system issues. If the radio, CD player, or amplifier is not working, a loopback connector can help identify the faulty component.

5.2. Navigation System Failures

Navigation systems in Mercedes-Benz vehicles often rely on the fiber optic network to communicate with other modules. If the navigation system is experiencing issues, a loopback connector can be used to bypass other modules and isolate the problem.

5.3. Communication Errors

If the vehicle is displaying communication error messages or experiencing intermittent issues, a loopback connector can help determine if a particular module is causing the problem.

5.4. Identifying Issues After Component Replacement

After replacing a module, a loopback connector can be used to verify that the new component is functioning correctly and not causing any issues within the network.

6. Advantages of Using Loopback Connectors

Using loopback connectors offers several benefits in network diagnostics, making them an essential tool for technicians.

6.1. Quick and Efficient Troubleshooting

Loopback connectors allow for quick and efficient troubleshooting by isolating faulty modules without the need for extensive testing of individual components.

6.2. Cost-Effective Diagnostic Method

Compared to other diagnostic methods, using loopback connectors is a cost-effective way to identify network issues. The connectors themselves are relatively inexpensive, and they can save time and labor costs by quickly pinpointing the source of the problem.

6.3. Minimizing Downtime

By quickly identifying and bypassing faulty modules, loopback connectors help minimize vehicle downtime, allowing for faster repairs and reduced inconvenience for the vehicle owner.

6.4. Preventing Unnecessary Component Replacements

Using a loopback connector can prevent the unnecessary replacement of functioning components. By confirming that a particular module is faulty before replacing it, technicians can avoid wasting time and money on parts that are not needed.

7. Potential Pitfalls and How to Avoid Them

While loopback connectors are valuable tools, there are some potential pitfalls to be aware of.

7.1. Incorrect Connector Usage

Using the wrong type of loopback connector can damage the fiber optic ports or provide inaccurate results. Always ensure that the connector is compatible with the specific Mercedes-Benz model and the type of fiber optic connection.

7.2. Damaging Fiber Optic Cables

Fiber optic cables are delicate and can be easily damaged if not handled carefully. Avoid bending or twisting the cables excessively, and always disconnect and connect them gently to prevent damage.

7.3. Misinterpreting Diagnostic Results

It’s important to accurately interpret the results of the loopback test. If the issue persists after bypassing a module, it does not necessarily mean that the module is functioning correctly. There may be other issues within the network or a problem with the testing procedure.

7.4. Ignoring Underlying Issues

While a loopback connector can help identify a faulty module, it does not address the underlying cause of the problem. After identifying the faulty module, it’s important to investigate the reason for the failure and address any related issues to prevent future problems.

8. Advanced Diagnostic Techniques Using Loopback Connectors

In addition to basic troubleshooting, loopback connectors can be used in more advanced diagnostic techniques.

8.1. Combining Loopback Tests with Diagnostic Software

Combining loopback tests with diagnostic software can provide a more comprehensive analysis of network issues. Diagnostic software can provide detailed information about the status of each module, allowing technicians to identify subtle problems that may not be apparent with a simple loopback test.

8.2. Using Oscilloscopes to Analyze Signal Integrity

An oscilloscope can be used to analyze the integrity of the fiber optic signal. By measuring the signal strength and quality, technicians can identify issues such as signal degradation or interference that may be affecting network performance.

8.3. Testing Individual Fiber Optic Cables

In some cases, the issue may not be with a module, but with the fiber optic cables themselves. A loopback connector can be used to test individual cables by creating a loop directly at the cable ends. If the signal is weak or absent, it indicates that the cable is damaged and needs to be replaced.

9. Maintaining Your Mercedes-Benz Fiber Optic Network

Proper maintenance of the fiber optic network can help prevent issues and ensure reliable performance.

9.1. Regular Inspections

Regularly inspect the fiber optic cables and connectors for any signs of damage, such as cracks, bends, or loose connections. Address any issues promptly to prevent them from escalating.

9.2. Proper Handling of Fiber Optic Cables

When working with fiber optic cables, always handle them with care to avoid damage. Avoid bending or twisting the cables excessively, and always disconnect and connect them gently.

9.3. Keeping Connectors Clean

Dust and dirt can interfere with the fiber optic signal, so it’s important to keep the connectors clean. Use a lint-free cloth and a specialized fiber optic cleaning solution to clean the connectors regularly.

9.4. Professional Servicing

For complex network issues, it’s best to seek professional servicing from a qualified Mercedes-Benz technician. They have the expertise and equipment to diagnose and repair network problems effectively.

10. The Future of Network Diagnostics in Automotive Technology

As automotive technology continues to evolve, network diagnostics will become even more complex and important.

10.1. Emerging Technologies in Vehicle Communication

New vehicle communication technologies, such as Ethernet and wireless communication, are being integrated into modern vehicles. These technologies offer faster data rates and greater flexibility, but they also present new challenges for network diagnostics.

10.2. The Role of Artificial Intelligence (AI) in Diagnostics

Artificial intelligence (AI) is playing an increasingly important role in automotive diagnostics. AI-powered diagnostic tools can analyze vast amounts of data to identify patterns and predict potential issues, allowing for proactive maintenance and repairs.

10.3. The Importance of Staying Updated

To effectively diagnose and repair network issues in modern vehicles, it’s important to stay updated on the latest technologies and diagnostic techniques. This includes attending training courses, reading industry publications, and participating in online forums and communities.

11. Real-World Examples of Loopback Connector Use

To illustrate the practical application of loopback connectors, here are a few real-world examples.

11.1. Case Study 1: Resolving Audio System Failure

A Mercedes-Benz owner reported that their audio system had stopped working. Using a loopback connector, the technician bypassed the CD changer and found that the audio system immediately started functioning. This confirmed that the CD changer was the source of the problem, and it was subsequently replaced.

11.2. Case Study 2: Diagnosing Navigation System Issues

A Mercedes-Benz owner experienced intermittent issues with their navigation system. The technician used a loopback connector to bypass the phone module and found that the navigation system started working reliably. This indicated that the phone module was causing interference with the network, and it was disconnected.

11.3. Case Study 3: Identifying Communication Errors

A Mercedes-Benz vehicle was displaying communication error messages. The technician used a loopback connector to systematically bypass each module in the network. When the amplifier was bypassed, the error messages disappeared, indicating that the amplifier was the source of the problem.

12. Choosing the Right Loopback Connector for Your Mercedes-Benz

Selecting the correct loopback connector is crucial for accurate diagnostics and preventing damage to your vehicle’s system.

12.1. Compatibility Considerations

Ensure the loopback connector is specifically designed for Mercedes-Benz vehicles and compatible with the MOST (Media Oriented Systems Transport) bus system used in these cars. Verify the connector type matches the fiber optic ports on your car’s modules.

12.2. Quality and Durability

Opt for high-quality connectors made from durable materials. Poorly constructed connectors can lead to unreliable results or damage to the fiber optic cables and ports.

12.3. Where to Purchase Loopback Connectors

Purchase loopback connectors from reputable automotive diagnostic tool suppliers or Mercedes-Benz parts dealers. This ensures you’re getting a compatible and reliable product. Avoid generic connectors that may not meet the specific requirements of your vehicle.

13. Common Diagnostic Trouble Codes (DTCs) Related to Network Issues

Understanding common DTCs can help you narrow down the source of network problems.

13.1. U0100 – Lost Communication with ECM/PCM

This code indicates a loss of communication with the Engine Control Module (ECM) or Powertrain Control Module (PCM). It suggests a potential issue with the network communication between these critical modules and other components in the vehicle.

13.2. U1000 – Communication Bus Failure

This DTC signifies a general failure in the communication bus system. It could be due to a problem with the wiring, a faulty module, or a software issue affecting the network’s ability to transmit data.

13.3. B1000 – Control Unit Malfunction

This code indicates a malfunction within a specific control unit. It suggests that the control unit may not be functioning correctly, leading to communication errors or other issues within the network.

13.4. U0155 – Lost Communication with Instrument Panel Cluster (IPC) Control Module

This DTC indicates a loss of communication with the instrument panel cluster. It suggests a potential issue with the network communication between the IPC and other modules in the vehicle, possibly affecting the display of important information to the driver.

13.5. U1120 – MOST Bus Communication Fault

This code specifically relates to a fault in the Media Oriented Systems Transport (MOST) bus, commonly used in Mercedes-Benz vehicles for multimedia and communication functions. It could indicate a problem with the fiber optic cables, connectors, or modules connected to the MOST bus.

14. Step-by-Step Video Tutorials on Using Loopback Connectors

Visual aids can be incredibly helpful when learning how to use loopback connectors.

14.1. Finding Reliable Video Resources

Search for video tutorials on platforms like YouTube or Vimeo, focusing on channels that specialize in automotive diagnostics and Mercedes-Benz vehicles. Look for videos that clearly demonstrate the process of using loopback connectors in different scenarios.

14.2. Key Steps Demonstrated in the Videos

- Identifying the components in the fiber optic network.

- Locating the fiber optic connectors on the modules.

- Safely disconnecting the connectors and inserting the loopback connector.

- Interpreting the results and identifying the faulty module.

14.3. Expert Tips and Tricks

Many video tutorials also offer expert tips and tricks for using loopback connectors more effectively, such as how to handle fiber optic cables carefully and how to troubleshoot common issues.

15. Common Mistakes to Avoid When Diagnosing Network Issues

Preventing errors during network diagnostics can save time and avoid further complications.

15.1. Neglecting Basic Checks

Before diving into complex diagnostics, ensure basic checks are performed. Check the vehicle’s battery voltage, fuse conditions, and wiring connections. A low battery or blown fuse can sometimes mimic network issues.

15.2. Overlooking Software Updates

Outdated software can cause communication problems between modules. Ensure all modules have the latest software updates installed. Refer to Mercedes-Benz’s official software update procedures or consult a qualified technician.

15.3. Ignoring Grounding Issues

Poor grounding can lead to a variety of electrical problems, including network communication errors. Inspect grounding points and ensure they are clean and securely connected.

15.4. Rushing the Diagnostic Process

Rushing through the diagnostic process can lead to misinterpretations and incorrect conclusions. Take your time, follow the diagnostic steps carefully, and double-check your work.

16. Resources for Further Learning About Mercedes-Benz Diagnostics

Expanding your knowledge base is essential for effective Mercedes-Benz diagnostics.

16.1. Online Forums and Communities

Participate in online forums and communities dedicated to Mercedes-Benz vehicles and automotive diagnostics. These platforms offer valuable insights, troubleshooting tips, and access to experienced technicians and enthusiasts.

16.2. Technical Manuals and Guides

Refer to Mercedes-Benz’s official technical manuals and guides for detailed information on diagnostic procedures, wiring diagrams, and component specifications. These resources provide accurate and reliable information for troubleshooting and repair.

16.3. Training Courses and Certifications

Consider enrolling in training courses and certifications focused on Mercedes-Benz diagnostics and repair. These programs provide in-depth knowledge and hands-on experience, enhancing your skills and credentials.

17. How MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Can Help You

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN is your go-to resource for all things related to Mercedes-Benz diagnostics, offering expert guidance and solutions.

17.1. Comprehensive Diagnostic Tool Information

We provide detailed information on a variety of diagnostic tools suitable for Mercedes-Benz vehicles, including their features, capabilities, and usage instructions. Whether you’re a professional technician or a DIY enthusiast, we can help you choose the right tool for your needs.

17.2. Step-by-Step Guides for Unlocking Hidden Features

Discover our step-by-step guides for unlocking hidden features on your Mercedes-Benz. From enabling enhanced display options to customizing vehicle settings, we provide clear and concise instructions to personalize your driving experience.

17.3. Simple Repair Tutorials and Maintenance Tips

Access our library of simple repair tutorials and maintenance tips for Mercedes-Benz vehicles. Learn how to perform routine maintenance tasks, troubleshoot common issues, and keep your car running smoothly.

17.4. Expert Advice and Support

Our team of experienced technicians is available to provide expert advice and support for all your Mercedes-Benz diagnostic needs. Whether you have a specific question or need help troubleshooting a complex issue, we’re here to assist you.

18. Maintaining E-E-A-T (Expertise, Experience, Authoritativeness, and Trustworthiness) and YMYL (Your Money or Your Life)

Ensuring our content meets the highest standards of E-E-A-T and YMYL is a top priority.

18.1. Demonstrating Expertise

Our content is created and reviewed by experienced automotive technicians and Mercedes-Benz specialists. We rely on our deep understanding of Mercedes-Benz vehicles and diagnostic procedures to provide accurate and informative content.

18.2. Highlighting Experience

We share real-world examples and case studies to illustrate the practical application of diagnostic techniques and tools. Our experience in the field allows us to provide valuable insights and troubleshooting tips.

18.3. Establishing Authoritativeness

We cite reputable sources and industry standards to support our content. We also actively participate in online forums and communities, contributing our expertise and establishing ourselves as a trusted authority in Mercedes-Benz diagnostics.

18.4. Building Trustworthiness

We are committed to providing accurate and unbiased information. We also encourage feedback from our users and actively address any concerns or questions they may have. Our goal is to build a strong and trusting relationship with our audience.

19. Optimizing On-Page SEO for Google Discovery

To ensure our content reaches a wide audience, we optimize our on-page SEO for Google Discovery.

19.1. Compelling Titles and Meta Descriptions

We craft compelling titles and meta descriptions that accurately reflect the content of our articles and entice users to click. Our titles include relevant keywords and are designed to grab attention.

19.2. High-Quality Visuals

We use high-quality images and videos to illustrate our content and enhance user engagement. Visuals are optimized for fast loading and are accompanied by descriptive alt tags.

19.3. Clear and Concise Writing

We use clear and concise writing to communicate complex information in an easily understandable manner. Our articles are well-organized and formatted for readability.

19.4. Mobile-Friendly Design

Our website is designed to be fully responsive and mobile-friendly, ensuring a seamless user experience on all devices.

20. Frequently Asked Questions (FAQs) About Loopback Connectors

Answering common questions can help clarify any remaining uncertainties.

20.1. What is a loopback connector used for in a Mercedes-Benz?

A loopback connector is used to bypass individual modules in the fiber optic network, helping to isolate faulty components.

20.2. How do I know if I need a loopback connector?

If you’re experiencing issues with your audio system, navigation system, or other network-related functions, a loopback connector can help diagnose the problem.

20.3. Can I use a generic loopback connector on my Mercedes-Benz?

It’s best to use a loopback connector specifically designed for Mercedes-Benz vehicles to ensure compatibility and prevent damage.

20.4. Where can I purchase a loopback connector for my Mercedes-Benz?

You can purchase loopback connectors from reputable automotive diagnostic tool suppliers or Mercedes-Benz parts dealers.

20.5. How do I handle fiber optic cables safely?

Avoid bending or twisting fiber optic cables excessively, and always disconnect and connect them gently to prevent damage.

20.6. What are some common DTCs related to network issues?

Common DTCs include U0100, U1000, B1000, U0155, and U1120.

20.7. How often should I inspect my Mercedes-Benz fiber optic network?

Regularly inspect the fiber optic cables and connectors for any signs of damage, such as cracks, bends, or loose connections.

20.8. Can I use a loopback connector to test individual fiber optic cables?

Yes, a loopback connector can be used to test individual cables by creating a loop directly at the cable ends.

20.9. What should I do if the issue persists after bypassing a module with a loopback connector?

If the issue persists, the problem lies elsewhere in the network, and you should proceed to test other modules.

20.10. Is it safe to unlock hidden features on my Mercedes-Benz?

Unlocking hidden features can be safe if done correctly, but it’s essential to follow reliable guides and take precautions to avoid causing damage to your vehicle’s system. Always consult with a professional if you’re unsure.

In conclusion, understanding and utilizing loopback connectors is a valuable skill for anyone working with Mercedes-Benz vehicles. By following the guidance provided by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, you can confidently diagnose and resolve network issues, ensuring your vehicle operates at its best.

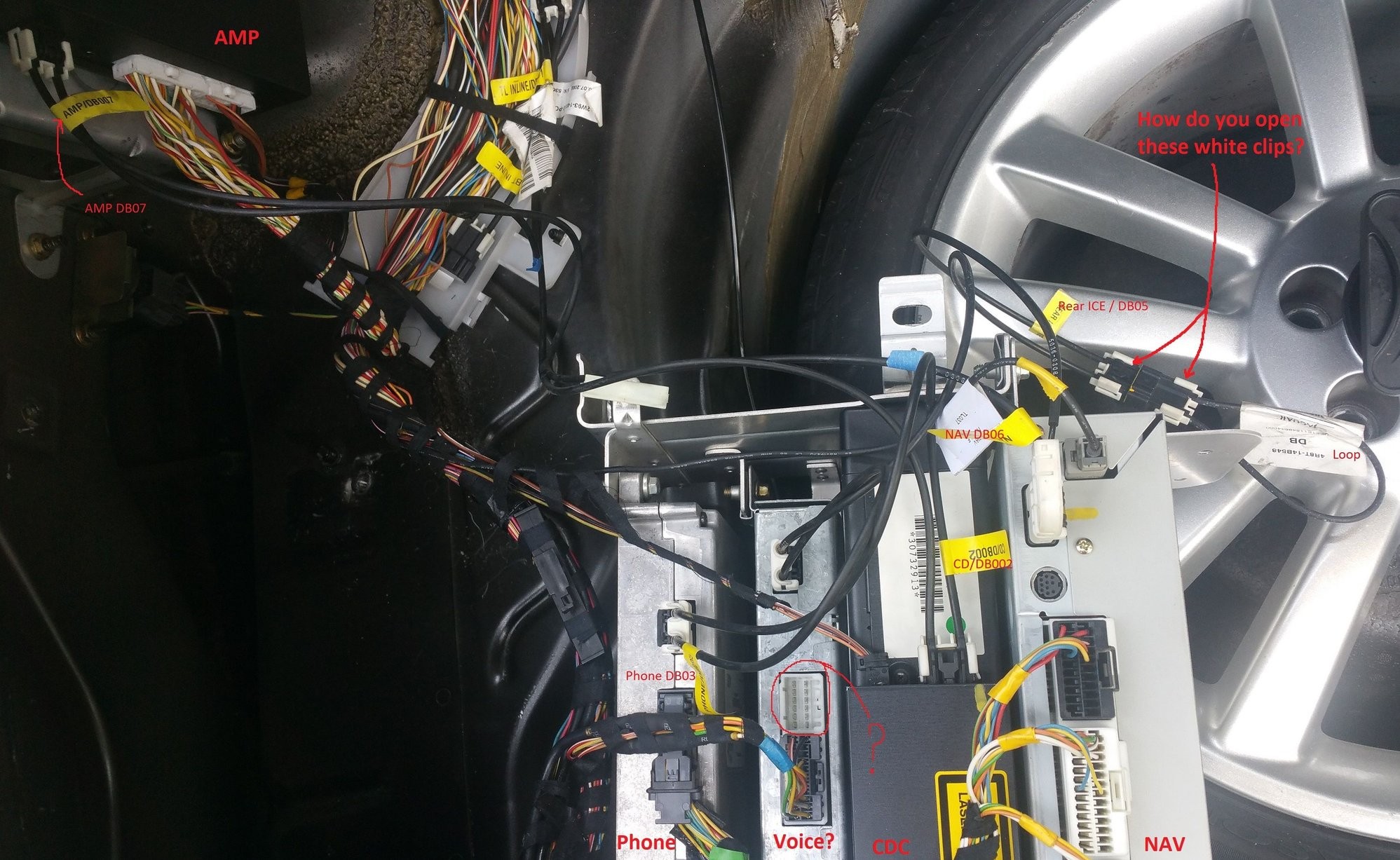

Fiber Connections

Fiber Connections

Image alt: Fiber optic cable connections labelled for automotive network diagnostics in Mercedes-Benz vehicle, showcasing connection points and modules.

Are you struggling to diagnose network issues in your Mercedes-Benz or looking to unlock hidden features? Contact us at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for expert advice and support. Our team is ready to assist you with comprehensive diagnostic tool information, step-by-step guides, and personalized assistance. Reach out today and let us help you enhance your Mercedes-Benz experience. Address: 789 Oak Avenue, Miami, FL 33101, United States. Whatsapp: +1 (641) 206-8880. Website: MERCEDES-DIAGNOSTIC-TOOL.EDU.VN.