DTCs related to the high-voltage interlock loop (HVIL) circuits in electric vehicles (EVs) and hybrids are very critical due to safety concerns, and at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we can help you address them. A faulty HVIL can lead to unexpected shutdowns and potential safety hazards, making their prompt diagnosis and resolution essential. With proper diagnostic tools, you can maintain the safety and reliability of your electric or hybrid Mercedes-Benz and the diagnostic process.

Contents

- 1. Understanding the High-Voltage Interlock Loop (HVIL)

- 1.1. Purpose of the HVIL

- 1.2. Components of the HVIL

- 1.3. How the HVIL Works

- 2. Diagnostic Trouble Codes (DTCs) Related to HVIL

- 2.1. Common HVIL-Related DTCs

- 2.2. Interpreting HVIL DTCs

- 2.3. Tools for Diagnosing HVIL Issues

- 3. Why HVIL DTCs Are Critical

- 3.1. Safety Implications

- 3.2. Potential Damage to Vehicle Systems

- 3.3. Fire Hazards

- 4. Diagnosing and Repairing HVIL Issues

- 4.1. Step-by-Step Diagnostic Process

- 4.2. Safety Precautions

- 4.3. Common Repair Procedures

- 5. Preventive Maintenance for HVIL Systems

- 5.1. Regular Inspections

- 5.2. Maintenance Tips

- 5.3. Benefits of Preventive Maintenance

- 6. Case Studies: Real-World Examples of HVIL Issues

- 6.1. Case Study 1: P0A0A Code on a Hybrid Vehicle

- 6.2. Case Study 2: Intermittent HVIL Fault on an Electric Vehicle

- 6.3. Case Study 3: HVIL Insulation Fault on a Hybrid Vehicle

- 7. The Role of MERCEDES-DIAGNOSTIC-TOOL.EDU.VN in HVIL Diagnostics

- 7.1. Diagnostic Tools and Equipment

- 7.2. Training and Support

- 7.3. Access to Information

- 8. Future Trends in HVIL Technology

- 8.1. Wireless HVIL Systems

- 8.2. Integrated HVIL Systems

- 8.3. Advanced Diagnostic Capabilities

- 9. FAQ: High-Voltage Interlock Loop (HVIL)

- 9.1. What is the High-Voltage Interlock Loop (HVIL)?

- 9.2. Why is the HVIL important?

- 9.3. What are the common DTCs related to HVIL?

- 9.4. How do I diagnose HVIL issues?

- 9.5. What tools are needed to diagnose HVIL issues?

- 9.6. What safety precautions should I take when working with HVIL systems?

- 9.7. How can I prevent HVIL issues?

- 9.8. What are the future trends in HVIL technology?

- 9.9. Can MERCEDES-DIAGNOSTIC-TOOL.EDU.VN help with HVIL diagnostics?

- 9.10. Where can I find more information about HVIL systems?

- 10. Conclusion: Prioritizing HVIL System Integrity

1. Understanding the High-Voltage Interlock Loop (HVIL)

The High-Voltage Interlock Loop (HVIL) is a crucial safety feature in electric vehicles (EVs) and hybrid electric vehicles (HEVs). It is designed to protect service technicians and vehicle occupants from high-voltage hazards by de-energizing the high-voltage system when a disconnection or fault is detected. Essentially, it’s a safety net that ensures high-voltage circuits are not exposed when they shouldn’t be.

1.1. Purpose of the HVIL

The primary purpose of the HVIL is to ensure that the high-voltage system is only active when all high-voltage components are properly connected and safe. The HVIL achieves this by creating a closed-loop circuit that monitors the integrity of the high-voltage system. If any part of the loop is broken, the system immediately shuts down the high voltage to prevent electrical shock or other hazards.

1.2. Components of the HVIL

The HVIL typically consists of the following components:

- HVIL Sense Wires: These are low-voltage wires that run along the high-voltage cables and connectors. They form the closed-loop circuit that is constantly monitored.

- Connectors with HVIL Contacts: High-voltage connectors are equipped with additional contacts for the HVIL circuit. These contacts ensure that the loop is complete when the connector is properly connected.

- Monitoring Module: This module monitors the continuity of the HVIL circuit. If the loop is broken, the module sends a signal to shut down the high-voltage system.

- High-Voltage Components: These components, such as the battery pack, inverter, and electric motor, are integrated into the HVIL system to ensure they are de-energized when a fault is detected.

1.3. How the HVIL Works

The HVIL operates on a simple principle: as long as the loop is complete, the high-voltage system can operate safely. When a connector is disconnected or a fault occurs, the loop is broken, and the monitoring module detects the open circuit. This triggers the system to shut down the high voltage, preventing any potential hazards.

The HVIL system is designed to be fail-safe. This means that if any component of the HVIL system fails, the high-voltage system will be shut down as a precaution. This ensures that even in the event of a failure, the system remains safe.

2. Diagnostic Trouble Codes (DTCs) Related to HVIL

Diagnostic Trouble Codes (DTCs) are codes generated by a vehicle’s onboard computer system to indicate a problem or malfunction. When it comes to HVIL circuits, specific DTCs can signal issues that require immediate attention. These codes are crucial for diagnosing and resolving problems within the high-voltage system of EVs and hybrids.

2.1. Common HVIL-Related DTCs

Several DTCs are commonly associated with HVIL issues. Here are a few examples:

- P0A0A: High Voltage Interlock Circuit Malfunction

- P0A0B: High Voltage Interlock Circuit High

- P0A0C: High Voltage Interlock Circuit Low

- P0A0D: High Voltage System Interlock Feedback Circuit Malfunction

These codes indicate that there is a problem with the HVIL circuit, such as an open circuit, short circuit, or other malfunction.

2.2. Interpreting HVIL DTCs

Interpreting HVIL DTCs requires a systematic approach. First, it’s essential to use a diagnostic scan tool to retrieve the specific DTCs stored in the vehicle’s computer system. Once the codes are retrieved, consult the vehicle’s service manual or a reliable database to understand the meaning of each code.

The service manual will provide detailed information about the possible causes of the DTC and the steps required to diagnose and repair the problem. It’s important to follow the diagnostic procedures outlined in the service manual to ensure accurate diagnosis and effective repair.

2.3. Tools for Diagnosing HVIL Issues

Diagnosing HVIL issues requires specialized tools and equipment. Here are some of the essential tools for diagnosing HVIL problems:

- Diagnostic Scan Tool: A diagnostic scan tool is essential for retrieving DTCs and monitoring the HVIL circuit.

- Multimeter: A multimeter is used to measure voltage, current, and resistance in the HVIL circuit.

- Insulation Tester: An insulation tester is used to check the insulation resistance of high-voltage cables and connectors.

- High-Voltage Gloves and Safety Gear: High-voltage gloves and other safety gear are essential for protecting technicians from electrical shock.

Using these tools, technicians can diagnose HVIL issues accurately and safely.

3. Why HVIL DTCs Are Critical

The criticality of HVIL DTCs stems from the inherent safety risks associated with high-voltage systems in EVs and hybrids. Ignoring these codes can lead to severe consequences, including electrical shock, system damage, and potential fire hazards. Therefore, understanding the implications of HVIL DTCs is crucial for maintaining vehicle safety and reliability.

3.1. Safety Implications

The primary concern with HVIL DTCs is the safety of technicians and vehicle occupants. The HVIL system is designed to prevent electrical shock by de-energizing the high-voltage system when a fault is detected. If the HVIL system is not functioning properly, technicians and occupants may be exposed to high-voltage hazards.

According to the National Highway Traffic Safety Administration (NHTSA), electrical shock is a significant risk associated with EVs and hybrids. In a report on electric vehicle safety, NHTSA noted that “high-voltage systems in EVs and hybrids can pose a significant electrical shock hazard if not properly handled.”

Therefore, it is essential to address HVIL DTCs promptly to ensure the safety of everyone who comes into contact with the vehicle.

3.2. Potential Damage to Vehicle Systems

In addition to safety concerns, HVIL DTCs can also indicate potential damage to vehicle systems. If the HVIL system is not functioning properly, the high-voltage system may not be de-energized in the event of a fault. This can lead to damage to high-voltage components such as the battery pack, inverter, and electric motor.

For example, if a connector is disconnected and the HVIL system does not shut down the high voltage, the exposed contacts can arc and cause damage to the connector and surrounding components. This can result in costly repairs and downtime.

3.3. Fire Hazards

Another potential consequence of ignoring HVIL DTCs is the risk of fire. If the HVIL system is not functioning properly, a short circuit or other fault can cause overheating and potentially lead to a fire.

The National Fire Protection Association (NFPA) has developed specific guidelines for handling EV and hybrid vehicle fires. According to NFPA, “EV and hybrid vehicle fires can be more difficult to extinguish than gasoline vehicle fires due to the high-voltage battery.”

Therefore, it is crucial to address HVIL DTCs promptly to prevent potential fire hazards.

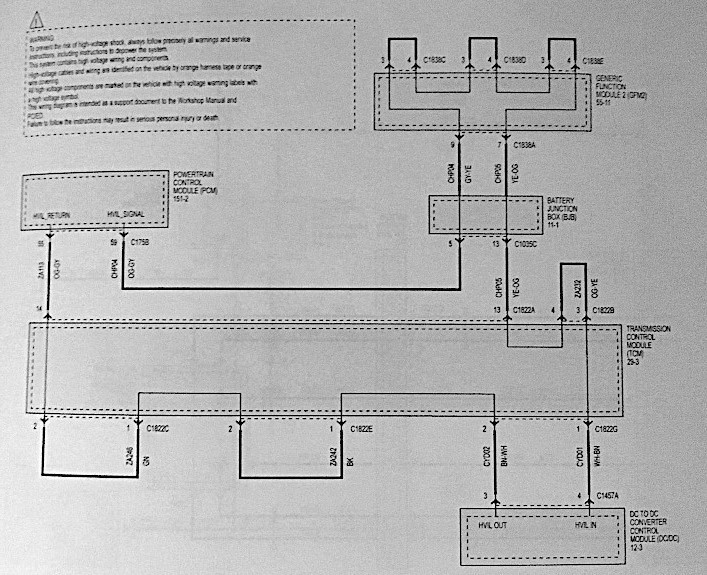

HVIL Wiring Diagram

HVIL Wiring Diagram

4. Diagnosing and Repairing HVIL Issues

Diagnosing and repairing HVIL issues requires a systematic approach, specialized tools, and a thorough understanding of the high-voltage system. Following the correct procedures and safety precautions is essential to ensure accurate diagnosis and effective repair.

4.1. Step-by-Step Diagnostic Process

The diagnostic process for HVIL issues typically involves the following steps:

- Retrieve DTCs: Use a diagnostic scan tool to retrieve the DTCs stored in the vehicle’s computer system.

- Consult Service Manual: Consult the vehicle’s service manual or a reliable database to understand the meaning of each DTC and the possible causes.

- Inspect Connectors and Wiring: Visually inspect the high-voltage connectors and wiring for signs of damage, corrosion, or loose connections.

- Test HVIL Circuit: Use a multimeter to test the continuity of the HVIL circuit and check for open circuits or short circuits.

- Isolate Fault: If a fault is detected, isolate the specific component or section of the circuit that is causing the problem.

- Repair or Replace Components: Repair or replace any damaged or faulty components, such as connectors, wiring, or sensors.

- Verify Repair: After completing the repair, use a diagnostic scan tool to clear the DTCs and verify that the HVIL system is functioning properly.

4.2. Safety Precautions

Working with high-voltage systems requires strict adherence to safety precautions. Here are some essential safety measures to follow:

- Wear High-Voltage Gloves: Always wear high-voltage gloves when working with high-voltage components.

- Use Insulated Tools: Use insulated tools to prevent electrical shock.

- Disconnect High Voltage: Disconnect the high-voltage system before working on any components.

- Follow Lockout/Tagout Procedures: Follow lockout/tagout procedures to ensure that the high-voltage system remains de-energized while you are working on it.

- Work in a Safe Area: Work in a well-ventilated area and avoid contact with flammable materials.

- Have a Partner: Work with a partner who can assist you in case of an emergency.

4.3. Common Repair Procedures

Common repair procedures for HVIL issues include:

- Replacing Damaged Connectors: Replace any connectors that are damaged, corroded, or have loose connections.

- Repairing Damaged Wiring: Repair any damaged wiring, such as frayed wires or broken insulation.

- Replacing Faulty Sensors: Replace any faulty sensors that are causing the HVIL system to malfunction.

- Reseating Connectors: Sometimes, simply reseating the connectors can resolve HVIL issues caused by loose connections.

- Applying Dielectric Grease: Applying dielectric grease to the connectors can help prevent corrosion and improve the connection.

5. Preventive Maintenance for HVIL Systems

Preventive maintenance is crucial for ensuring the long-term reliability and safety of HVIL systems. Regular inspections and maintenance can help identify potential problems before they lead to costly repairs or safety hazards.

5.1. Regular Inspections

Regular inspections of the HVIL system should include:

- Visual Inspection of Connectors and Wiring: Check for signs of damage, corrosion, or loose connections.

- Testing HVIL Circuit Continuity: Use a multimeter to test the continuity of the HVIL circuit and check for open circuits or short circuits.

- Insulation Testing: Use an insulation tester to check the insulation resistance of high-voltage cables and connectors.

- Checking for DTCs: Use a diagnostic scan tool to check for any stored DTCs related to the HVIL system.

5.2. Maintenance Tips

Here are some maintenance tips for HVIL systems:

- Keep Connectors Clean and Dry: Keep the connectors clean and dry to prevent corrosion.

- Apply Dielectric Grease: Apply dielectric grease to the connectors to help prevent corrosion and improve the connection.

- Replace Damaged Components: Replace any damaged components, such as connectors, wiring, or sensors, as soon as possible.

- Follow Manufacturer’s Recommendations: Follow the manufacturer’s recommendations for maintenance and inspection intervals.

5.3. Benefits of Preventive Maintenance

Preventive maintenance offers several benefits, including:

- Improved Safety: Regular inspections and maintenance can help identify and address potential safety hazards before they lead to accidents.

- Reduced Downtime: Preventive maintenance can help prevent unexpected breakdowns and reduce downtime.

- Lower Repair Costs: Identifying and addressing problems early can help prevent costly repairs.

- Extended Component Life: Regular maintenance can help extend the life of high-voltage components.

- Increased Reliability: Preventive maintenance can help ensure the long-term reliability of the HVIL system.

6. Case Studies: Real-World Examples of HVIL Issues

Examining real-world examples of HVIL issues can provide valuable insights into the types of problems that can occur and the steps required to resolve them. Here are a few case studies:

6.1. Case Study 1: P0A0A Code on a Hybrid Vehicle

A hybrid vehicle owner reported a P0A0A code (High Voltage Interlock Circuit Malfunction). The vehicle would occasionally shut down while driving, and the owner was concerned about safety.

Diagnosis:

- The technician retrieved the P0A0A code using a diagnostic scan tool.

- The technician consulted the vehicle’s service manual to understand the meaning of the code and the possible causes.

- The technician visually inspected the high-voltage connectors and wiring for signs of damage or loose connections.

- The technician used a multimeter to test the continuity of the HVIL circuit and found an open circuit in one of the connectors.

Repair:

- The technician replaced the faulty connector with a new one.

- The technician applied dielectric grease to the connector to help prevent corrosion and improve the connection.

- The technician used a diagnostic scan tool to clear the DTC and verify that the HVIL system was functioning properly.

Outcome:

The repair resolved the issue, and the vehicle no longer shut down while driving. The owner was pleased with the outcome and appreciated the technician’s thoroughness.

6.2. Case Study 2: Intermittent HVIL Fault on an Electric Vehicle

An electric vehicle owner reported an intermittent HVIL fault. The vehicle would occasionally display a warning message indicating a problem with the high-voltage system.

Diagnosis:

- The technician retrieved a stored DTC related to the HVIL system using a diagnostic scan tool.

- The technician consulted the vehicle’s service manual to understand the meaning of the code and the possible causes.

- The technician used a multimeter to monitor the HVIL circuit while wiggling the connectors and wiring.

- The technician found that the HVIL circuit would intermittently open when one of the connectors was wiggled.

Repair:

- The technician reseated the connector and applied dielectric grease to improve the connection.

- The technician secured the connector with a zip tie to prevent it from coming loose again.

- The technician used a diagnostic scan tool to clear the DTC and verify that the HVIL system was functioning properly.

Outcome:

The repair resolved the issue, and the vehicle no longer displayed the warning message. The owner was happy with the outcome and appreciated the technician’s attention to detail.

6.3. Case Study 3: HVIL Insulation Fault on a Hybrid Vehicle

A hybrid vehicle owner reported a problem with the high-voltage system. The vehicle would not start, and the owner suspected a problem with the HVIL system.

Diagnosis:

- The technician retrieved a stored DTC related to the HVIL system using a diagnostic scan tool.

- The technician consulted the vehicle’s service manual to understand the meaning of the code and the possible causes.

- The technician used an insulation tester to check the insulation resistance of the high-voltage cables and connectors.

- The technician found that the insulation resistance of one of the cables was below the specified value, indicating an insulation fault.

Repair:

- The technician replaced the faulty cable with a new one.

- The technician ensured that the cable was properly routed and secured to prevent chafing or damage.

- The technician used a diagnostic scan tool to clear the DTC and verify that the HVIL system was functioning properly.

Outcome:

The repair resolved the issue, and the vehicle started normally. The owner was relieved to have the problem fixed and appreciated the technician’s expertise.

7. The Role of MERCEDES-DIAGNOSTIC-TOOL.EDU.VN in HVIL Diagnostics

At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we understand the critical importance of HVIL systems in EVs and hybrids. Our expertise and resources can help you diagnose and repair HVIL issues effectively.

7.1. Diagnostic Tools and Equipment

We offer a wide range of diagnostic tools and equipment specifically designed for diagnosing HVIL issues. Our tools are compatible with Mercedes-Benz EVs and hybrids and provide accurate and reliable results.

Our diagnostic scan tools can retrieve DTCs, monitor the HVIL circuit, and perform other diagnostic functions. We also offer multimeters, insulation testers, and other specialized tools for diagnosing HVIL problems.

7.2. Training and Support

We provide comprehensive training and support to help you diagnose and repair HVIL issues. Our training programs cover the fundamentals of HVIL systems, diagnostic procedures, and repair techniques.

Our experienced technicians are available to provide technical support and answer your questions. We can help you troubleshoot HVIL problems, interpret DTCs, and perform repairs.

7.3. Access to Information

We provide access to a wealth of information about HVIL systems, including service manuals, technical bulletins, and diagnostic guides. Our resources can help you understand the intricacies of HVIL systems and diagnose problems accurately.

Our website, MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, is a valuable resource for information about HVIL systems and other automotive topics. You can find articles, videos, and other resources to help you stay informed and up-to-date.

8. Future Trends in HVIL Technology

As EV and hybrid technology continues to evolve, HVIL systems are also expected to advance. Here are some future trends in HVIL technology:

8.1. Wireless HVIL Systems

Wireless HVIL systems are being developed to eliminate the need for physical wires and connectors. These systems use wireless technology to monitor the integrity of the HVIL circuit and shut down the high voltage in the event of a fault.

Wireless HVIL systems offer several advantages, including reduced weight, improved reliability, and increased flexibility.

8.2. Integrated HVIL Systems

Integrated HVIL systems are being developed to integrate the HVIL function into other vehicle systems, such as the battery management system (BMS) and the motor control system.

Integrated HVIL systems offer several advantages, including reduced complexity, improved performance, and lower cost.

8.3. Advanced Diagnostic Capabilities

Future HVIL systems are expected to have advanced diagnostic capabilities, such as the ability to detect and diagnose faults in real-time. These systems will be able to provide detailed information about the nature and location of the fault, making it easier to repair.

Advanced diagnostic capabilities will help reduce downtime and improve the reliability of EVs and hybrids.

9. FAQ: High-Voltage Interlock Loop (HVIL)

Here are some frequently asked questions about High-Voltage Interlock Loop (HVIL):

9.1. What is the High-Voltage Interlock Loop (HVIL)?

The High-Voltage Interlock Loop (HVIL) is a safety feature in electric vehicles (EVs) and hybrid electric vehicles (HEVs) designed to protect service technicians and vehicle occupants from high-voltage hazards by de-energizing the high-voltage system when a disconnection or fault is detected.

9.2. Why is the HVIL important?

The HVIL is important because it prevents electrical shock and other hazards associated with high-voltage systems. It ensures that the high-voltage system is only active when all components are properly connected and safe.

9.3. What are the common DTCs related to HVIL?

Common DTCs related to HVIL include P0A0A (High Voltage Interlock Circuit Malfunction), P0A0B (High Voltage Interlock Circuit High), P0A0C (High Voltage Interlock Circuit Low), and P0A0D (High Voltage System Interlock Feedback Circuit Malfunction).

9.4. How do I diagnose HVIL issues?

Diagnosing HVIL issues requires a systematic approach, specialized tools, and a thorough understanding of the high-voltage system. The diagnostic process typically involves retrieving DTCs, consulting the service manual, inspecting connectors and wiring, and testing the HVIL circuit.

9.5. What tools are needed to diagnose HVIL issues?

Essential tools for diagnosing HVIL issues include a diagnostic scan tool, multimeter, insulation tester, and high-voltage gloves and safety gear.

9.6. What safety precautions should I take when working with HVIL systems?

When working with HVIL systems, it is essential to wear high-voltage gloves, use insulated tools, disconnect the high-voltage system, follow lockout/tagout procedures, work in a safe area, and have a partner.

9.7. How can I prevent HVIL issues?

Preventive maintenance is crucial for ensuring the long-term reliability and safety of HVIL systems. Regular inspections and maintenance can help identify potential problems before they lead to costly repairs or safety hazards.

9.8. What are the future trends in HVIL technology?

Future trends in HVIL technology include wireless HVIL systems, integrated HVIL systems, and advanced diagnostic capabilities.

9.9. Can MERCEDES-DIAGNOSTIC-TOOL.EDU.VN help with HVIL diagnostics?

Yes, at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we offer a wide range of diagnostic tools and equipment specifically designed for diagnosing HVIL issues. We also provide comprehensive training and support to help you diagnose and repair HVIL problems effectively.

9.10. Where can I find more information about HVIL systems?

You can find more information about HVIL systems on our website, MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, and in vehicle service manuals and technical bulletins.

10. Conclusion: Prioritizing HVIL System Integrity

In conclusion, DTCs related to high-voltage interlock loop (HVIL) circuits in EVs and hybrids are very critical due to safety concerns. These codes indicate potential problems with the high-voltage system that can lead to electrical shock, system damage, and fire hazards. Therefore, it is essential to address HVIL DTCs promptly and effectively.

At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we are committed to helping you diagnose and repair HVIL issues effectively. We offer a wide range of diagnostic tools and equipment, comprehensive training and support, and access to a wealth of information about HVIL systems.

Don’t compromise on safety when it comes to your electric or hybrid Mercedes-Benz. Contact us today at +1 (641) 206-8880 or visit our website at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN to learn more about how we can help you maintain the integrity of your HVIL system and ensure the safety of your vehicle. Our address is 789 Oak Avenue, Miami, FL 33101, United States. Let us help you keep your high-voltage systems running safely and efficiently! Contact us on Whatsapp for immediate assistance with diagnostic tools, unlocking hidden features, and expert repair and maintenance advice for your Mercedes-Benz.