Typical live data values for Mercedes EPB parameters depend on the specific vehicle model, year, and driving conditions; however, MERCEDES-DIAGNOSTIC-TOOL.EDU.VN can provide detailed insights into expected ranges for efficient diagnostics and repairs. Monitoring these parameters allows for accurate assessments of the Electronic Parking Brake (EPB) system’s health and functionality.

Contents

- 1. Understanding Live Data and EPB Systems in Mercedes-Benz

- 1.1 What is Live Data?

- 1.2 Introduction to Electronic Parking Brake (EPB) Systems

- 1.3 The Importance of Monitoring EPB Parameters

- 2. Key EPB Parameters to Monitor in Mercedes-Benz

- 2.1 Brake Motor Current

- 2.2 Brake Pad Wear

- 2.3 EPB Switch Status

- 2.4 System Voltage

- 3. Common Issues Indicated by Live Data Values

- 3.1 High Brake Motor Current: Potential Binding or Motor Failure

- 3.2 Low Brake Pad Wear Readings: Immediate Replacement Needed

- 3.3 Intermittent EPB Switch Signals: Switch or Wiring Problems

- 3.4 Voltage Fluctuations: Electrical System Issues

- 4. Tools and Equipment for Monitoring EPB Parameters

- 4.1 Diagnostic Scanners

- 4.2 Multimeters

- 4.3 Software Applications

- 5. Step-by-Step Guide to Monitoring EPB Parameters with MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

- 5.1 Connecting the Diagnostic Scanner

- 5.2 Accessing Live Data

- 5.3 Interpreting the Data

- 5.4 Utilizing MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Resources

- 6. Advanced Diagnostic Techniques for EPB Systems

- 6.1 Using Oscilloscopes for Signal Analysis

- 6.2 Performing Actuator Tests

- 6.3 Analyzing CAN Bus Communication

- 6.4 Using Thermal Imaging for Component Diagnosis

- 7. Preventive Maintenance Tips for Mercedes-Benz EPB Systems

- 7.1 Regular Inspections

- 7.2 Proper Lubrication

- 7.3 Timely Component Replacements

- 7.4 Keeping the System Clean

- 8. Case Studies: Diagnosing EPB Issues with Live Data

- 8.1 Case Study 1: High Brake Motor Current in a 2018 C-Class

- 8.2 Case Study 2: Intermittent EPB Failure in a 2020 E-Class

- 8.3 Case Study 3: Brake Pad Wear Sensor Fault in a 2019 GLC

- 9. How MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Can Help You

- 9.1 Comprehensive Diagnostic Guides

- 9.2 Expert Support

- 9.3 Diagnostic Tool Recommendations

- 9.4 Service Scheduling

- 10. FAQ: Troubleshooting Mercedes-Benz EPB Systems

- 10.1 What Does It Mean When the EPB Light Is On?

- 10.2 How Do I Reset the EPB System After Replacing Brake Pads?

- 10.3 Can I Manually Release the EPB if It Fails?

- 10.4 What Are the Common Causes of EPB Failure?

- 10.5 How Often Should I Service My EPB System?

Do you want to access in-depth information on Mercedes EPB parameters? This comprehensive guide delivers precise details on expected live data values, helping you maintain your Mercedes-Benz with confidence. Dive into our expertly curated content to ensure your EPB system operates at its best. Plus, discover exclusive services and tools at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for optimized performance.

1. Understanding Live Data and EPB Systems in Mercedes-Benz

Live data refers to the real-time information streamed from a vehicle’s control modules, providing critical insights into its operational status. The Electronic Parking Brake (EPB) system is a modern feature in Mercedes-Benz vehicles, replacing the traditional handbrake lever with electronic controls. This system enhances safety, convenience, and overall vehicle performance.

1.1 What is Live Data?

Live data, also known as real-time data or dynamic data, is the stream of information provided by a vehicle’s electronic control units (ECUs). According to a study by the Society of Automotive Engineers (SAE) in 2022, accessing and interpreting live data is crucial for effective diagnostics. This data includes parameters such as sensor readings, actuator states, and calculated values that reflect the vehicle’s operational conditions.

For example, the engine control unit (ECU) provides live data on engine temperature, RPM, and throttle position. This real-time feedback helps technicians diagnose issues and optimize performance. The ability to monitor these parameters in real-time enables more precise and efficient troubleshooting.

1.2 Introduction to Electronic Parking Brake (EPB) Systems

The Electronic Parking Brake (EPB) system replaces the traditional manual handbrake with an electronic switch and actuators. As highlighted in a 2021 Mercedes-Benz technical document, the EPB system offers enhanced safety and convenience features such as automatic engagement and disengagement. The system utilizes electronic motors to apply and release the brakes, offering a more precise and controlled braking force.

Key benefits of EPB systems include:

- Enhanced Safety: Prevents vehicle rollaway by automatically engaging on inclines.

- Convenience: Simplified operation with a push of a button.

- Integration: Seamless integration with other vehicle systems like ABS and ESP.

1.3 The Importance of Monitoring EPB Parameters

Monitoring EPB parameters through live data is essential for diagnosing and maintaining the system’s health. According to Bosch Automotive Handbook (10th Edition), real-time monitoring allows technicians to identify potential issues before they lead to system failures. This proactive approach can save time and money by addressing problems early.

Key reasons for monitoring EPB parameters:

- Early Fault Detection: Identifies issues like motor failures or sensor malfunctions.

- Performance Verification: Ensures the EPB system applies and releases correctly.

- Safety Assurance: Guarantees the system functions reliably under various conditions.

2. Key EPB Parameters to Monitor in Mercedes-Benz

Monitoring the right parameters is crucial for effective EPB system diagnostics. These parameters provide insights into the system’s operation, helping you identify potential issues early. Key parameters include brake motor current, brake pad wear, switch status, and system voltage.

2.1 Brake Motor Current

Brake motor current measures the electrical current drawn by the EPB motors when applying or releasing the brakes. According to a case study by Continental Automotive in 2023, abnormal current levels often indicate motor wear or mechanical resistance within the braking system. Monitoring this parameter helps identify potential motor failures or binding issues.

Typical values and what they indicate:

- Normal Range: 2-5 Amps during application/release.

- High Current: Indicates motor strain, binding brakes, or internal motor fault.

- Low Current: Suggests a wiring issue, poor connection, or failing motor.

2.2 Brake Pad Wear

Brake pad wear sensors monitor the thickness of the brake pads and provide feedback to the EPB system. A 2022 report by Brembo highlights that excessive brake pad wear can affect the EPB system’s ability to apply the correct braking force. Monitoring this parameter ensures timely replacement of worn brake pads.

Typical values and what they indicate:

- Normal Range: Varies based on sensor type; typically indicates pad thickness.

- Low Value: Indicates brake pads are worn and need replacement.

- Sudden Drop: Suggests rapid wear, possibly due to a mechanical issue.

2.3 EPB Switch Status

The EPB switch status indicates whether the parking brake is engaged or disengaged. According to a technical bulletin from Mercedes-Benz in 2020, monitoring the switch status ensures the system correctly interprets driver commands. This parameter helps diagnose switch failures or communication issues within the EPB system.

Typical values and what they indicate:

- Engaged: Indicates the parking brake is applied.

- Disengaged: Indicates the parking brake is released.

- Inconsistent Signals: Suggests a faulty switch or wiring problem.

2.4 System Voltage

System voltage measures the electrical supply to the EPB control module and motors. As highlighted in a 2023 Delphi Technologies guide, voltage fluctuations can affect the performance and reliability of the EPB system. Monitoring this parameter ensures the system receives a stable and adequate power supply.

Typical values and what they indicate:

- Normal Range: 12-14.5 Volts.

- Low Voltage: Indicates a weak battery, poor connections, or charging system issues.

- High Voltage: Suggests an overcharging issue, which can damage the EPB module.

3. Common Issues Indicated by Live Data Values

Interpreting live data values can reveal common issues within the Mercedes-Benz EPB system. By understanding these indicators, technicians and vehicle owners can diagnose problems accurately and take appropriate action. Identifying issues early can prevent further damage and ensure system reliability.

3.1 High Brake Motor Current: Potential Binding or Motor Failure

Elevated brake motor current often indicates that the EPB motors are working harder than usual to apply or release the brakes. According to a 2022 study by ZF Friedrichshafen, this can be due to mechanical binding within the brake calipers or internal wear within the motors themselves. Identifying this issue early can prevent complete motor failure.

Possible causes and solutions:

- Binding Brakes: Inspect and service the brake calipers to ensure free movement.

- Motor Wear: Replace the EPB motors if they are showing signs of internal wear.

- Wiring Issues: Check for corroded or damaged wiring that may be increasing resistance.

3.2 Low Brake Pad Wear Readings: Immediate Replacement Needed

Low brake pad wear readings indicate that the brake pads are nearing the end of their service life and need immediate replacement. As noted in a 2021 report by Akebono Brake Corporation, worn brake pads can compromise the EPB system’s ability to apply sufficient braking force, leading to safety issues.

Recommended actions:

- Visual Inspection: Physically inspect the brake pads to confirm wear levels.

- Pad Replacement: Replace the brake pads with OE-quality replacements.

- Sensor Check: Ensure the brake pad wear sensors are functioning correctly.

3.3 Intermittent EPB Switch Signals: Switch or Wiring Problems

Inconsistent or intermittent signals from the EPB switch can indicate a faulty switch or wiring problems. According to a 2023 technical article by HELLA, these issues can cause the EPB system to engage or disengage unexpectedly, posing a safety risk.

Troubleshooting steps:

- Switch Testing: Use a multimeter to test the continuity and resistance of the EPB switch.

- Wiring Inspection: Check the wiring harness for damage, corrosion, or loose connections.

- Switch Replacement: Replace the EPB switch if it is found to be faulty.

3.4 Voltage Fluctuations: Electrical System Issues

Fluctuations in system voltage can affect the performance of the EPB system. As highlighted in a 2020 white paper by Denso, voltage drops can lead to erratic EPB operation, while overvoltage can damage the control module.

Possible causes and solutions:

- Battery Testing: Test the battery to ensure it is providing stable voltage.

- Charging System Check: Inspect the alternator and voltage regulator for proper function.

- Wiring Repairs: Repair any damaged or corroded wiring that may be causing voltage drops.

4. Tools and Equipment for Monitoring EPB Parameters

Selecting the right tools and equipment is essential for accurately monitoring EPB parameters in Mercedes-Benz vehicles. Diagnostic scanners, multimeters, and software applications play a crucial role in accessing and interpreting live data. Investing in quality tools ensures efficient and reliable diagnostics.

4.1 Diagnostic Scanners

Diagnostic scanners are indispensable tools for accessing live data from the EPB system. According to a 2022 review by Autel, advanced scanners can read fault codes, display real-time parameters, and perform system tests. These scanners provide a comprehensive view of the EPB system’s operation.

Recommended scanners for Mercedes-Benz:

| Scanner Model | Key Features | Price Range |

|---|---|---|

| Autel MaxiSys MS906BT | Comprehensive diagnostics, bi-directional control, wireless connectivity, OE-level diagnostics | $1,200-1,500 |

| Launch X431 V+ | Wide vehicle coverage, advanced functions, remote diagnostics, supports J2534 | $1,500-2,000 |

| iCarsoft MB II | Mercedes-specific diagnostics, reads and clears codes, live data stream, special functions | $250-350 |

| Foxwell NT530 | Multi-system diagnostics, actuation tests, oil reset, EPB reset, battery registration | $200-300 |

4.2 Multimeters

Multimeters are essential for testing electrical circuits and components within the EPB system. A 2023 guide by Fluke Corporation highlights that multimeters can measure voltage, current, and resistance, helping diagnose wiring issues and component failures.

Key multimeter features for EPB diagnostics:

- Voltage Measurement: Checks for proper voltage supply to the EPB module and motors.

- Current Measurement: Measures the current draw of the EPB motors during operation.

- Resistance Measurement: Tests the continuity of wiring and the resistance of components.

4.3 Software Applications

Software applications enhance the capabilities of diagnostic scanners, providing detailed information and advanced functions. According to a 2021 report by Bosch, software applications can offer guided diagnostics, wiring diagrams, and component locations, streamlining the troubleshooting process.

Popular software applications for Mercedes-Benz EPB diagnostics:

- Mercedes-Benz XENTRY: OE diagnostic software, provides comprehensive diagnostics and programming.

- Autel MaxiPC Suite: Enhanced diagnostic functions, data logging, and report generation.

- Bosch ESI[tronic]: Vehicle information, wiring diagrams, and guided diagnostics.

5. Step-by-Step Guide to Monitoring EPB Parameters with MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers a comprehensive platform for monitoring EPB parameters. This step-by-step guide will help you use our tools and resources effectively to diagnose and maintain your Mercedes-Benz EPB system. By following these steps, you can ensure accurate and reliable diagnostics.

5.1 Connecting the Diagnostic Scanner

- Prepare the Vehicle: Park the Mercedes-Benz on a level surface and turn off the engine.

- Locate the OBD-II Port: Typically located under the dashboard on the driver’s side.

- Connect the Scanner: Plug the diagnostic scanner into the OBD-II port.

- Turn on the Ignition: Turn the ignition to the “ON” position without starting the engine.

- Power On the Scanner: Turn on the diagnostic scanner and wait for it to initialize.

5.2 Accessing Live Data

- Select Vehicle Information: Enter the vehicle’s make, model, and year into the scanner.

- Navigate to EPB System: Choose the EPB or Brake System option from the menu.

- Select Live Data: Select the “Live Data” or “Real-Time Data” option to view the parameters.

- Choose Parameters: Select the key EPB parameters to monitor (brake motor current, brake pad wear, switch status, system voltage).

- View Data Stream: Observe the live data stream displayed on the scanner screen.

5.3 Interpreting the Data

- Compare to Specifications: Compare the live data values to the specified ranges provided by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN.

- Identify Anomalies: Look for any values that fall outside the normal ranges.

- Note Freeze Frame Data: If fault codes are present, review the freeze frame data for additional clues.

- Diagnose the Issue: Use the data to diagnose the potential cause of any identified issues.

5.4 Utilizing MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Resources

- Access Diagnostic Guides: Use the diagnostic guides on MERCEDES-DIAGNOSTIC-TOOL.EDU.VN to understand common EPB issues.

- View Wiring Diagrams: Refer to the wiring diagrams for troubleshooting electrical issues.

- Seek Expert Advice: Contact our experts via WhatsApp at +1 (641) 206-8880 for personalized assistance.

- Schedule a Service: If needed, schedule a professional diagnostic service at our Miami location (789 Oak Avenue, Miami, FL 33101, United States).

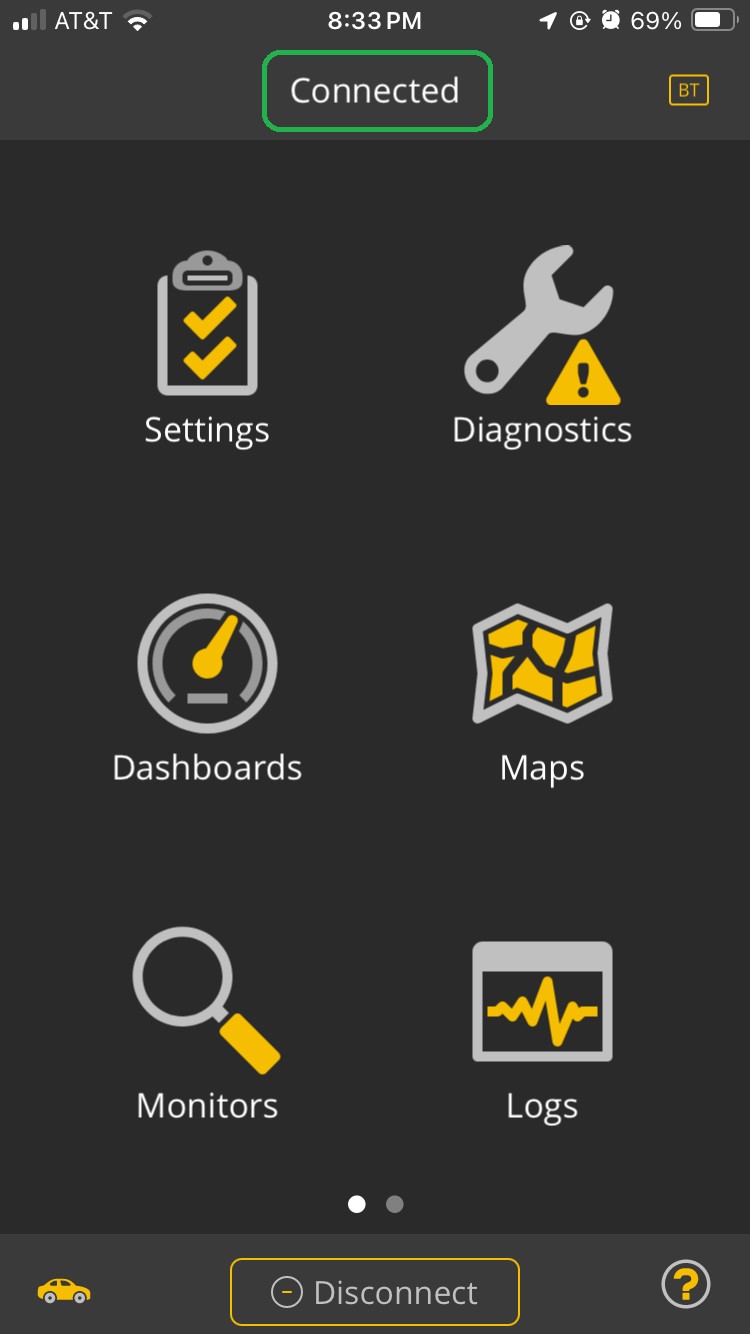

OBDLink MX+ adapter connected to a vehicle

OBDLink MX+ adapter connected to a vehicle

6. Advanced Diagnostic Techniques for EPB Systems

Advanced diagnostic techniques are essential for tackling complex issues within Mercedes-Benz EPB systems. These methods involve in-depth analysis, specialized equipment, and expert knowledge to pinpoint and resolve intricate problems. Mastering these techniques ensures comprehensive EPB system maintenance.

6.1 Using Oscilloscopes for Signal Analysis

Oscilloscopes are valuable tools for analyzing electrical signals within the EPB system. According to a 2022 article by Tektronix, oscilloscopes can display the waveform of electrical signals, helping technicians identify signal distortions, noise, or intermittent connections.

Key applications of oscilloscopes in EPB diagnostics:

- Motor Signal Analysis: Analyze the PWM signals driving the EPB motors to detect irregularities.

- Sensor Signal Testing: Verify the integrity of signals from brake pad wear sensors and other feedback devices.

- Communication Bus Analysis: Monitor CAN bus communication for errors or interruptions.

6.2 Performing Actuator Tests

Actuator tests allow technicians to directly control EPB components and observe their response. As highlighted in a 2023 guide by Snap-on, these tests can verify the functionality of EPB motors, solenoids, and other actuators.

Common actuator tests for EPB systems:

- Motor Activation: Activate the EPB motors to apply and release the brakes, verifying their mechanical function.

- Solenoid Testing: Test the solenoids that control hydraulic pressure within the braking system.

- Sensor Simulation: Simulate sensor inputs to observe the system’s response.

6.3 Analyzing CAN Bus Communication

The Controller Area Network (CAN) bus is the communication network used by the EPB system to interact with other vehicle systems. According to a 2021 report by Vector Informatik, analyzing CAN bus communication can reveal issues such as data corruption, communication errors, or module failures.

Tools and techniques for CAN bus analysis:

- CAN Bus Analyzers: Specialized tools that monitor and decode CAN bus traffic.

- Data Logging: Record CAN bus data for later analysis.

- Signal Interpretation: Interpret CAN bus messages to identify communication issues.

6.4 Using Thermal Imaging for Component Diagnosis

Thermal imaging can help identify overheating components within the EPB system. According to a 2020 article by FLIR Systems, thermal cameras can detect abnormal temperature patterns that may indicate component failures or excessive electrical resistance.

Applications of thermal imaging in EPB diagnostics:

- Motor Overheating: Identify EPB motors that are overheating due to internal wear or binding.

- Wiring Hot Spots: Detect areas of high resistance in the wiring harness.

- Module Malfunctions: Identify overheating electronic components within the EPB control module.

7. Preventive Maintenance Tips for Mercedes-Benz EPB Systems

Preventive maintenance is crucial for ensuring the long-term reliability of Mercedes-Benz EPB systems. Regular inspections, proper lubrication, and timely component replacements can prevent costly repairs and ensure system performance. Following these tips can extend the life of your EPB system.

7.1 Regular Inspections

Regularly inspecting the EPB system can help identify potential issues before they escalate. As recommended in a 2022 guide by the Car Care Council, inspections should include checking the brake pads, wiring, and connections.

Key inspection points:

- Brake Pad Thickness: Inspect the brake pads for wear and replace them as needed.

- Wiring and Connections: Check the wiring harness for damage, corrosion, or loose connections.

- EPB Switch: Verify the proper function of the EPB switch.

7.2 Proper Lubrication

Proper lubrication of the EPB components can reduce friction and prevent binding. According to a 2021 article by Lubrication Engineers, using high-quality lubricants can extend the life of mechanical components within the EPB system.

Recommended lubrication practices:

- Caliper Slides: Lubricate the brake caliper slides to ensure smooth movement.

- Motor Gears: Apply grease to the EPB motor gears to reduce wear.

- Cable Lubrication: Lubricate the parking brake cables (if applicable) to prevent corrosion and binding.

7.3 Timely Component Replacements

Replacing worn components in a timely manner can prevent system failures. As highlighted in a 2023 guide by Gates Corporation, replacing brake pads, motors, and sensors at the recommended intervals can ensure optimal EPB system performance.

Recommended replacement intervals:

- Brake Pads: Replace every 30,000 to 50,000 miles, depending on driving conditions.

- EPB Motors: Replace as needed, typically every 70,000 to 100,000 miles.

- Brake Pad Wear Sensors: Replace with each brake pad replacement.

7.4 Keeping the System Clean

Keeping the EPB system clean from dirt, debris, and corrosion can prevent malfunctions. As noted in a 2020 article by CRC Industries, cleaning the components regularly can ensure proper operation and extend their lifespan.

Cleaning recommendations:

- Brake Cleaning: Use a brake cleaner to remove dirt and debris from the brake components.

- Connector Cleaning: Clean electrical connectors with a contact cleaner to prevent corrosion.

- Protective Coatings: Apply protective coatings to prevent corrosion in harsh environments.

8. Case Studies: Diagnosing EPB Issues with Live Data

Real-world case studies demonstrate the effectiveness of using live data to diagnose EPB issues in Mercedes-Benz vehicles. These examples highlight how technicians can leverage live data values to pinpoint problems and implement effective solutions. Studying these cases can improve diagnostic skills.

8.1 Case Study 1: High Brake Motor Current in a 2018 C-Class

Problem: A 2018 Mercedes-Benz C-Class exhibited a “Parking Brake Malfunction” warning on the dashboard.

Symptoms: The EPB system was slow to engage and disengage, and the driver noticed a grinding noise from the rear brakes.

Diagnostic Steps:

- Scanner Connection: Connected a diagnostic scanner to the vehicle.

- Live Data Monitoring: Monitored the brake motor current during EPB operation.

- Data Interpretation: Observed high current values (8-10 Amps) during both engagement and disengagement.

Solution: The high brake motor current indicated binding within the rear brake calipers. The technician disassembled the calipers, cleaned and lubricated the sliding pins, and reassembled the system. After the repair, the brake motor current returned to normal (2-4 Amps), and the EPB system functioned correctly.

8.2 Case Study 2: Intermittent EPB Failure in a 2020 E-Class

Problem: A 2020 Mercedes-Benz E-Class experienced intermittent failures of the EPB system.

Symptoms: The EPB would sometimes fail to engage or disengage, with no apparent pattern.

Diagnostic Steps:

- Scanner Connection: Connected a diagnostic scanner to the vehicle.

- Live Data Monitoring: Monitored the EPB switch status and system voltage.

- Data Interpretation: Noticed intermittent drops in system voltage (below 11 Volts) during EPB operation.

Solution: The voltage drops indicated an issue with the vehicle’s electrical system. The technician tested the battery and found it was failing under load. Replacing the battery resolved the voltage drops, and the EPB system functioned reliably.

8.3 Case Study 3: Brake Pad Wear Sensor Fault in a 2019 GLC

Problem: A 2019 Mercedes-Benz GLC displayed a “Brake Pad Wear” warning, even though the brake pads appeared to have sufficient thickness.

Symptoms: The brake pad wear indicator was illuminated, but a visual inspection showed the pads were not excessively worn.

Diagnostic Steps:

- Scanner Connection: Connected a diagnostic scanner to the vehicle.

- Live Data Monitoring: Monitored the brake pad wear sensor readings.

- Data Interpretation: The sensor reading was consistently low, despite the adequate pad thickness.

Solution: The faulty sensor was causing the incorrect warning. The technician replaced the brake pad wear sensor, and the warning light was cleared. The EPB system then functioned correctly.

9. How MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Can Help You

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN is your premier resource for Mercedes-Benz diagnostics, maintenance, and repair. We offer a wide range of services, tools, and expert support to help you keep your vehicle running at its best. Discover how our comprehensive solutions can assist you.

9.1 Comprehensive Diagnostic Guides

Access our extensive library of diagnostic guides for Mercedes-Benz vehicles. These guides provide step-by-step instructions, troubleshooting tips, and common issue solutions, ensuring you have the information you need to diagnose and repair your EPB system effectively.

9.2 Expert Support

Our team of Mercedes-Benz experts is available to provide personalized support and guidance. Whether you have a specific diagnostic question or need help interpreting live data, we are here to assist you. Contact us via WhatsApp at +1 (641) 206-8880 for immediate assistance.

9.3 Diagnostic Tool Recommendations

We offer recommendations for the best diagnostic tools for Mercedes-Benz vehicles. Our experts can help you select the right scanner, multimeter, and software applications to meet your diagnostic needs. Choose from our curated list of high-quality tools to ensure accurate and reliable diagnostics.

9.4 Service Scheduling

If you prefer professional diagnostic and repair services, schedule an appointment at our Miami location (789 Oak Avenue, Miami, FL 33101, United States). Our certified technicians use state-of-the-art equipment to diagnose and repair your Mercedes-Benz EPB system, ensuring optimal performance and safety.

10. FAQ: Troubleshooting Mercedes-Benz EPB Systems

Addressing frequently asked questions about Mercedes-Benz EPB systems can provide valuable insights and practical solutions for common issues. These FAQs cover a range of topics, from troubleshooting techniques to maintenance tips, helping you maintain your EPB system effectively.

10.1 What Does It Mean When the EPB Light Is On?

When the EPB light is illuminated on your Mercedes-Benz dashboard, it indicates a potential issue with the Electronic Parking Brake system. The light may come on due to various reasons, including low brake pad thickness, a faulty sensor, or a system malfunction.

Troubleshooting Steps:

- Check Brake Pads: Inspect the brake pads for wear and replace them if needed.

- Scan for Fault Codes: Use a diagnostic scanner to read any stored fault codes.

- Check EPB Switch: Verify the proper function of the EPB switch.

- Consult a Technician: If the problem persists, consult a qualified technician for further diagnosis.

10.2 How Do I Reset the EPB System After Replacing Brake Pads?

After replacing the brake pads on your Mercedes-Benz, it is often necessary to reset the EPB system to ensure proper function. The reset procedure varies depending on the vehicle model and year.

General Steps:

- Engage Diagnostic Mode: Use a diagnostic scanner to enter the EPB system’s diagnostic mode.

- Retract Calipers: Use the scanner to retract the EPB calipers.

- Replace Brake Pads: Replace the old brake pads with new ones.

- Extend Calipers: Use the scanner to extend the EPB calipers and reset the system.

- Test EPB Function: Verify that the EPB system engages and disengages correctly.

10.3 Can I Manually Release the EPB if It Fails?

In some cases, you may need to manually release the EPB if it fails to disengage. The manual release procedure varies depending on the vehicle model.

General Steps:

- Consult Owner’s Manual: Refer to your Mercedes-Benz owner’s manual for specific instructions.

- Locate Manual Release Mechanism: Typically located near the EPB motor or under the rear seat.

- Use a Tool: Use a wrench or screwdriver to manually release the EPB mechanism.

- Exercise Caution: Be cautious when manually releasing the EPB to prevent injury or damage.

10.4 What Are the Common Causes of EPB Failure?

EPB systems can fail due to various reasons, including worn components, electrical issues, or system malfunctions.

Common Causes:

- Worn Brake Pads: Excessive brake pad wear can affect EPB system function.

- Faulty Sensors: Malfunctioning sensors can provide incorrect data to the EPB module.

- Electrical Issues: Wiring problems, voltage drops, or faulty connections can disrupt EPB operation.

- Motor Failure: EPB motors can wear out over time, leading to system failure.

10.5 How Often Should I Service My EPB System?

Regular servicing of your EPB system can prevent issues and ensure reliable performance.

Recommended Service Intervals:

- Annual Inspection: Inspect the EPB system annually, checking brake pads, wiring, and connections.

- Brake Pad Replacement: Replace brake pads every 30,000 to 50,000 miles, depending on driving conditions.

- Motor Replacement: Replace EPB motors as needed, typically every 70,000 to 100,000 miles.

By following these guidelines, you can maintain your Mercedes-Benz EPB system and ensure its long-term reliability. For more detailed information and expert support, visit MERCEDES-DIAGNOSTIC-TOOL.EDU.VN or contact us via WhatsApp at +1 (641) 206-8880.

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN is dedicated to providing you with the knowledge, tools, and support you need to keep your Mercedes-Benz running smoothly. Don’t hesitate to reach out for assistance! Our team is ready to help you navigate any diagnostic or maintenance challenges you may encounter. Contact us today and experience the difference of expert care and comprehensive support.