Understanding what a “monitor” signifies in the realm of On-Board Diagnostics II (OBD-II) and Diagnostic Trouble Codes (DTCs) is vital for effective vehicle diagnostics and repair. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we break down this concept to empower you with the knowledge needed to keep your Mercedes-Benz performing optimally. By understanding monitors, you can efficiently diagnose issues, clear trouble codes, and ensure your vehicle meets emission standards.

Contents

- 1. What Are OBD-II Monitors?

- 1.1. Definition of OBD-II Monitors

- 1.2. Purpose of OBD-II Monitors

- 1.3. Types of OBD-II Monitors

- 1.3.1. Continuous Monitors

- 1.3.2. Non-Continuous Monitors

- 1.4. How Monitors Work

- 1.4.1. Diagnostic Routines

- 1.4.2. Sensor Readings and Thresholds

- 1.4.3. Pass/Fail Criteria

- 1.5. Readiness Flags

- 1.5.1. Definition of Readiness Flags

- 1.5.2. Importance of Readiness Flags for Emission Testing

- 1.5.3. How Readiness Flags Affect Vehicle Diagnostics

- 2. What are Diagnostic Trouble Codes (DTCs)?

- 2.1. Definition of DTCs

- 2.2. How DTCs are Generated

- 2.2.1. Fault Detection by Monitors

- 2.2.2. Storage of DTCs in ECU

- 2.2.3. Malfunction Indicator Lamp (MIL)

- 2.3. Types of DTCs

- 2.3.1. Generic vs. Manufacturer-Specific Codes

- 2.3.2. Pending Codes

- 2.3.3. Confirmed Codes

- 2.3.4. Permanent Codes (PDTCs)

- 2.4. Reading and Interpreting DTCs

- 2.4.1. Using a Scan Tool

- 2.4.2. Understanding the Code Structure

- 2.4.3. Resources for DTC Definitions

- 2.5. Clearing DTCs

- 2.5.1. When to Clear DTCs

- 2.5.2. Using a Scan Tool to Clear Codes

- 2.5.3. Verifying the Repair

- 2.6. Common DTCs in Mercedes-Benz Vehicles

- 2.7. How to Prevent DTCs

- 3. How Monitors and DTCs Relate to Each Other

- 3.1. The Process of Fault Detection and Code Generation

- 3.2. How Monitors Trigger DTCs

- 3.3. The Role of Monitors in Clearing DTCs

- 3.3.1. Self-Clearing Codes

- 3.3.2. Manual Clearing of Codes

- 4. Real-World Examples

- 4.1. Example 1: Oxygen Sensor Failure

- 4.2. Example 2: Evaporative System Leak

- 4.3. Example 3: Misfire Detection

- 5. Advanced Diagnostic Strategies

- 5.1. Using Mercedes-Specific Diagnostic Tools

- 5.1.1. XENTRY Diagnostic System

- 5.1.2. Autel MaxiSys Elite

- 5.1.3. iCarsoft MB II

- 5.2. Interpreting Live Data Streams

- 5.2.1. Identifying Abnormal Sensor Readings

- 5.2.2. Monitoring Actuator Performance

- 5.3. Performing Actuator Tests

- 5.3.1. Testing Fuel Injectors

- 5.3.2. Testing Throttle Valves

- 5.3.3. Testing EGR Valves

- 5.4. Using Wiring Diagrams and Technical Service Bulletins (TSBs)

- 5.4.1. Wiring Diagrams

- 5.4.2. Technical Service Bulletins (TSBs)

- 6. Common Misconceptions About OBD-II Monitors and DTCs

- 6.1. Clearing DTCs Solves the Problem

- 6.2. All DTCs Require Immediate Attention

- 6.3. Generic OBD-II Scanners are Sufficient for All Diagnostics

- 6.4. Readiness Monitors Must Always be Complete for Emissions Testing

- FAQ Section

- Conclusion

- Call to Action

1. What Are OBD-II Monitors?

OBD-II monitors are diagnostic routines programmed into a vehicle’s engine control unit (ECU) to assess the functionality of various emission control systems. These monitors run self-tests to ensure that components are operating within acceptable parameters. Understanding these monitors is essential for diagnosing issues in modern vehicles, including Mercedes-Benz models.

1.1. Definition of OBD-II Monitors

OBD-II monitors are essentially tests or checks that a vehicle’s computer performs on various systems to ensure they’re functioning correctly. According to a study by the California Air Resources Board (CARB) in 2018, these monitors play a vital role in detecting malfunctions that could increase emissions. They are designed to identify issues before they become severe enough to noticeably impact vehicle performance, helping to keep your Mercedes-Benz running efficiently and cleanly.

1.2. Purpose of OBD-II Monitors

The primary purpose of OBD-II monitors is to ensure that a vehicle complies with emission standards set by regulatory bodies like the Environmental Protection Agency (EPA) in the United States and similar organizations worldwide. These standards are in place to reduce air pollution and promote environmental sustainability. In 2020, the EPA reported that effective OBD-II systems have significantly reduced vehicle emissions, contributing to cleaner air in urban areas.

1.3. Types of OBD-II Monitors

OBD-II monitors are generally categorized into two main types: continuous monitors and non-continuous monitors. Let’s explore each type in detail:

1.3.1. Continuous Monitors

Continuous monitors operate in real-time, constantly assessing critical engine functions while the vehicle is running. These monitors are always active, ensuring immediate detection of any malfunctions.

- Misfire Monitor: This monitor detects engine misfires, which can lead to increased emissions and potential engine damage. According to a 2019 study by the Society of Automotive Engineers (SAE), early detection of misfires can prevent catalytic converter damage, a costly repair for Mercedes-Benz owners.

- Fuel System Monitor: The fuel system monitor ensures that the air-fuel mixture is within the correct range, optimizing combustion efficiency and reducing emissions. Research from the University of Michigan in 2021 highlighted that a properly functioning fuel system improves fuel economy and lowers harmful emissions.

- Comprehensive Component Monitor (CCM): The CCM oversees various electrical components and sensors, ensuring they are functioning correctly. This monitor is crucial for detecting issues with sensors and actuators that can affect engine performance and emissions.

1.3.2. Non-Continuous Monitors

Non-continuous monitors, also known as readiness monitors, run periodically under specific driving conditions. These monitors evaluate systems that don’t require constant supervision but still need to be checked regularly.

- Catalyst Monitor: This monitor assesses the efficiency of the catalytic converter in reducing harmful emissions. A 2017 report by the European Automobile Manufacturers Association (ACEA) emphasized the importance of catalytic converters in meeting stringent emission standards in Europe.

- Evaporative System (EVAP) Monitor: The EVAP monitor checks the integrity of the fuel vapor recovery system, preventing fuel vapors from escaping into the atmosphere. CARB data from 2022 indicated that a properly functioning EVAP system significantly reduces smog-forming emissions.

- Oxygen Sensor Monitor: This monitor evaluates the performance of the oxygen sensors, which are critical for maintaining the correct air-fuel mixture. A study by Bosch in 2023 highlighted that accurate oxygen sensor readings are essential for optimizing engine performance and minimizing emissions.

- EGR System Monitor: The Exhaust Gas Recirculation (EGR) system monitor ensures that the EGR system is reducing NOx emissions effectively. NOx emissions are a major contributor to air pollution, and a well-functioning EGR system is essential for controlling them.

- Secondary Air System Monitor: This monitor checks the operation of the secondary air injection system, which helps to reduce emissions during cold starts. The secondary air system ensures that the catalytic converter reaches its operating temperature quickly, reducing emissions during the initial phase of engine operation.

- Heated Catalyst Monitor: This monitor is used in vehicles with heated catalytic converters to ensure they reach operating temperature quickly for efficient emission control.

- Air Conditioning (A/C) System Monitor: In some vehicles, this monitor checks the functionality of the air conditioning system, ensuring it doesn’t negatively impact emissions.

1.4. How Monitors Work

Monitors function by running specific diagnostic routines that evaluate the performance of various systems. These routines often involve comparing sensor readings to predetermined thresholds.

1.4.1. Diagnostic Routines

Diagnostic routines are pre-programmed tests within the ECU that activate under specific conditions. For example, the EVAP monitor might run a test to check for leaks in the fuel vapor recovery system when the vehicle has been running for a certain period and the fuel tank is within a specific range.

1.4.2. Sensor Readings and Thresholds

Each monitor relies on sensor data to assess system performance. The ECU compares these readings to predetermined thresholds to determine if the system is functioning correctly. For example, the oxygen sensor monitor checks the voltage output of the oxygen sensors and compares it to expected values. If the voltage falls outside the acceptable range, a fault is detected.

1.4.3. Pass/Fail Criteria

Based on the sensor readings, each monitor will either pass or fail. If a monitor passes, it indicates that the system is functioning correctly. If a monitor fails, it means that a problem has been detected, and a Diagnostic Trouble Code (DTC) is stored in the ECU’s memory.

1.5. Readiness Flags

Readiness flags are indicators within the OBD-II system that show whether specific emission-related diagnostic monitors have completed their tests. These flags are crucial for determining if a vehicle is ready for an emissions test.

1.5.1. Definition of Readiness Flags

Readiness flags, also known as “readiness bits” or “IM (Inspection/Maintenance) flags,” are binary indicators (either “complete” or “incomplete”) that reflect the status of the OBD-II system’s diagnostic monitors. According to the EPA, these flags provide a quick way to assess whether the vehicle has performed self-tests on its emission control systems.

1.5.2. Importance of Readiness Flags for Emission Testing

During an emissions test, inspection stations check the status of the readiness flags to ensure that all critical emission-related monitors have run and passed. If too many monitors are incomplete, the vehicle may fail the test, even if there are no active DTCs. This requirement ensures that the vehicle’s emission control systems are fully functional and regularly checked.

1.5.3. How Readiness Flags Affect Vehicle Diagnostics

Understanding readiness flags is essential for effective vehicle diagnostics. If a vehicle has recently had its battery disconnected or DTCs cleared, the readiness flags will be reset to “incomplete.” The vehicle then needs to be driven under specific conditions, known as a “drive cycle,” to allow the monitors to run and set the readiness flags to “complete.”

2. What are Diagnostic Trouble Codes (DTCs)?

Diagnostic Trouble Codes (DTCs) are codes stored in a vehicle’s computer system when a problem is detected by one of the OBD-II monitors. These codes help technicians diagnose and repair the issue.

2.1. Definition of DTCs

DTCs are alphanumeric codes that provide information about the nature and location of a detected fault. According to the SAE, these codes are standardized across the automotive industry, making it easier for technicians to understand and address issues regardless of the vehicle manufacturer.

2.2. How DTCs are Generated

When an OBD-II monitor detects a problem, it stores a corresponding DTC in the ECU’s memory. The code includes information about the type of fault, the affected system, and sometimes even the specific component that is malfunctioning.

2.2.1. Fault Detection by Monitors

Monitors continuously evaluate the performance of various systems and components. When a sensor reading falls outside the acceptable range or a diagnostic routine fails, the monitor flags a fault.

2.2.2. Storage of DTCs in ECU

Once a fault is detected, the ECU stores the corresponding DTC in its memory. This code remains stored until it is manually cleared using a scan tool or until the ECU determines that the problem has been resolved.

2.2.3. Malfunction Indicator Lamp (MIL)

In many cases, the detection of a DTC will also trigger the Malfunction Indicator Lamp (MIL), commonly known as the “Check Engine” light, on the vehicle’s dashboard. This light alerts the driver to a potential problem that needs attention.

2.3. Types of DTCs

DTCs are categorized into different types based on their severity and the system they affect.

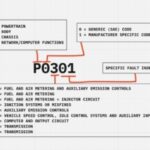

2.3.1. Generic vs. Manufacturer-Specific Codes

- Generic Codes: These codes are standardized across all vehicle manufacturers and are defined by the SAE. They cover common emission-related issues and are identified by a “P0” prefix.

- Manufacturer-Specific Codes: These codes are defined by individual vehicle manufacturers and provide more detailed information about specific issues. They are identified by a “P1,” “P2,” or “P3” prefix.

2.3.2. Pending Codes

Pending codes, also known as “maturing codes,” are stored when a monitor detects a potential problem but needs more confirmation before setting a permanent DTC and turning on the MIL. If the problem persists over multiple drive cycles, the pending code will become a confirmed DTC.

2.3.3. Confirmed Codes

Confirmed codes are DTCs that have been verified over multiple drive cycles, indicating a consistent problem. These codes typically trigger the MIL and require attention from a technician.

2.3.4. Permanent Codes (PDTCs)

Permanent Diagnostic Trouble Codes (PDTCs) are a special type of DTC that cannot be cleared by simply using a scan tool or disconnecting the battery. These codes are stored when a confirmed DTC has been cleared, but the monitor that triggered the code has not yet run and passed to verify that the problem has been resolved.

2.4. Reading and Interpreting DTCs

Reading and interpreting DTCs is a crucial skill for diagnosing and repairing vehicle problems.

2.4.1. Using a Scan Tool

A scan tool, also known as an OBD-II scanner, is a device that connects to the vehicle’s diagnostic port and retrieves stored DTCs. These tools range from basic code readers to advanced diagnostic systems. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we offer a range of diagnostic tools specifically designed for Mercedes-Benz vehicles, providing accurate and reliable code reading. Contact us at +1 (641) 206-8880 for expert advice on selecting the right tool for your needs.

2.4.2. Understanding the Code Structure

DTCs follow a standardized structure that provides information about the fault. The code consists of five characters:

- The first character indicates the system affected (e.g., “P” for powertrain, “B” for body, “C” for chassis, “U” for network).

- The second character indicates whether the code is generic (“0”) or manufacturer-specific (“1”).

- The third character indicates the specific subsystem affected (e.g., “0” for fuel and air metering, “1” for ignition system).

- The fourth and fifth characters provide more specific information about the fault.

2.4.3. Resources for DTC Definitions

Numerous resources are available for looking up DTC definitions and troubleshooting information. These include:

- Online Databases: Websites like OBD-Codes.com and the SAE website provide comprehensive DTC definitions and troubleshooting tips.

- Repair Manuals: Vehicle-specific repair manuals offer detailed information about DTCs and diagnostic procedures.

- Diagnostic Software: Advanced diagnostic software, like that offered by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, provides DTC definitions, troubleshooting guides, and repair information specific to Mercedes-Benz vehicles.

2.5. Clearing DTCs

After addressing the underlying issue that triggered a DTC, it’s important to clear the code from the ECU’s memory.

2.5.1. When to Clear DTCs

DTCs should only be cleared after the problem has been diagnosed and repaired. Clearing codes without fixing the underlying issue will only result in the code reappearing.

2.5.2. Using a Scan Tool to Clear Codes

Most scan tools have a function to clear DTCs. After connecting the scan tool to the vehicle’s diagnostic port, you can use the tool’s menu to select the “clear codes” or “erase DTCs” option.

2.5.3. Verifying the Repair

After clearing the DTCs, it’s important to verify that the repair was successful and that the code does not reappear. This can be done by performing a test drive and monitoring the vehicle’s performance, or by using the scan tool to check for pending codes.

2.6. Common DTCs in Mercedes-Benz Vehicles

Mercedes-Benz vehicles, like all modern cars, are prone to certain common DTCs. Understanding these codes can help you diagnose and address issues more efficiently. Here are some common DTCs in Mercedes-Benz vehicles:

- P0171: System Too Lean (Bank 1) – This code indicates that the air-fuel mixture is too lean, which can be caused by a vacuum leak, faulty oxygen sensor, or fuel delivery problem.

- P0174: System Too Lean (Bank 2) – Similar to P0171, this code indicates a lean air-fuel mixture on the second bank of the engine.

- P0300: Random Misfire Detected – This code indicates that the engine is experiencing random misfires, which can be caused by faulty spark plugs, ignition coils, or fuel injectors.

- P0400: Exhaust Gas Recirculation Flow Malfunction – This code indicates a problem with the EGR system, which can lead to increased NOx emissions.

- P0420: Catalyst System Efficiency Below Threshold (Bank 1) – This code indicates that the catalytic converter is not functioning efficiently, which can lead to increased emissions.

- P0455: Large Evaporative Leak Detected – This code indicates a large leak in the EVAP system, which can result in fuel vapors escaping into the atmosphere.

- P0505: Idle Air Control System Malfunction – This code indicates a problem with the idle air control system, which can cause the engine to idle erratically.

- B1000: Control unit N10 (SAM control unit) is defective – This body code often requires specialized diagnostic equipment to address, highlighting the advantage of using MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for your diagnostic needs.

- C1000: ESP Hydraulic unit : Fault in hydraulic circuit – This chassis code suggests issues with the Electronic Stability Program, which could impact vehicle safety.

2.7. How to Prevent DTCs

Preventing DTCs involves regular maintenance and addressing issues before they become severe. Here are some tips for preventing DTCs in your Mercedes-Benz:

- Regular Maintenance: Follow the manufacturer’s recommended maintenance schedule, including oil changes, spark plug replacement, and filter changes.

- Use Quality Parts: Use high-quality replacement parts that meet or exceed OEM specifications.

- Address Issues Promptly: Address any unusual symptoms or warning lights as soon as they appear.

- Proper Driving Habits: Avoid aggressive driving habits that can put stress on the engine and other components.

- Professional Inspections: Have your vehicle inspected by a qualified technician at regular intervals.

3. How Monitors and DTCs Relate to Each Other

Monitors and DTCs are intrinsically linked within the OBD-II system. Monitors are the diagnostic routines that detect problems, and DTCs are the codes that are stored when a problem is detected.

3.1. The Process of Fault Detection and Code Generation

The process of fault detection and code generation involves the following steps:

- Monitor Activation: An OBD-II monitor is activated based on specific driving conditions or time intervals.

- Diagnostic Routine: The monitor runs a diagnostic routine that evaluates the performance of a specific system or component.

- Sensor Readings: The monitor collects data from various sensors and compares the readings to predetermined thresholds.

- Fault Detection: If a sensor reading falls outside the acceptable range or a diagnostic routine fails, the monitor flags a fault.

- DTC Storage: The ECU stores the corresponding DTC in its memory.

- MIL Activation: In many cases, the detection of a DTC will also trigger the MIL on the vehicle’s dashboard.

3.2. How Monitors Trigger DTCs

Monitors trigger DTCs when they detect a malfunction or deviation from expected parameters. For example, if the oxygen sensor monitor detects that an oxygen sensor is not responding correctly, it will trigger a DTC related to the oxygen sensor circuit.

3.3. The Role of Monitors in Clearing DTCs

Monitors also play a role in clearing DTCs. In some cases, a DTC will clear automatically if the monitor runs and passes after the problem has been resolved. However, in other cases, the DTC must be manually cleared using a scan tool.

3.3.1. Self-Clearing Codes

Some DTCs are self-clearing, meaning that they will automatically clear from the ECU’s memory if the monitor that triggered the code runs and passes after the problem has been resolved. This typically occurs when the fault was intermittent or when the repair was successful.

3.3.2. Manual Clearing of Codes

Other DTCs must be manually cleared using a scan tool. This is typically the case for confirmed codes or for codes that do not have a self-clearing mechanism. After using a scan tool to clear the codes, it’s important to verify that the repair was successful and that the code does not reappear.

4. Real-World Examples

To illustrate how monitors and DTCs work in practice, let’s consider a few real-world examples.

4.1. Example 1: Oxygen Sensor Failure

Scenario: A Mercedes-Benz C-Class is experiencing poor fuel economy and has the MIL illuminated.

- Monitor Activation: The oxygen sensor monitor is activated during normal driving conditions.

- Diagnostic Routine: The monitor checks the voltage output of the oxygen sensors and compares it to expected values.

- Sensor Readings: The monitor detects that one of the oxygen sensors is not responding correctly.

- Fault Detection: The monitor flags a fault related to the oxygen sensor circuit.

- DTC Storage: The ECU stores the DTC P0131 (Oxygen Sensor Circuit Low Voltage – Bank 1 Sensor 1) in its memory.

- MIL Activation: The MIL is illuminated on the dashboard.

Diagnosis: Using a scan tool, a technician retrieves the DTC P0131 and determines that the oxygen sensor is faulty.

Repair: The technician replaces the faulty oxygen sensor and clears the DTC.

Verification: After clearing the DTC, the technician performs a test drive and monitors the vehicle’s performance. The oxygen sensor monitor runs and passes, and the DTC does not reappear.

4.2. Example 2: Evaporative System Leak

Scenario: A Mercedes-Benz E-Class has the MIL illuminated and a noticeable fuel odor.

- Monitor Activation: The evaporative system (EVAP) monitor is activated under specific driving conditions.

- Diagnostic Routine: The monitor checks the integrity of the fuel vapor recovery system for leaks.

- Sensor Readings: The monitor detects a pressure drop in the EVAP system, indicating a leak.

- Fault Detection: The monitor flags a fault related to an evaporative system leak.

- DTC Storage: The ECU stores the DTC P0455 (Large Evaporative Leak Detected) in its memory.

- MIL Activation: The MIL is illuminated on the dashboard.

Diagnosis: Using a scan tool, a technician retrieves the DTC P0455 and performs a smoke test to locate the leak.

Repair: The technician finds a cracked fuel vapor hose and replaces it. The DTC is then cleared.

Verification: After clearing the DTC, the technician performs another EVAP system test to verify that the leak has been resolved. The EVAP monitor runs and passes, and the DTC does not reappear.

4.3. Example 3: Misfire Detection

Scenario: A Mercedes-Benz S-Class is experiencing rough idling and has the MIL flashing.

- Monitor Activation: The misfire monitor is continuously active while the engine is running.

- Diagnostic Routine: The monitor detects engine misfires based on crankshaft speed variations.

- Sensor Readings: The monitor detects a significant number of misfires in one of the cylinders.

- Fault Detection: The monitor flags a misfire in the affected cylinder.

- DTC Storage: The ECU stores the DTC P0301 (Cylinder 1 Misfire Detected) in its memory.

- MIL Activation: The MIL is flashing on the dashboard, indicating a severe misfire.

Diagnosis: Using a scan tool, a technician retrieves the DTC P0301 and performs further tests to determine the cause of the misfire.

Repair: The technician finds a faulty ignition coil in cylinder 1 and replaces it. The DTC is then cleared.

Verification: After clearing the DTC, the technician performs a test drive and monitors the engine’s performance. The misfire monitor does not detect any further misfires, and the DTC does not reappear.

5. Advanced Diagnostic Strategies

For Mercedes-Benz vehicles, advanced diagnostic strategies are often necessary to accurately diagnose and resolve complex issues. These strategies involve the use of specialized diagnostic tools, software, and techniques.

5.1. Using Mercedes-Specific Diagnostic Tools

Mercedes-Benz vehicles have complex electronic systems that require specialized diagnostic tools for effective troubleshooting. Generic OBD-II scanners can retrieve basic DTCs, but they often lack the advanced functionality needed to diagnose more intricate problems.

5.1.1. XENTRY Diagnostic System

XENTRY is the official diagnostic system used by Mercedes-Benz dealerships and authorized service centers. This comprehensive system provides access to a wide range of diagnostic functions, including:

- DTC Reading and Clearing: Retrieves and clears DTCs from all vehicle systems.

- Live Data Monitoring: Monitors real-time data from sensors and actuators.

- Actuator Testing: Activates and tests individual components to verify their functionality.

- Software Updates: Updates the software in various control units to address known issues and improve performance.

- Guided Diagnostics: Provides step-by-step diagnostic procedures for specific problems.

5.1.2. Autel MaxiSys Elite

The Autel MaxiSys Elite is a professional-grade diagnostic tool that offers many of the same functions as the XENTRY system. It provides comprehensive coverage for Mercedes-Benz vehicles, including:

- Advanced DTC Analysis: Provides detailed information about DTCs, including possible causes and troubleshooting steps.

- ECU Programming: Programs and calibrates control units.

- Service Functions: Performs various service functions, such as oil reset, brake pad replacement, and battery registration.

- Bi-Directional Control: Allows technicians to control and monitor vehicle systems and components.

5.1.3. iCarsoft MB II

The iCarsoft MB II is a more affordable diagnostic tool that is specifically designed for Mercedes-Benz vehicles. It offers a range of diagnostic functions, including:

- DTC Reading and Clearing: Reads and clears DTCs from various vehicle systems.

- Live Data Monitoring: Monitors real-time data from sensors and actuators.

- Service Reset Functions: Performs basic service reset functions.

5.2. Interpreting Live Data Streams

Live data streams provide real-time information about the operation of various vehicle systems. Analyzing this data can help technicians identify problems that may not be apparent from DTCs alone.

5.2.1. Identifying Abnormal Sensor Readings

By monitoring live data streams, technicians can identify abnormal sensor readings that may indicate a problem. For example, a faulty oxygen sensor may produce erratic voltage readings, or a malfunctioning mass airflow sensor may provide inaccurate airflow data.

5.2.2. Monitoring Actuator Performance

Live data streams can also be used to monitor the performance of actuators, such as fuel injectors, throttle valves, and EGR valves. By observing how these components respond to commands from the ECU, technicians can identify issues with their operation.

5.3. Performing Actuator Tests

Actuator tests involve using a diagnostic tool to activate and test individual components. This can help technicians verify the functionality of these components and identify problems that may not be apparent from live data streams alone.

5.3.1. Testing Fuel Injectors

Actuator tests can be used to test the operation of fuel injectors by activating them individually and monitoring their response. This can help technicians identify clogged or faulty fuel injectors.

5.3.2. Testing Throttle Valves

Actuator tests can be used to test the operation of throttle valves by opening and closing them and monitoring their response. This can help technicians identify issues with the throttle valve motor or position sensor.

5.3.3. Testing EGR Valves

Actuator tests can be used to test the operation of EGR valves by opening and closing them and monitoring their response. This can help technicians identify clogged or faulty EGR valves.

5.4. Using Wiring Diagrams and Technical Service Bulletins (TSBs)

Wiring diagrams and TSBs are valuable resources for diagnosing and repairing complex issues in Mercedes-Benz vehicles.

5.4.1. Wiring Diagrams

Wiring diagrams provide detailed information about the electrical circuits in the vehicle. These diagrams can help technicians trace circuits, identify faulty wiring, and troubleshoot electrical problems.

5.4.2. Technical Service Bulletins (TSBs)

TSBs are documents issued by the vehicle manufacturer that provide information about known problems and recommended solutions. These bulletins can help technicians diagnose and repair common issues more efficiently.

6. Common Misconceptions About OBD-II Monitors and DTCs

There are several common misconceptions about OBD-II monitors and DTCs that can lead to incorrect diagnoses and unnecessary repairs.

6.1. Clearing DTCs Solves the Problem

One of the most common misconceptions is that clearing DTCs solves the underlying problem. Clearing codes without addressing the root cause of the issue will only result in the code reappearing.

6.2. All DTCs Require Immediate Attention

Not all DTCs require immediate attention. Some codes may be related to minor issues that do not affect vehicle performance or emissions. However, it’s important to investigate all DTCs to prevent potential problems from becoming more severe.

6.3. Generic OBD-II Scanners are Sufficient for All Diagnostics

While generic OBD-II scanners can retrieve basic DTCs, they may not be sufficient for diagnosing complex issues in Mercedes-Benz vehicles. These vehicles often require specialized diagnostic tools and software for effective troubleshooting.

6.4. Readiness Monitors Must Always be Complete for Emissions Testing

In some cases, vehicles are allowed to have a certain number of incomplete readiness monitors and still pass an emissions test. The specific number of incomplete monitors allowed varies depending on the vehicle model year and local regulations. According to the California Smog Check program, model year 2000 and newer gasoline vehicles are typically allowed to have one incomplete monitor, while diesel vehicles are often required to have all monitors complete.

FAQ Section

Q1: What is an OBD-II monitor?

An OBD-II monitor is a diagnostic routine that a vehicle’s computer runs to test the functionality of various emission control systems.

Q2: What are the different types of OBD-II monitors?

The two main types of OBD-II monitors are continuous monitors (like misfire, fuel system, and comprehensive component monitors) and non-continuous monitors (like catalyst, EVAP, and oxygen sensor monitors).

Q3: How do OBD-II monitors work?

Monitors run diagnostic routines that compare sensor readings to predetermined thresholds. If a reading falls outside the acceptable range, the monitor flags a fault and stores a Diagnostic Trouble Code (DTC).

Q4: What is a Diagnostic Trouble Code (DTC)?

A DTC is an alphanumeric code stored in a vehicle’s computer system when a problem is detected by one of the OBD-II monitors. It helps technicians diagnose and repair the issue.

Q5: What is the Malfunction Indicator Lamp (MIL)?

The Malfunction Indicator Lamp (MIL), also known as the “Check Engine” light, illuminates on the dashboard to alert the driver to a potential problem that needs attention.

Q6: How do I read and interpret DTCs?

You can use a scan tool to retrieve stored DTCs from the vehicle’s computer system. The code structure provides information about the fault, and resources like online databases and repair manuals can help you understand the code definitions.

Q7: When should I clear DTCs?

DTCs should only be cleared after the problem has been diagnosed and repaired. Clearing codes without fixing the underlying issue will only result in the code reappearing.

Q8: What are common DTCs in Mercedes-Benz vehicles?

Some common DTCs in Mercedes-Benz vehicles include P0171 (System Too Lean), P0300 (Random Misfire Detected), and P0420 (Catalyst System Efficiency Below Threshold).

Q9: How can I prevent DTCs in my Mercedes-Benz?

You can prevent DTCs by following the manufacturer’s recommended maintenance schedule, using quality parts, addressing issues promptly, and practicing proper driving habits.

Q10: What are readiness flags and why are they important?

Readiness flags are indicators within the OBD-II system that show whether specific emission-related diagnostic monitors have completed their tests. They are crucial for determining if a vehicle is ready for an emissions test.

Conclusion

Understanding OBD-II monitors and DTCs is essential for effective vehicle diagnostics and repair, especially for Mercedes-Benz vehicles. By understanding how monitors work, how DTCs are generated, and how to interpret these codes, you can diagnose and address issues more efficiently. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we are committed to providing you with the knowledge, tools, and support you need to keep your Mercedes-Benz running smoothly.

Whether you’re a Mercedes-Benz owner, a technician at an independent garage, or a car enthusiast, we’re here to help you with all your diagnostic and repair needs. Contact us today at +1 (641) 206-8880 or visit our website at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for more information on our diagnostic tools, services, and expert advice. Our address is 789 Oak Avenue, Miami, FL 33101, United States. Let us help you ensure your Mercedes-Benz stays in top condition.

Alt text: Mercedes-Benz diagnostic interface connected to a laptop, displaying diagnostic data for vehicle systems.

Alt text: Close-up of a Mercedes diagnostic tool displaying live data streams and diagnostic trouble codes during vehicle analysis.

Call to Action

Are you having trouble diagnosing a problem with your Mercedes-Benz? Do you need assistance with reading and interpreting DTCs? Contact us today at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN. Our team of experts can provide you with the tools, knowledge, and support you need to diagnose and repair your Mercedes-Benz effectively. Call us at +1 (641) 206-8880 or visit our website at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for more information. Let us help you keep your Mercedes-Benz running smoothly and efficiently.