Interpreting Mercedes seatbelt buckle switch status live data involves understanding the signals from the Hall Effect sensors in the seatbelt buckles, and MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides expert insights into diagnosing and addressing restraint system issues. By using a diagnostic scan tool, you can accurately assess the electronic controls and communication related to seatbelt switch operation. This allows for efficient troubleshooting and maintenance, ensuring the safety and functionality of your Mercedes-Benz’s safety systems with detailed diagnostic assistance and access to specialized tools. Gain deeper insights into safety features, occupant restraint systems, and electronic control units.

Contents

- 1. What is Mercedes Seatbelt Buckle Switch Status Live Data?

- 1.1 Understanding the Hall Effect Sensor

- 1.2 Role in Vehicle Safety Systems

- 1.3 How Live Data is Transmitted

- 2. Why is Interpreting Seatbelt Buckle Switch Data Important?

- 2.1 Diagnostic Accuracy

- 2.2 Ensuring System Functionality

- 2.3 Preventing Unnecessary Repairs

- 3. Tools Needed to Interpret Mercedes Seatbelt Switch Status

- 3.1 Diagnostic Scan Tool

- 3.2 Multimeter

- 3.3 Wiring Diagrams and Technical Service Bulletins (TSBs)

- 4. Step-by-Step Guide to Interpreting Seatbelt Switch Data

- 4.1 Connecting the Diagnostic Scan Tool

- 4.2 Accessing Live Data

- 4.3 Analyzing the Data

- 5. Common Issues and How to Identify Them

- 5.1 Faulty Seatbelt Switch

- 5.2 Wiring Problems

- 5.3 Module Malfunctions

- 6. Interpreting Specific Data Readings

- 6.1 “Buckled” Status

- 6.2 “Unbuckled” Status

- 6.3 Voltage Readings

- 6.4 Resistance Readings

- 7. Advanced Diagnostic Techniques

- 7.1 Using an Oscilloscope

- 7.2 Component Testing

- 7.3 Consulting Mercedes-Benz Technical Resources

- 8. Preventative Maintenance for Seatbelt Systems

- 8.1 Regular Inspection

- 8.2 Cleaning Seatbelt Components

- 8.3 Lubricating Buckle Mechanisms

- 9. Case Studies: Real-World Examples

- 9.1 Case Study 1: Intermittent Seatbelt Warning Light

- 9.2 Case Study 2: Airbag System Malfunction

- 9.3 Case Study 3: Seatbelt Reminder System Failure

- 10. The Future of Seatbelt System Diagnostics

- 10.1 AI-Powered Diagnostics

- 10.2 Remote Diagnostics

- 10.3 Enhanced Sensor Technology

- FAQ Section

- 1. What does seatbelt buckle switch status live data indicate?

- 2. How do I access seatbelt buckle switch status live data?

- 3. What tools are needed to interpret Mercedes seatbelt switch data?

- 4. What does “Buckled” status mean in live data?

- 5. What does “Unbuckled” status mean in live data?

- 6. What are common issues that can affect seatbelt buckle switch functionality?

- 7. How can I diagnose a faulty seatbelt switch?

- 8. What should I do if the seatbelt warning light remains on even when the seatbelt is buckled?

- 9. How can I prevent seatbelt system issues?

- 10. Can advanced technologies like AI improve seatbelt system diagnostics?

1. What is Mercedes Seatbelt Buckle Switch Status Live Data?

Mercedes seatbelt buckle switch status live data refers to the real-time information provided by the seatbelt buckle switches, which are Hall Effect-type sensors that indicate whether the seatbelt is buckled or unbuckled. These sensors are crucial for the proper functioning of the vehicle’s safety systems, including airbag deployment and seatbelt reminder systems. By monitoring this data, technicians can diagnose issues related to the seatbelt system and ensure passenger safety.

1.1 Understanding the Hall Effect Sensor

The Hall Effect sensor is a key component in the seatbelt buckle switch. According to a study by the University of California, Berkeley’s Sensors and Actuators Center, Hall Effect sensors are widely used in automotive applications due to their reliability and precision. These sensors consist of a Hall Effect Integrated Circuit (IC) chip and a small permanent magnet within the seatbelt buckle. When the seatbelt is buckled, the magnet’s field induces a current in the chip, signaling that the seatbelt is in use. Conversely, when unbuckled, the current is reduced, indicating the seatbelt is not in use.

1.2 Role in Vehicle Safety Systems

The data from the seatbelt buckle switches plays a vital role in several safety systems:

- Airbag Deployment: The Occupant Restraint Controller (ORC) uses the seatbelt status to determine airbag deployment strategies.

- Seatbelt Reminder System: The Instrument Panel Cluster (IPC) receives electronic seatbelt switch status messages via the Controller Area Network (CAN) data bus, activating the seatbelt warning light and audible alerts.

- Occupant Classification: The Occupant Classification Module (OCM) uses seatbelt status, particularly for the passenger seat, to classify the occupant for optimal airbag deployment.

1.3 How Live Data is Transmitted

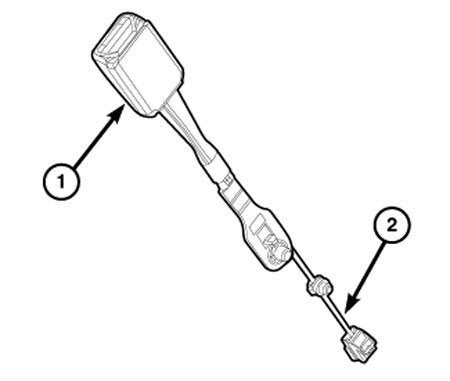

The seatbelt switches are connected to the vehicle’s electrical system through a two-lead pigtail wire and connector. This connection transmits data to the ORC or OCM. These modules then communicate the seatbelt status to other vehicle systems, such as the IPC, via the CAN data bus. Diagnostic tools can tap into this data stream to provide real-time information on the seatbelt buckle switch status.

2. Why is Interpreting Seatbelt Buckle Switch Data Important?

Interpreting seatbelt buckle switch data is crucial for diagnosing and resolving issues within the vehicle’s restraint system, which directly impacts safety. Accurate interpretation ensures that the seatbelt reminder system functions correctly and that the airbags deploy appropriately in the event of a collision. Proper diagnosis can prevent unnecessary repairs and ensure that all safety features operate as intended.

2.1 Diagnostic Accuracy

According to the National Highway Traffic Safety Administration (NHTSA), seatbelt use is a critical factor in reducing injuries and fatalities in vehicle accidents. By accurately interpreting seatbelt buckle switch data, technicians can:

- Identify faulty switches that may not correctly register seatbelt usage.

- Ensure the seatbelt reminder system alerts drivers when seatbelts are not fastened.

- Verify that the airbag system is receiving accurate information for deployment calculations.

2.2 Ensuring System Functionality

The seatbelt buckle switch data influences multiple vehicle systems, including the ORC, OCM, and IPC. Correct data interpretation helps to:

- Confirm that the ORC receives accurate input for airbag deployment strategies.

- Validate the OCM’s classification of occupants for optimal airbag deployment.

- Guarantee that the IPC displays the correct seatbelt warning indicators.

2.3 Preventing Unnecessary Repairs

Misdiagnosing seatbelt buckle switch issues can lead to unnecessary replacement of components. By accurately interpreting live data, technicians can:

- Distinguish between a faulty switch and wiring problems.

- Avoid replacing the entire seatbelt buckle assembly when only the switch is at fault.

- Save time and money by pinpointing the exact source of the problem.

3. Tools Needed to Interpret Mercedes Seatbelt Switch Status

To effectively interpret Mercedes seatbelt switch status, you’ll need specific diagnostic tools, including a diagnostic scan tool, a multimeter, and access to wiring diagrams and technical service bulletins. These tools allow you to read live data, perform circuit testing, and access manufacturer-specific information. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers resources and support for selecting and using these tools.

3.1 Diagnostic Scan Tool

A diagnostic scan tool is essential for reading live data from the seatbelt buckle switches. Modern scan tools can display the status of the switches in real-time, allowing technicians to quickly determine if the switches are functioning correctly.

- Functionality: Scan tools read Diagnostic Trouble Codes (DTCs) and display live data parameters related to the seatbelt system.

- Benefits: Provides a comprehensive view of the seatbelt system’s operation, including switch status, circuit voltage, and communication signals.

- Examples: Autel MaxiSys MS906BT, Launch X431 V+, and Mercedes-Benz Star Diagnosis.

3.2 Multimeter

A multimeter is necessary for performing circuit testing and verifying the integrity of the wiring connected to the seatbelt buckle switches.

- Functionality: Measures voltage, current, and resistance in electrical circuits.

- Benefits: Helps identify open circuits, short circuits, and faulty grounds in the seatbelt switch wiring.

- Usage: Test the voltage at the seatbelt switch connector to ensure proper power supply and ground connections.

3.3 Wiring Diagrams and Technical Service Bulletins (TSBs)

Access to wiring diagrams and TSBs is crucial for understanding the specific configuration of the seatbelt system and identifying any known issues or updates.

- Wiring Diagrams: Provide detailed schematics of the seatbelt switch circuits, including wire colors, connector locations, and component connections.

- TSBs: Offer information on common problems, diagnostic procedures, and repair instructions for specific Mercedes-Benz models.

- Resources: Available through online subscription services like Alldata, Mitchell OnDemand, and the official Mercedes-Benz technical information portal.

Mercedes Seatbelt Buckle

Mercedes Seatbelt Buckle

4. Step-by-Step Guide to Interpreting Seatbelt Switch Data

Interpreting seatbelt switch data involves a systematic approach that includes connecting the diagnostic scan tool, accessing live data, and analyzing the data for accurate readings. Follow these steps to diagnose and resolve seatbelt system issues effectively.

4.1 Connecting the Diagnostic Scan Tool

- Locate the OBD-II Port: The OBD-II port is typically located under the dashboard on the driver’s side.

- Connect the Scan Tool: Plug the scan tool into the OBD-II port.

- Turn on the Ignition: Turn the ignition to the “ON” position without starting the engine.

- Power on the Scan Tool: Follow the scan tool’s instructions to power it on and establish a connection with the vehicle’s computer.

4.2 Accessing Live Data

- Select the Vehicle: Choose the correct vehicle make, model, and year in the scan tool menu.

- Navigate to Restraint System: Look for the “Restraint System,” “Airbag System,” or “Body Control Module” in the menu.

- Choose Live Data: Select the “Live Data” or “Data Stream” option.

- Find Seatbelt Switch Parameters: Locate the parameters related to the seatbelt buckle switches, such as “Driver Seatbelt Status” and “Passenger Seatbelt Status.”

4.3 Analyzing the Data

- Monitor Switch Status: Observe the live data as you buckle and unbuckle the seatbelts.

- Verify Correct Readings: The scan tool should display “Buckled” when the seatbelt is fastened and “Unbuckled” when it is released.

- Check for Errors: If the status does not change or shows an incorrect reading, there may be a problem with the switch, wiring, or related module.

- Record Data: Document any discrepancies or unusual readings for further diagnosis.

5. Common Issues and How to Identify Them

Several common issues can affect seatbelt buckle switch functionality, including faulty switches, wiring problems, and module malfunctions. Understanding these issues and how to identify them is essential for effective diagnosis and repair.

5.1 Faulty Seatbelt Switch

A faulty seatbelt switch is one of the most common causes of seatbelt system problems.

- Symptoms:

- The seatbelt warning light remains on even when the seatbelt is buckled.

- The airbag system may not function correctly.

- The scan tool displays an incorrect seatbelt status.

- Diagnosis:

- Use a multimeter to test the switch’s continuity. A good switch should show continuity when buckled and no continuity when unbuckled.

- Check for physical damage or corrosion on the switch.

- Solution: Replace the seatbelt buckle assembly with a new unit.

5.2 Wiring Problems

Wiring issues can also cause seatbelt switch malfunctions.

- Symptoms:

- Intermittent seatbelt warning light.

- No response from the seatbelt switch.

- Diagnostic Trouble Codes (DTCs) related to the seatbelt circuit.

- Diagnosis:

- Inspect the wiring harness for damage, breaks, or corrosion.

- Use a multimeter to check the continuity of the wires.

- Verify the voltage at the seatbelt switch connector.

- Solution: Repair or replace the damaged wiring. Ensure proper connections and secure the harness to prevent future issues.

5.3 Module Malfunctions

In some cases, the ORC, OCM, or IPC may be the source of the problem.

- Symptoms:

- Multiple seatbelt system issues.

- Communication errors with other vehicle systems.

- Inability to read seatbelt switch data with the scan tool.

- Diagnosis:

- Use the scan tool to check for DTCs related to the ORC, OCM, or IPC.

- Verify the power supply and ground connections to the modules.

- Check for software updates or reprogramming options for the modules.

- Solution: Replace or reprogram the faulty module.

6. Interpreting Specific Data Readings

Specific data readings from the seatbelt buckle switches can indicate various issues. Understanding how to interpret these readings is crucial for accurate diagnosis and effective repair.

6.1 “Buckled” Status

- Normal: Indicates the seatbelt is properly fastened.

- Problem: If the seatbelt is not buckled and the scan tool still shows “Buckled,” the switch is likely faulty.

6.2 “Unbuckled” Status

- Normal: Indicates the seatbelt is unfastened.

- Problem: If the seatbelt is buckled and the scan tool shows “Unbuckled,” the switch or wiring may be faulty.

6.3 Voltage Readings

- Normal: The voltage at the seatbelt switch connector should match the vehicle’s system voltage (typically 12V).

- Problem: Low or no voltage indicates a wiring issue, such as a break in the circuit or a faulty ground connection.

6.4 Resistance Readings

- Normal: The resistance of the seatbelt switch should be within the specified range when buckled.

- Problem: High or infinite resistance indicates a faulty switch or a break in the circuit.

7. Advanced Diagnostic Techniques

For complex seatbelt system issues, advanced diagnostic techniques may be necessary. These techniques include using an oscilloscope, performing component testing, and consulting with Mercedes-Benz technical resources.

7.1 Using an Oscilloscope

An oscilloscope can be used to analyze the signal from the seatbelt switch in real-time.

- Functionality: Displays the voltage waveform of the signal, allowing technicians to identify intermittent problems or signal distortions.

- Benefits: Provides a more detailed view of the switch’s operation compared to a multimeter.

- Usage: Connect the oscilloscope to the seatbelt switch signal wire and monitor the waveform as the seatbelt is buckled and unbuckled.

7.2 Component Testing

Component testing involves removing the seatbelt buckle assembly and testing the switch independently.

- Functionality: Isolates the switch from the vehicle’s electrical system, allowing for more accurate testing.

- Benefits: Eliminates the possibility of wiring or module issues affecting the test results.

- Usage: Use a multimeter to test the switch’s continuity and resistance while manually operating the buckle mechanism.

7.3 Consulting Mercedes-Benz Technical Resources

Mercedes-Benz provides extensive technical resources for diagnosing and repairing vehicle systems.

- Resources:

- Mercedes-Benz Workshop Information System (WIS)

- Mercedes-Benz Electronic Parts Catalogue (EPC)

- Mercedes-Benz Technical Service Bulletins (TSBs)

- Benefits: Provides access to factory-level diagnostic procedures, repair instructions, and parts information.

- Usage: Consult these resources for specific diagnostic steps, wiring diagrams, and component specifications.

8. Preventative Maintenance for Seatbelt Systems

Preventative maintenance can help prolong the life of seatbelt systems and prevent common issues. Regular inspection and cleaning of the seatbelt components can ensure proper functionality and safety.

8.1 Regular Inspection

- Procedure: Inspect the seatbelts, buckles, and retractors for damage, wear, and proper operation.

- Frequency: Perform inspections during routine maintenance, such as oil changes or tire rotations.

- Benefits: Early detection of potential problems can prevent more serious issues down the road.

8.2 Cleaning Seatbelt Components

- Procedure: Clean the seatbelts, buckles, and retractors with a mild soap and water solution.

- Frequency: Clean the components as needed, especially if they become dirty or sticky.

- Benefits: Removes dirt and debris that can interfere with the proper operation of the seatbelt system.

8.3 Lubricating Buckle Mechanisms

- Procedure: Apply a small amount of silicone-based lubricant to the buckle mechanisms.

- Frequency: Lubricate the mechanisms as needed, especially if they become stiff or difficult to operate.

- Benefits: Keeps the buckle mechanisms working smoothly and prevents corrosion.

9. Case Studies: Real-World Examples

Examining real-world case studies can provide valuable insights into diagnosing and repairing seatbelt system issues. These examples illustrate common problems and effective solutions.

9.1 Case Study 1: Intermittent Seatbelt Warning Light

- Vehicle: 2016 Mercedes-Benz C300

- Symptoms: The seatbelt warning light would intermittently turn on and off, even when the seatbelt was buckled.

- Diagnosis: Using a diagnostic scan tool, the technician found a DTC related to the driver’s side seatbelt switch. Live data showed the switch status fluctuating between “Buckled” and “Unbuckled” even when the seatbelt was fastened.

- Solution: The technician replaced the driver’s side seatbelt buckle assembly. After the replacement, the seatbelt warning light no longer appeared intermittently, and the live data showed a stable “Buckled” status when the seatbelt was fastened.

9.2 Case Study 2: Airbag System Malfunction

- Vehicle: 2018 Mercedes-Benz E350

- Symptoms: The airbag warning light was on, and the scan tool showed a DTC related to the passenger’s side seatbelt switch.

- Diagnosis: Live data from the scan tool indicated that the passenger’s side seatbelt switch was always showing “Unbuckled,” even when the seatbelt was fastened. A multimeter test revealed a break in the wiring harness leading to the switch.

- Solution: The technician repaired the damaged wiring harness. After the repair, the airbag warning light turned off, and the live data showed the correct seatbelt status.

9.3 Case Study 3: Seatbelt Reminder System Failure

- Vehicle: 2020 Mercedes-Benz GLC300

- Symptoms: The seatbelt reminder system was not functioning correctly. The warning light and audible alert did not activate when the driver’s seatbelt was unbuckled.

- Diagnosis: Using the scan tool, the technician found that the driver’s side seatbelt switch was functioning correctly. However, there was a communication error between the ORC and the IPC.

- Solution: The technician reprogrammed the ORC with the latest software update. After the reprogramming, the seatbelt reminder system functioned as intended.

10. The Future of Seatbelt System Diagnostics

The future of seatbelt system diagnostics will likely involve more advanced technologies, such as artificial intelligence (AI) and machine learning, to improve diagnostic accuracy and efficiency. These technologies can analyze large amounts of data to identify patterns and predict potential issues before they occur.

10.1 AI-Powered Diagnostics

- Functionality: AI algorithms can analyze live data from the seatbelt system to identify anomalies and predict potential failures.

- Benefits: Improved diagnostic accuracy, reduced repair time, and proactive maintenance.

- Example: AI-powered scan tools can automatically identify faulty components based on data patterns.

10.2 Remote Diagnostics

- Functionality: Technicians can remotely access vehicle data and perform diagnostics from a remote location.

- Benefits: Convenient, efficient, and cost-effective diagnostic services.

- Example: Remote diagnostic tools can allow technicians to monitor seatbelt system data in real-time and provide remote assistance.

10.3 Enhanced Sensor Technology

- Functionality: Advanced sensors can provide more detailed information about the seatbelt system’s operation.

- Benefits: More accurate and comprehensive diagnostics.

- Example: High-resolution sensors can detect subtle changes in the seatbelt switch signal, allowing for early detection of potential problems.

By understanding and effectively interpreting Mercedes seatbelt buckle switch status live data, you can ensure the safety and functionality of your vehicle’s restraint system. This knowledge empowers you to diagnose and resolve issues promptly, preventing unnecessary repairs and ensuring that all safety features operate as intended.

For expert assistance with diagnosing and repairing your Mercedes-Benz, contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN. Our team of experienced technicians is ready to help you with all your diagnostic needs. Reach out to us at 789 Oak Avenue, Miami, FL 33101, United States, or call us on Whatsapp at +1 (641) 206-8880. Visit our website at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for more information. We offer comprehensive diagnostic services, including advanced scan tools, wiring diagrams, and technical support. We are here to assist you with any questions or concerns regarding your Mercedes-Benz.

FAQ Section

1. What does seatbelt buckle switch status live data indicate?

Seatbelt buckle switch status live data indicates whether the seatbelt is buckled or unbuckled in real-time, providing crucial information for the vehicle’s safety systems. This data helps the Occupant Restraint Controller (ORC) and Occupant Classification Module (OCM) to determine airbag deployment strategies and activate the seatbelt reminder system.

2. How do I access seatbelt buckle switch status live data?

You can access seatbelt buckle switch status live data using a diagnostic scan tool connected to the vehicle’s OBD-II port, typically located under the dashboard on the driver’s side.

3. What tools are needed to interpret Mercedes seatbelt switch data?

The essential tools include a diagnostic scan tool, a multimeter, and access to wiring diagrams and Technical Service Bulletins (TSBs) for Mercedes-Benz vehicles.

4. What does “Buckled” status mean in live data?

“Buckled” status indicates that the seatbelt is properly fastened. If the scan tool shows “Buckled” when the seatbelt is not buckled, it suggests a faulty switch.

5. What does “Unbuckled” status mean in live data?

“Unbuckled” status indicates that the seatbelt is unfastened. If the scan tool shows “Unbuckled” when the seatbelt is buckled, the switch or wiring may be faulty.

6. What are common issues that can affect seatbelt buckle switch functionality?

Common issues include faulty seatbelt switches, wiring problems (such as breaks, shorts, or corrosion), and module malfunctions (ORC, OCM, or IPC).

7. How can I diagnose a faulty seatbelt switch?

You can diagnose a faulty seatbelt switch by using a multimeter to test its continuity and resistance while manually operating the buckle mechanism. A diagnostic scan tool can also provide live data to confirm the switch’s status.

8. What should I do if the seatbelt warning light remains on even when the seatbelt is buckled?

If the seatbelt warning light remains on, check the seatbelt switch status using a scan tool. If the switch is faulty, replace the seatbelt buckle assembly. Also, inspect the wiring for any damage or corrosion.

9. How can I prevent seatbelt system issues?

Preventative maintenance includes regularly inspecting the seatbelts, buckles, and retractors for damage, cleaning the components, and lubricating the buckle mechanisms.

10. Can advanced technologies like AI improve seatbelt system diagnostics?

Yes, advanced technologies like AI can analyze live data to identify anomalies and predict potential failures, improving diagnostic accuracy and efficiency. Remote diagnostics and enhanced sensor technology can also provide more detailed and comprehensive diagnostics.