OBD2, or On-Board Diagnostics II, is your Mercedes-Benz’s built-in self-diagnostic system, and at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN we can help you understand it better. This standardized protocol enables the extraction of diagnostic trouble codes (DTCs) and real-time data through the OBD2 connector, empowering you to maintain and troubleshoot your vehicle effectively. Understanding OBD2 protocols, scan tools, and Mercedes-Benz specific applications ensures optimal performance.

Contents

- 1. Understanding the Basics of OBD2

- 1.1 What is OBD2?

- 1.2 How Does OBD2 Work?

- 2. Is My Mercedes-Benz OBD2 Compliant?

- 2.1 OBD2 Compliance by Region and Year

- 2.2 Identifying OBD2 Compliance

- 3. The Future of OBD2: What’s on the Horizon?

- 3.1 OBD3 and Telematics

- 3.2 Alternatives to Traditional OBD2

- 3.3 Challenges in Accessing Data

- 4. OBD2 Standards: SAE and ISO

- 4.1 Understanding the Layers

- 4.2 The OBD2 Connector (SAE J1962)

- 4.3 Type A vs. Type B Connectors

- 5. OBD2 and CAN Bus: ISO 15765-4

- 5.1 CAN Bus as the Mandatory Protocol

- 5.2 OBD2 CAN Identifiers

- 5.3 OBD2 vs. Proprietary CAN Protocols

- 5.4 Bit-Rate and ID Validation

- 5.5 Five Lower-Layer OBD2 Protocols

- 6. Transporting OBD2 Messages via ISO-TP: ISO 15765-2

- 6.1 Understanding ISO-TP

- 6.2 Single Frame Communication

- 7. The OBD2 Diagnostic Message: SAE J1979, ISO 15031-5

- 7.1 Structure of an OBD2 Message

- 7.2 Example: OBD2 Request/Response

- 7.3 OBD2 Services (Modes)

- 7.4 OBD2 Parameter IDs (PIDs)

- 8. Logging and Decoding OBD2 Data

- 8.1 Practical Example

- 8.2 Steps for Logging and Decoding

- 9. OBD2 Multi-Frame Examples

- 9.1 Understanding Multi-Frame Communication

- 9.2 Example 1: Vehicle Identification Number (VIN)

- 9.3 Example 2: Multi-PID Request (6x)

- 9.4 Example 3: Diagnostic Trouble Codes (DTCs)

- 10. OBD2 Data Logging: Use Case Examples

- 10.1 Various Applications

- FAQ: Understanding OBD2 for Your Mercedes-Benz

- 1. What is the Primary Function of OBD2 in My Mercedes-Benz?

- 2. Where Can I Find the OBD2 Port in My Mercedes-Benz?

- 3. What Kind of OBD2 Scanner Do I Need for My Mercedes-Benz?

- 4. Can I Use OBD2 to Monitor Real-Time Data on My Mercedes-Benz?

- 5. How Do I Interpret the Diagnostic Trouble Codes (DTCs) from My Mercedes-Benz?

- 6. Will Using an OBD2 Scanner Void My Mercedes-Benz Warranty?

- 7. What Should I Do if My Mercedes-Benz Fails an OBD2 Emissions Test?

- 8. Can OBD2 Be Used to Unlock Hidden Features on My Mercedes-Benz?

- 9. How Often Should I Scan My Mercedes-Benz with an OBD2 Scanner?

- 10. Are There Any Risks Associated with Using OBD2 on My Mercedes-Benz?

- Conclusion: Empowering Your Mercedes-Benz Ownership

1. Understanding the Basics of OBD2

1.1 What is OBD2?

OBD2 is a standardized system that allows you to access your vehicle’s self-diagnostic information. It provides access to diagnostic trouble codes (DTCs) and real-time data through a standard connector. The Society of Automotive Engineers (SAE) standardized DTCs and the OBD connector across manufacturers (SAE J1962). This standardization is key to allowing a single tool to interface with a wide variety of vehicles.

1.2 How Does OBD2 Work?

When your Mercedes-Benz detects an issue, it stores a diagnostic trouble code (DTC). A mechanic or you can connect an OBD2 scanner to the 16-pin connector, typically located near the steering wheel. The scanner sends requests to the car, which responds with data like speed, fuel level, or DTCs. This data helps diagnose issues more efficiently. According to a study by the University of California, using OBD2 scanners can reduce diagnostic time by up to 40%.

2. Is My Mercedes-Benz OBD2 Compliant?

2.1 OBD2 Compliance by Region and Year

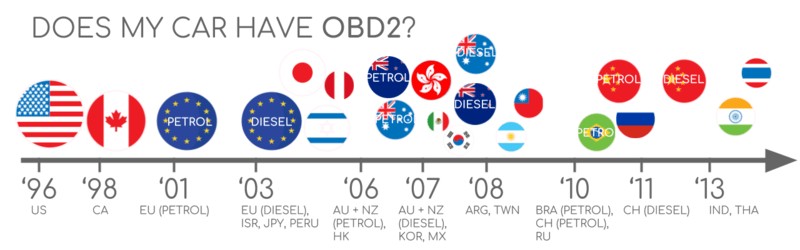

Most modern cars, including Mercedes-Benz models, support OBD2. The implementation timeline varies by region:

- 1996: OBD2 became mandatory in the USA for cars and light trucks.

- 2001: Required in the EU for gasoline cars.

- 2003: Required in the EU for diesel cars (EOBD).

- 2005: OBD2 required in the US for medium-duty vehicles.

- 2008: US cars required to use ISO 15765-4 (CAN) as the OBD2 basis.

- 2010: OBD2 required in the US for heavy-duty vehicles.

2.2 Identifying OBD2 Compliance

Even if your older Mercedes-Benz has a 16-pin connector, it might not fully support OBD2. A reliable way to check is by its manufacturing date and intended market. If your car was sold new in the US after 1996, it is likely OBD2 compliant.

3. The Future of OBD2: What’s on the Horizon?

3.1 OBD3 and Telematics

The future points towards OBD3, integrating telematics into all vehicles for remote diagnostics. OBD3 would add a small radio transponder to cars, allowing the vehicle identification number (VIN) and DTCs to be sent via WiFi to a central server for checks. This saves costs and offers convenience but raises surveillance concerns. Many devices, like the CANedge2 and CANedge3, already facilitate transferring CAN or OBD2 data via WiFi/cellular.

3.2 Alternatives to Traditional OBD2

Modern alternatives are being developed to address the limitations of OBD2, including WWH-OBD (World Wide Harmonized OBD) and OBDonUDS (OBD on UDS). Both enhance OBD communication by using the UDS protocol as a basis.

3.3 Challenges in Accessing Data

The German car industry aims to control access to vehicle data, arguing that OBD2 was intended for repair shops, not for third parties to build data-driven economies. The proposal involves disabling OBD2 functionality while driving and collecting data in a central server. This raises security concerns but is viewed by many as a commercial move.

4. OBD2 Standards: SAE and ISO

4.1 Understanding the Layers

OBD2 is a higher-layer protocol like a language, while CAN is the communication method akin to a phone. OBD2 standards specify the connector, lower-layer protocols, and parameter IDs (PIDs). Standards are organized using the 7-layer OSI model, with both SAE and ISO standards covering different layers. SAE standards are typically for the US market, while ISO standards are for the EU market. Several standards are technically equivalent, like SAE J1979 vs. ISO 15031-5 and SAE J1962 vs. ISO 15031-3.

4.2 The OBD2 Connector (SAE J1962)

The 16-pin OBD2 connector, specified in SAE J1962 / ISO 15031-3, provides easy access to your car’s data. Key points to remember:

- The connector is typically near the steering wheel.

- Pin 16 supplies battery power.

- The OBD2 pinout depends on the communication protocol.

- CAN bus is the most common lower-layer protocol, using pins 6 (CAN-H) and 14 (CAN-L).

4.3 Type A vs. Type B Connectors

You might encounter type A and type B OBD2 connectors. Type A is common in cars, while type B is found in medium and heavy-duty vehicles. They share similar pinouts but offer different power supply outputs (12V for type A and 24V for type B). Type B connectors have an interrupted groove in the middle to distinguish them physically.

5. OBD2 and CAN Bus: ISO 15765-4

5.1 CAN Bus as the Mandatory Protocol

Since 2008, CAN bus has been the mandatory lower-layer protocol for OBD2 in all cars sold in the US, according to ISO 15765. ISO 15765-4, or Diagnostics over CAN (DoCAN), standardizes the CAN interface for test equipment, focusing on the physical, data link, and network layers. Key specifications include:

- CAN bus bit-rate of 250K or 500K.

- 11-bit or 29-bit CAN IDs.

- Specific CAN IDs for OBD requests/responses.

- Diagnostic CAN frame data length of 8 bytes.

- OBD2 adapter cable length max of 5 meters.

5.2 OBD2 CAN Identifiers

All OBD2 communication involves request/response messages. In most cars, 11-bit CAN IDs are used, with the Functional Addressing ID at 0x7DF. ECUs respond with IDs 0x7E8-0x7EF. In some vehicles, 29-bit CAN identifiers are used, with the Functional Addressing CAN ID at 0x18DB33F1.

5.3 OBD2 vs. Proprietary CAN Protocols

Your Mercedes-Benz’s ECUs do not rely on OBD2 to function. Each OEM implements proprietary CAN protocols specific to the vehicle brand, model, and year. OBD2 is an additional higher-layer protocol parallel to the OEM-specific protocol. In newer cars, a gateway may block access to OEM-specific CAN data, enabling only OBD2 communication via the OBD2 connector.

5.4 Bit-Rate and ID Validation

OBD2 may use two bit-rates (250K, 500K) and two CAN ID lengths (11-bit, 29-bit), resulting in four potential combinations. ISO 15765-4 provides recommendations for a systematic initialization sequence to determine the correct combination. Newer versions account for OBD communication via OBDonUDS rather than OBDonEDS.

5.5 Five Lower-Layer OBD2 Protocols

While CAN is the primary lower-layer protocol, older cars may use one of four others:

- ISO 15765 (CAN bus).

- ISO14230-4 (KWP2000).

- ISO 9141-2.

- SAE J1850 (VPW).

- SAE J1850 (PWM).

6. Transporting OBD2 Messages via ISO-TP: ISO 15765-2

6.1 Understanding ISO-TP

All OBD2 data is communicated on the CAN bus through ISO-TP (ISO 15765-2), enabling communication of payloads exceeding 8 bytes. This is essential for extracting the VIN or DTCs. ISO 15765-2 facilitates segmentation, flow control, and reassembly.

6.2 Single Frame Communication

When OBD2 data fits in a single CAN frame, ISO 15765-2 specifies using a Single Frame (SF). The first data byte (PCI field) contains the payload length, leaving 7 bytes for OBD2 communication.

7. The OBD2 Diagnostic Message: SAE J1979, ISO 15031-5

7.1 Structure of an OBD2 Message

An OBD2 message consists of an identifier, data length (PCI field), and data, split into Mode, parameter ID (PID), and data bytes.

7.2 Example: OBD2 Request/Response

Consider the example of requesting vehicle speed:

- External tool sends a request to the car with CAN ID 0x7DF and 2 payload bytes: Mode 0x01 and PID 0x0D.

- The car responds via CAN ID 0x7E8 with 3 payload bytes, including the vehicle speed value in the 4th byte, 0x32 (50 in decimal).

- Looking up the decoding rules for OBD2 PID 0x0D, the physical value is 50 km/h.

7.3 OBD2 Services (Modes)

There are 10 OBD2 diagnostic services or modes. Mode 0x01 shows current real-time data, while others show/clear DTCs or freeze-frame data. Vehicles don’t have to support all OBD2 modes. In OBD2 messages, the mode is in the 2nd byte; in the response, 0x40 is added to the mode.

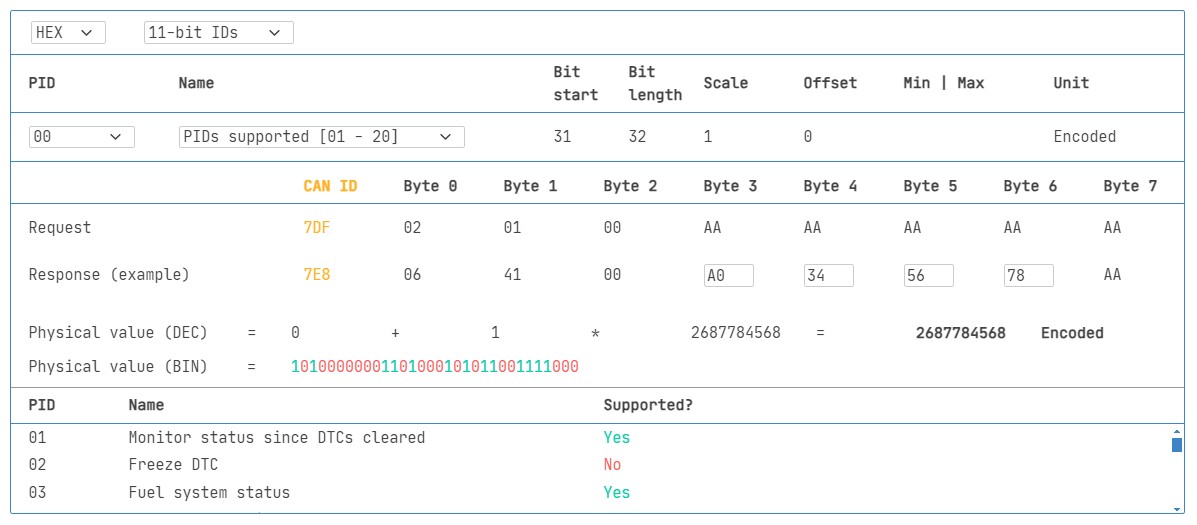

7.4 OBD2 Parameter IDs (PIDs)

Each OBD2 mode contains parameter IDs (PIDs). Mode 0x01 contains ~200 standardized PIDs with real-time data like speed, RPM, and fuel level. Vehicles don’t have to support all PIDs in a mode, and most support only a subset. If an emissions-related ECU supports any OBD2 services, it must support mode 0x01 PID 0x00, which informs whether it supports PIDs 0x01-0x20.

OBD2 PID overview tool

OBD2 PID overview tool

8. Logging and Decoding OBD2 Data

8.1 Practical Example

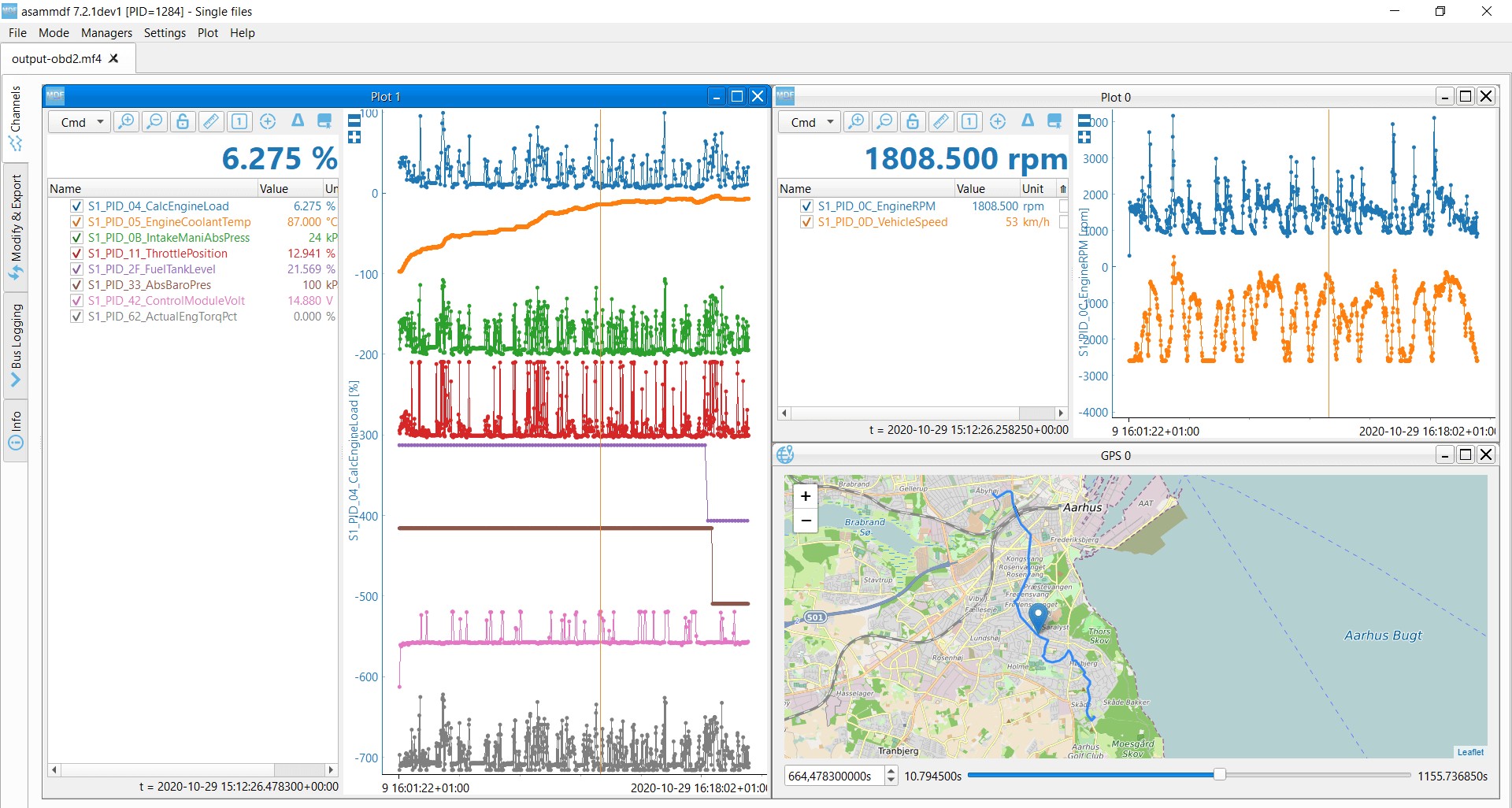

Here’s how to log OBD2 data using a CAN bus data logger like the CANedge. Configure the CANedge to transmit custom CAN frames for OBD2 logging and connect it to your vehicle via an OBD2-DB9 adapter cable.

8.2 Steps for Logging and Decoding

- Test bit-rate, IDs, and supported PIDs:

- Send a CAN frame at 500K and check if successful (else try 250K).

- Use the identified bit-rate for communication.

- Send multiple ‘Supported PIDs’ requests and review the results.

- Based on response IDs, determine 11-bit vs. 29-bit.

- Based on response data, identify supported PIDs.

- Configure OBD2 PID requests:

- Shift to ‘Physical Addressing’ request IDs (e.g., 0x7E0) to avoid multiple responses.

- Add 300-500 ms between each OBD2 request to avoid spamming ECUs.

- Use triggers to stop transmitting when the vehicle is inactive to avoid battery drain.

- Add filters to record only OBD2 responses if your vehicle outputs OEM-specific CAN data.

- DBC decode raw OBD2 data:

- Use decoding information from ISO 15031-5/SAE J1979 and a free OBD2 DBC file to decode the data into physical values.

- Leverage both the CAN ID, OBD2 mode, and OBD2 PID to identify the signal.

OBD2 data decoded visual plot asammdf CAN bus DBC file

OBD2 data decoded visual plot asammdf CAN bus DBC file

9. OBD2 Multi-Frame Examples

9.1 Understanding Multi-Frame Communication

OBD2 data is communicated using ISO-TP, and multi-frame communication requires flow control frames. You can transmit a static flow control frame 50 ms after the initial request frame. Multi-frame OBD2 responses require CAN software/API tools that support ISO-TP.

9.2 Example 1: Vehicle Identification Number (VIN)

To extract the VIN from your Mercedes-Benz, use mode 0x09 and PID 0x02.

- The tester tool sends a Single Frame request with the PCI field (0x02), request service identifier (0x09), and PID (0x02).

- The vehicle responds with a First Frame containing the PCI, length, mode (0x49), and PID (0x02), followed by the byte 0x01 (NODI).

- The remaining 17 bytes equal the VIN, which can be translated from HEX to ASC.

9.3 Example 2: Multi-PID Request (6x)

External tools can request up to 6 mode 0x01 OBD2 PIDs in a single request frame. The ECU responds with data for supported PIDs across multiple frames. This method requires careful signal encoding and isn’t recommended for generic OBD2 DBC files.

9.4 Example 3: Diagnostic Trouble Codes (DTCs)

Use OBD2 mode 0x03 to request emissions-related DTCs. The targeted ECU(s) will respond with the number of stored DTCs. Multi-frame responses are necessary when more than 2 DTCs are stored. The 2-byte DTC value is split into two parts: the category and a 4-digit code.

10. OBD2 Data Logging: Use Case Examples

10.1 Various Applications

OBD2 data from your Mercedes-Benz can be used in various scenarios:

- Logging data from cars: Reduce fuel costs, improve driving habits, test prototype parts, and for insurance purposes.

- Real-time car diagnostics: Stream human-readable OBD2 data in real-time to diagnose vehicle issues.

- Predictive maintenance: Monitor cars via IoT OBD2 loggers in the cloud to predict and avoid breakdowns.

- Vehicle blackbox logger: Serve as a ‘blackbox’ for vehicles, providing data for disputes or diagnostics.

FAQ: Understanding OBD2 for Your Mercedes-Benz

1. What is the Primary Function of OBD2 in My Mercedes-Benz?

OBD2’s primary function is to monitor your Mercedes-Benz’s engine and emissions systems, reporting any malfunctions through diagnostic trouble codes (DTCs). This helps identify issues for timely repairs.

2. Where Can I Find the OBD2 Port in My Mercedes-Benz?

In most Mercedes-Benz models, the OBD2 port is located under the dashboard on the driver’s side, typically near the steering column.

3. What Kind of OBD2 Scanner Do I Need for My Mercedes-Benz?

For a Mercedes-Benz, it’s best to use an OBD2 scanner that supports CAN (Controller Area Network) protocol, as this is the standard communication protocol for modern vehicles.

4. Can I Use OBD2 to Monitor Real-Time Data on My Mercedes-Benz?

Yes, OBD2 can monitor real-time data such as engine speed, coolant temperature, and oxygen sensor readings, providing valuable insights into your vehicle’s performance.

5. How Do I Interpret the Diagnostic Trouble Codes (DTCs) from My Mercedes-Benz?

DTCs are five-character codes. You can look them up using an OBD2 code reader, online databases, or consult a professional mechanic to understand the issue.

6. Will Using an OBD2 Scanner Void My Mercedes-Benz Warranty?

Using an OBD2 scanner for diagnostics will not void your warranty, but modifying the car’s software or hardware based on the data might affect it.

7. What Should I Do if My Mercedes-Benz Fails an OBD2 Emissions Test?

If your Mercedes-Benz fails, review the DTCs to identify the problem, fix any issues, clear the codes, and then retest to ensure compliance.

8. Can OBD2 Be Used to Unlock Hidden Features on My Mercedes-Benz?

Some advanced OBD2 tools can unlock or customize certain vehicle features, but ensure the tool and procedures are compatible with your Mercedes-Benz model to avoid issues. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we offer expert guidance on how to do this safely and effectively.

9. How Often Should I Scan My Mercedes-Benz with an OBD2 Scanner?

Scan your Mercedes-Benz whenever the check engine light comes on or if you notice any unusual behavior, such as reduced fuel efficiency or rough idling.

10. Are There Any Risks Associated with Using OBD2 on My Mercedes-Benz?

Improper use of OBD2 tools can lead to inaccurate readings or, in rare cases, disrupt the car’s computer system. Always use reputable tools and follow instructions carefully.

Conclusion: Empowering Your Mercedes-Benz Ownership

Understanding OBD2 empowers you to take control of your Mercedes-Benz’s maintenance and diagnostics. By leveraging the capabilities of OBD2, you can ensure optimal performance, address issues promptly, and potentially save on repair costs.

Ready to dive deeper into OBD2 for your Mercedes-Benz? Contact us at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for expert advice, tools, and support!

Address: 789 Oak Avenue, Miami, FL 33101, United States

WhatsApp: +1 (641) 206-8880

Website: MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

Let us help you unlock the full potential of your Mercedes-Benz!