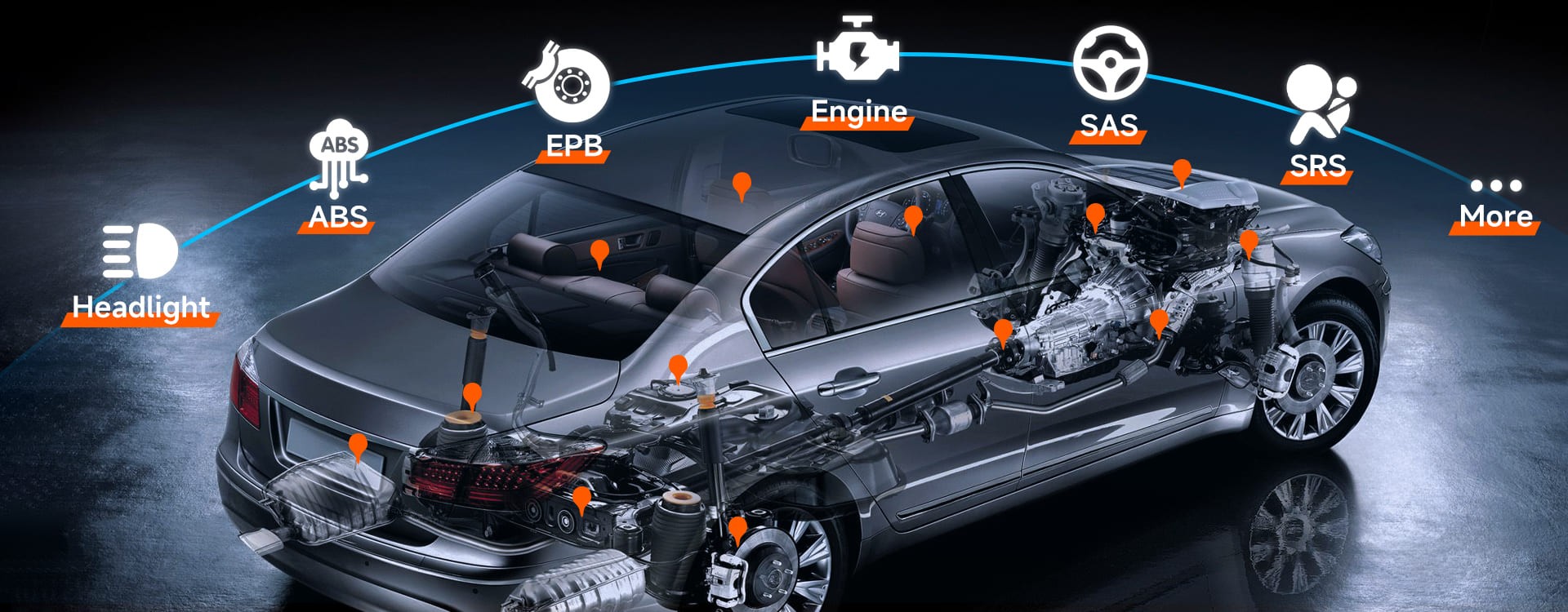

Gone are the days when diagnosing car issues required expensive tools or visits to the mechanic. Now, with an OBD2 scanner, you can perform essential diagnostics from the comfort of your garage, such as battery health assessments and short circuit detection. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we help you identify issues early and provide maintenance tips for keeping your electrical system in peak condition, potentially saving you from costly repairs. With our expertise, you’ll keep your Mercedes running smoothly and efficiently using code readers and diagnostic tools.

Contents

- 1. How to Use an OBD2 Scanner to Check Battery Health

- 1.1. Step-by-Step Battery Check

- 1.2. Comprehensive Performance Analysis

- 1.3. Interpreting the Results

- 1.4. Common Issues and Troubleshooting

- 2. How to Detect Vehicle System Shorts Using an OBD2 Scanner

- 2.1. Identifying Short Circuits

- 2.2. Detailed Inspection Process

- 2.3. Advanced Diagnostic Techniques

- 2.4. Limitations of OBD2 Scanners

- 3. Common OBD2 Error Codes and Their Meaning

- 3.1. System Voltage Codes

- 3.2. Control Module Codes

- 3.3. Other Important Codes

- 3.4. Practical Tips for Using OBD2 Codes

- 4. Maintain Your Car Battery and Electrical System

- 4.1. Regular Maintenance Tips

- 4.2. Advanced Maintenance Procedures

- 4.3. Common Issues and Prevention

- 5. What to Do After Detecting a Short or Battery Issue

- 5.1. Addressing System Shorts

- 5.2. Resolving Battery Issues

- 5.3. Step-by-Step Guide to Battery Replacement

- 5.4. Tips for Preventing Future Issues

- Conclusion

- FAQs

- 1. How to check battery voltage with OBD2 scanner?

- 2. Will an OBD2 scanner read battery light?

- 3. Can an OBD2 scanner test an alternator?

- 4. What does State of Health (SOH) mean for a car battery?

- 5. What does Cold Cranking Amps (CCA) mean for a car battery?

- 6. How often should I check my car battery’s health?

- 7. Can a low battery cause other issues in my car?

- 8. What are the signs of a parasitic drain on my car battery?

- 9. Is it safe to perform electrical system diagnostics myself?

- 10. Where can I find reliable information about OBD2 error codes?

1. How to Use an OBD2 Scanner to Check Battery Health

Regularly inspecting your battery health with an OBD2 scanner, can prevent unexpected battery replacement hassles. Battery testing delivers comprehensive performance analysis features and insights beyond simple voltage readings.

1.1. Step-by-Step Battery Check

Here’s a detailed guide on how to check your battery using an OBD2 scanner:

1.1.1. Connect the Scanner:

- Plug your OBD2 scanner into your vehicle’s diagnostic port. This port is typically located under the dashboard on the driver’s side.

- Turn on your vehicle’s ignition without starting the engine. This provides power to the scanner.

1.1.2. Navigate to Battery Test:

- Using the scanner’s menu, navigate to the battery test or voltage test option. This might be located under “Diagnostics,” “System Tests,” or a similar category.

- Select the appropriate test to begin reading your battery’s health.

1.1.3. Read the Voltage:

- Once the test begins, the scanner will display your battery’s voltage.

- A healthy battery should read around 12.6 volts when the engine is off. If the reading is significantly lower, it could indicate a problem with your battery.

1.1.4. Check Cold Cranking Amps (CCA):

- Some advanced OBD2 scanners can also read the battery’s CCA.

- Compare the reading with the manufacturer’s specification for your battery. A significantly lower CCA suggests that your battery may not be able to start the car effectively, especially in cold weather.

Car Scanner Functions | Foxwell

Car Scanner Functions | Foxwell

Image alt: Comprehensive OBDII EOBD protocol and full system diagnostic via car scanner.

1.2. Comprehensive Performance Analysis

OBD2 scanners offer comprehensive performance analysis, giving you a detailed understanding of your battery’s condition.

1.2.1. State of Health (SOH)

SOH indicates the overall condition of your battery compared to when it was new.

- A high SOH percentage means your battery is in good condition.

- A low SOH percentage suggests that your battery is nearing the end of its lifespan.

1.2.2. State of Charge (SOC)

SOC shows how much charge is currently stored in your battery.

- A high SOC percentage means your battery is well-charged.

- A low SOC percentage suggests that your battery might be struggling to hold a charge.

1.2.3. Internal Resistance

Internal resistance affects your battery’s ability to deliver power.

- High internal resistance can reduce your battery’s performance.

- Monitoring internal resistance can help you identify potential issues before they become major problems.

1.2.4. Voltage Under Load

This test measures the battery’s voltage while it’s under a load, such as starting the engine.

- A significant drop in voltage under load can indicate a weak battery.

- This test can help you determine if your battery can handle the demands of your vehicle.

1.3. Interpreting the Results

Understanding the data provided by your OBD2 scanner is crucial for making informed decisions about your battery’s maintenance.

1.3.1. Voltage Readings

- 12.6V or higher: Indicates a fully charged battery in good condition.

- 12.4V to 12.6V: Suggests a healthy battery that is slightly discharged.

- 12.2V to 12.4V: Indicates a battery that needs to be charged soon.

- Below 12.2V: Suggests a significantly discharged or failing battery.

1.3.2. CCA Readings

- Compare the CCA reading with the manufacturer’s specifications.

- If the reading is within 10% of the specified value, the battery is likely in good condition.

- If the reading is significantly lower, the battery may need to be replaced.

1.3.3. SOH and SOC Readings

- An SOH above 80% and an SOC above 90% indicates a healthy battery.

- If either reading is below these values, consider having your battery professionally tested or replaced.

1.3.4. Charging System Test

- 13.5V to 14.5V: Indicates the charging system is working properly.

- Below 13.5V: Suggests that the alternator might not be charging the battery effectively.

- Above 14.5V: Suggests overcharging, which can damage the battery.

1.4. Common Issues and Troubleshooting

Even with the best tools, you might encounter issues. Here are some common problems and how to troubleshoot them:

1.4.1. Scanner Not Connecting

- Check the Connection: Ensure the OBD2 scanner is securely plugged into the diagnostic port.

- Verify Power: Make sure the vehicle’s ignition is turned on but the engine is off.

- Compatibility: Ensure the scanner is compatible with your vehicle’s make and model.

- Scanner Issues: Try using the scanner on another vehicle to see if the problem persists, indicating a fault with the scanner itself.

1.4.2. Inaccurate Readings

- Battery Condition: Ensure the battery is not severely discharged before testing.

- Clean Terminals: Clean any corrosion from the battery terminals.

- Scanner Calibration: Check if the scanner needs to be calibrated or updated.

- Environmental Factors: Extreme temperatures can affect battery performance, so test in moderate conditions.

1.4.3. Error Codes

- Record the Codes: Write down any error codes displayed by the scanner.

- Research: Look up the error codes in your vehicle’s repair manual or online to understand their meaning.

- Address the Issues: Follow the recommended steps to address the issues indicated by the error codes.

By following these steps and understanding how to interpret the results, you can effectively use an OBD2 scanner to monitor your battery’s health and prevent unexpected issues.

2. How to Detect Vehicle System Shorts Using an OBD2 Scanner

Electrical shorts are among the more complex problems to diagnose. They may cause intermittent issues, random dashboard warnings, or worse, failure of critical electrical components. An OBD2 scanner can assist with this task by reading specific error codes associated with such shorts.

2.1. Identifying Short Circuits

An OBD2 scanner can help identify short circuits by reading trouble codes.

2.1.1. Connect and Access Error Codes

- Plug your OBD2 scanner into the vehicle’s diagnostic port and access its error code menu.

- The scanner will display any stored trouble codes (DTCs) that indicate electrical faults in its memory.

2.1.2. Locate Relevant Codes

Codes such as:

- P0562 (System Voltage Low)

- P2503 (Charging System Voltage Low)

Could indicate an electrical short, pointing towards specific areas needing attention, such as battery, alternator, or wiring problems.

2.1.3. Investigate the Wiring

- Once you’ve identified an error code, inspect the wiring in the affected area.

- Electrical shorts often occur due to frayed wires or loose connections.

- Fix any visible issues to avoid further damage.

2.2. Detailed Inspection Process

To effectively detect vehicle system shorts using an OBD2 scanner, follow this detailed inspection process.

2.2.1. Initial Scan and Code Retrieval

- Preparation: Ensure the vehicle is parked safely and the ignition is turned off.

- Connection: Plug the OBD2 scanner into the diagnostic port.

- Power On: Turn the ignition to the “ON” position without starting the engine.

- Access Codes: Navigate to the “Read Codes” or “Diagnostic Codes” option on the scanner.

- Record Codes: Write down all the Diagnostic Trouble Codes (DTCs) that appear.

2.2.2. Code Analysis

- Reference Material: Consult the vehicle’s service manual or a reliable online database to understand the meaning of each DTC.

- Identify Relevant Codes: Look for codes that specifically indicate electrical issues such as:

- P0600-P0699: Indicates issues with the vehicle’s control modules.

- BXXXX: Body codes, often related to electrical components like lights, windows, and door locks.

- UXXXX: Network communication codes, which can sometimes be triggered by electrical shorts affecting the vehicle’s communication network.

- Prioritize: Focus on codes that appear frequently or are related to the specific symptoms you are experiencing.

2.2.3. Visual Inspection

- Battery:

- Check Terminals: Look for corrosion or loose connections.

- Inspect Cables: Ensure the battery cables are in good condition with no fraying or damage.

- Wiring Harnesses:

- Trace Wires: Follow the wiring harnesses connected to the components identified by the DTCs.

- Look for Damage: Check for cuts, abrasions, or melted insulation.

- Inspect Connectors: Ensure connectors are properly seated and free from corrosion.

- Fuses and Relays:

- Check Fuses: Use a fuse tester or multimeter to check the continuity of each fuse.

- Inspect Relays: Look for signs of overheating or damage. Swap relays with a known good one to see if the issue resolves.

2.2.4. Testing with a Multimeter

- Voltage Drop Test:

- Setup: Set the multimeter to measure voltage.

- Procedure: With the circuit active, measure the voltage drop across each connection.

- Interpretation: A high voltage drop indicates excessive resistance, which can be caused by corrosion or loose connections.

- Continuity Test:

- Setup: Set the multimeter to measure continuity.

- Procedure: With the circuit de-energized, check the continuity of wires and connections.

- Interpretation: A lack of continuity indicates a break in the circuit.

- Resistance Test:

- Setup: Set the multimeter to measure resistance.

- Procedure: With the circuit de-energized, measure the resistance of components and wires.

- Interpretation: A high resistance value indicates a potential issue with the component or wire.

2.2.5. Component Testing

- Sensors:

- Check Signal: Use the OBD2 scanner to monitor sensor readings.

- Compare Values: Compare the sensor readings with the expected values in the service manual.

- Actuators:

- Activate Component: Use the OBD2 scanner to activate the component.

- Verify Function: Ensure the component is functioning correctly.

2.2.6. Final Steps

- Repair: Fix any damaged wires, replace faulty components, and clean corroded connections.

- Clear Codes: Use the OBD2 scanner to clear the DTCs.

- Test Drive: Take the vehicle for a test drive to ensure the issue is resolved and no new codes appear.

- Re-scan: After the test drive, re-scan the vehicle to confirm that all codes have been cleared.

2.3. Advanced Diagnostic Techniques

For more complex electrical issues, consider these advanced diagnostic techniques:

2.3.1. Wiring Diagrams

- Obtain Diagrams: Refer to the vehicle’s service manual for detailed wiring diagrams.

- Trace Circuits: Use the diagrams to trace the circuits and identify potential problem areas.

2.3.2. Oscilloscope Testing

- Connect Oscilloscope: Connect the oscilloscope to the circuit.

- Analyze Waveforms: Analyze the waveforms to identify signal irregularities or noise.

2.3.3. Load Testing

- Apply Load: Use a load tester to apply a load to the circuit.

- Monitor Voltage: Monitor the voltage to see how the circuit performs under load.

2.4. Limitations of OBD2 Scanners

OBD2 scanners cannot pinpoint exactly where a short exists. However, they can significantly shorten your search process, saving you time and energy.

By following these steps, you can use an OBD2 scanner to effectively detect and diagnose electrical shorts in your vehicle. For complex or persistent issues, consult a professional mechanic. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we provide the tools and expertise you need to keep your Mercedes running smoothly.

3. Common OBD2 Error Codes and Their Meaning

Understanding OBD2 error codes can provide essential clues when diagnosing electrical problems. Be wary of the following codes.

3.1. System Voltage Codes

3.1.1. P0562 – System Voltage Low

This error indicates that your electrical system isn’t receiving sufficient voltage due to a failing alternator or shorted wiring, potentially due to a lack of alternator function or shorting out wires.

-

Possible Causes:

- Faulty alternator

- Loose or corroded battery terminals

- Short circuit in the wiring

- Defective voltage regulator

-

Troubleshooting Steps:

- Check battery terminals for corrosion and clean if necessary.

- Test the alternator output voltage.

- Inspect the wiring for shorts or damage.

- Replace the voltage regulator if it’s defective.

3.1.2. P2503 – Charging System Voltage Low

If the charging system voltage drops too low, your alternator could improperly charge the battery, leading to underperformance and performance degradation.

-

Possible Causes:

- Failing alternator

- Worn or loose alternator belt

- Faulty battery

- Electrical shorts

-

Troubleshooting Steps:

- Check the alternator belt for wear and tension.

- Test the alternator output voltage.

- Inspect the battery for damage or low voltage.

- Check for any shorts in the charging system wiring.

3.1.3. P0563 – System Voltage High

If the system voltage rises too much, an alternator overcharges and significantly decreases the battery lifespan.

-

Possible Causes:

- Defective voltage regulator

- Faulty alternator

- Poor grounding

-

Troubleshooting Steps:

- Test the alternator output voltage.

- Inspect the voltage regulator for proper function.

- Check the grounding connections for corrosion or looseness.

3.2. Control Module Codes

3.2.1. B1325 – Control Module Power Circuit Low

This code indicates an issue with one of your vehicle’s control modules requiring power, possibly caused by a short.

-

Possible Causes:

- Short circuit in the control module power circuit

- Faulty control module

- Loose or corroded connections

-

Troubleshooting Steps:

- Inspect the wiring and connections to the control module.

- Check for shorts in the power circuit.

- Test the control module for proper function.

3.3. Other Important Codes

3.3.1. P0300 – Random/Multiple Cylinder Misfire Detected

While not directly related to the electrical system, this code can sometimes be caused by electrical issues.

-

Possible Causes:

- Faulty ignition coil

- Bad spark plugs

- Vacuum leaks

- Low fuel pressure

-

Troubleshooting Steps:

- Check the spark plugs and ignition coils.

- Look for vacuum leaks.

- Test the fuel pressure.

3.3.2. U0100 – Lost Communication With ECM/PCM

This code indicates a loss of communication with the Engine Control Module (ECM) or Powertrain Control Module (PCM).

-

Possible Causes:

- Faulty ECM/PCM

- Wiring issues

- CAN bus problems

-

Troubleshooting Steps:

- Check the wiring and connections to the ECM/PCM.

- Inspect the CAN bus wiring.

- Test the ECM/PCM for proper function.

3.3.3. B1001 – ECU Internal Failure

This code indicates an internal failure within the Electronic Control Unit (ECU).

-

Possible Causes:

- Faulty ECU

- Software issues

- Power supply problems

-

Troubleshooting Steps:

- Check the power supply to the ECU.

- Try to reflash the ECU software.

- Replace the ECU if necessary.

3.4. Practical Tips for Using OBD2 Codes

- Record Codes: Always write down the exact code and any accompanying information.

- Prioritize Codes: Address the most critical codes first.

- Clear Codes: After making repairs, clear the codes and re-scan to ensure the issue is resolved.

- Consult a Professional: If you’re unsure about any code or repair, consult a professional mechanic.

Understanding these common OBD2 error codes can help you diagnose and address electrical problems in your vehicle more effectively. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we provide the tools and resources you need to keep your Mercedes in top condition.

4. Maintain Your Car Battery and Electrical System

Preventing battery and electrical system issues by performing proper maintenance will go a long way toward mitigating them. Regular inspections and proactive care should be taken to avoid unexpected breakdowns.

4.1. Regular Maintenance Tips

4.1.1. Clean Battery Terminals

Keep the terminals of your battery clean to prevent corrosion from interfering with charging correctly, which could prevent it from doing so. Mixing baking soda and water as an easy solution will do just the trick to ensure a strong connection between the battery and charger.

- Why: Corrosion can impede the flow of electricity and reduce battery performance.

- How:

- Disconnect the battery cables (negative first).

- Mix baking soda and water to form a paste.

- Apply the paste to the terminals and scrub with a brush.

- Rinse with water and dry thoroughly.

- Reconnect the cables, applying a corrosion-resistant grease.

4.1.2. Regular Voltage Checks

Another essential aspect of car maintenance is checking your battery’s voltage regularly. If your car remains idle for extended periods, its batteries could drain significantly over time.

- Why: Monitoring voltage helps identify potential issues before they become major problems.

- How:

- Use a voltmeter or an OBD2 scanner to measure the voltage.

- Check the voltage with the engine off and running.

- Look for values within the recommended range (12.6V when off, 13.5V to 14.5V when running).

4.1.3. Inspect Wiring

Check your car’s electrical system’s wiring for signs of fraying or wear and tear that could result in shorts; fix any exposed wires or loose connections to avoid electrical problems.

- Why: Damaged wiring can cause shorts, voltage drops, and other electrical issues.

- How:

- Visually inspect the wiring for cuts, abrasions, or melted insulation.

- Check for loose connections at connectors and terminals.

- Repair or replace any damaged wiring.

4.1.4. Monitor Alternator Performance

Finally, monitor your alternator’s performance. Your alternator is responsible for keeping the battery charged when driving; if it stops functioning properly, your battery could become undercharged or overcharged, leading to premature failure. Testing its output regularly will help ensure it delivers an appropriate voltage output.

- Why: The alternator keeps the battery charged and powers the electrical system while the engine is running.

- How:

- Use an OBD2 scanner or voltmeter to check the alternator’s output voltage.

- Ensure the voltage is within the recommended range (13.5V to 14.5V).

- Listen for unusual noises from the alternator.

4.2. Advanced Maintenance Procedures

For more thorough maintenance, consider these advanced procedures:

4.2.1. Load Testing the Battery

- Why: Load testing assesses the battery’s ability to deliver power under load.

- How:

- Use a load tester to apply a load to the battery.

- Monitor the voltage during the test.

- Compare the results with the manufacturer’s specifications.

4.2.2. Checking for Parasitic Drain

- Why: Parasitic drain can deplete the battery when the vehicle is off.

- How:

- Disconnect the negative battery cable.

- Connect a multimeter in series between the cable and the battery terminal.

- Measure the current draw.

- A high current draw indicates a parasitic drain.

- Systematically remove fuses to identify the source of the drain.

4.2.3. Using a Battery Maintainer

- Why: A battery maintainer keeps the battery charged during periods of inactivity.

- How:

- Connect the battery maintainer to the battery.

- Plug the maintainer into a power outlet.

- The maintainer will automatically charge and maintain the battery’s voltage.

4.3. Common Issues and Prevention

4.3.1. Battery Corrosion

- Issue: Corrosion on battery terminals.

- Prevention: Clean terminals regularly and apply corrosion-resistant grease.

4.3.2. Loose Connections

- Issue: Loose battery cables and wiring connections.

- Prevention: Regularly check and tighten connections.

4.3.3. Overcharging/Undercharging

- Issue: Alternator issues leading to overcharging or undercharging.

- Prevention: Monitor alternator performance and replace if necessary.

4.3.4. Parasitic Drain

- Issue: Excessive current draw when the vehicle is off.

- Prevention: Check for parasitic drain and address the source.

Diagnosis Oil Car Scanner | Foxwell

Diagnosis Oil Car Scanner | Foxwell

Image alt: Diagnosing and resetting oil service light using a car scanner.

5. What to Do After Detecting a Short or Battery Issue

Alright, so you’ve detected a problem. What now? If you’ve found a short or your battery’s on its last legs, here’s what to do next:

5.1. Addressing System Shorts

5.1.1. Detailed Inspection

- Visual Check: Look for visibly damaged wires or connectors that could lead to shorts. Frayed or exposed to moisture or metal wires often fray and become frayed over time, leading to shorts. Be especially wary around the battery, alternator, and fuse box wiring harnesses where such shorts may occur.

- Fuse Check: Take care when inspecting and replacing fuses; blown ones could indicate shorts or be an easy fix for minor issues. Switch out blown ones with new ones to see if the problem reappears; if so, deeper wiring issues may be at play.

5.1.2. Professional Consultation

- When to Consult: Consult a mechanic if you’re having difficulty pinpointing the problem yourself. Electrical systems can be complex and, at times, dangerous if mismanaged; professional mechanics have access to the tools and expertise necessary to diagnose shorts accurately.

5.2. Resolving Battery Issues

5.2.1. Battery Testing

- Under-Load Testing: Under-load testing can help verify whether a battery is truly weak. It’s often the best way to assess whether it can handle real-world conditions, such as starting the car on cold mornings or powering accessories.

- Professional Testing: Have the battery professionally tested to confirm its condition.

5.2.2. Battery Replacement

- Age of Battery: If the battery is over three years old, it may be time for replacement. Batteries only last so long before starting to degrade; once this occurs, buying new batteries often proves more cost-effective than simply continuing to charge the existing ones.

- Choosing a Replacement: Select a battery that meets or exceeds the vehicle’s specifications.

5.2.3. Alternator Check

- Importance: Never neglect your alternator. Faulty alternators can quickly cause even new batteries to fail. An OBD2 scanner or voltmeter is used to check its output and ensure that everything functions as it should.

- Voltage Output: Ensure the alternator is providing the correct voltage output (13.5V to 14.5V).

5.3. Step-by-Step Guide to Battery Replacement

5.3.1. Preparation

- Gather Tools: Collect the necessary tools, including a wrench, socket set, battery terminal cleaner, and gloves.

- Safety First: Wear safety glasses and gloves to protect yourself from battery acid.

5.3.2. Removal

- Disconnect Cables: Disconnect the negative battery cable first, followed by the positive cable.

- Remove Hold-Down: Remove the battery hold-down clamp or strap.

- Lift Out Battery: Carefully lift the old battery out of the tray.

5.3.3. Installation

- Clean Tray: Clean the battery tray to remove any debris or corrosion.

- Place New Battery: Place the new battery in the tray.

- Secure Hold-Down: Secure the battery with the hold-down clamp or strap.

- Connect Cables: Connect the positive battery cable first, followed by the negative cable.

- Apply Grease: Apply corrosion-resistant grease to the terminals.

5.3.4. Post-Installation

- Start Vehicle: Start the vehicle to ensure the new battery is functioning correctly.

- Check Voltage: Use an OBD2 scanner or voltmeter to check the battery voltage.

- Clear Codes: Clear any diagnostic trouble codes (DTCs) that may have been triggered during the process.

5.4. Tips for Preventing Future Issues

- Regular Checks: Perform regular battery and electrical system checks.

- Maintenance: Follow the recommended maintenance schedule.

- Quality Parts: Use high-quality replacement parts.

- Professional Help: Don’t hesitate to seek professional help when needed.

By taking these steps, you can effectively address shorts and battery issues, ensuring your vehicle remains reliable and safe. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we are committed to providing you with the knowledge and tools necessary to keep your Mercedes running smoothly.

Conclusion

Utilizing an OBD2 scanner to monitor the health and detect system shorts on your car can save you from costly repairs or unexpected breakdowns. These diagnostic tools empower you to take a proactive approach to vehicle maintenance, ensuring optimal performance and longevity.

An OBD2 scanner is invaluable in staying ahead of maintenance requirements and understanding more about your ride, whether you are an independent mechanic, DIY enthusiast, or simply interested in understanding more about your automobile. By regularly inspecting its battery, alternator, and wiring system before replacing anything on its electrical system, you can ensure its continued excellence for years.

For expert guidance and top-of-the-line diagnostic tools tailored for your Mercedes-Benz, reach out to us at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN. Let us help you keep your Mercedes performing at its best. Contact us today for personalized support and the right solutions for your diagnostic needs.

FAQs

1. How to check battery voltage with OBD2 scanner?

You can check battery voltage by connecting the OBD2 scanner to your car’s diagnostic port and navigating to the battery or electrical system section in the scanner’s menu. The scanner will display the battery’s voltage, typically showing whether it’s within a healthy range (around 12.6V when the car is off).

2. Will an OBD2 scanner read battery light?

Yes, an OBD2 scanner can detect issues related to the battery light. It can pull diagnostic trouble codes (DTCs) from the car’s system that explain why the battery light is illuminated, helping you pinpoint problems such as a weak battery, alternator failure, or other electrical issues.

3. Can an OBD2 scanner test an alternator?

Yes, an OBD2 scanner can test an alternator by reading the voltage levels while the engine is running. The scanner can tell you if the alternator is charging the battery properly by checking whether the output voltage is between the normal range of 13.5V to 14.5V.

4. What does State of Health (SOH) mean for a car battery?

State of Health (SOH) refers to the condition of your car battery compared to when it was new. It’s an indicator of the battery’s overall lifespan and performance capability, often expressed as a percentage. A higher SOH percentage indicates a healthier battery.

5. What does Cold Cranking Amps (CCA) mean for a car battery?

Cold Cranking Amps (CCA) is a rating used to describe a battery’s ability to start an engine in cold temperatures. It specifies the number of amps a 12-volt battery can deliver for 30 seconds at 0 degrees Fahrenheit (-17.8 degrees Celsius) while maintaining a voltage of at least 7.2 volts.

6. How often should I check my car battery’s health?

It’s recommended to check your car battery’s health at least twice a year, typically before the start of summer and winter. Extreme temperatures can impact battery performance, so regular checks can help you avoid unexpected issues.

7. Can a low battery cause other issues in my car?

Yes, a low battery can cause a variety of issues in your car, including difficulty starting the engine, dimming headlights, malfunctioning electrical systems, and even triggering warning lights on the dashboard.

8. What are the signs of a parasitic drain on my car battery?

Signs of a parasitic drain include a battery that frequently dies, especially if the car has been sitting for a short period. You may also notice slow engine cranking or electrical systems that don’t function properly.

9. Is it safe to perform electrical system diagnostics myself?

While many basic electrical system diagnostics can be performed safely, it’s essential to take precautions. Always disconnect the battery before working on electrical components and consult a professional if you’re unsure about any step.

10. Where can I find reliable information about OBD2 error codes?

You can find reliable information about OBD2 error codes in your vehicle’s service manual, online databases, and forums dedicated to car diagnostics. Ensure the information is specific to your vehicle’s make and model for accuracy.

Ready to take control of your Mercedes-Benz’s health? Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN today for expert guidance and the best diagnostic tools. Our team is here to help you diagnose issues, unlock hidden features, and maintain your vehicle with confidence.

Address: 789 Oak Avenue, Miami, FL 33101, United States

WhatsApp: +1 (641) 206-8880

Website: MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

Reach out now and experience the difference of professional support and cutting-edge diagnostic solutions. Your Mercedes deserves the best!