The steps involved in adjusting or repairing the power liftgate mechanism include diagnosing the issue, resetting the system, or replacing faulty components, all of which can be efficiently guided by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN. Addressing these issues promptly ensures the convenience and safety features of your Mercedes-Benz remain optimal, enhancing your overall driving experience through proper liftgate maintenance and troubleshooting, utilizing advanced diagnostic tools and resources for informed decisions.

Contents

- 1. Understanding the Power Liftgate Mechanism

- 1.1. Key Components of the Power Liftgate System

- 1.2. Operational Sequence

- 2. Identifying Common Issues with the Power Liftgate

- 2.1. Liftgate Not Opening or Closing

- 2.2. Liftgate Opens or Closes Partially

- 2.3. Unusual Noises During Operation

- 2.4. Liftgate Opening on Its Own

- 2.5. Diagnostic Trouble Codes (DTCs)

- 3. Essential Tools and Equipment

- 3.1. Diagnostic Scan Tool

- 3.2. Basic Hand Tools

- 3.3. Multimeter

- 3.4. Special Tools

- 3.5. Safety Equipment

- 4. Step-by-Step Guide to Adjusting the Power Liftgate Mechanism

- 4.1. Resetting the Power Liftgate System

- 4.2. Adjusting the Liftgate Height

- 4.3. Adjusting the Latch Mechanism

- 5. Step-by-Step Guide to Repairing the Power Liftgate Mechanism

- 5.1. Replacing the Liftgate Motor

- 5.2. Replacing the Liftgate Struts

- 5.3. Replacing a Faulty Sensor

- 6. Safety Precautions

- 7. Advanced Diagnostics and Troubleshooting

- 8. Regular Maintenance Tips

- 9. Utilizing MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Resources

- 10. Understanding Mercedes-Benz Specifics

- 10.1. Specific Power Liftgate Features

- 10.2. Diagnostic Nuances

- 11. Potential Costs and When to Seek Professional Help

- 11.1. DIY vs. Professional Repair

- 11.2. When to Seek Professional Help

- 12. Case Studies

- 12.1. Case Study 1: Liftgate Not Opening

- 12.2. Case Study 2: Liftgate Opening Partially

- 13. The Future of Power Liftgate Technology

- 13.1. Advancements in Technology

- 13.2. Preparing for Future Repairs

- 14. Maximizing the Life of Your Power Liftgate

- 14.1. Environmental Considerations

- 14.2. Operational Best Practices

- 15. Leveraging Community Knowledge

- 15.1. Online Forums

- 15.2. Owner Groups

- 16. Legal and Warranty Considerations

- 16.1. Warranty Coverage

- 16.2. Legal Issues

- 17. Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Expert Assistance

- 17.1. How We Can Help

- 17.2. Get in Touch

- 18. FAQ: Power Liftgate Adjustments and Repairs

- 18.1. What are common signs of a failing power liftgate?

- 18.2. Can I adjust the height of my power liftgate?

- 18.3. What tools do I need to diagnose power liftgate issues?

- 18.4. How do I reset the power liftgate system?

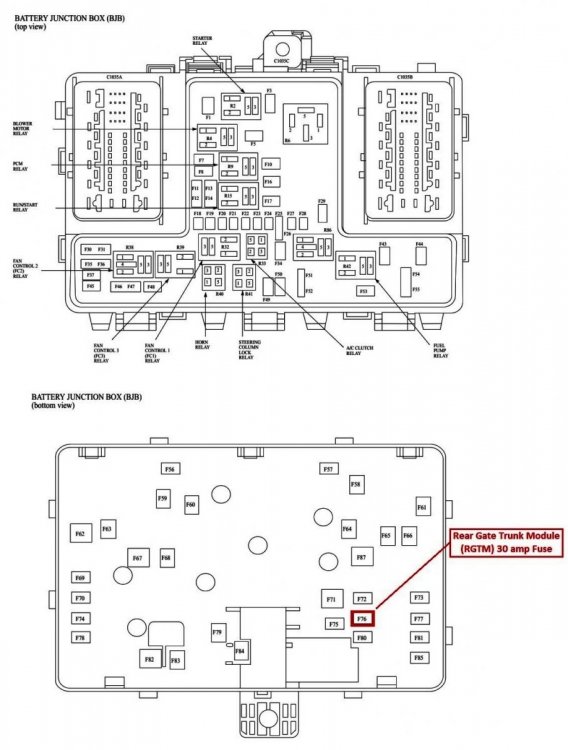

- 18.5. What is the RGTM?

- 18.6. How do I know if my liftgate motor is failing?

- 18.7. Are aftermarket power liftgate parts reliable?

- 18.8. Can I replace the liftgate struts myself?

- 18.9. What safety precautions should I take when working on the power liftgate?

- 18.10. When should I seek professional help for power liftgate repairs?

1. Understanding the Power Liftgate Mechanism

Before diving into the adjustments or repairs, it’s crucial to understand how the power liftgate mechanism operates. The power liftgate system in a Mercedes-Benz is a complex assembly of electronic and mechanical components working in harmony to provide automated opening and closing of the vehicle’s rear hatch. This system integrates with various vehicle modules, including the Rear Gate Module (RGTM) and the Body Control Module (BCM), to ensure seamless operation.

1.1. Key Components of the Power Liftgate System

- Liftgate Motor: The electric motor that drives the opening and closing of the liftgate.

- Liftgate Latch Assembly: Secures the liftgate in the closed position and includes sensors to detect its state.

- RGTM (Rear Gate Module): Controls the power liftgate functions, receiving signals from switches and sensors.

- BCM (Body Control Module): Communicates with the RGTM and other vehicle systems to manage liftgate operation based on user input (e.g., key fob, interior switch).

- Position Sensors: Monitor the liftgate’s position and velocity during operation, ensuring smooth movement and obstacle detection.

- Anti-Pinch Sensors: Detect obstructions during closing, preventing injury and damage.

- Hydraulic or Pneumatic Struts: Provide assistance in lifting and lowering the liftgate, complementing the motor’s effort.

- Wiring Harness: Connects all the components, transmitting power and signals throughout the system.

1.2. Operational Sequence

The power liftgate system follows a precise sequence of operations, as detailed in the vehicle’s workshop manual. Here’s an overview:

- Initiation: The process starts when the RGTM receives a signal from one of the activation sources, such as the key fob, interior switch, or hands-free sensor.

- Verification: The RGTM verifies the vehicle’s status, such as gear selector position and vehicle speed, to ensure it’s safe to operate the liftgate.

- Unlatching: The RGTM activates the unlatch motor to release the liftgate latch.

- Opening/Closing: The RGTM powers the drive motor, which moves the liftgate to the desired position while monitoring the liftgate motor position sensor.

- Obstruction Detection: During movement, the system monitors anti-pinch sensors and motor load to detect any obstructions. If an obstruction is detected, the motor stops, and the liftgate may reverse direction.

- Latching: Once the liftgate reaches the fully closed position, the system engages the latching mechanism and may use a cinching motor to ensure a tight seal.

Understanding these components and their roles is essential for effective troubleshooting and repair. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers comprehensive guides and resources to help you identify each component and understand its function within your specific Mercedes-Benz model.

Power Liftgate Motor

Power Liftgate Motor

2. Identifying Common Issues with the Power Liftgate

Power liftgate systems, while convenient, can encounter issues over time. Identifying these problems early can prevent more extensive damage and costly repairs. Here are some common issues:

2.1. Liftgate Not Opening or Closing

One of the most common problems is the liftgate failing to open or close. This can stem from several causes:

- Faulty Motor: The liftgate motor may be worn out or damaged, preventing it from operating.

- Electrical Issues: Problems in the wiring harness, fuses, or relays can disrupt power supply to the motor.

- Sensor Malfunctions: Defective position or anti-pinch sensors can prevent the system from initiating movement.

- RGTM Failure: A malfunctioning Rear Gate Module can fail to send the necessary signals to activate the liftgate.

2.2. Liftgate Opens or Closes Partially

If the liftgate only opens or closes partially, the following could be the reasons:

- Weak Struts: Worn hydraulic or pneumatic struts may not provide enough assistance, especially in colder temperatures.

- Obstruction Issues: Sensitivity settings may be too high, causing the system to stop due to false obstruction detection.

- Motor Position Sensor Problems: Inaccurate readings from the motor position sensor can cause the system to stop prematurely.

2.3. Unusual Noises During Operation

Strange noises during operation can indicate mechanical issues:

- Grinding or Clicking: This could indicate worn gears in the motor assembly or problems with the latching mechanism.

- Squeaking or Groaning: This might be due to dry or worn hinges, struts, or other moving parts.

2.4. Liftgate Opening on Its Own

This is a less common but potentially serious issue:

- Switch Problems: A faulty liftgate switch (either on the key fob, interior, or exterior) can send unintended signals.

- BCM or RGTM Issues: Malfunctions in these modules can cause erratic behavior of the liftgate.

2.5. Diagnostic Trouble Codes (DTCs)

Modern Mercedes-Benz vehicles store Diagnostic Trouble Codes (DTCs) that can help pinpoint the source of the problem. Using a diagnostic tool compatible with Mercedes-Benz systems, such as those recommended by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, can help retrieve these codes. Common DTCs related to the power liftgate include:

- B220513: Component Y146/1 (Power Liftgate Drive Motor) has a malfunction. Open circuit.

- B220515: Component Y146/1 (Power Liftgate Drive Motor) has a malfunction. Short circuit to ground.

- B220909: The hall sensor for power liftgate motor has a malfunction. There is a component fault.

- B221077: Component S183/1 (Liftgate closing aid switch) is defective. The signal is not plausible.

These DTCs, along with a thorough inspection, can provide valuable insights into the nature of the problem.

3. Essential Tools and Equipment

Before starting any adjustments or repairs on the power liftgate mechanism, gather the necessary tools and equipment. Having the right tools will make the job easier, safer, and more efficient.

3.1. Diagnostic Scan Tool

A diagnostic scan tool is essential for reading and clearing Diagnostic Trouble Codes (DTCs) stored in the vehicle’s computer. For Mercedes-Benz vehicles, it’s important to use a tool that supports the manufacturer’s specific diagnostic protocols. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN recommends several diagnostic tools compatible with Mercedes-Benz, such as:

- Mercedes-Benz Star Diagnostic System (SDS): The official diagnostic tool used by Mercedes-Benz dealerships.

- Autel MaxiSYS: A versatile aftermarket scan tool with extensive coverage for Mercedes-Benz vehicles.

- iCarsoft MB II: A more affordable option that provides basic diagnostic functions for Mercedes-Benz models.

3.2. Basic Hand Tools

A set of basic hand tools is necessary for disassembling and reassembling the power liftgate components. These include:

- Socket Set: Metric sockets in various sizes to remove bolts and nuts.

- Wrench Set: Metric wrenches for tasks that require a wrench instead of a socket.

- Screwdrivers: Phillips head and flathead screwdrivers for removing screws.

- Pliers: For gripping, cutting, and bending wires and components.

- Trim Removal Tools: Plastic trim removal tools to avoid damaging interior panels.

3.3. Multimeter

A multimeter is used to test electrical circuits for voltage, continuity, and resistance. This is essential for diagnosing electrical issues in the power liftgate system.

3.4. Special Tools

Depending on the specific repair, you may need specialized tools:

- Strut Compressor: To safely compress and remove the liftgate struts.

- Torque Wrench: To tighten bolts to the correct torque specifications.

- Wiring Diagram: A wiring diagram specific to your Mercedes-Benz model can be invaluable for tracing electrical circuits.

3.5. Safety Equipment

Safety should always be a priority when working on automotive systems:

- Safety Glasses: To protect your eyes from debris.

- Gloves: To protect your hands from sharp edges and chemicals.

- Work Light: To provide adequate lighting in the work area.

4. Step-by-Step Guide to Adjusting the Power Liftgate Mechanism

Adjusting the power liftgate mechanism can involve several procedures, depending on the specific issue. Here’s a step-by-step guide to some common adjustments:

4.1. Resetting the Power Liftgate System

Sometimes, the power liftgate system may need to be reset to restore normal operation. This can be done by following these steps:

- Disconnect the Battery: Disconnect the negative terminal of the vehicle’s battery.

- Wait: Wait for about 20-30 minutes to allow the system to fully reset.

- Reconnect the Battery: Reconnect the negative terminal of the battery.

- Initialize the System: In some cases, you may need to perform an initialization procedure using a diagnostic scan tool. Follow the instructions provided by the tool manufacturer.

4.2. Adjusting the Liftgate Height

If the liftgate does not open to the desired height, you may need to adjust the height setting. Here’s how:

- Manually Open the Liftgate: Open the liftgate manually to the desired height.

- Press and Hold the Close Button: Press and hold the liftgate close button until you hear a chime, indicating that the new height has been programmed.

- Test the New Setting: Test the new height by opening and closing the liftgate using the power function.

4.3. Adjusting the Latch Mechanism

If the liftgate is not latching properly, you may need to adjust the latch mechanism:

- Inspect the Striker: Inspect the striker plate on the vehicle body for any signs of damage or misalignment.

- Loosen the Striker Bolts: Loosen the bolts that secure the striker plate.

- Adjust the Striker Position: Adjust the position of the striker plate slightly to ensure proper alignment with the latch.

- Tighten the Bolts: Tighten the striker bolts to the correct torque specification.

- Test the Latch: Test the latch by closing the liftgate and ensuring that it latches securely.

5. Step-by-Step Guide to Repairing the Power Liftgate Mechanism

Repairing the power liftgate mechanism may involve replacing faulty components. Here’s a step-by-step guide to some common repairs:

5.1. Replacing the Liftgate Motor

- Disconnect the Battery: Disconnect the negative terminal of the vehicle’s battery.

- Remove Interior Trim: Remove the interior trim panels around the liftgate motor.

- Disconnect Electrical Connectors: Disconnect the electrical connectors from the liftgate motor.

- Remove the Old Motor: Remove the bolts that secure the old motor and carefully remove it from the liftgate.

- Install the New Motor: Install the new motor, ensuring that it is properly aligned and secured with the bolts.

- Reconnect Electrical Connectors: Reconnect the electrical connectors to the new motor.

- Reinstall Interior Trim: Reinstall the interior trim panels.

- Test the Liftgate: Test the liftgate to ensure that the new motor is functioning properly.

5.2. Replacing the Liftgate Struts

- Support the Liftgate: Use a support to hold the liftgate in the open position.

- Disconnect the Old Struts: Disconnect the old struts from the liftgate and the vehicle body.

- Install the New Struts: Install the new struts, ensuring that they are properly aligned and secured.

- Remove the Support: Remove the support and test the liftgate to ensure that the new struts are functioning properly.

5.3. Replacing a Faulty Sensor

- Identify the Faulty Sensor: Use a diagnostic scan tool to identify the faulty sensor.

- Disconnect the Battery: Disconnect the negative terminal of the vehicle’s battery.

- Remove Interior Trim: Remove any interior trim panels that may be blocking access to the sensor.

- Disconnect Electrical Connector: Disconnect the electrical connector from the sensor.

- Remove the Old Sensor: Remove the old sensor and install the new sensor.

- Reconnect Electrical Connector: Reconnect the electrical connector to the new sensor.

- Reinstall Interior Trim: Reinstall any interior trim panels that were removed.

- Test the Liftgate: Test the liftgate to ensure that the new sensor is functioning properly.

Replacing Liftgate Struts

Replacing Liftgate Struts

6. Safety Precautions

Working on the power liftgate mechanism involves several safety considerations. It’s essential to take precautions to prevent injury and damage to the vehicle:

- Disconnect the Battery: Always disconnect the negative terminal of the vehicle’s battery before starting any electrical work.

- Support the Liftgate: When working on the liftgate struts or latch mechanism, use a support to hold the liftgate in the open position.

- Wear Safety Gear: Wear safety glasses and gloves to protect your eyes and hands.

- Follow Torque Specifications: Always tighten bolts to the correct torque specifications to prevent damage to components.

- Work in a Well-Ventilated Area: If you are working with chemicals or solvents, work in a well-ventilated area.

- Consult the Vehicle’s Repair Manual: Always consult the vehicle’s repair manual for specific instructions and safety precautions.

7. Advanced Diagnostics and Troubleshooting

For more complex issues, advanced diagnostics and troubleshooting may be required. This may involve using a diagnostic scan tool to perform advanced functions, such as:

- Actuator Testing: Testing the operation of the liftgate motor and other actuators.

- Sensor Calibration: Calibrating the position sensors to ensure accurate readings.

- Module Programming: Reprogramming the RGTM or BCM to correct software issues.

If you are not comfortable performing these advanced diagnostics, it’s best to seek the help of a qualified technician.

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides access to advanced diagnostic resources and support to help you troubleshoot complex issues. Our team of experts can provide guidance and support to help you get your power liftgate system back in working order.

8. Regular Maintenance Tips

Regular maintenance can help prevent problems with the power liftgate system. Here are some maintenance tips:

- Keep the Liftgate Clean: Keep the liftgate clean and free of debris.

- Lubricate Moving Parts: Lubricate the hinges, latch mechanism, and struts with a silicone-based lubricant.

- Inspect Wiring: Inspect the wiring harness for any signs of damage or corrosion.

- Check the Struts: Check the struts for any signs of wear or leakage.

- Test the System Regularly: Test the power liftgate system regularly to ensure that it is functioning properly.

9. Utilizing MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Resources

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers a wealth of resources to help you diagnose, adjust, and repair your Mercedes-Benz power liftgate mechanism. These resources include:

- Diagnostic Tool Recommendations: Recommendations for diagnostic tools that are compatible with Mercedes-Benz vehicles.

- Step-by-Step Guides: Detailed step-by-step guides for common adjustments and repairs.

- Wiring Diagrams: Wiring diagrams for various Mercedes-Benz models.

- Technical Support: Access to our team of experts who can provide guidance and support.

- Community Forum: A community forum where you can ask questions and share your experiences with other Mercedes-Benz owners.

By utilizing these resources, you can save time and money on repairs and keep your Mercedes-Benz in top condition.

10. Understanding Mercedes-Benz Specifics

Mercedes-Benz vehicles often have unique diagnostic and repair procedures. For example, the S-Class (W222) and newer models may have more integrated systems than C-Class (W205) models. Always consult the repair manual specific to your model. According to a Mercedes-Benz technical service bulletin, proper diagnostic steps must be followed, or new parts may not function correctly due to software incompatibilities.

10.1. Specific Power Liftgate Features

Mercedes-Benz power liftgates often include features like:

- Hands-Free Access: Opening the liftgate with a foot motion under the rear bumper.

- Programmable Height: Adjusting the maximum opening height to prevent damage in garages with low ceilings.

- Obstruction Detection: Automatically stopping and reversing if an obstacle is detected.

10.2. Diagnostic Nuances

When diagnosing Mercedes-Benz power liftgates, consider the following:

- Software Updates: Ensure the RGTM and BCM have the latest software. Outdated software can cause malfunctions.

- CAN Bus Communication: Verify the RGTM is communicating correctly with the CAN bus. Problems here can manifest as intermittent failures.

- Sensor Calibration: After replacing sensors, proper calibration is crucial. Use a diagnostic tool to perform the calibration procedure.

11. Potential Costs and When to Seek Professional Help

The cost of adjusting or repairing a power liftgate can vary widely depending on the issue and whether you choose to do it yourself or seek professional help.

11.1. DIY vs. Professional Repair

- DIY: If you are comfortable with basic automotive repairs and have the necessary tools, you can save money by doing the work yourself. The cost will primarily be for parts, which can range from $50 for a sensor to $300+ for a liftgate motor.

- Professional Repair: If you are not comfortable doing the work yourself, or if the issue is complex, it’s best to seek the help of a qualified technician. Labor costs can range from $100 to $200 per hour, and the total cost of the repair can easily exceed $500 or more.

11.2. When to Seek Professional Help

- Complex Electrical Issues: If you suspect a complex electrical issue, such as a problem with the CAN bus or the RGTM, it’s best to seek professional help.

- Advanced Diagnostics Required: If advanced diagnostics are required, such as actuator testing or module programming, it’s best to seek professional help.

- Unsure of the Problem: If you are unsure of the problem, it’s best to seek professional help to avoid further damage to the vehicle.

12. Case Studies

To illustrate the process of adjusting and repairing the power liftgate mechanism, let’s look at a couple of case studies:

12.1. Case Study 1: Liftgate Not Opening

- Vehicle: 2017 Mercedes-Benz C-Class (W205)

- Problem: The power liftgate would not open using the key fob, interior switch, or exterior handle.

- Diagnosis: Using a diagnostic scan tool, a DTC was found indicating a faulty liftgate motor.

- Repair: The liftgate motor was replaced, and the system was reset.

- Outcome: The power liftgate functioned normally after the repair.

12.2. Case Study 2: Liftgate Opening Partially

- Vehicle: 2019 Mercedes-Benz GLE (W167)

- Problem: The power liftgate would only open partially, stopping about halfway.

- Diagnosis: The struts were found to be weak and not providing enough assistance.

- Repair: The liftgate struts were replaced.

- Outcome: The power liftgate functioned normally after the repair.

13. The Future of Power Liftgate Technology

Power liftgate technology is continually evolving. Modern systems incorporate more sensors, smarter control modules, and integration with vehicle telematics. According to a study by Grand View Research, the global automotive power liftgate system market is expected to reach $6.8 billion by 2027, driven by increasing demand for convenience and safety features.

13.1. Advancements in Technology

Future power liftgate systems are likely to include:

- Gesture Control: Opening and closing the liftgate with simple hand gestures.

- Smartphone Integration: Controlling the liftgate with a smartphone app.

- AI-Powered Obstruction Detection: Using artificial intelligence to improve obstruction detection and prevent false stops.

13.2. Preparing for Future Repairs

As technology advances, it’s important to stay informed about the latest diagnostic and repair techniques. Resources like MERCEDES-DIAGNOSTIC-TOOL.EDU.VN will continue to provide valuable information and support to help you keep your Mercedes-Benz power liftgate system in top condition.

14. Maximizing the Life of Your Power Liftgate

To maximize the life of your power liftgate, consider the following best practices:

14.1. Environmental Considerations

- Avoid Overloading: Do not overload the liftgate with heavy items, as this can strain the motor and struts.

- Clear Snow and Ice: Clear any snow and ice from the liftgate before operating it.

- Protect from Extreme Temperatures: Avoid prolonged exposure to extreme temperatures, as this can damage the struts and seals.

14.2. Operational Best Practices

- Use Proper Activation Methods: Use the key fob, interior switch, or exterior handle to activate the liftgate. Avoid manually forcing the liftgate open or closed.

- Regular Inspections: Regularly inspect the liftgate for any signs of damage or wear.

- Prompt Repairs: Address any issues promptly to prevent further damage to the system.

15. Leveraging Community Knowledge

One of the best resources for troubleshooting and repairing your power liftgate is the Mercedes-Benz community. Online forums and owner groups can provide valuable insights and tips from other owners who have experienced similar issues.

15.1. Online Forums

- MBWorld: A popular Mercedes-Benz forum with a dedicated section for technical discussions.

- BenzWorld: Another well-known forum with a wealth of information on Mercedes-Benz vehicles.

- MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Community Forum: A community forum where you can ask questions and share your experiences with other Mercedes-Benz owners.

15.2. Owner Groups

- Local Mercedes-Benz Clubs: Connect with other Mercedes-Benz owners in your area.

- Online Social Media Groups: Join online social media groups dedicated to Mercedes-Benz vehicles.

By leveraging community knowledge, you can gain valuable insights and tips to help you troubleshoot and repair your power liftgate.

16. Legal and Warranty Considerations

Before performing any adjustments or repairs on your power liftgate, it’s important to consider the legal and warranty implications.

16.1. Warranty Coverage

- New Vehicle Warranty: If your vehicle is still under the new vehicle warranty, any repairs may be covered by the manufacturer.

- Extended Warranty: If you have an extended warranty, check the terms and conditions to see if power liftgate repairs are covered.

16.2. Legal Issues

- Modifications: Be aware that certain modifications to the power liftgate system may void your warranty.

- Safety Standards: Ensure that any repairs or modifications comply with all applicable safety standards.

17. Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Expert Assistance

If you’re facing challenges with your Mercedes-Benz power liftgate, don’t hesitate to reach out to us at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN. Our team of experts is ready to provide personalized assistance, from diagnosing complex issues to recommending the right diagnostic tools and repair procedures. We understand the intricacies of Mercedes-Benz vehicles and can guide you through every step of the process.

17.1. How We Can Help

- Diagnostic Support: We can help you interpret diagnostic trouble codes and identify the root cause of your power liftgate issues.

- Tool Recommendations: We offer recommendations for Mercedes-Benz compatible diagnostic tools, ensuring you have the right equipment for the job.

- Repair Guidance: Our experts can provide step-by-step guidance on performing adjustments and repairs, ensuring you do it safely and effectively.

- Community Forum: Join our community forum to connect with other Mercedes-Benz owners, share experiences, and get advice from fellow enthusiasts.

17.2. Get in Touch

Ready to get started? Contact us today:

- Address: 789 Oak Avenue, Miami, FL 33101, United States

- WhatsApp: +1 (641) 206-8880

- Website: MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

We’re here to help you keep your Mercedes-Benz in top condition, ensuring your power liftgate operates smoothly and reliably. Don’t let a malfunctioning liftgate inconvenience you—reach out to MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for expert assistance.

18. FAQ: Power Liftgate Adjustments and Repairs

18.1. What are common signs of a failing power liftgate?

Common signs include the liftgate not opening or closing, opening or closing partially, unusual noises during operation, or opening on its own.

18.2. Can I adjust the height of my power liftgate?

Yes, most Mercedes-Benz models allow you to program the maximum opening height of the power liftgate.

18.3. What tools do I need to diagnose power liftgate issues?

You’ll need a diagnostic scan tool, basic hand tools, a multimeter, and possibly some specialized tools like a strut compressor or torque wrench.

18.4. How do I reset the power liftgate system?

Disconnect the negative terminal of the vehicle’s battery for 20-30 minutes, then reconnect it. You may need to perform an initialization procedure using a diagnostic scan tool.

18.5. What is the RGTM?

The RGTM (Rear Gate Module) controls the power liftgate functions, receiving signals from switches and sensors.

18.6. How do I know if my liftgate motor is failing?

Signs of a failing liftgate motor include the liftgate not opening or closing, unusual noises during operation, or diagnostic trouble codes indicating a motor fault.

18.7. Are aftermarket power liftgate parts reliable?

The reliability of aftermarket parts can vary. It’s best to use high-quality parts from reputable manufacturers.

18.8. Can I replace the liftgate struts myself?

Yes, replacing the liftgate struts is a relatively straightforward repair that most DIYers can handle with the right tools.

18.9. What safety precautions should I take when working on the power liftgate?

Disconnect the battery, support the liftgate, wear safety gear, follow torque specifications, and work in a well-ventilated area.

18.10. When should I seek professional help for power liftgate repairs?

Seek professional help for complex electrical issues, advanced diagnostics, or if you’re unsure of the problem.

By addressing these frequently asked questions, you can gain a better understanding of power liftgate adjustments and repairs and make informed decisions about maintaining your Mercedes-Benz. Remember, MERCEDES-DIAGNOSTIC-TOOL.EDU.VN is always here to provide expert assistance and support.

In conclusion, adjusting or repairing the power liftgate mechanism on your Mercedes-Benz requires a systematic approach, starting with understanding the system’s components and identifying common issues. With the right tools, knowledge, and resources like those offered by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, you can effectively maintain and repair your power liftgate, ensuring it operates smoothly and reliably for years to come.