What Data Streams Are Relevant For Diagnosing Air Suspension Issues? Relevant data streams for diagnosing air suspension problems include compressor relay status and the absolute height of each shock absorber, which can be efficiently analyzed using diagnostic software like that offered by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN. By monitoring these parameters, you can pinpoint leaks and overheating issues, saving time and effort. This approach allows for a precise diagnosis, ensuring you address the root cause of the problem for effective repairs.

Contents

- 1. Understanding Air Suspension Systems in Mercedes-Benz Vehicles

- 2. Why Accurate Data Streams Are Essential for Diagnosing Air Suspension Issues

- 3. Identifying Key Data Streams for Air Suspension Diagnostics

- 4. Detailed Look at Relevant Data Parameters

- 4.1. Air Spring Pressure (Individual)

- 4.2. Compressor Status

- 4.3. Height Sensor Readings

- 4.4. Valve Block Activity

- 4.5. System Voltage

- 4.6. Temperature Readings

- 5. Using Diagnostic Tools to Access Data Streams

- 5.1. Step-by-Step Guide to Accessing Data Streams

- 5.2. Interpreting Diagnostic Data

- 6. Case Studies: Real-World Examples of Data Stream Analysis

- 6.1. Case Study 1: Diagnosing a Leaking Air Spring

- 6.2. Case Study 2: Diagnosing a Faulty Compressor

- 6.3. Case Study 3: Diagnosing a Malfunctioning Height Sensor

- 7. Common Mistakes to Avoid When Diagnosing Air Suspension Issues

- 8. Advanced Diagnostic Techniques for Air Suspension Systems

- 9. Maintenance Tips to Prevent Air Suspension Problems

- 10. How MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Can Help

- 11. Addressing Air Suspension Error Codes

- 11.1. Common Air Suspension Error Codes

- 11.2. Interpreting Error Codes

- 11.3. Clearing Error Codes

- 12. Ensuring Safety During Air Suspension Repairs

- 13. The Future of Air Suspension Diagnostics

- 14. FAQ: Diagnosing Air Suspension Issues

- 14.1. What are the most common symptoms of air suspension problems?

- 14.2. What data streams are most important for diagnosing air suspension issues?

- 14.3. What diagnostic tools are recommended for Mercedes-Benz air suspension systems?

- 14.4. How can I identify a leaking air spring?

- 14.5. What does it mean if the air compressor is running constantly?

- 14.6. How do I check the height sensors?

- 14.7. What should I do if I find an error code in the air suspension system?

- 14.8. How important is it to vent the air suspension system before performing repairs?

- 14.9. Can I diagnose air suspension problems myself, or should I take my car to a professional?

- 14.10. How can MERCEDES-DIAGNOSTIC-TOOL.EDU.VN help me diagnose air suspension issues?

1. Understanding Air Suspension Systems in Mercedes-Benz Vehicles

Air suspension systems in Mercedes-Benz vehicles provide a smooth and comfortable ride by using air springs instead of traditional steel springs. These systems automatically adjust the vehicle’s height and damping based on road conditions and driving style. The main components include:

- Air compressor: Supplies pressurized air to the system.

- Air springs: Replace traditional coil springs and support the vehicle’s weight.

- Height sensors: Monitor the vehicle’s ride height.

- Control unit (ECU): Manages the system based on sensor data.

- Valve block: Distributes air to the individual air springs.

- Air lines: Connect all components and carry pressurized air.

- Reservoir: Stores compressed air for immediate use.

When issues arise, identifying the relevant data streams becomes crucial for accurate diagnosis. Proper diagnosis and repair not only restores comfort but also ensures vehicle safety. With the help of MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, you can gain access to comprehensive diagnostic information, enabling you to address air suspension issues efficiently.

2. Why Accurate Data Streams Are Essential for Diagnosing Air Suspension Issues

Accurate data streams are essential for diagnosing air suspension issues for several key reasons:

- Precise Problem Identification: Data streams provide real-time information, allowing technicians to pinpoint the exact component causing the issue, whether it’s a leaking air spring, a malfunctioning compressor, or a faulty height sensor.

- Reduced Guesswork: Relying on data streams minimizes guesswork, which can lead to unnecessary parts replacements and wasted time.

- Comprehensive System View: Data streams offer a comprehensive view of the entire air suspension system, enabling technicians to see how different components interact and identify any abnormal patterns.

- Faster Diagnosis: Real-time data speeds up the diagnostic process, allowing technicians to identify and resolve issues more quickly.

- Cost-Effectiveness: By accurately identifying the problem, technicians can avoid unnecessary repairs, saving both time and money.

Without accurate data streams, diagnosing air suspension issues becomes a time-consuming and error-prone process. The ability to access and interpret real-time data is essential for efficient and effective troubleshooting.

3. Identifying Key Data Streams for Air Suspension Diagnostics

Identifying the key data streams is crucial for accurately diagnosing air suspension issues. These data streams provide real-time information about the system’s performance, allowing technicians to pinpoint the source of the problem. Here are some of the most important data streams to monitor:

- Individual Air Spring Pressures: Monitoring the pressure in each air spring can reveal leaks or pressure imbalances.

- Compressor Status: This data stream indicates whether the compressor is running, its duty cycle, and any error codes.

- Height Sensor Readings: These readings show the ride height at each corner of the vehicle, helping to identify issues with leveling or height adjustments.

- Valve Block Activity: Monitoring the valve block activity can reveal issues with air distribution to the individual air springs.

- System Voltage: Monitoring the system voltage ensures that all components are receiving adequate power.

- Temperature Readings: Monitoring the temperature of the compressor can prevent overheating and potential damage.

By analyzing these data streams, technicians can quickly identify the root cause of air suspension problems, leading to more effective repairs.

4. Detailed Look at Relevant Data Parameters

When diagnosing air suspension issues, certain data parameters provide critical insights into the system’s health and performance. Here’s a detailed look at some of the most relevant parameters:

4.1. Air Spring Pressure (Individual)

Monitoring the pressure in each air spring is essential for identifying leaks and imbalances. The diagnostic tool should display the current pressure in each air spring in real-time.

- Normal Operation: Pressures should be within a specified range and relatively equal across all air springs.

- Potential Issues:

- Low Pressure: Indicates a leak in the air spring, air line, or valve.

- Pressure Imbalance: Suggests a problem with the height sensors, valve block, or air spring itself.

- Sudden Pressure Drop: Points to a major leak or component failure.

Analyzing air spring pressures helps pinpoint the exact location of leaks and identify issues with individual components.

4.2. Compressor Status

The compressor status data stream provides information about the compressor’s operation, including its on/off state, duty cycle, and any error codes.

- Normal Operation: The compressor should cycle on and off as needed to maintain the correct system pressure.

- Potential Issues:

- Continuous Operation: Indicates a leak in the system, causing the compressor to run constantly to maintain pressure.

- No Operation: Suggests a faulty compressor, relay, or electrical connection.

- Overheating: Indicates excessive compressor use due to a leak or other issue.

- Error Codes: Provides specific information about compressor malfunctions, such as low voltage or high temperature.

Monitoring the compressor status helps identify issues that may be causing the compressor to work harder than necessary or fail altogether.

4.3. Height Sensor Readings

Height sensors measure the distance between the vehicle’s chassis and the road surface, providing data to the control unit for automatic leveling and height adjustments.

- Normal Operation: Height sensor readings should be within a specified range and consistent across all corners of the vehicle.

- Potential Issues:

- Incorrect Readings: Indicates a faulty height sensor, miscalibration, or mechanical issue.

- Inconsistent Readings: Suggests a problem with the leveling system, such as a malfunctioning valve block or air spring.

- No Change in Readings: Points to a sensor failure or wiring issue.

Analyzing height sensor readings helps identify problems with the vehicle’s leveling system and ensure proper ride height.

4.4. Valve Block Activity

The valve block controls the distribution of air to the individual air springs, allowing the system to adjust the ride height and maintain level.

- Normal Operation: The valve block should open and close valves as needed to regulate air flow to the air springs.

- Potential Issues:

- Valve Stuck Open/Closed: Prevents proper air distribution, leading to uneven ride height or system failure.

- Erratic Valve Operation: Suggests a problem with the control unit, wiring, or valve block itself.

- No Valve Activity: Points to a lack of communication between the control unit and valve block.

Monitoring valve block activity helps identify issues with air distribution and ensure proper system function.

4.5. System Voltage

Monitoring the system voltage is crucial for ensuring that all components are receiving adequate power.

- Normal Operation: The system voltage should be within a specified range, typically between 12 and 14 volts.

- Potential Issues:

- Low Voltage: Indicates a weak battery, poor connection, or excessive electrical load.

- High Voltage: Suggests a problem with the charging system or voltage regulator.

- Voltage Fluctuations: Points to a loose connection or intermittent electrical issue.

Maintaining proper system voltage is essential for the reliable operation of all air suspension components.

4.6. Temperature Readings

Monitoring the temperature of the compressor can help prevent overheating and potential damage.

- Normal Operation: The compressor temperature should remain within a specified range, even during extended use.

- Potential Issues:

- High Temperature: Indicates excessive compressor use due to a leak or other issue.

- Rapid Temperature Increase: Suggests a problem with the compressor’s cooling system or internal components.

- No Temperature Change: Points to a sensor failure or wiring issue.

Monitoring compressor temperature helps prevent overheating and prolong the life of the compressor.

By carefully analyzing these data parameters, technicians can accurately diagnose air suspension issues and implement effective repairs.

Mercedes-Benz Airmatic System Compressor Failure Symptoms

Mercedes-Benz Airmatic System Compressor Failure Symptoms

5. Using Diagnostic Tools to Access Data Streams

Accessing data streams requires the use of appropriate diagnostic tools that are compatible with Mercedes-Benz vehicles. These tools connect to the vehicle’s diagnostic port (OBD-II) and allow technicians to read real-time data from the air suspension system. Here are some popular diagnostic tools:

- Mercedes-Benz Star Diagnosis: The official diagnostic tool used by Mercedes-Benz dealerships.

- Autel MaxiSys: A versatile aftermarket tool that supports a wide range of vehicle makes and models, including Mercedes-Benz.

- iCarsoft MB II: A more affordable option that is specifically designed for Mercedes-Benz vehicles.

- LAUNCH X431: Another popular aftermarket tool with comprehensive diagnostic capabilities.

5.1. Step-by-Step Guide to Accessing Data Streams

Here’s a step-by-step guide to accessing data streams using a diagnostic tool:

- Connect the Diagnostic Tool: Plug the diagnostic tool into the vehicle’s OBD-II port, typically located under the dashboard.

- Power On: Turn on the diagnostic tool and follow the on-screen prompts to select the vehicle’s make, model, and year.

- Select Air Suspension System: Navigate to the air suspension system in the diagnostic tool’s menu. This may be listed as “Airmatic,” “Air Suspension,” or a similar term.

- Choose Live Data or Data Stream: Select the “Live Data” or “Data Stream” option to view real-time data from the system.

- Select Relevant Parameters: Choose the data parameters you want to monitor, such as individual air spring pressures, compressor status, height sensor readings, and valve block activity.

- Monitor Data: Observe the data streams and look for any abnormal readings or patterns.

5.2. Interpreting Diagnostic Data

Interpreting diagnostic data requires a good understanding of the air suspension system and its components. Here are some tips for interpreting the data:

- Compare Data: Compare the data from different components to identify any discrepancies. For example, compare the height sensor readings at each corner of the vehicle to check for leveling issues.

- Check for Error Codes: Look for any error codes that may be present in the system. These codes can provide valuable information about the nature and location of the problem.

- Monitor Trends: Observe how the data changes over time. For example, monitor the air spring pressures while the vehicle is being driven to see if any leaks are present.

- Refer to Service Manuals: Consult the vehicle’s service manual for information about normal operating ranges and diagnostic procedures.

By using diagnostic tools and carefully interpreting the data, technicians can accurately diagnose air suspension issues and implement effective repairs.

6. Case Studies: Real-World Examples of Data Stream Analysis

To illustrate the importance of data stream analysis, let’s look at some real-world case studies.

6.1. Case Study 1: Diagnosing a Leaking Air Spring

Symptoms: The vehicle is sitting lower on one corner, and the air compressor is running frequently.

Data Stream Analysis:

- Individual Air Spring Pressures: The pressure in the affected air spring is significantly lower than the others.

- Compressor Status: The compressor is running almost continuously, trying to maintain system pressure.

- Height Sensor Readings: The height sensor reading on the affected corner is lower than the others.

Diagnosis: A leaking air spring is causing the pressure to drop, leading to the vehicle sitting lower on that corner and the compressor running continuously.

Solution: Replace the leaking air spring.

6.2. Case Study 2: Diagnosing a Faulty Compressor

Symptoms: The air suspension system is not working at all, and the vehicle is sitting low on all corners.

Data Stream Analysis:

- Compressor Status: The compressor is not running, and there are no error codes present.

- System Voltage: The system voltage is normal.

- Individual Air Spring Pressures: The pressure in all air springs is low.

Diagnosis: A faulty compressor is preventing the system from maintaining pressure.

Solution: Replace the faulty compressor.

6.3. Case Study 3: Diagnosing a Malfunctioning Height Sensor

Symptoms: The vehicle is uneven, with one side sitting higher than the other.

Data Stream Analysis:

- Height Sensor Readings: The height sensor readings on one side of the vehicle are significantly different from the readings on the other side.

- Individual Air Spring Pressures: The air spring pressures are also uneven, with the higher side having more pressure.

Diagnosis: A malfunctioning height sensor is providing incorrect data to the control unit, causing the system to overinflate one side of the vehicle.

Solution: Replace the malfunctioning height sensor and recalibrate the system.

These case studies demonstrate how data stream analysis can be used to accurately diagnose a wide range of air suspension issues.

7. Common Mistakes to Avoid When Diagnosing Air Suspension Issues

When diagnosing air suspension issues, it’s important to avoid common mistakes that can lead to incorrect diagnoses and unnecessary repairs. Here are some mistakes to avoid:

- Not Checking for Error Codes: Always start by checking for error codes in the system. These codes can provide valuable information about the nature and location of the problem.

- Relying Solely on Symptoms: Don’t rely solely on the symptoms to diagnose the problem. Use data stream analysis to confirm your suspicions and identify the root cause of the issue.

- Not Following Diagnostic Procedures: Follow the diagnostic procedures outlined in the vehicle’s service manual. These procedures are designed to help you accurately diagnose the problem and avoid making mistakes.

- Replacing Parts Without Testing: Don’t replace parts without testing them first. This can lead to unnecessary repairs and wasted money.

- Ignoring System Voltage: Always check the system voltage to ensure that all components are receiving adequate power. Low voltage can cause a wide range of issues with the air suspension system.

- Not Venting the System: Never open any part of the suspension system without first venting the system. This can prevent injuries and damage to components.

- Forgetting Jacking Mode: Never jack up a car with air suspension without first putting it in jacking mode. This can prevent damage to the system and ensure that the vehicle is properly supported.

By avoiding these common mistakes, technicians can improve their diagnostic accuracy and reduce the risk of unnecessary repairs.

8. Advanced Diagnostic Techniques for Air Suspension Systems

In addition to basic data stream analysis, there are several advanced diagnostic techniques that can be used to troubleshoot air suspension systems. These techniques can help technicians identify intermittent problems, diagnose complex issues, and verify the effectiveness of repairs. Here are some advanced diagnostic techniques:

- Actuator Tests: Actuator tests allow technicians to control individual components of the air suspension system, such as the air compressor, valves, and solenoids. This can help identify components that are not functioning properly.

- Component Testing: Component testing involves using specialized tools to test the individual components of the air suspension system, such as the air springs, height sensors, and control unit. This can help identify components that are faulty or out of specification.

- Wiring Diagrams: Reviewing wiring diagrams can help technicians trace circuits, identify shorts or opens, and verify the integrity of wiring connections.

- Oscilloscope Analysis: An oscilloscope can be used to analyze the electrical signals in the air suspension system. This can help identify intermittent problems, noise, and other electrical issues.

- Pressure Testing: Pressure testing involves using specialized tools to measure the pressure in different parts of the air suspension system. This can help identify leaks and other pressure-related issues.

- Data Logging: Data logging involves recording data from the air suspension system over a period of time. This can help identify intermittent problems and track system performance.

- Freeze Frame Data: Freeze frame data captures the data stream values at the moment a diagnostic trouble code (DTC) is set. This information can provide valuable clues about the conditions that caused the DTC to be triggered.

By using these advanced diagnostic techniques, technicians can effectively troubleshoot even the most challenging air suspension issues.

9. Maintenance Tips to Prevent Air Suspension Problems

Preventive maintenance is essential for keeping air suspension systems in good working order and avoiding costly repairs. Here are some maintenance tips to prevent air suspension problems:

- Regular Inspections: Inspect the air suspension system regularly for signs of damage or wear, such as cracks, leaks, or corrosion.

- Clean Air Springs: Clean the air springs regularly to remove dirt and debris. This can help prevent damage and prolong the life of the air springs.

- Check Air Lines: Check the air lines for leaks, cracks, or kinks. Replace any damaged air lines immediately.

- Inspect Height Sensors: Inspect the height sensors for damage or corrosion. Replace any faulty height sensors.

- Maintain Proper System Voltage: Ensure that the system voltage is within the specified range. Low voltage can cause a wide range of issues with the air suspension system.

- Replace Air Filter: Replace the air filter for the compressor regularly. A clogged air filter can cause the compressor to overheat and fail.

- Keep System Dry: Keep the air suspension system dry. Moisture can damage the components and cause corrosion.

- Follow Service Intervals: Follow the service intervals recommended by the vehicle manufacturer. This can help ensure that the air suspension system is properly maintained.

By following these maintenance tips, vehicle owners can help prevent air suspension problems and keep their vehicles riding smoothly.

10. How MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Can Help

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN is your reliable resource for diagnosing and resolving air suspension issues in Mercedes-Benz vehicles. We offer a range of services and information to assist you, including:

- Expert Advice: Our team of experienced technicians can provide expert advice and guidance on diagnosing and repairing air suspension systems.

- Diagnostic Tools: We offer a variety of diagnostic tools that are compatible with Mercedes-Benz vehicles, allowing you to access real-time data streams and identify the root cause of air suspension problems.

- Step-by-Step Guides: Our step-by-step guides provide detailed instructions on how to diagnose and repair air suspension systems, even if you’re not a professional technician.

- Technical Articles: Our technical articles cover a wide range of topics related to air suspension systems, including diagnostic techniques, repair procedures, and maintenance tips.

- Community Forum: Our community forum allows you to connect with other Mercedes-Benz owners and technicians, share your experiences, and ask questions.

Whether you’re a professional technician or a DIY enthusiast, MERCEDES-DIAGNOSTIC-TOOL.EDU.VN can help you diagnose and resolve air suspension issues in your Mercedes-Benz vehicle. Don’t let air suspension problems keep you from enjoying a smooth and comfortable ride.

Address: 789 Oak Avenue, Miami, FL 33101, United States

Whatsapp: +1 (641) 206-8880

Website: MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

Contact us today for expert advice and assistance. Let us help you keep your Mercedes-Benz riding smoothly and safely.

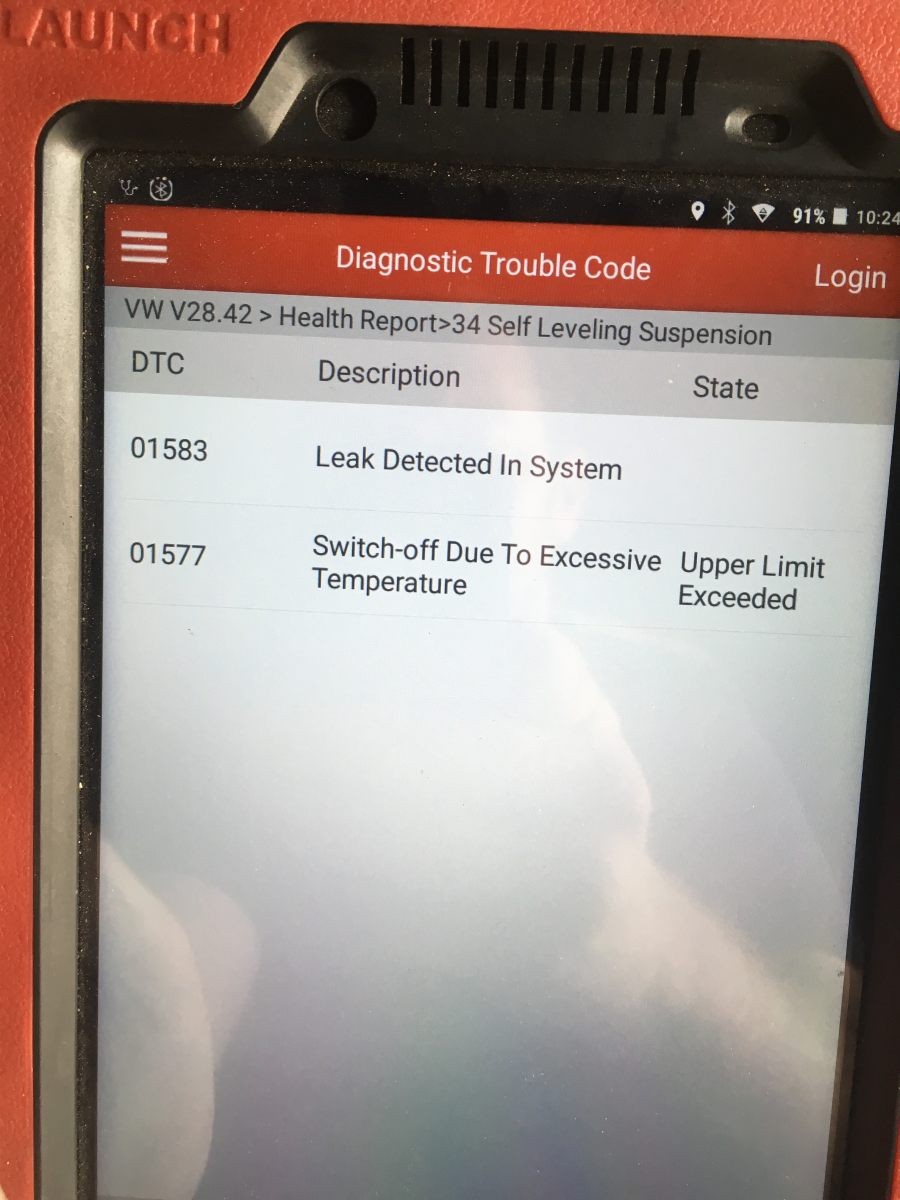

11. Addressing Air Suspension Error Codes

Error codes are a crucial part of diagnosing air suspension issues, providing specific information about the system’s malfunctions. When an issue occurs, the system’s control unit stores a diagnostic trouble code (DTC) that can be retrieved using a diagnostic tool.

11.1. Common Air Suspension Error Codes

Here are some common air suspension error codes that you may encounter:

- C1566: Component Y36/6 (Right front axle air suspension solenoid valve) is faulty.

- C1567: Component Y36/5 (Left front axle air suspension solenoid valve) is faulty.

- C1577: Shutoff due to excessive temperature of component A9/1 (air suspension compressor unit).

- C1583: Leakage is detected in the air suspension system.

- C15A6: Level control is implausible.

- C15A7: The vehicle level is too low.

- 5298: The pressure in the system is too low.

- 5503: Component A9/1 (air suspension compressor unit) is overheating.

11.2. Interpreting Error Codes

Interpreting error codes requires a good understanding of the air suspension system and its components. Here are some tips for interpreting error codes:

- Look Up the Code: Use a diagnostic tool or online resource to look up the definition of the error code. This will provide information about the specific component or system that is affected.

- Consider the Symptoms: Consider the symptoms that the vehicle is exhibiting. This can help you narrow down the possible causes of the error code.

- Check the Wiring: Check the wiring and connections related to the affected component. A loose connection or damaged wire can cause an error code to be set.

- Test the Component: Test the affected component using a diagnostic tool or multimeter. This can help you determine if the component is faulty or out of specification.

- Refer to Service Manuals: Consult the vehicle’s service manual for information about troubleshooting error codes and repairing the air suspension system.

11.3. Clearing Error Codes

After repairing the air suspension system, it’s important to clear the error codes from the control unit. This will reset the system and allow you to verify that the repair was successful. To clear error codes:

- Connect the diagnostic tool to the vehicle’s OBD-II port.

- Turn on the diagnostic tool and select the vehicle’s make, model, and year.

- Navigate to the air suspension system in the diagnostic tool’s menu.

- Select the “Clear Codes” or “Erase Codes” option.

- Follow the on-screen prompts to clear the error codes.

After clearing the error codes, test the air suspension system to ensure that it is functioning properly. If the error codes return, there may still be an issue with the system that needs to be addressed.

By understanding and addressing air suspension error codes, technicians can effectively diagnose and repair air suspension issues.

12. Ensuring Safety During Air Suspension Repairs

Safety should always be a top priority when working on air suspension systems. These systems contain pressurized air, which can be dangerous if not handled properly. Here are some safety precautions to take during air suspension repairs:

- Vent the System: Always vent the air suspension system before disconnecting any components. This will release the pressurized air and prevent injuries. Most diagnostic tools have a function to vent the system.

- Wear Safety Glasses: Wear safety glasses to protect your eyes from debris and pressurized air.

- Use Proper Tools: Use the proper tools for the job. This will help prevent damage to components and injuries.

- Disconnect the Battery: Disconnect the battery before working on the electrical system. This will prevent electrical shocks and damage to components.

- Support the Vehicle: Use jack stands to support the vehicle when it is raised. This will prevent the vehicle from falling and causing injuries.

- Follow Service Manuals: Follow the service manuals for the vehicle. This will ensure that you are using the proper procedures and taking the necessary safety precautions.

- Be Aware of Surroundings: Be aware of your surroundings and avoid distractions. This will help prevent accidents.

- No Open Flames: Never use open flames near the air suspension system. The pressurized air can be flammable and cause an explosion.

- Proper Training: Ensure you have proper training and knowledge of the system before attempting any repairs.

By following these safety precautions, technicians can minimize the risk of injuries and ensure that air suspension repairs are performed safely.

13. The Future of Air Suspension Diagnostics

The field of air suspension diagnostics is constantly evolving, with new technologies and techniques emerging all the time. Here are some trends that are shaping the future of air suspension diagnostics:

- Increased Use of Data Analytics: Data analytics is being used to analyze data from air suspension systems and identify patterns that can help predict failures and optimize performance.

- Remote Diagnostics: Remote diagnostics is allowing technicians to diagnose and repair air suspension systems remotely, using telematics and diagnostic tools.

- Artificial Intelligence (AI): AI is being used to develop diagnostic tools that can automatically identify and diagnose air suspension problems.

- Cloud-Based Diagnostics: Cloud-based diagnostics is allowing technicians to access diagnostic data and resources from anywhere in the world.

- Improved Sensors: New and improved sensors are providing more accurate and detailed data about the performance of air suspension systems.

- Integration with Other Systems: Air suspension systems are being integrated with other vehicle systems, such as the braking system and stability control system. This is allowing for more sophisticated control and diagnostics.

- Augmented Reality (AR): AR is being used to create diagnostic tools that overlay diagnostic data onto the real world, making it easier for technicians to identify and repair problems.

As these technologies continue to develop, air suspension diagnostics will become more accurate, efficient, and accessible.

14. FAQ: Diagnosing Air Suspension Issues

Here are some frequently asked questions about diagnosing air suspension issues:

14.1. What are the most common symptoms of air suspension problems?

Common symptoms include a sagging vehicle, uneven ride height, a rough or bouncy ride, and a constantly running air compressor.

14.2. What data streams are most important for diagnosing air suspension issues?

Key data streams include individual air spring pressures, compressor status, height sensor readings, and valve block activity.

14.3. What diagnostic tools are recommended for Mercedes-Benz air suspension systems?

Recommended tools include Mercedes-Benz Star Diagnosis, Autel MaxiSys, iCarsoft MB II, and LAUNCH X431.

14.4. How can I identify a leaking air spring?

Monitor individual air spring pressures and look for a significant drop in pressure in one of the springs. You can also use soapy water to check for leaks.

14.5. What does it mean if the air compressor is running constantly?

A constantly running air compressor typically indicates a leak in the system.

14.6. How do I check the height sensors?

Use a diagnostic tool to monitor the height sensor readings at each corner of the vehicle. Compare the readings and look for any discrepancies.

14.7. What should I do if I find an error code in the air suspension system?

Look up the definition of the error code and follow the troubleshooting steps outlined in the vehicle’s service manual.

14.8. How important is it to vent the air suspension system before performing repairs?

Venting the system is crucial for safety. It releases pressurized air and prevents injuries.

14.9. Can I diagnose air suspension problems myself, or should I take my car to a professional?

While some basic diagnostics can be done at home, more complex issues require professional tools and expertise.

14.10. How can MERCEDES-DIAGNOSTIC-TOOL.EDU.VN help me diagnose air suspension issues?

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides expert advice, diagnostic tools, step-by-step guides, technical articles, and a community forum to assist with diagnosing and repairing air suspension systems.

By addressing these frequently asked questions, we aim to provide comprehensive guidance on diagnosing air suspension issues.

Don’t let air suspension problems compromise your driving experience. Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN today for expert assistance and reliable solutions. Visit us at 789 Oak Avenue, Miami, FL 33101, United States, or reach us via WhatsApp at +1 (641) 206-8880. For more information, visit our website at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN.