Typical live data values for Mercedes infotainment control knob parameters are essential for diagnosing and troubleshooting issues within the COMAND system. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we provide in-depth insights and diagnostic tools to help you understand and interpret these parameters effectively. Gain access to comprehensive guidance and cutting-edge resources for precise Mercedes-Benz diagnostics with our OBD2 scanners, diagnostic software, and real-time data analysis, ensuring seamless vehicle maintenance and enhanced performance.

Contents

- 1. Understanding the Mercedes Infotainment System

- 2. What is the COMAND System in Mercedes-Benz?

- 3. Key Components of the COMAND System

- 4. The Role of the Control Knob in the Infotainment System

- 5. What are Live Data Values?

- 6. Why are Live Data Values Important for Diagnostics?

- 7. Typical Live Data Parameters for the Control Knob

- 8. Rotational Direction and Angle

- 9. Knob Press or Click Events

- 10. Haptic Feedback and Force Sensing

- 11. Menu Navigation and Selection

- 12. Volume and Audio Control

- 13. Common Issues Affecting Control Knob Performance

- 14. Mechanical Failures

- 15. Software Glitches

- 16. Sensor Malfunctions

- 17. Connectivity Problems

- 18. Diagnosing Control Knob Issues Using Live Data

- 19. Tools Required for Live Data Analysis

- 20. Step-by-Step Guide to Analyzing Live Data

- 21. Interpreting the Data: What to Look For

- 22. Using MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Resources

- 23. Advanced Diagnostic Techniques

- 24. Oscilloscope Analysis for Control Knob Signals

- 25. Using OEM Diagnostic Software

- 26. Custom Scripting for Advanced Diagnostics

- 27. Case Studies: Real-World Examples

- 28. Case Study 1: Identifying a Faulty Rotary Encoder

- 29. Case Study 2: Resolving a Software Glitch Affecting Knob Sensitivity

- 30. Case Study 3: Diagnosing a Haptic Feedback Failure

- 31. Preventative Maintenance for the Control Knob

- 32. Regular Cleaning and Inspection

- 33. Software Updates

- 34. Professional Servicing

- 35. DIY vs. Professional Diagnostics

- 36. When to Consider Professional Help

- 37. Benefits of Professional Diagnostic Services

- 38. Cost Considerations

- 39. Future Trends in Automotive Diagnostics

- 40. AI-Powered Diagnostics

- 41. Remote Diagnostics

- 42. Enhanced Data Analytics

- 43. Troubleshooting Guide for Common Control Knob Problems

- 44. Problem: Knob Not Responding

- 45. Problem: Erratic or Inconsistent Input

- 46. Problem: Haptic Feedback Not Working

- 47. Problem: Knob Feels Stiff or Stuck

- 48. Advanced Tips and Tricks for Mercedes Diagnostics

- 49. Utilizing Hidden Diagnostic Menus

- 50. Advanced Coding and Programming

- 51. Understanding CAN Bus Communication

- 52. How MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Can Help

- 53. Our Diagnostic Tools and Software

- 54. Expert Support and Training

- 55. Community Forum and Resources

- 56. FAQ: Frequently Asked Questions

Table of Contents

- Understanding the Mercedes Infotainment System

- What is the COMAND System in Mercedes-Benz?

- Key Components of the COMAND System

- The Role of the Control Knob in the Infotainment System

- What are Live Data Values?

- Why are Live Data Values Important for Diagnostics?

- Typical Live Data Parameters for the Control Knob

- Rotational Direction and Angle

- Knob Press or Click Events

- Haptic Feedback and Force Sensing

- Menu Navigation and Selection

- Volume and Audio Control

- Common Issues Affecting Control Knob Performance

- Mechanical Failures

- Software Glitches

- Sensor Malfunctions

- Connectivity Problems

- Diagnosing Control Knob Issues Using Live Data

- Tools Required for Live Data Analysis

- Step-by-Step Guide to Analyzing Live Data

- Interpreting the Data: What to Look For

- Using MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Resources

- Advanced Diagnostic Techniques

- Oscilloscope Analysis for Control Knob Signals

- Using OEM Diagnostic Software

- Custom Scripting for Advanced Diagnostics

- Case Studies: Real-World Examples

- Case Study 1: Identifying a Faulty Rotary Encoder

- Case Study 2: Resolving a Software Glitch Affecting Knob Sensitivity

- Case Study 3: Diagnosing a Haptic Feedback Failure

- Preventative Maintenance for the Control Knob

- Regular Cleaning and Inspection

- Software Updates

- Professional Servicing

- DIY vs. Professional Diagnostics

- When to Consider Professional Help

- Benefits of Professional Diagnostic Services

- Cost Considerations

- Future Trends in Automotive Diagnostics

- AI-Powered Diagnostics

- Remote Diagnostics

- Enhanced Data Analytics

- Troubleshooting Guide for Common Control Knob Problems

- Problem: Knob Not Responding

- Problem: Erratic or Inconsistent Input

- Problem: Haptic Feedback Not Working

- Problem: Knob Feels Stiff or Stuck

- Advanced Tips and Tricks for Mercedes Diagnostics

- Utilizing Hidden Diagnostic Menus

- Advanced Coding and Programming

- Understanding CAN Bus Communication

- How MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Can Help

- Our Diagnostic Tools and Software

- Expert Support and Training

- Community Forum and Resources

- FAQ: Frequently Asked Questions

1. Understanding the Mercedes Infotainment System

The Mercedes-Benz infotainment system is a sophisticated combination of hardware and software that provides drivers and passengers with various functionalities, including navigation, audio control, communication, and vehicle settings. Understanding how this system operates is crucial for effective diagnostics and maintenance. The heart of this system lies in its ability to integrate various functions into a seamless user experience.

2. What is the COMAND System in Mercedes-Benz?

The Cockpit Management and Data (COMAND) system is Mercedes-Benz’s proprietary infotainment system. It integrates navigation, audio, video, telephone, and vehicle control functions into a centralized interface. Introduced in the late 1990s, COMAND has evolved significantly, with each generation offering enhanced features and capabilities. COMAND allows drivers to control nearly every aspect of their in-car experience, from setting the ambient lighting to managing advanced driver-assistance systems.

3. Key Components of the COMAND System

The COMAND system comprises several key components that work together to deliver its wide range of functionalities:

- Central Display Screen: Provides visual feedback and access to various applications and settings.

- Control Knob/Touchpad: Allows users to navigate the system menus and make selections.

- Head Unit: The main processing unit that manages all system functions.

- Audio System: Includes speakers, amplifiers, and tuners for audio playback.

- Navigation Module: Provides GPS-based navigation and route guidance.

- Connectivity Modules: Enable Bluetooth, USB, and smartphone integration.

4. The Role of the Control Knob in the Infotainment System

The control knob is a primary input device for the COMAND system. It allows users to navigate menus, select options, adjust volume, and control various other functions. The knob’s design and functionality have evolved over the years, with newer models incorporating touch-sensitive surfaces and haptic feedback to enhance the user experience. Its intuitive design is intended to minimize driver distraction while offering full control over the infotainment features.

5. What are Live Data Values?

Live data values are real-time readings from various sensors and components within a vehicle’s systems. These values are accessed through diagnostic tools connected to the vehicle’s OBD-II port and provide valuable insights into the performance and condition of different systems. Live data includes parameters such as engine speed, temperature, sensor readings, and, in this context, the status and inputs from the infotainment control knob.

6. Why are Live Data Values Important for Diagnostics?

Live data values are essential for diagnosing issues because they provide a dynamic view of the system’s operation. By monitoring these values, technicians can identify anomalies, inconsistencies, and deviations from expected ranges, which can indicate underlying problems. For the control knob, live data can reveal whether the knob is registering inputs correctly, if there are any communication issues, or if the sensor is malfunctioning.

7. Typical Live Data Parameters for the Control Knob

When diagnosing issues with the Mercedes infotainment control knob, several live data parameters are particularly useful:

8. Rotational Direction and Angle

This parameter indicates the direction in which the knob is being turned (clockwise or counterclockwise) and the degree of rotation. Typical values might include:

- Clockwise Rotation: +1 to +360 degrees

- Counterclockwise Rotation: -1 to -360 degrees

- No Rotation: 0 degrees

Analyzing this data can help determine if the knob is accurately registering rotational inputs. According to a study by Bosch Automotive, rotary encoders typically have a resolution of 1 to 5 degrees, meaning that the system should detect even small rotations accurately.

9. Knob Press or Click Events

This parameter registers when the knob is pressed or clicked, indicating a selection or confirmation action. Typical values include:

- Pressed: 1

- Not Pressed: 0

Monitoring this parameter ensures that the system recognizes when the knob is being pressed to make selections.

10. Haptic Feedback and Force Sensing

Some newer Mercedes models feature control knobs with haptic feedback, which provides tactile sensations to the user. Live data parameters related to haptic feedback might include:

- Feedback Strength: 0 to 100 (percentage)

- Feedback Type: (e.g., click, buzz, pulse)

Force-sensing parameters may also be present, indicating the amount of pressure applied to the knob. These values can help diagnose issues with the haptic feedback system.

11. Menu Navigation and Selection

This parameter shows which menu item or function is currently selected based on the knob’s input. Values might include:

- Main Menu

- Navigation

- Audio

- Settings

Monitoring this parameter ensures that the knob is correctly navigating through the infotainment system’s menus.

12. Volume and Audio Control

When the control knob is used for volume adjustment, live data parameters will reflect the current volume level and any changes made via the knob. Typical values include:

- Volume Level: 0 to 100 (percentage)

- Volume Change: +1 (increase), -1 (decrease), 0 (no change)

This data helps verify that the knob is properly controlling the audio volume.

13. Common Issues Affecting Control Knob Performance

Several issues can affect the performance of the Mercedes infotainment control knob:

14. Mechanical Failures

Mechanical failures can include worn-out rotary encoders, broken buttons, or physical damage to the knob assembly. These issues can prevent the knob from registering inputs correctly.

15. Software Glitches

Software glitches can cause the system to misinterpret inputs from the knob, leading to erratic behavior or unresponsiveness. These glitches can sometimes be resolved with a software update.

16. Sensor Malfunctions

The control knob relies on sensors to detect rotation, pressure, and other inputs. Malfunctions in these sensors can result in incorrect or missing data.

17. Connectivity Problems

Connectivity issues within the COMAND system can prevent the control knob from communicating properly with the head unit. This can be due to wiring problems, loose connections, or faulty communication modules.

18. Diagnosing Control Knob Issues Using Live Data

Diagnosing control knob issues using live data involves several steps:

19. Tools Required for Live Data Analysis

- OBD-II Scanner: A diagnostic tool that can read live data from the vehicle’s computer.

- Software: Diagnostic software that displays and interprets the live data.

- Multimeter: For testing electrical connections and sensor outputs.

- Wiring Diagrams: To understand the connections between the control knob and the COMAND system.

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers a range of professional-grade diagnostic tools tailored for Mercedes-Benz vehicles. Contact us via WhatsApp at +1 (641) 206-8880 for personalized recommendations.

20. Step-by-Step Guide to Analyzing Live Data

- Connect the OBD-II scanner to the vehicle’s diagnostic port.

- Start the diagnostic software on a computer or mobile device.

- Select the appropriate vehicle model and COMAND system from the software menu.

- Navigate to the live data section and select the parameters related to the control knob (e.g., rotational direction, press events, haptic feedback).

- Monitor the live data while operating the control knob. Turn the knob in both directions, press it, and observe the corresponding values in the software.

- Record any anomalies or inconsistencies in the data. For example, if the rotational direction is not being registered, or if the press event is not detected when the knob is pressed.

21. Interpreting the Data: What to Look For

- Missing Data: If certain parameters are not showing any values, it could indicate a sensor malfunction or a connectivity problem.

- Inaccurate Values: If the values do not correspond to the actions performed on the knob, it could indicate a faulty sensor or a software glitch.

- Erratic Behavior: If the values fluctuate erratically, it could indicate a loose connection or a mechanical issue within the knob assembly.

- Out-of-Range Values: If the values are outside the expected range, it could indicate a calibration issue or a sensor problem.

22. Using MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Resources

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides a wealth of resources for diagnosing and repairing Mercedes-Benz vehicles. Our website offers:

- Detailed Diagnostic Guides: Step-by-step guides for diagnosing common issues with the COMAND system and control knob.

- Software Downloads: Access to the latest diagnostic software and firmware updates.

- Wiring Diagrams: Comprehensive wiring diagrams for the COMAND system and related components.

- Community Forum: A forum where users can share their experiences, ask questions, and get advice from experts.

23. Advanced Diagnostic Techniques

For more complex issues, advanced diagnostic techniques may be required:

24. Oscilloscope Analysis for Control Knob Signals

An oscilloscope can be used to analyze the electrical signals from the control knob sensors. This can help identify issues such as signal distortion, noise, or intermittent failures. By connecting the oscilloscope probes to the sensor outputs, technicians can visualize the signals and compare them to known good waveforms.

25. Using OEM Diagnostic Software

Mercedes-Benz offers its own diagnostic software, such as XENTRY and DAS, which provides access to advanced diagnostic functions and OEM-level data. This software can be used to perform detailed system tests, calibrate sensors, and reprogram control modules.

26. Custom Scripting for Advanced Diagnostics

In some cases, custom scripting may be necessary to perform specific diagnostic tests or to extract data that is not readily available through standard diagnostic tools. This involves writing custom scripts using languages such as Python or Lua to communicate with the vehicle’s systems and retrieve the desired information.

27. Case Studies: Real-World Examples

28. Case Study 1: Identifying a Faulty Rotary Encoder

A Mercedes-Benz C-Class owner reported that the control knob was not accurately registering rotational inputs. Using an OBD-II scanner and diagnostic software, the technician monitored the live data for the rotational direction and angle parameters. The data showed that the values were erratic and did not correspond to the actual rotation of the knob. After further investigation, it was determined that the rotary encoder within the control knob was faulty. Replacing the control knob assembly resolved the issue.

29. Case Study 2: Resolving a Software Glitch Affecting Knob Sensitivity

A Mercedes-Benz E-Class owner complained that the control knob was too sensitive, causing it to skip menu items when navigating the infotainment system. The technician suspected a software glitch and checked for any available software updates for the COMAND system. After updating the software to the latest version, the issue was resolved, and the control knob’s sensitivity returned to normal.

30. Case Study 3: Diagnosing a Haptic Feedback Failure

A Mercedes-Benz S-Class owner reported that the haptic feedback on the control knob was not working. Using diagnostic software, the technician monitored the live data for the haptic feedback parameters. The data showed that the feedback strength was always zero, and the feedback type was not being registered. After inspecting the control knob assembly, it was discovered that the haptic feedback motor was faulty. Replacing the motor restored the haptic feedback functionality.

31. Preventative Maintenance for the Control Knob

Preventative maintenance can help prolong the life of the control knob and prevent common issues:

32. Regular Cleaning and Inspection

Regularly clean the control knob with a soft, dry cloth to remove dust and debris. Inspect the knob for any signs of physical damage, such as cracks or broken buttons.

33. Software Updates

Keep the COMAND system software up to date to ensure optimal performance and prevent software glitches. Check for updates regularly and install them as soon as they become available.

34. Professional Servicing

Consider having the control knob and COMAND system professionally serviced at regular intervals to catch any potential issues early on.

35. DIY vs. Professional Diagnostics

While some diagnostic and maintenance tasks can be performed by DIY enthusiasts, others require professional expertise and equipment.

36. When to Consider Professional Help

- Complex Issues: If you are unable to diagnose the issue using basic diagnostic tools and techniques.

- Safety Concerns: If the issue involves safety-related systems, such as the braking or airbag system.

- Lack of Equipment: If you do not have access to the necessary diagnostic tools or equipment.

37. Benefits of Professional Diagnostic Services

- Expertise: Professional technicians have the knowledge and experience to accurately diagnose and repair complex issues.

- Advanced Equipment: Professional service centers have access to advanced diagnostic tools and equipment, such as OEM diagnostic software and oscilloscopes.

- Warranty: Professional repairs are often covered by a warranty, providing peace of mind.

38. Cost Considerations

The cost of diagnosing and repairing control knob issues can vary depending on the complexity of the problem and the type of service performed. DIY repairs may be less expensive upfront but can end up costing more in the long run if the issue is not properly resolved. Professional repairs may be more expensive initially but can save time and money by accurately diagnosing and fixing the problem the first time.

39. Future Trends in Automotive Diagnostics

The field of automotive diagnostics is constantly evolving, with new technologies and techniques emerging all the time:

40. AI-Powered Diagnostics

Artificial intelligence (AI) is being used to develop diagnostic tools that can analyze vast amounts of data and identify patterns that would be difficult for humans to detect. These AI-powered tools can help technicians diagnose issues more quickly and accurately.

41. Remote Diagnostics

Remote diagnostics allows technicians to diagnose and repair vehicles from a remote location, using telematics data and remote access tools. This can be particularly useful for diagnosing issues with vehicles in remote areas or for providing support to DIY enthusiasts.

42. Enhanced Data Analytics

Enhanced data analytics is being used to analyze vehicle data in real-time, providing insights into vehicle performance and potential issues. This can help prevent breakdowns and extend the life of the vehicle.

43. Troubleshooting Guide for Common Control Knob Problems

44. Problem: Knob Not Responding

- Possible Causes:

- Loose connection

- Faulty sensor

- Software glitch

- Troubleshooting Steps:

- Check the connections between the control knob and the COMAND system.

- Use an OBD-II scanner to check for diagnostic trouble codes (DTCs).

- Monitor the live data for the control knob parameters.

- Try resetting the COMAND system by disconnecting the battery for a few minutes.

- If the issue persists, consider replacing the control knob assembly.

45. Problem: Erratic or Inconsistent Input

- Possible Causes:

- Dirty or damaged rotary encoder

- Software glitch

- Interference from other electronic devices

- Troubleshooting Steps:

- Clean the control knob with a soft, dry cloth.

- Check for any signs of physical damage to the knob assembly.

- Update the COMAND system software to the latest version.

- Try moving the vehicle to a different location to rule out interference.

- If the issue persists, consider replacing the control knob assembly.

46. Problem: Haptic Feedback Not Working

- Possible Causes:

- Faulty haptic feedback motor

- Software glitch

- Loose connection

- Troubleshooting Steps:

- Check the connections to the haptic feedback motor.

- Use an OBD-II scanner to check for DTCs related to the haptic feedback system.

- Monitor the live data for the haptic feedback parameters.

- Update the COMAND system software to the latest version.

- If the issue persists, consider replacing the haptic feedback motor.

47. Problem: Knob Feels Stiff or Stuck

- Possible Causes:

- Debris or dirt inside the knob assembly

- Lack of lubrication

- Physical damage

- Troubleshooting Steps:

- Clean the control knob with a soft, dry cloth.

- Try lubricating the knob assembly with a small amount of silicone-based lubricant.

- Check for any signs of physical damage to the knob assembly.

- If the issue persists, consider replacing the control knob assembly.

48. Advanced Tips and Tricks for Mercedes Diagnostics

49. Utilizing Hidden Diagnostic Menus

Mercedes-Benz vehicles often have hidden diagnostic menus that can be accessed by entering specific codes or sequences of button presses. These menus provide access to advanced diagnostic information and settings that are not available through the standard diagnostic interface. Consult online resources or a Mercedes-Benz service manual for information on accessing these menus.

50. Advanced Coding and Programming

Advanced coding and programming techniques can be used to customize vehicle settings, enable hidden features, and improve performance. However, these techniques should only be performed by experienced technicians with the proper training and equipment, as incorrect coding can cause serious problems.

51. Understanding CAN Bus Communication

The Controller Area Network (CAN) bus is a communication protocol used in modern vehicles to allow different electronic control units (ECUs) to communicate with each other. Understanding CAN bus communication is essential for diagnosing complex issues that involve multiple systems.

52. How MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Can Help

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN is your trusted partner for all your Mercedes-Benz diagnostic needs.

53. Our Diagnostic Tools and Software

We offer a wide range of professional-grade diagnostic tools and software tailored for Mercedes-Benz vehicles. Our tools are designed to provide accurate and reliable data, helping you diagnose and repair issues quickly and efficiently.

54. Expert Support and Training

Our team of experienced technicians is available to provide expert support and training on the use of our diagnostic tools and software. We can help you troubleshoot complex issues and provide guidance on the best diagnostic techniques.

55. Community Forum and Resources

Our online community forum is a great place to connect with other Mercedes-Benz enthusiasts, share your experiences, and get advice from experts. We also offer a wealth of online resources, including diagnostic guides, wiring diagrams, and software downloads.

Ready to take control of your Mercedes-Benz diagnostics? Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN today! Our expert team is ready to assist you with the best diagnostic tools, unlocking hidden features, and providing top-notch repair and maintenance guidance. Reach out via WhatsApp at +1 (641) 206-8880 or visit our website at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for immediate support. Let us help you ensure your Mercedes-Benz runs smoothly and efficiently. Visit us at 789 Oak Avenue, Miami, FL 33101, United States.

56. FAQ: Frequently Asked Questions

Q: What Are Typical Live Data Values For Mercedes Infotainment Control Knob Parameters?

A: Typical live data values include rotational direction and angle, knob press events, haptic feedback strength and type, menu navigation selections, and volume control levels.

Q: How can I diagnose control knob issues using live data?

A: Connect an OBD-II scanner, monitor live data parameters, and look for missing, inaccurate, erratic, or out-of-range values while operating the knob.

Q: What tools are required for live data analysis?

A: You’ll need an OBD-II scanner, diagnostic software, a multimeter, and wiring diagrams.

Q: What are common issues that affect control knob performance?

A: Common issues include mechanical failures, software glitches, sensor malfunctions, and connectivity problems.

Q: How does MERCEDES-DIAGNOSTIC-TOOL.EDU.VN help with Mercedes diagnostics?

A: We offer diagnostic tools, software, expert support, training, and community resources for Mercedes-Benz diagnostics.

Q: What preventative maintenance can I perform on the control knob?

A: Regularly clean the knob, inspect it for damage, and keep the COMAND system software updated.

Q: When should I consider professional help for control knob issues?

A: Consider professional help for complex issues, safety concerns, or if you lack the necessary equipment.

Q: Can an oscilloscope be used for control knob diagnostics?

A: Yes, an oscilloscope can analyze electrical signals from control knob sensors to identify issues.

Q: What is CAN bus communication, and why is it important?

A: CAN bus is a communication protocol used in modern vehicles, and understanding it is essential for diagnosing complex issues.

Q: How can I access hidden diagnostic menus in my Mercedes-Benz?

A: Consult online resources or a Mercedes-Benz service manual for information on accessing these menus.

By understanding the typical live data values for Mercedes infotainment control knob parameters and utilizing the resources available at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, you can effectively diagnose and resolve issues with your vehicle’s COMAND system, ensuring a seamless and enjoyable driving experience.

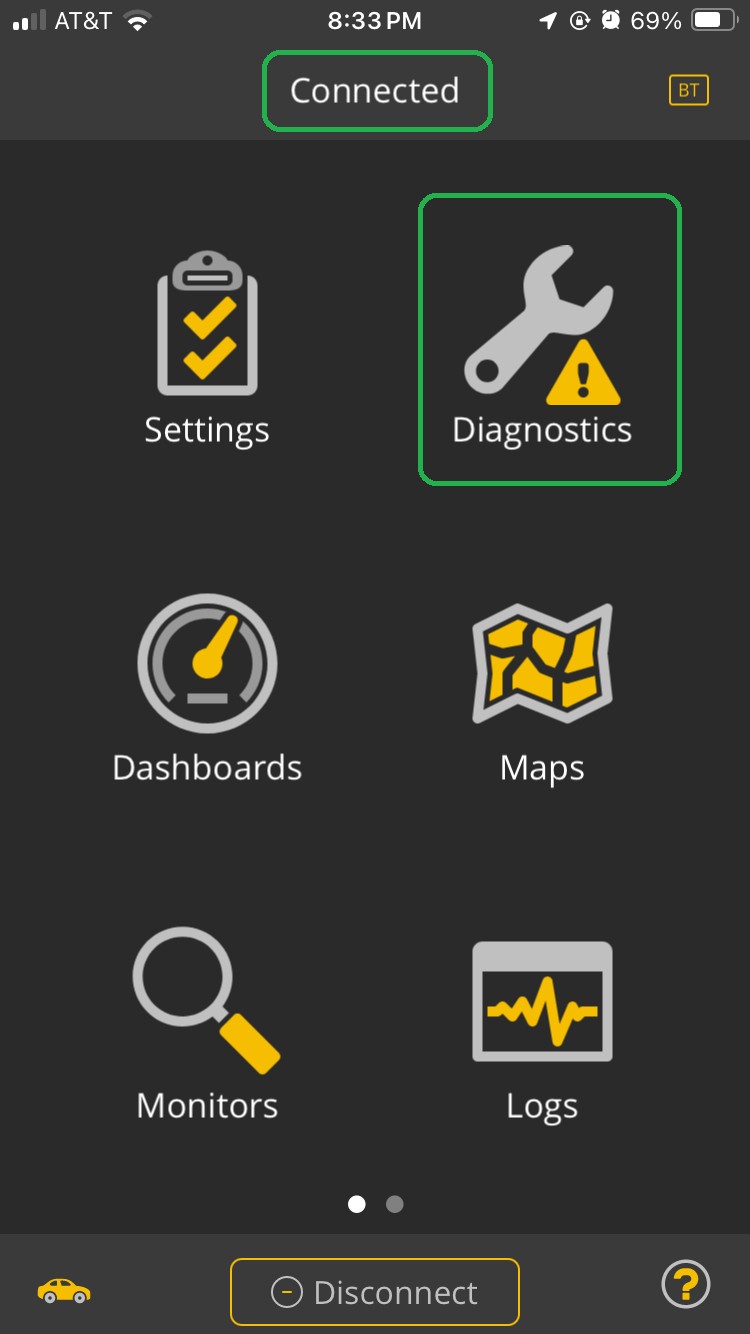

iOS home screen. The Connected button and the Diagnostics selection are highlighted.

iOS home screen. The Connected button and the Diagnostics selection are highlighted.

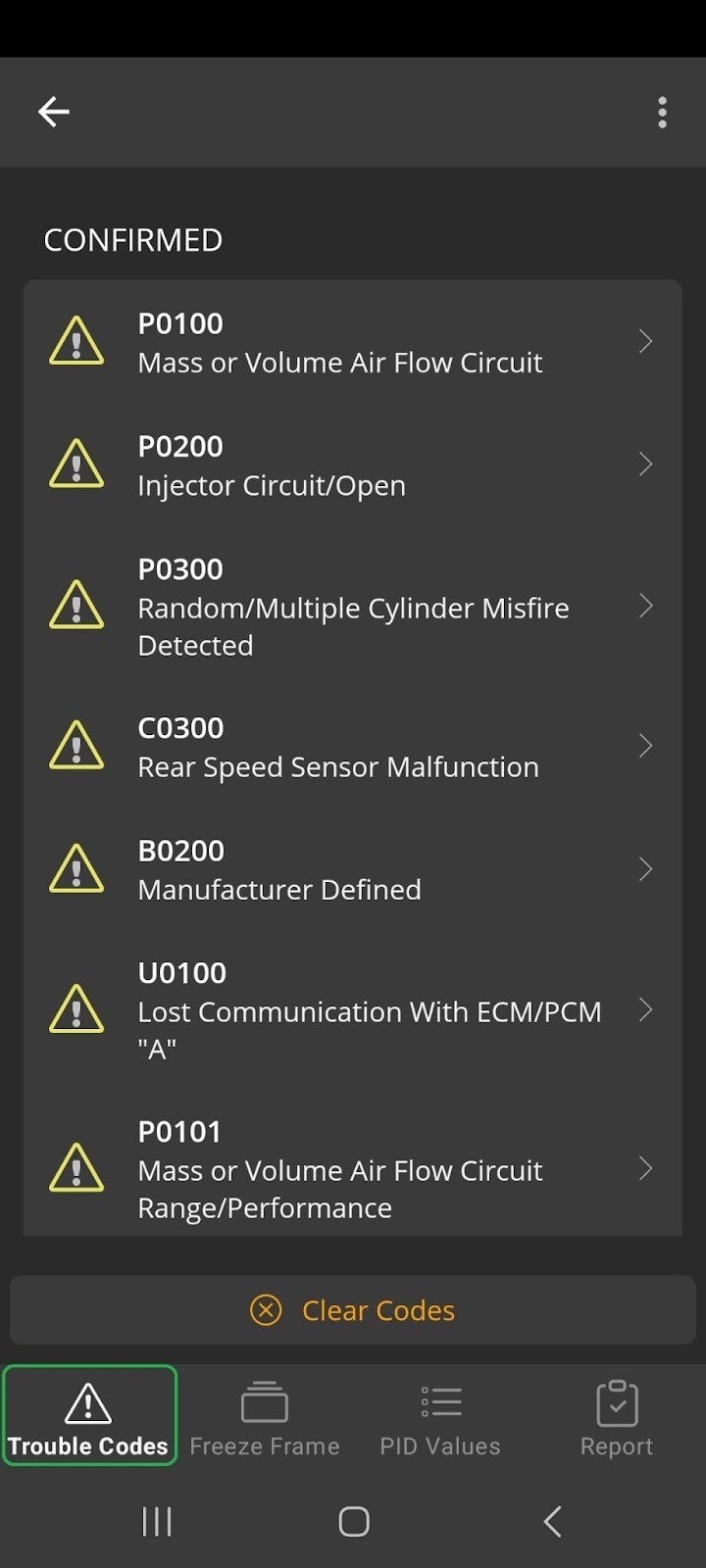

Android screen showing Trouble Codes tab when trouble codes are detected.

Android screen showing Trouble Codes tab when trouble codes are detected.