Unsure how to calibrate your power steering with diagnostic tools? Diagnostic tools play a vital role in calibrating the power steering system, ensuring optimal performance and safety. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we offer expert insights and solutions to help you navigate this process effectively. Explore our comprehensive guide to understand how diagnostic tools, along with related tools and equipment, can streamline power steering calibration.

Contents

- 1. Understanding Electric Power Steering (EPS) Systems

- 1.1 How EPS Works

- 1.2 Key Components of an EPS System

- 2. The Role of Diagnostic Tools in EPS Calibration

- 2.1 Identifying Issues with Diagnostic Trouble Codes (DTCs)

- 2.2 Recalibration and Adjustment

- 3. Step-by-Step Guide to Calibrating EPS Using Diagnostic Tools

- 3.1 Preparation

- 3.2 Connecting the Diagnostic Tool

- 3.3 Reading Diagnostic Trouble Codes (DTCs)

- 3.4 Steering Angle Sensor Calibration

- 3.5 Torque Sensor Calibration

- 3.6 Test Drive and Verification

- 4. Common Issues and Solutions

- 4.1 Steering Wheel is Difficult to Turn

- 4.2 Uneven Left-Right Power Steering Assist

- 4.3 Noises in the Steering Wheel

- 5. Advanced Diagnostic Procedures

- 5.1 Using Oscilloscopes

- 5.2 Data Logging and Analysis

- 6. Benefits of Professional Calibration Services

- 6.1 Expertise and Experience

- 6.2 Advanced Tools and Equipment

- 6.3 Warranty and Support

- 7. Maintaining Your EPS System

- 7.1 Regular Inspections

- 7.2 Software Updates

- 7.3 Professional Check-ups

- 8. The Future of EPS Diagnostics

- 8.1 AI-Powered Diagnostics

- 8.2 Remote Diagnostics

- 8.3 Enhanced Sensor Technology

- 9. Choosing the Right Diagnostic Tool

- 9.1 Comparison of Diagnostic Tools

- 9.2 Key Considerations When Choosing a Tool

- 10. Understanding Steering Geometry and Its Impact

- 10.1 Key Steering Geometry Angles

- 10.2 How Misalignment Affects EPS

- 10.3 Correcting Steering Geometry

- 11. Regular Maintenance Tasks for EPS Systems

- 11.1 Checking and Replacing Fluids

- 11.2 Inspecting Electrical Components

- 11.3 Monitoring Tire Condition

- 11.4 Keeping Software Updated

- 12. Real-World Examples and Case Studies

- 12.1 Case Study 1: Steering Angle Sensor Calibration

- 12.2 Example 2: Torque Sensor Adjustment

- 13. Safety Precautions When Working with EPS Systems

- 13.1 Disconnecting the Battery

- 13.2 Using Proper Tools

- 13.3 Following Manufacturer Guidelines

- 14. Emerging Trends in Power Steering Technology

- 14.1 Steer-by-Wire Systems

- 14.2 Advanced Driver-Assistance Systems (ADAS)

- 14.3 Customizable Steering Profiles

- 15. How to Choose a Reliable EPS Repair Service

- 15.1 Check for Certifications

- 15.2 Read Online Reviews

- 15.3 Ask About Warranty

- 16. Common Myths About EPS Systems

- 16.1 Myth: EPS Systems Are Unreliable

- 16.2 Myth: EPS Systems Require No Maintenance

- 16.3 Myth: EPS Problems Always Require Replacement

- 17. EPS System Do’s and Don’ts

- 17.1 Do’s

- 17.2 Don’ts

- 18. Benefits of Upgrading to a Modern EPS System

- 18.1 Improved Fuel Efficiency

- 18.2 Customizable Steering Feel

- 18.3 Enhanced Safety Features

- 19. Key Terms and Definitions

- 19.1 EPS (Electric Power Steering)

- 19.2 ECU (Electronic Control Unit)

- 19.3 DTC (Diagnostic Trouble Code)

- 19.4 Steering Angle Sensor

- 19.5 Torque Sensor

- 20. Resources and Further Reading

- 20.1 Online Forums

- 20.2 Manufacturer Websites

- 20.3 Technical Publications

- FAQ: Calibrating Your Mercedes-Benz Power Steering System

- 1. What diagnostic tools are recommended for calibrating the power steering system on a Mercedes-Benz?

- 2. How often should I calibrate the power steering system on my Mercedes-Benz?

- 3. What are the symptoms of a miscalibrated power steering system?

- 4. Can I calibrate the power steering system myself, or should I seek professional help?

- 5. What safety precautions should I take when working with an EPS?

- 6. What are the key components of an electric power steering (EPS) system?

- 7. How does wheel alignment affect the power steering system?

- 8. What maintenance tasks can help prolong the life of my EPS?

- 9. Are there any common myths about EPS systems that I should be aware of?

- 10. How do I choose a reliable EPS repair service?

1. Understanding Electric Power Steering (EPS) Systems

Electric Power Steering (EPS) systems have become increasingly common in modern vehicles, replacing traditional hydraulic power steering. Unlike hydraulic systems that rely on a fluid pump, EPS uses an electric motor to provide steering assistance. This system offers several advantages, including improved fuel efficiency and customizable steering feel.

1.1 How EPS Works

EPS systems work through a network of sensors that detect driver input, such as steering wheel torque, speed, and position. This data is then sent to the Electronic Control Unit (ECU), which calculates the necessary amount of assistive torque. The ECU then commands the electric motor to apply the appropriate amount of assistance to the steering system.

1.2 Key Components of an EPS System

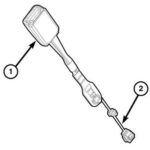

- Torque Sensor: Measures the force applied by the driver to the steering wheel.

- Steering Angle Sensor: Determines the position and angle of the steering wheel.

- ECU (Electronic Control Unit): Processes sensor data and controls the electric motor.

- Electric Motor: Provides the assistive torque to the steering system.

Alt Text: Key components of an electric power steering system including torque sensor, steering angle sensor, ECU and electric motor.

2. The Role of Diagnostic Tools in EPS Calibration

Diagnostic tools are essential for identifying and resolving issues within EPS systems. These tools can read Diagnostic Trouble Codes (DTCs) stored in the ECU, providing valuable insights into potential problems. Additionally, diagnostic tools are used to calibrate various EPS components, ensuring they function correctly.

2.1 Identifying Issues with Diagnostic Trouble Codes (DTCs)

When an EPS system detects a fault, it generates a DTC. These codes can be read using a diagnostic tool, helping technicians pinpoint the source of the problem. For instance, a ‘C-series’ code might indicate issues with the electrical assist, while a ‘U-series’ code could suggest problems with communication between the EPS and other vehicle systems.

2.2 Recalibration and Adjustment

Calibration is necessary after replacing or repairing EPS components such as the steering angle sensor or torque sensor. Diagnostic tools guide technicians through the recalibration process, ensuring that the new or repaired components are correctly aligned and functioning within specified parameters.

3. Step-by-Step Guide to Calibrating EPS Using Diagnostic Tools

Calibrating an EPS system involves several key steps, each requiring precision and attention to detail. Here’s a detailed guide:

3.1 Preparation

Before beginning the calibration process, ensure you have the necessary tools and information.

- Diagnostic Tool: A professional-grade scan tool compatible with your vehicle’s EPS system.

- Vehicle Information: The vehicle’s make, model, and year.

- Service Manual: The vehicle-specific service manual for EPS calibration procedures.

- Stable Power Supply: To prevent voltage fluctuations during the process.

3.2 Connecting the Diagnostic Tool

- Locate the OBD-II Port: Typically found under the dashboard on the driver’s side.

- Connect the Scan Tool: Plug the diagnostic tool into the OBD-II port.

- Power On: Turn on the ignition to power the vehicle’s electrical system.

3.3 Reading Diagnostic Trouble Codes (DTCs)

- Access EPS Module: Use the scan tool to navigate to the EPS module.

- Read Codes: Retrieve any stored DTCs and record them.

- Clear Codes: Clear the DTCs after noting them, as this can help identify if the issue is resolved after calibration.

3.4 Steering Angle Sensor Calibration

The steering angle sensor is crucial for the EPS system to accurately determine the steering wheel’s position.

- Select Calibration Function: In the scan tool, select the steering angle sensor calibration function.

- Follow On-Screen Instructions: The tool will provide step-by-step instructions, which may include turning the steering wheel to specific angles.

- Verify Calibration: After calibration, verify the sensor readings are accurate by comparing them to the specified values in the service manual.

3.5 Torque Sensor Calibration

The torque sensor measures the force applied to the steering wheel, and its calibration ensures the EPS provides appropriate assistance.

- Select Calibration Function: Choose the torque sensor calibration function in the scan tool.

- Follow Prompts: The tool will guide you through the calibration, often requiring the steering wheel to be held in a neutral position.

- Confirm Calibration: Check that the torque sensor readings are within the acceptable range.

3.6 Test Drive and Verification

- Perform a Test Drive: Drive the vehicle to assess the EPS performance.

- Monitor Steering Feel: Ensure the steering is smooth and responsive.

- Recheck DTCs: Use the scan tool to recheck for any new DTCs.

Alt Text: A vehicle diagnostic tool connected to the OBD-II port for accessing vehicle data.

4. Common Issues and Solutions

Even with diagnostic tools, certain issues can complicate the EPS calibration process.

4.1 Steering Wheel is Difficult to Turn

Possible Causes:

- Torque sensor malfunction

- Tire issues

- Electric steering rack/pump/column problems

- Steering column shaft issues

- Steering ECU or supply voltage problems

- Vehicle speed sensor issues

Solutions:

- Inspect and replace faulty sensors.

- Check and correct tire pressure and condition.

- Examine and repair or replace the electric steering rack, pump, or column.

- Check the steering column shaft for damage.

- Verify the steering ECU and supply voltage.

- Ensure vehicle speed sensors are functioning correctly.

4.2 Uneven Left-Right Power Steering Assist

Possible Causes:

- Torque sensor calibration issues

- Wheel alignment problems

- Electric steering pump/rack issues

- Steering ECU malfunctions

Solutions:

- Recalibrate the torque sensor.

- Perform a wheel alignment.

- Inspect and repair or replace the electric steering pump/rack.

- Check and repair or replace the steering ECU.

4.3 Noises in the Steering Wheel

Possible Causes:

- Steering gear issues (e.g., steering rack)

- Steering column problems

- Electric motor squeaking

Solutions:

- Inspect and repair or replace the steering gear.

- Check the steering column for issues.

- Examine the electric motor for wear or damage.

5. Advanced Diagnostic Procedures

For more complex EPS issues, advanced diagnostic procedures may be necessary.

5.1 Using Oscilloscopes

An oscilloscope can be used to analyze the signals from sensors and actuators, providing a detailed view of their performance. This is particularly useful for diagnosing intermittent issues or signal noise.

5.2 Data Logging and Analysis

Diagnostic tools with data logging capabilities allow technicians to record EPS system data during a test drive. This data can then be analyzed to identify anomalies or deviations from normal operation.

6. Benefits of Professional Calibration Services

While it’s possible to perform EPS calibration yourself, professional services offer several advantages.

6.1 Expertise and Experience

Professional technicians have the knowledge and experience to accurately diagnose and calibrate EPS systems.

6.2 Advanced Tools and Equipment

Professional shops have access to advanced diagnostic tools and equipment, ensuring precise and reliable calibration.

6.3 Warranty and Support

Professional services often come with a warranty, providing peace of mind and support in case of issues.

7. Maintaining Your EPS System

Regular maintenance can help prevent EPS issues and prolong the system’s lifespan.

7.1 Regular Inspections

Periodically inspect the EPS system for any signs of damage or wear.

7.2 Software Updates

Keep the EPS system software up to date to ensure optimal performance and compatibility.

7.3 Professional Check-ups

Schedule regular check-ups with a qualified technician to identify and address potential issues early.

8. The Future of EPS Diagnostics

The field of EPS diagnostics is constantly evolving, with new technologies and techniques emerging.

8.1 AI-Powered Diagnostics

Artificial intelligence (AI) is being used to analyze EPS data and predict potential failures, enabling proactive maintenance.

8.2 Remote Diagnostics

Remote diagnostic tools allow technicians to diagnose and calibrate EPS systems remotely, reducing downtime and improving efficiency.

8.3 Enhanced Sensor Technology

Advancements in sensor technology are providing more accurate and detailed data, improving the precision of EPS diagnostics and calibration.

9. Choosing the Right Diagnostic Tool

Selecting the appropriate diagnostic tool is crucial for effectively calibrating your Mercedes’ power steering system. Here’s a comparison of some top-rated tools, highlighting their key features and benefits:

9.1 Comparison of Diagnostic Tools

| Feature | Autel MaxiSYS Elite II Pro | Launch X431 V+ Pro | Bosch ADS 625 |

|---|---|---|---|

| Compatibility | Wide range of vehicles | Extensive vehicle coverage | Bosch and other major brands |

| Key Functions | Advanced diagnostics, coding | Full system diagnostics, ECU | Comprehensive diagnostics and |

| programming | coding | service functions | |

| Ease of Use | User-friendly interface | Intuitive navigation | Streamlined user interface |

| Special Features | J2534 programming, online | Remote diagnostics, TPMS | Cloud-based updates, detailed |

| updates | functionality | repair information | |

| Price Range | High | Mid-range | Mid-range |

| Recommended For | Professional technicians | DIY enthusiasts to pros | Independent repair shops |

9.2 Key Considerations When Choosing a Tool

- Compatibility: Ensure the tool supports your Mercedes model and year.

- Functionality: Look for tools that offer steering angle sensor calibration, torque sensor adjustment, and DTC reading/clearing capabilities.

- Ease of Use: Choose a tool with an intuitive interface and clear instructions.

- Updates: Opt for tools with regular software updates to maintain compatibility with the latest vehicle models and diagnostic protocols.

Alt Text: The Autel MaxiSYS Elite II Pro diagnostic tool offering advanced diagnostics and coding programming.

10. Understanding Steering Geometry and Its Impact

Steering geometry plays a vital role in your vehicle’s handling and tire wear. Properly aligned wheels ensure optimal contact with the road, improving stability and reducing uneven tire wear. Calibrating the power steering system often requires a thorough understanding of these angles:

10.1 Key Steering Geometry Angles

- Caster: The angle of the steering axis relative to the vertical, affecting steering stability.

- Camber: The angle of the wheel relative to the vertical when viewed from the front, influencing tire wear.

- Toe: The angle of the wheels relative to each other, affecting steering response and tire wear.

10.2 How Misalignment Affects EPS

Misaligned wheels can cause the EPS system to work harder, leading to uneven power assist, increased wear on components, and potential safety issues.

10.3 Correcting Steering Geometry

Use alignment machines to measure and adjust these angles to the manufacturer’s specifications. This ensures the EPS system operates within its intended parameters, improving overall vehicle performance.

11. Regular Maintenance Tasks for EPS Systems

Regular maintenance is key to ensuring the longevity and reliability of your Mercedes’ EPS system. Here are some essential tasks:

11.1 Checking and Replacing Fluids

Although EPS systems don’t use hydraulic fluid, checking and maintaining the electrical connections and wiring is crucial.

11.2 Inspecting Electrical Components

Regularly inspect the wiring, connectors, and sensors for any signs of damage or corrosion. Clean and protect these components to ensure reliable performance.

11.3 Monitoring Tire Condition

Maintain proper tire pressure and monitor tire wear patterns. Uneven tire wear can indicate issues with steering geometry, which can affect the EPS system.

11.4 Keeping Software Updated

Ensure the EPS system’s software is up to date. Software updates often include performance improvements and bug fixes that can enhance the system’s operation.

12. Real-World Examples and Case Studies

To illustrate the importance of diagnostic tools in calibrating EPS systems, let’s explore a few real-world examples and case studies.

12.1 Case Study 1: Steering Angle Sensor Calibration

Problem: A Mercedes C-Class exhibited erratic steering behavior after a front-end collision. The EPS system was providing inconsistent power assist, making the vehicle difficult to control.

Solution: Technicians used a diagnostic tool to read DTCs, which indicated a faulty steering angle sensor. After replacing the sensor, they used the diagnostic tool to calibrate it. Post-calibration, the steering behavior returned to normal, and the vehicle handled predictably.

12.2 Example 2: Torque Sensor Adjustment

Problem: A Mercedes E-Class owner reported that the steering felt too stiff at low speeds. A diagnostic scan revealed that the torque sensor was not properly calibrated.

Solution: Using a professional-grade diagnostic tool, the technicians adjusted the torque sensor settings. This adjustment improved the steering feel at low speeds, making the vehicle easier to maneuver.

13. Safety Precautions When Working with EPS Systems

Working with EPS systems involves electrical components, so safety should always be a top priority.

13.1 Disconnecting the Battery

Before performing any diagnostic or calibration work, disconnect the vehicle’s battery to prevent electrical shocks and accidental damage.

13.2 Using Proper Tools

Always use the correct tools for the job. Using the wrong tools can damage components and compromise safety.

13.3 Following Manufacturer Guidelines

Adhere to the manufacturer’s guidelines for diagnostic and calibration procedures. These guidelines provide important safety information and ensure the job is done correctly.

14. Emerging Trends in Power Steering Technology

The future of power steering technology is heading towards more sophisticated and integrated systems.

14.1 Steer-by-Wire Systems

Steer-by-wire systems eliminate the mechanical connection between the steering wheel and the wheels, relying entirely on electronic signals.

14.2 Advanced Driver-Assistance Systems (ADAS)

EPS systems are increasingly integrated with ADAS features like lane keeping assist and park assist, enhancing vehicle safety and convenience.

14.3 Customizable Steering Profiles

Modern vehicles offer customizable steering profiles, allowing drivers to adjust the steering feel and responsiveness to their preferences.

15. How to Choose a Reliable EPS Repair Service

If you prefer to have a professional handle your EPS calibration, choosing a reliable repair service is essential.

15.1 Check for Certifications

Look for repair shops with certifications from organizations like ASE (Automotive Service Excellence).

15.2 Read Online Reviews

Check online reviews to gauge the reputation and quality of service provided by the repair shop.

15.3 Ask About Warranty

Choose a service that offers a warranty on their work, providing peace of mind and protection against future issues.

16. Common Myths About EPS Systems

There are several misconceptions about EPS systems. Let’s debunk some of the most common ones.

16.1 Myth: EPS Systems Are Unreliable

Fact: Modern EPS systems are highly reliable and designed to last the lifespan of the vehicle.

16.2 Myth: EPS Systems Require No Maintenance

Fact: While EPS systems don’t require fluid changes, regular inspections and software updates are necessary to ensure optimal performance.

16.3 Myth: EPS Problems Always Require Replacement

Fact: Many EPS issues can be resolved with calibration, sensor replacement, or software updates, without needing to replace the entire system.

17. EPS System Do’s and Don’ts

To keep your EPS system in top condition, follow these do’s and don’ts.

17.1 Do’s

- Do keep your tires properly inflated.

- Do have your wheel alignment checked regularly.

- Do schedule regular inspections of the EPS system.

- Do keep the EPS software updated.

17.2 Don’ts

- Don’t ignore warning lights on the dashboard.

- Don’t use excessive force when steering.

- Don’t attempt to repair the EPS system without proper knowledge and tools.

- Don’t neglect regular maintenance tasks.

18. Benefits of Upgrading to a Modern EPS System

If you’re driving an older vehicle with a hydraulic power steering system, upgrading to a modern EPS system can offer significant benefits.

18.1 Improved Fuel Efficiency

EPS systems consume less energy than hydraulic systems, improving fuel efficiency.

18.2 Customizable Steering Feel

Modern EPS systems offer customizable steering profiles, allowing you to adjust the steering feel to your preferences.

18.3 Enhanced Safety Features

EPS systems are often integrated with advanced safety features like lane keeping assist and park assist, enhancing vehicle safety.

19. Key Terms and Definitions

To better understand EPS systems and calibration, here’s a glossary of key terms:

19.1 EPS (Electric Power Steering)

A system that uses an electric motor to provide steering assistance.

19.2 ECU (Electronic Control Unit)

A computer that controls the EPS system, processing sensor data and controlling the electric motor.

19.3 DTC (Diagnostic Trouble Code)

A code generated by the EPS system when a fault is detected.

19.4 Steering Angle Sensor

A sensor that measures the position and angle of the steering wheel.

19.5 Torque Sensor

A sensor that measures the force applied to the steering wheel.

20. Resources and Further Reading

To deepen your understanding of EPS systems and calibration, here are some valuable resources:

20.1 Online Forums

Join online forums dedicated to automotive diagnostics and repair to connect with other enthusiasts and professionals.

20.2 Manufacturer Websites

Visit the websites of diagnostic tool manufacturers for product information, software updates, and support resources.

20.3 Technical Publications

Consult technical publications and service manuals for detailed information on EPS systems and calibration procedures.

Navigating EPS calibration can seem daunting, but with the right knowledge and tools, you can ensure your Mercedes’ power steering system operates at its best. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we’re dedicated to providing the expertise and resources you need.

Facing EPS calibration challenges? Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN today for expert guidance on diagnostic tools, unlocking hidden features, and comprehensive repair and maintenance advice for your Mercedes. Our team is ready to help you optimize your vehicle’s performance and safety. Reach out now for personalized support. Visit us at 789 Oak Avenue, Miami, FL 33101, United States, or connect via Whatsapp at +1 (641) 206-8880. For more information, explore MERCEDES-DIAGNOSTIC-TOOL.EDU.VN. Let us help you keep your Mercedes in top condition with our diagnostic services and unlocking services today.

FAQ: Calibrating Your Mercedes-Benz Power Steering System

1. What diagnostic tools are recommended for calibrating the power steering system on a Mercedes-Benz?

For calibrating the power steering system on a Mercedes-Benz, professional-grade diagnostic tools like Autel MaxiSYS Elite II Pro, Launch X431 V+ Pro, and Bosch ADS 625 are highly recommended due to their comprehensive features and compatibility.

2. How often should I calibrate the power steering system on my Mercedes-Benz?

Calibration should be performed whenever you replace or repair EPS components, such as the steering angle sensor or torque sensor, or if you notice issues like uneven power assist or stiff steering.

3. What are the symptoms of a miscalibrated power steering system?

Symptoms of a miscalibrated power steering system include stiff steering, uneven power assist (easier to turn in one direction), erratic steering behavior, and the EPS warning light illuminating on the dashboard.

4. Can I calibrate the power steering system myself, or should I seek professional help?

While it’s possible to calibrate the power steering system yourself with the right diagnostic tools and technical knowledge, professional services offer expertise, advanced equipment, and warranty support, ensuring precise and reliable calibration.

5. What safety precautions should I take when working with an EPS?

Always disconnect the vehicle’s battery before performing any diagnostic or calibration work, use the correct tools for the job, and adhere to the manufacturer’s guidelines for diagnostic and calibration procedures to prevent electrical shocks and accidental damage.

6. What are the key components of an electric power steering (EPS) system?

Key components of an EPS system include the torque sensor, steering angle sensor, ECU (Electronic Control Unit), and electric motor, which work together to provide steering assistance based on driver input and vehicle conditions.

7. How does wheel alignment affect the power steering system?

Misaligned wheels can cause the EPS system to work harder, leading to uneven power assist, increased wear on components, and potential safety issues, making proper alignment crucial for optimal EPS performance.

8. What maintenance tasks can help prolong the life of my EPS?

Regular maintenance tasks include inspecting electrical components, monitoring tire condition, keeping the EPS software updated, and scheduling periodic check-ups with a qualified technician to identify and address potential issues early.

9. Are there any common myths about EPS systems that I should be aware of?

Common myths include the notion that EPS systems are unreliable or require no maintenance. In reality, modern EPS systems are reliable, and regular inspections and software updates are necessary for optimal performance.

10. How do I choose a reliable EPS repair service?

To choose a reliable EPS repair service, check for certifications like ASE (Automotive Service Excellence), read online reviews to gauge reputation, and ask about warranty to ensure quality and protection against future issues.