Diagnostic procedures for vehicles with illuminated seatbelt warning lights involve a systematic approach to identify and resolve the underlying issue, ensuring the safety systems function correctly. This article brought to you by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN will walk you through the diagnostic procedures for Mercedes-Benz vehicles with seatbelt warning lights illuminated. From basic visual inspections to advanced diagnostic tool applications, discover how to troubleshoot effectively. Understanding these processes enhances vehicle safety and system reliability.

Contents

- 1. Understanding The Seatbelt Warning Light System

- 2. Identifying Common Causes of Seatbelt Warning Light Illumination

- 3. Preliminary Checks Before Diagnostics

- 4. Diagnostic Tools and Equipment

- 5. Step-by-Step Diagnostic Procedures

- 6. Using Mercedes-Benz Specific Diagnostic Tools (XENTRY/DAS)

- 7. Addressing Faulty Seatbelt Buckle Sensors

- 8. Troubleshooting Seat Occupancy Sensor Issues

- 9. Diagnosing and Repairing Wiring Problems

- 10. Control Module Diagnosis and Replacement

- 11. Addressing Software Glitches and Updates

- 12. Advanced Diagnostic Techniques

1. Understanding The Seatbelt Warning Light System

The seatbelt warning system is a crucial safety feature in modern vehicles, including Mercedes-Benz models. It is designed to alert the driver and passengers when seatbelts are not properly fastened. When the system detects an unbuckled seatbelt while the vehicle is in motion or the ignition is on, it illuminates a warning light on the dashboard and may also trigger an audible alarm. The system relies on a network of sensors, wiring, and control modules to function correctly.

The primary components of the seatbelt warning system include:

- Seatbelt Buckle Sensors: These sensors are located within the seatbelt buckles and detect when the seatbelts are fastened or unfastened.

- Seat Occupancy Sensors: These sensors are integrated into the seats and determine whether a seat is occupied.

- Wiring Harness: A network of wires connects the sensors to the control module, transmitting signals and power.

- Control Module: The control module, often integrated into the airbag control unit or body control module, processes the signals from the sensors and activates the warning light and audible alarm.

- Dashboard Warning Light: The warning light is located on the dashboard and illuminates when the system detects an issue.

- Audible Alarm: Some vehicles are equipped with an audible alarm that sounds in conjunction with the warning light.

The system functions by continuously monitoring the status of the seatbelts and seat occupancy. When the ignition is turned on, the control module checks the status of each seat. If a seat is occupied and the seatbelt is not fastened, the warning light and alarm are activated. Once the seatbelt is buckled, the sensor signals the control module, and the warning is deactivated.

Understanding the components and functions of the seatbelt warning system is crucial for effective diagnostics. It allows technicians and owners to pinpoint potential issues and address them systematically. This knowledge is essential for maintaining the safety and reliability of your Mercedes-Benz.

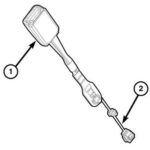

Alt text: A close-up of a Mercedes-Benz seatbelt buckle sensor.

2. Identifying Common Causes of Seatbelt Warning Light Illumination

Several factors can cause the seatbelt warning light to illuminate in a Mercedes-Benz vehicle. Identifying these common causes is the first step in diagnosing the problem. Here are some of the most frequent reasons for the warning light to activate:

- Unbuckled Seatbelts: The most obvious reason is that one or more seatbelts are not buckled when the vehicle is in motion. This triggers the warning light and audible alarm, reminding occupants to fasten their seatbelts.

- Faulty Seatbelt Buckle Sensors: The sensors within the seatbelt buckles can malfunction, providing incorrect signals to the control module. This can cause the warning light to stay on even when the seatbelt is buckled, or vice versa.

- Seat Occupancy Sensor Issues: The seat occupancy sensors, which detect whether a seat is occupied, can also fail. If a sensor incorrectly detects that a seat is occupied when it is not, the warning light may activate.

- Wiring Problems: Damaged, corroded, or loose wiring can disrupt the signals between the sensors and the control module. This can lead to intermittent or constant illumination of the warning light.

- Control Module Malfunctions: The control module itself can malfunction due to electrical issues, software glitches, or internal failures. This can result in incorrect processing of sensor data and activation of the warning light.

- Software Glitches: Modern vehicles rely on complex software to manage various systems, including the seatbelt warning system. Software glitches or errors can cause the system to behave erratically, triggering the warning light unnecessarily.

- Low Battery Voltage: Low battery voltage can sometimes cause the electronic control units to malfunction which can trigger warning lights.

- Other System Interference: In some cases, issues with other vehicle systems, such as the airbag system or body control module, can indirectly affect the seatbelt warning system and cause the light to illuminate.

By understanding these common causes, technicians and vehicle owners can narrow down the possible issues and focus their diagnostic efforts more effectively. A systematic approach to troubleshooting, starting with the most likely causes, can save time and effort in resolving the problem.

3. Preliminary Checks Before Diagnostics

Before diving into advanced diagnostic procedures, performing preliminary checks can often identify simple issues and save time. These checks involve visual inspections and basic troubleshooting steps that can be easily performed without specialized tools. Here are some essential preliminary checks to conduct:

-

Visual Inspection of Seatbelts and Buckles:

- Ensure all seatbelts are in good condition, with no signs of damage, fraying, or wear.

- Check the seatbelt buckles for any obstructions, debris, or foreign objects that may prevent proper latching.

- Verify that the seatbelts retract and extend smoothly without binding or sticking.

-

Check Seat Occupancy:

- Ensure that items are not placed on the passenger seat that could trigger the occupancy sensor.

- Make sure no one is leaning on the passenger seat when it’s not occupied.

-

Check Dashboard Warning Light:

- Turn on the ignition and observe the seatbelt warning light.

- Note whether the light illuminates consistently or intermittently.

- Check if the light turns off when all seatbelts are buckled.

-

Verify Proper Latching of Seatbelts:

- Buckle and unbuckle each seatbelt several times to ensure they latch securely and release properly.

- Listen for a distinct “click” sound when the seatbelt is buckled, indicating proper engagement.

- Check if the warning light turns off immediately after each seatbelt is buckled.

-

Check for Loose Connections:

- Inspect the wiring harnesses and connectors under the seats for any signs of damage, corrosion, or loose connections.

- Gently wiggle the connectors to see if the warning light flickers or changes, indicating a potential wiring issue.

- Ensure all connectors are securely plugged in.

-

Check Battery Voltage:

- Use a multimeter to measure the voltage across the battery terminals.

- A fully charged battery should read approximately 12.6 volts.

- Low voltage can cause erratic behavior in electronic systems.

By performing these preliminary checks, many common issues can be quickly identified and resolved. If the warning light persists after these checks, more advanced diagnostic procedures may be necessary to pinpoint the root cause of the problem.

4. Diagnostic Tools and Equipment

When preliminary checks fail to resolve the seatbelt warning light issue, diagnostic tools and equipment become essential for pinpointing the root cause. These tools allow technicians and vehicle owners to access and interpret data from the vehicle’s electronic systems, enabling accurate and efficient troubleshooting. Here are some of the key diagnostic tools and equipment used for diagnosing seatbelt warning light problems in Mercedes-Benz vehicles:

-

OBD-II Scanner:

- An OBD-II (On-Board Diagnostics II) scanner is a basic tool that reads diagnostic trouble codes (DTCs) from the vehicle’s computer.

- It connects to the OBD-II port, typically located under the dashboard, and retrieves codes related to the seatbelt warning system.

- While a generic OBD-II scanner can provide basic information, it may not offer the depth of diagnostics needed for complex systems.

-

Mercedes-Benz Specific Diagnostic Tools (e.g., XENTRY/DAS):

- Mercedes-Benz specific diagnostic tools, such as XENTRY/DAS (Diagnostic Assistance System), are professional-grade tools designed specifically for Mercedes-Benz vehicles.

- These tools offer advanced diagnostic capabilities, including reading manufacturer-specific DTCs, accessing live data streams, performing component testing, and programming control modules.

- XENTRY/DAS provides in-depth access to the seatbelt warning system, allowing technicians to diagnose issues with greater precision.

-

Multimeter:

- A multimeter is an essential tool for electrical testing.

- It can be used to measure voltage, current, and resistance in the wiring harnesses and connectors of the seatbelt warning system.

- A multimeter helps identify wiring issues, such as shorts, opens, and voltage drops.

-

Wiring Diagrams:

- Wiring diagrams provide a detailed map of the electrical circuits in the vehicle.

- They are essential for tracing wires, identifying components, and understanding the flow of electricity in the seatbelt warning system.

- Mercedes-Benz wiring diagrams are available in service manuals and online databases.

-

Laptop or Tablet with Diagnostic Software:

- Many diagnostic tools require a laptop or tablet to run the diagnostic software.

- The software provides a user interface for accessing vehicle data, running tests, and viewing results.

- Ensure the laptop or tablet meets the minimum system requirements and has the latest software updates installed.

Using the right diagnostic tools and equipment is crucial for accurate and efficient troubleshooting. While basic tools like OBD-II scanners can provide some information, Mercedes-Benz specific tools offer the depth and precision needed to diagnose complex issues in the seatbelt warning system. Combining these tools with wiring diagrams and a multimeter enables technicians to pinpoint the root cause of the problem and perform effective repairs.

Alt text: A Mercedes-Benz XENTRY diagnostic tool being used on a vehicle.

5. Step-by-Step Diagnostic Procedures

Once you have gathered the necessary diagnostic tools and equipment, you can begin the step-by-step diagnostic procedures. Following a systematic approach ensures thorough troubleshooting and accurate identification of the problem. Here are the key steps to diagnose a seatbelt warning light issue in a Mercedes-Benz vehicle:

-

Step 1: Retrieve Diagnostic Trouble Codes (DTCs)

- Connect the OBD-II scanner or Mercedes-Benz specific diagnostic tool (e.g., XENTRY/DAS) to the vehicle’s OBD-II port.

- Turn on the ignition and follow the tool’s instructions to retrieve any stored DTCs related to the seatbelt warning system.

- Record all DTCs and their descriptions for further analysis.

- Common DTCs may include codes related to seatbelt buckle sensors, seat occupancy sensors, wiring faults, and control module issues.

-

Step 2: Analyze DTCs and Prioritize Troubleshooting

- Consult the Mercedes-Benz service manual or online database to understand the meaning and potential causes of each DTC.

- Prioritize troubleshooting based on the severity and frequency of the DTCs.

- Focus on DTCs that directly relate to the seatbelt warning system and its components.

-

Step 3: Inspect Seatbelt Buckle Sensors

- Use the diagnostic tool to access live data streams for the seatbelt buckle sensors.

- Monitor the sensor readings as you buckle and unbuckle each seatbelt.

- Verify that the sensor readings change correctly when the seatbelt is fastened or unfastened.

- If a sensor reading is erratic or does not change, the sensor may be faulty.

-

Step 4: Evaluate Seat Occupancy Sensors

- Use the diagnostic tool to access live data streams for the seat occupancy sensors.

- Monitor the sensor readings as you apply and remove weight from each seat.

- Verify that the sensor readings change correctly when the seat is occupied or unoccupied.

- If a sensor reading is erratic or does not change, the sensor may be faulty.

-

Step 5: Check Wiring Harness and Connectors

- Refer to the wiring diagrams to locate the wiring harnesses and connectors associated with the seatbelt warning system.

- Visually inspect the wiring for any signs of damage, corrosion, or loose connections.

- Use a multimeter to test the continuity and voltage of the wiring circuits.

- Check for shorts to ground, opens, and excessive resistance in the wiring.

- Repair or replace any damaged wiring or connectors.

-

Step 6: Test Control Module Functionality

- Use the diagnostic tool to perform component testing on the control module.

- Run diagnostic tests to verify that the control module is processing sensor data correctly and activating the warning light and audible alarm as intended.

- If the control module fails the component tests, it may need to be reprogrammed or replaced.

-

Step 7: Clear DTCs and Verify Repair

- After completing the necessary repairs, use the diagnostic tool to clear all DTCs from the vehicle’s computer.

- Turn off the ignition and then turn it back on to reset the system.

- Monitor the seatbelt warning light to ensure it operates correctly.

- Perform a test drive to verify that the warning light does not illuminate under normal driving conditions.

By following these step-by-step diagnostic procedures, technicians and vehicle owners can systematically troubleshoot the seatbelt warning light issue and identify the root cause of the problem. Accurate diagnosis leads to effective repairs and ensures the safety and reliability of the vehicle.

6. Using Mercedes-Benz Specific Diagnostic Tools (XENTRY/DAS)

Mercedes-Benz specific diagnostic tools, such as XENTRY/DAS (Diagnostic Assistance System), provide advanced capabilities for diagnosing and troubleshooting seatbelt warning light issues. These tools offer in-depth access to the vehicle’s electronic systems, allowing technicians to perform comprehensive diagnostics and component testing. Here’s how to effectively use XENTRY/DAS for diagnosing seatbelt warning light problems:

-

Connecting to the Vehicle:

- Connect the XENTRY/DAS diagnostic interface to the vehicle’s OBD-II port.

- Ensure the interface is properly connected to a laptop or tablet running the XENTRY/DAS software.

- Turn on the ignition and launch the XENTRY/DAS software.

-

Vehicle Identification:

- Allow XENTRY/DAS to automatically identify the vehicle’s make, model, and year.

- Alternatively, manually enter the vehicle’s information if automatic identification fails.

-

Accessing the Seatbelt Warning System:

- Navigate through the XENTRY/DAS menu to locate the seatbelt warning system or supplemental restraint system (SRS).

- Select the appropriate control module, such as the airbag control unit or body control module, that manages the seatbelt warning system.

-

Reading Diagnostic Trouble Codes (DTCs):

- Select the option to read DTCs from the control module.

- Record all DTCs and their descriptions for further analysis.

- XENTRY/DAS provides manufacturer-specific DTCs, which offer more detailed information about the issue compared to generic OBD-II codes.

-

Live Data Streaming:

- Access the live data stream for the seatbelt buckle sensors and seat occupancy sensors.

- Monitor the sensor readings as you buckle and unbuckle each seatbelt and apply/remove weight from each seat.

- Verify that the sensor readings change correctly and are within the specified range.

- Identify any erratic or inconsistent sensor readings that may indicate a faulty sensor or wiring issue.

-

Component Testing:

- Use the component testing feature to perform individual tests on the seatbelt buckle sensors, seat occupancy sensors, and control module.

- Follow the on-screen instructions to activate and test each component.

- Evaluate the test results to determine if the components are functioning correctly.

-

Actuation Tests:

- Perform actuation tests to manually activate the seatbelt warning light and audible alarm.

- Verify that the warning light illuminates and the alarm sounds as expected.

- This test helps confirm the functionality of the control module and wiring circuits.

-

Clearing DTCs:

- After completing the necessary repairs, select the option to clear DTCs from the control module.

- Turn off the ignition and then turn it back on to reset the system.

- Monitor the seatbelt warning light to ensure it operates correctly.

-

Programming and Calibration:

- In some cases, replacing a faulty control module or sensor may require programming or calibration.

- Use XENTRY/DAS to program the new component with the correct software and calibrate it to the vehicle’s specifications.

-

Referencing Service Manuals and Technical Information:

- XENTRY/DAS often provides access to Mercedes-Benz service manuals and technical information.

- Use these resources to obtain detailed information about the seatbelt warning system, wiring diagrams, component locations, and repair procedures.

By leveraging the advanced capabilities of XENTRY/DAS, technicians can perform comprehensive diagnostics, component testing, and programming, leading to accurate and effective repairs of seatbelt warning light issues in Mercedes-Benz vehicles.

Alt text: A screenshot of Mercedes-Benz XENTRY diagnostic and coding software.

7. Addressing Faulty Seatbelt Buckle Sensors

Faulty seatbelt buckle sensors are a common cause of seatbelt warning light illumination in Mercedes-Benz vehicles. These sensors, located within the seatbelt buckles, detect when the seatbelts are fastened or unfastened. When a sensor malfunctions, it can send incorrect signals to the control module, causing the warning light to stay on even when the seatbelt is buckled, or vice versa. Here’s how to address faulty seatbelt buckle sensors:

-

Identifying a Faulty Sensor:

- Use a Mercedes-Benz specific diagnostic tool (e.g., XENTRY/DAS) to read DTCs and access live data streams for the seatbelt buckle sensors.

- Monitor the sensor readings as you buckle and unbuckle each seatbelt.

- A faulty sensor will typically show erratic readings or fail to change state when the seatbelt is fastened or unfastened.

- Compare the sensor readings to the specified range in the service manual to confirm the fault.

-

Testing the Sensor with a Multimeter:

- Disconnect the seatbelt buckle sensor from the wiring harness.

- Use a multimeter to measure the resistance across the sensor terminals.

- The resistance should change when the seatbelt is buckled and unbuckled.

- If the resistance is consistently high, low, or does not change, the sensor is likely faulty.

-

Replacing the Seatbelt Buckle Sensor:

- Disconnect the negative terminal of the battery to prevent electrical shock.

- Remove the seat from the vehicle to access the seatbelt buckle.

- Disconnect the wiring harness from the seatbelt buckle sensor.

- Remove the faulty sensor from the seatbelt buckle assembly.

- Install the new seatbelt buckle sensor in the seatbelt buckle assembly.

- Reconnect the wiring harness to the new sensor.

- Reinstall the seat in the vehicle and reconnect the negative terminal of the battery.

-

Verifying the Repair:

- Use the diagnostic tool to clear all DTCs from the vehicle’s computer.

- Turn off the ignition and then turn it back on to reset the system.

- Monitor the seatbelt warning light to ensure it operates correctly.

- Buckle and unbuckle the seatbelt several times to verify that the new sensor is functioning properly and the warning light turns off when the seatbelt is buckled.

-

Considerations:

- Ensure you purchase a genuine Mercedes-Benz seatbelt buckle sensor or a high-quality aftermarket replacement.

- Follow the manufacturer’s instructions for installation and torque specifications.

- If you are not comfortable performing the replacement yourself, seek assistance from a qualified technician at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN.

By following these steps, you can effectively address faulty seatbelt buckle sensors and resolve seatbelt warning light issues in your Mercedes-Benz vehicle. Accurate diagnosis and proper replacement of the sensor ensure the safety and reliability of the seatbelt warning system.

8. Troubleshooting Seat Occupancy Sensor Issues

Seat occupancy sensors play a crucial role in the seatbelt warning system by detecting whether a seat is occupied. If a sensor malfunctions, it can send incorrect signals to the control module, causing the warning light to illuminate even when the seat is unoccupied, or fail to activate when the seat is occupied. Here’s how to troubleshoot seat occupancy sensor issues in Mercedes-Benz vehicles:

-

Identifying a Faulty Sensor:

- Use a Mercedes-Benz specific diagnostic tool (e.g., XENTRY/DAS) to read DTCs and access live data streams for the seat occupancy sensors.

- Monitor the sensor readings as you apply and remove weight from each seat.

- A faulty sensor will typically show erratic readings or fail to change state when the seat is occupied or unoccupied.

- Compare the sensor readings to the specified range in the service manual to confirm the fault.

-

Verifying Sensor Calibration:

- Some seat occupancy sensors require calibration to ensure accurate readings.

- Use the diagnostic tool to check the calibration status of the sensor.

- If the sensor is not calibrated or the calibration is incorrect, follow the tool’s instructions to perform the calibration procedure.

-

Checking Wiring and Connectors:

- Refer to the wiring diagrams to locate the wiring harnesses and connectors associated with the seat occupancy sensors.

- Visually inspect the wiring for any signs of damage, corrosion, or loose connections.

- Use a multimeter to test the continuity and voltage of the wiring circuits.

- Check for shorts to ground, opens, and excessive resistance in the wiring.

- Repair or replace any damaged wiring or connectors.

-

Testing Sensor Output:

- If the wiring and calibration are correct, use a multimeter to measure the sensor output voltage.

- The output voltage should change as you apply and remove weight from the seat.

- If the output voltage is consistently high, low, or does not change, the sensor is likely faulty.

-

Replacing the Seat Occupancy Sensor:

- Disconnect the negative terminal of the battery to prevent electrical shock.

- Remove the seat from the vehicle to access the seat occupancy sensor.

- Disconnect the wiring harness from the seat occupancy sensor.

- Remove the faulty sensor from the seat assembly.

- Install the new seat occupancy sensor in the seat assembly.

- Reconnect the wiring harness to the new sensor.

- Reinstall the seat in the vehicle and reconnect the negative terminal of the battery.

-

Verifying the Repair:

- Use the diagnostic tool to clear all DTCs from the vehicle’s computer.

- Turn off the ignition and then turn it back on to reset the system.

- Monitor the seatbelt warning light to ensure it operates correctly.

- Apply and remove weight from the seat several times to verify that the new sensor is functioning properly and the warning light turns off when the seat is unoccupied.

-

Considerations:

- Ensure you purchase a genuine Mercedes-Benz seat occupancy sensor or a high-quality aftermarket replacement.

- Follow the manufacturer’s instructions for installation and torque specifications.

- If you are not comfortable performing the replacement yourself, seek assistance from a qualified technician at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN.

By following these steps, you can effectively troubleshoot seat occupancy sensor issues and resolve seatbelt warning light problems in your Mercedes-Benz vehicle. Accurate diagnosis and proper replacement or calibration of the sensor ensure the safety and reliability of the seatbelt warning system.

9. Diagnosing and Repairing Wiring Problems

Wiring problems are a common source of issues in vehicle electrical systems, including the seatbelt warning system in Mercedes-Benz vehicles. Damaged, corroded, or loose wiring can disrupt the signals between the sensors and the control module, leading to intermittent or constant illumination of the warning light. Here’s how to diagnose and repair wiring problems in the seatbelt warning system:

-

Visual Inspection:

- Begin by visually inspecting the wiring harnesses and connectors associated with the seatbelt warning system.

- Look for any signs of damage, such as frayed wires, cracked insulation, corrosion, or loose connections.

- Pay close attention to areas where the wiring may be exposed to stress or abrasion, such as under the seats or near moving parts.

-

Using Wiring Diagrams:

- Refer to the Mercedes-Benz wiring diagrams to identify the specific wires and connectors related to the seatbelt warning system.

- The wiring diagrams provide a detailed map of the electrical circuits, allowing you to trace wires and identify components.

-

Continuity Testing:

- Use a multimeter to perform continuity testing on the wiring circuits.

- Disconnect the battery and the components at both ends of the wire.

- Set the multimeter to the continuity setting and touch the probes to each end of the wire.

- If the multimeter shows continuity (a beep or a reading of 0 ohms), the wire is intact.

- If the multimeter shows no continuity, the wire is broken and needs to be repaired or replaced.

-

Voltage Testing:

- Use a multimeter to perform voltage testing on the wiring circuits.

- Turn on the ignition and set the multimeter to the voltage setting.

- Touch the probes to the appropriate terminals to measure the voltage.

- Compare the measured voltage to the specified voltage in the service manual.

- If the voltage is too high, too low, or nonexistent, there may be a wiring problem.

-

Ground Testing:

- Use a multimeter to test for shorts to ground in the wiring circuits.

- Disconnect the battery and set the multimeter to the continuity setting.

- Touch one probe to the wire in question and the other probe to a known good ground, such as the vehicle’s chassis.

- If the multimeter shows continuity, the wire is shorted to ground.

-

Repairing Wiring Problems:

- Once you have identified the wiring problem, repair or replace the damaged wire or connector.

- For minor damage, you may be able to repair the wire by splicing it together and insulating it with electrical tape or heat-shrink tubing.

- For more severe damage, it may be necessary to replace the entire wiring harness or connector.

-

Verifying the Repair:

- After completing the wiring repairs, use the diagnostic tool to clear all DTCs from the vehicle’s computer.

- Turn off the ignition and then turn it back on to reset the system.

- Monitor the seatbelt warning light to ensure it operates correctly.

- Perform a test drive to verify that the warning light does not illuminate under normal driving conditions.

-

Considerations:

- Use high-quality wiring and connectors that meet or exceed the original equipment specifications.

- Ensure all wiring repairs are properly insulated to prevent shorts and corrosion.

- If you are not comfortable performing wiring repairs yourself, seek assistance from a qualified technician at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN.

By following these steps, you can effectively diagnose and repair wiring problems in the seatbelt warning system of your Mercedes-Benz vehicle. Accurate diagnosis and proper repair of the wiring ensure the safety and reliability of the system.

10. Control Module Diagnosis and Replacement

The control module, often integrated into the airbag control unit or body control module, plays a central role in the seatbelt warning system. It processes signals from the seatbelt buckle sensors and seat occupancy sensors, and activates the warning light and audible alarm as needed. If the control module malfunctions, it can lead to a variety of issues, including constant illumination of the warning light, failure to activate the warning, or incorrect processing of sensor data. Here’s how to diagnose and replace the control module in a Mercedes-Benz vehicle:

-

Identifying a Faulty Control Module:

- Use a Mercedes-Benz specific diagnostic tool (e.g., XENTRY/DAS) to read DTCs and perform component testing on the control module.

- Look for DTCs that specifically indicate a control module malfunction, such as “internal fault,” “processor error,” or “communication failure.”

- Run component tests to verify that the control module is processing sensor data correctly and activating the warning light and audible alarm as intended.

- If the control module fails the component tests or exhibits erratic behavior, it may need to be replaced.

-

Checking Power and Ground:

- Before replacing the control module, verify that it is receiving proper power and ground.

- Refer to the wiring diagrams to identify the power and ground circuits for the control module.

- Use a multimeter to measure the voltage and continuity of these circuits.

- Ensure that the control module is receiving the specified voltage and has a good ground connection.

-

Programming and Coding:

- When replacing the control module, it is typically necessary to program and code the new module to the vehicle’s specifications.

- Use the Mercedes-Benz specific diagnostic tool (e.g., XENTRY/DAS) to perform the programming and coding procedure.

- Follow the on-screen instructions to enter the vehicle’s VIN (Vehicle Identification Number) and other relevant information.

- The diagnostic tool will download the appropriate software and configuration data to the new control module.

-

Replacing the Control Module:

- Disconnect the negative terminal of the battery to prevent electrical shock.

- Locate the control module in the vehicle. It is often located under the dashboard, under the seats, or in the center console.

- Disconnect the wiring harnesses from the control module.

- Remove the faulty control module from its mounting bracket.

- Install the new control module in the mounting bracket.

- Reconnect the wiring harnesses to the new control module.

- Reinstall any trim panels or components that were removed to access the control module.

- Reconnect the negative terminal of the battery.

-

Verifying the Repair:

- Use the diagnostic tool to clear all DTCs from the vehicle’s computer.

- Turn off the ignition and then turn it back on to reset the system.

- Monitor the seatbelt warning light to ensure it operates correctly.

- Perform a test drive to verify that the warning light does not illuminate under normal driving conditions.

-

Considerations:

- Ensure you purchase a genuine Mercedes-Benz control module or a high-quality aftermarket replacement.

- Follow the manufacturer’s instructions for installation and programming.

- If you are not comfortable performing control module replacement and programming yourself, seek assistance from a qualified technician at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN.

By following these steps, you can effectively diagnose and replace a faulty control module in the seatbelt warning system of your Mercedes-Benz vehicle. Proper programming and coding of the new module ensure the safety and reliability of the system.

11. Addressing Software Glitches and Updates

Software glitches can sometimes cause the seatbelt warning system to behave erratically, triggering the warning light unnecessarily. Modern vehicles rely on complex software to manage various systems, and software errors can occur due to programming bugs, corrupted data, or conflicts with other software modules. Here’s how to address software glitches and updates in the seatbelt warning system of a Mercedes-Benz vehicle:

-

Identifying Software-Related Issues:

- Use a Mercedes-Benz specific diagnostic tool (e.g., XENTRY/DAS) to read DTCs and check for software-related error codes.

- Look for DTCs that indicate a software malfunction, such as “software error,” “programming fault,” or “data corruption.”

- Note any unusual behavior of the seatbelt warning system, such as intermittent illumination of the warning light, failure to activate the warning, or incorrect processing of sensor data.

-

Checking for Software Updates:

- Use the diagnostic tool to check for available software updates for the control module that manages the seatbelt warning system.

- Mercedes-Benz regularly releases software updates to address known issues, improve performance, and enhance system reliability.

- If a software update is available, follow the tool’s instructions to download and install the update.

-

Performing Software Reprogramming:

- In some cases, it may be necessary to reprogram the control module with the latest software version to resolve software glitches.

- Use the diagnostic tool to perform the software reprogramming procedure.

- Follow the on-screen instructions carefully, as incorrect programming can damage the control module.

-

Clearing Adaptation Data:

- After performing a software update or reprogramming, it may be necessary to clear the adaptation data for the seatbelt warning system.

- Adaptation data refers to the stored values that the control module has learned over time to optimize system performance.

- Clearing the adaptation data allows the control module to relearn these values and adapt to the current conditions.

-

Verifying the Repair:

- After completing the software update or reprogramming, use the diagnostic tool to clear all DTCs from the vehicle’s computer.

- Turn off the ignition and then turn it back on to reset the system.

- Monitor the seatbelt warning light to ensure it operates correctly.

- Perform a test drive to verify that the warning light does not illuminate under normal driving conditions.

-

Considerations:

- Ensure you have a stable power supply during software updates and reprogramming to prevent interruptions.

- Follow the manufacturer’s instructions carefully to avoid damaging the control module.

- If you are not comfortable performing software updates and reprogramming yourself, seek assistance from a qualified technician at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN.

By following these steps, you can effectively address software glitches and update the software in the seatbelt warning system of your Mercedes-Benz vehicle. Keeping the software up-to-date ensures optimal performance and reliability of the system.

12. Advanced Diagnostic Techniques

In complex cases where basic diagnostic procedures fail to identify the root cause of the seatbelt warning light issue, advanced diagnostic techniques may be necessary. These techniques involve specialized tools, in-depth analysis, and a thorough understanding of the vehicle’s electrical systems. Here are some advanced diagnostic techniques that can be used to troubleshoot seatbelt warning light problems in Mercedes-Benz vehicles:

-

Oscilloscope Analysis:

- An oscilloscope is a powerful tool for analyzing electrical signals in real-time.

- It can be used to visualize the waveforms of the signals from the seatbelt buckle sensors, seat occupancy sensors, and control module.

- By analyzing the waveforms, you can identify subtle issues such as signal distortion, noise, or intermittent dropouts that may not be apparent with a multimeter.

-

Network Communication Analysis:

- Modern vehicles use complex communication networks, such as CAN (Controller Area Network), to transmit data between control modules.

- If there are communication issues on the network, it can affect the performance of the seatbelt warning system.

- Use a diagnostic tool that supports network communication analysis to monitor the data being transmitted on the CAN bus.

- Look for any error messages, data corruption, or communication delays that may indicate a network problem.

-

Component Simulation:

- Component simulation involves using a specialized tool to simulate the signals from the seatbelt buckle sensors and seat occupancy sensors.

- This allows you to test the control module and wiring circuits without having to physically manipulate the sensors.

- By simulating different sensor states, you can verify that the control module is responding correctly and that the wiring circuits are functioning properly.

-

Harness Stress Testing:

- Harness stress testing involves applying mechanical stress to the wiring harnesses to identify intermittent wiring problems.

- Gently wiggle, bend, and pull on the wiring harnesses while monitoring the seatbelt warning light and sensor readings.

- If the warning light flickers or the sensor readings change, it indicates a potential wiring issue in the area being stressed.

-

Environmental Testing:

- Environmental testing involves subjecting the vehicle to different environmental conditions to identify temperature-sensitive or moisture-sensitive issues.

- For example, you can use a heat gun to warm up specific components or wiring harnesses, or spray them with water to simulate moisture.