Obd2 Connections are your car’s self-diagnostic link, and at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we help you understand and utilize this powerful tool. Through the standardized On-Board Diagnostics II protocol, you can access diagnostic trouble codes and real-time data, enabling faster and more informed vehicle maintenance. Discover the power of vehicle diagnostics, car diagnostic tools, and OBDII scanners to keep your Mercedes running smoothly.

Contents

- 1. Understanding OBD2 Connections

- What is OBD2?

- History of OBD2

- Why is OBD2 Important?

- Key Components of the OBD2 System

- 2. Identifying the OBD2 Connector

- Location of the OBD2 Connector

- Types of OBD2 Connectors: A vs. B

- Pinout of the OBD2 Connector

- Compatibility Considerations

- 3. How OBD2 Connections Work

- Communication Protocols

- Data Acquisition Process

- Diagnostic Trouble Codes (DTCs)

- Real-Time Data Parameters

- Understanding OBD2 Modes

- 4. Choosing the Right OBD2 Diagnostic Tool

- Basic Code Readers

- Scan Tools

- Advanced Diagnostic Systems

- Factors to Consider When Choosing a Tool

- 5. Connecting and Using an OBD2 Diagnostic Tool

- Step-by-Step Connection Guide

- Reading and Interpreting DTCs

- Viewing Real-Time Data

- Performing Component Tests

- Clearing Diagnostic Trouble Codes

- Safety Precautions and Best Practices

- 6. Advanced OBD2 Techniques

- Bi-Directional Control

- Programming and Coding

- Accessing OEM-Specific Data

- Data Logging and Analysis

- Customizing Vehicle Settings

- 7. The Future of OBD2 Connections

- OBD3 and Remote Diagnostics

- WWH-OBD and OBDonUDS

- Electric Vehicle Diagnostics

- Data Security and Access

- Integration with Mobile Apps and Cloud Services

- 8. Common OBD2 Issues and Troubleshooting

- Communication Errors

- Inaccurate Data

- False DTCs

- Tool Malfunctions

- Seeking Professional Assistance

- 9. OBD2 Data Logging – Use Case Examples

- Personal Vehicle Maintenance

- Commercial Fleet Management

- Performance Tuning and Optimization

- Insurance and Accident Reconstruction

- 10. Frequently Asked Questions About OBD2 Connections

1. Understanding OBD2 Connections

OBD2 (On-Board Diagnostics II) is a standardized system that provides access to the health and performance data of your vehicle. It’s like having a built-in doctor for your car, constantly monitoring various parameters and reporting any issues it detects.

What is OBD2?

OBD2 is a self-diagnostic system present in most modern vehicles. According to the Society of Automotive Engineers (SAE), it standardizes the way vehicles report diagnostic information. When something goes wrong, such as an engine misfire or an emissions problem, the vehicle stores a diagnostic trouble code (DTC) that can be accessed via the OBD2 connector. This connector is typically located under the dashboard on the driver’s side.

History of OBD2

The history of OBD2 is rooted in California’s efforts to control vehicle emissions. In 1991, the California Air Resources Board (CARB) mandated OBD systems in all new cars sold in California. This requirement was expanded in 1996 when the U.S. Environmental Protection Agency (EPA) required OBD2 for all new cars and light trucks nationwide. The rollout continued with:

- 2001: Required in the EU for gasoline cars.

- 2003: Required in the EU for diesel cars (EOBD).

- 2005: OBD2 required in the US for medium-duty vehicles.

- 2008: US cars must use ISO 15765-4 (CAN) as the OBD2 basis.

- 2010: OBD2 required in US heavy-duty vehicles.

Alt Text: Illustration showing the history of OBD2 from emission control to modern car data on the CAN bus.

Why is OBD2 Important?

OBD2 is important for several reasons:

- Emission Control: The original purpose of OBD2 was to monitor and control vehicle emissions, ensuring that cars meet environmental standards.

- Diagnostics: OBD2 allows mechanics and car owners to diagnose problems quickly and accurately. By reading the DTCs, they can pinpoint the source of the issue and perform targeted repairs.

- Data Access: OBD2 provides access to a wealth of real-time data about the vehicle’s performance, including engine speed, coolant temperature, and fuel consumption. This data can be used for performance tuning, fuel efficiency optimization, and preventive maintenance.

Key Components of the OBD2 System

The OBD2 system consists of several key components:

- OBD2 Connector: A 16-pin connector (SAE J1962) that provides access to the vehicle’s diagnostic data.

- Sensors: Various sensors throughout the vehicle monitor different parameters, such as engine temperature, oxygen levels, and throttle position.

- Engine Control Unit (ECU): The ECU is the brain of the OBD2 system. It receives data from the sensors, analyzes it, and stores diagnostic trouble codes when it detects a problem.

- Diagnostic Tools: These tools, ranging from simple code readers to advanced scan tools, plug into the OBD2 connector and allow users to retrieve diagnostic data and perform various tests.

2. Identifying the OBD2 Connector

The OBD2 connector, as defined by SAE J1962, is a standardized 16-pin port found in virtually all cars and light trucks sold in the United States since 1996. Its purpose is to provide access to the vehicle’s onboard diagnostic system.

Location of the OBD2 Connector

The OBD2 connector is typically located within a few feet of the steering wheel. Common locations include:

- Under the dashboard on the driver’s side

- Near the center console

- Behind a small access panel

Alt Text: Illustration showing the malfunction indicator light (MIL) and an OBD2 scan tool connected to the OBD2 port.

Types of OBD2 Connectors: A vs. B

There are two main types of OBD2 connectors: Type A and Type B. Type A is commonly found in cars and light trucks, providing a 12V power supply, while Type B is typically used in medium and heavy-duty vehicles, offering a 24V power supply.

To distinguish between the two, Type B connectors have an interrupted groove in the middle. A Type B adapter cable is compatible with both Type A and Type B sockets, but a Type A cable will not fit into a Type B socket. Understanding this distinction is vital when selecting the right tools and adapters for your vehicle.

Pinout of the OBD2 Connector

The OBD2 connector has a standardized pinout, but the function of each pin can vary depending on the vehicle’s communication protocol. Here’s a general overview of the pin functions:

- Pin 2: SAE J1850 Bus+

- Pin 4: Chassis Ground

- Pin 5: Signal Ground

- Pin 6: CAN High (ISO 15765-4)

- Pin 7: ISO 9141-2 K-Line

- Pin 10: SAE J1850 Bus-

- Pin 14: CAN Low (ISO 15765-4)

- Pin 15: ISO 9141-2 L-Line

- Pin 16: Battery Power

Compatibility Considerations

While the OBD2 connector is standardized, not all vehicles implement the same communication protocols. It’s essential to ensure that your diagnostic tool is compatible with your vehicle’s protocol. Common protocols include:

- CAN (Controller Area Network): The most common protocol used in modern vehicles.

- ISO 9141-2: Used in some older European and Asian vehicles.

- SAE J1850 VPW and PWM: Used in older GM and Ford vehicles, respectively.

3. How OBD2 Connections Work

OBD2 connections facilitate communication between your vehicle’s computer and diagnostic tools, providing access to a wealth of information about the vehicle’s health and performance. This communication follows specific protocols and standards, ensuring that diagnostic tools can effectively retrieve and interpret the data.

Communication Protocols

The communication between the diagnostic tool and the vehicle’s computer relies on specific protocols. These protocols dictate how data is transmitted and interpreted. The most common protocols include:

- CAN (Controller Area Network): Dominant in modern vehicles, CAN is a robust protocol allowing various ECUs to communicate. Standardized under ISO 15765-4 for OBD2, it specifies bit rates (250K or 500K), CAN ID lengths (11-bit or 29-bit), and CAN IDs for OBD requests/responses.

- ISO 9141-2: Used in older European and Asian vehicles, this protocol employs asynchronous serial communication.

- SAE J1850 VPW and PWM: Utilized in older GM and Ford vehicles, these protocols use variable pulse width modulation (VPW) and pulse width modulation (PWM) for data transmission.

- ISO 14230 (KWP2000): This was a common protocol for 2003+ cars in e.g. Asia

Data Acquisition Process

The data acquisition process involves several steps:

- Connection: The diagnostic tool is connected to the OBD2 connector.

- Request: The diagnostic tool sends a request to the vehicle’s computer for specific data. This request includes a service ID (or mode) and a parameter ID (PID).

- Response: The vehicle’s computer processes the request and sends a response containing the requested data.

- Interpretation: The diagnostic tool interprets the data and presents it in a user-friendly format, such as numerical values, graphs, or diagnostic trouble codes (DTCs).

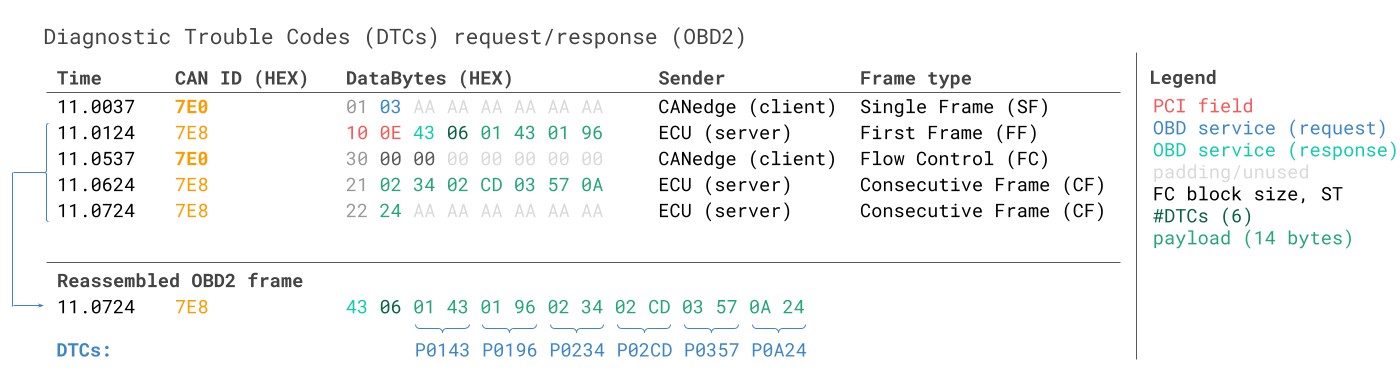

Diagnostic Trouble Codes (DTCs)

DTCs are standardized codes used to identify specific problems in the vehicle. These codes are stored in the vehicle’s computer when a fault is detected. DTCs are typically five characters long, with the first character indicating the system where the fault occurred:

- P: Powertrain (engine, transmission)

- B: Body (airbags, power windows)

- C: Chassis (ABS, suspension)

- U: Network (communication)

The remaining characters provide more specific information about the fault. For example, a DTC of P0300 indicates a random or multiple cylinder misfire in the engine.

Real-Time Data Parameters

OBD2 connections also provide access to a wealth of real-time data parameters, including:

- Engine Speed (RPM)

- Vehicle Speed

- Coolant Temperature

- Fuel Trim

- Oxygen Sensor Readings

- Mass Airflow (MAF)

- Throttle Position

This data can be used to monitor the vehicle’s performance, diagnose problems, and optimize fuel efficiency.

Alt Text: Illustration breaking down the OBD2 message structure, including identifier, data length, mode, parameter ID (PID), and data bytes.

Understanding OBD2 Modes

OBD2 operates using different modes, each designed for specific diagnostic functions. Here are some key modes:

- Mode 01: Displays current real-time data.

- Mode 03: Shows stored Diagnostic Trouble Codes (DTCs).

- Mode 04: Clears DTCs and resets diagnostic monitors.

- Mode 09: Requests vehicle information, such as the VIN.

Vehicles may not support all OBD2 modes and can include OEM-specific modes. In OBD2 messages, the mode is in the 2nd byte.

4. Choosing the Right OBD2 Diagnostic Tool

Selecting the right OBD2 diagnostic tool depends on your needs and budget. The market offers a wide range of tools, from basic code readers to advanced scan tools with extensive capabilities.

Basic Code Readers

Basic code readers are the simplest and most affordable OBD2 diagnostic tools. They can read and clear diagnostic trouble codes (DTCs), allowing you to identify and resolve minor issues. However, basic code readers typically have limited capabilities beyond reading and clearing codes.

- Pros: Affordable, easy to use, and portable.

- Cons: Limited functionality, may not provide detailed information.

- Best For: Car owners who want to diagnose and clear basic engine codes.

Scan Tools

Scan tools offer more advanced features compared to basic code readers. They can read and clear DTCs, display real-time data parameters, perform component tests, and provide access to advanced diagnostic functions. Scan tools are available in various configurations, including handheld devices and PC-based software.

- Pros: More features and capabilities, detailed diagnostic information, component testing.

- Cons: More expensive than basic code readers, may require some technical knowledge.

- Best For: Car owners, DIY mechanics, and professional technicians.

Advanced Diagnostic Systems

Advanced diagnostic systems are the most comprehensive OBD2 tools available. They offer advanced features such as bi-directional control, programming, and coding. These systems are typically used by professional technicians in repair shops and dealerships.

- Pros: Extensive features and capabilities, bi-directional control, programming, and coding.

- Cons: Most expensive, requires extensive technical knowledge and training.

- Best For: Professional technicians in repair shops and dealerships.

Factors to Consider When Choosing a Tool

When selecting an OBD2 diagnostic tool, consider the following factors:

- Compatibility: Ensure the tool is compatible with your vehicle’s make, model, and year.

- Features: Determine which features you need, such as real-time data, component testing, or bi-directional control.

- Ease of Use: Choose a tool with a user-friendly interface and clear instructions.

- Price: Set a budget and find a tool that offers the best value for your money.

- Updates: Check if the tool receives regular software updates to support new vehicles and features.

5. Connecting and Using an OBD2 Diagnostic Tool

Once you have selected the right OBD2 diagnostic tool, the next step is to connect it to your vehicle and use it to retrieve diagnostic information. The process is generally straightforward, but it’s essential to follow the manufacturer’s instructions to ensure a successful connection.

Step-by-Step Connection Guide

- Locate the OBD2 Connector: Find the OBD2 connector in your vehicle, typically located under the dashboard on the driver’s side.

- Turn Off the Ignition: Ensure the vehicle’s ignition is turned off before connecting the diagnostic tool.

- Plug in the Tool: Plug the diagnostic tool into the OBD2 connector, ensuring a secure connection.

- Turn On the Ignition: Turn the vehicle’s ignition to the “ON” position, but do not start the engine.

- Power On the Tool: Turn on the diagnostic tool and follow the on-screen instructions to establish a connection with the vehicle’s computer.

- Retrieve Data: Once the connection is established, you can retrieve diagnostic trouble codes (DTCs), view real-time data parameters, and perform component tests.

Reading and Interpreting DTCs

After connecting the OBD2 diagnostic tool, you can read and interpret diagnostic trouble codes (DTCs). DTCs are standardized codes used to identify specific problems in the vehicle. The diagnostic tool will display the DTCs along with a brief description of the fault.

To get a more detailed explanation of the DTC, you can consult the vehicle’s repair manual or search online databases such as RepairPal. This information will help you understand the cause of the fault and determine the appropriate repair procedure.

Viewing Real-Time Data

OBD2 diagnostic tools can also display real-time data parameters, providing valuable insights into the vehicle’s performance. You can view parameters such as engine speed (RPM), vehicle speed, coolant temperature, fuel trim, and oxygen sensor readings.

This data can be used to monitor the vehicle’s performance, diagnose problems, and optimize fuel efficiency. For example, if you notice that the engine speed is erratic or that the fuel trim values are outside the normal range, it could indicate a problem with the engine or fuel system.

Performing Component Tests

Some OBD2 diagnostic tools offer the ability to perform component tests. These tests allow you to activate or deactivate specific components in the vehicle to verify their functionality. For example, you can activate the fuel injectors, turn on the cooling fan, or cycle the ABS pump.

Component tests can be helpful in diagnosing problems with specific components or systems in the vehicle. However, it’s essential to follow the manufacturer’s instructions carefully when performing these tests to avoid damaging the vehicle.

OBD2 Diagnostic Trouble Codes DTC CAN Bus Request Response Example

OBD2 Diagnostic Trouble Codes DTC CAN Bus Request Response Example

Alt Text: Example of OBD2 diagnostic trouble codes (DTC) displayed in a CAN bus trace, illustrating a request-response sequence.

Clearing Diagnostic Trouble Codes

Once you have diagnosed and repaired the fault, you can clear the diagnostic trouble codes (DTCs) using the OBD2 diagnostic tool. Clearing the DTCs will turn off the check engine light and reset the vehicle’s computer.

However, it’s essential to ensure that the fault has been properly repaired before clearing the DTCs. If the underlying problem persists, the DTCs will likely reappear.

Safety Precautions and Best Practices

When using an OBD2 diagnostic tool, follow these safety precautions and best practices:

- Read and understand the manufacturer’s instructions before using the tool.

- Ensure the vehicle is parked in a safe location with the parking brake engaged.

- Do not operate the tool while driving.

- Follow all safety precautions and warnings in the vehicle’s repair manual.

- If you are not comfortable performing diagnostic or repair procedures, consult a qualified technician.

6. Advanced OBD2 Techniques

For advanced users and professional technicians, OBD2 offers a range of advanced techniques and capabilities that go beyond basic code reading and real-time data viewing.

Bi-Directional Control

Bi-directional control allows the diagnostic tool to send commands to the vehicle’s computer, enabling you to activate or deactivate specific components and systems. This feature can be helpful in diagnosing problems with components such as fuel injectors, cooling fans, and ABS pumps.

Programming and Coding

Some advanced OBD2 tools offer programming and coding capabilities, allowing you to reprogram the vehicle’s computer or configure new features. This feature is typically used by professional technicians to install software updates, program new keys, or enable advanced features.

Accessing OEM-Specific Data

While OBD2 provides access to standardized data parameters, some manufacturers also offer access to OEM-specific data through the OBD2 connector. This data can include information about the vehicle’s performance, diagnostics, and maintenance requirements.

Accessing OEM-specific data typically requires a specialized diagnostic tool or software subscription. However, it can provide valuable insights into the vehicle’s health and performance.

Data Logging and Analysis

Advanced OBD2 tools offer data logging capabilities, allowing you to record real-time data parameters over a period of time. This data can be analyzed to identify trends, diagnose intermittent problems, and optimize vehicle performance.

Data logging and analysis can be particularly helpful in diagnosing problems that only occur under certain conditions, such as during acceleration or at high speeds.

Customizing Vehicle Settings

Some advanced OBD2 tools allow you to customize various vehicle settings, such as idle speed, ignition timing, and fuel mixture. These adjustments can be used to optimize vehicle performance, improve fuel efficiency, or modify the vehicle’s behavior.

However, it’s essential to proceed with caution when customizing vehicle settings, as incorrect adjustments can damage the vehicle or affect its safety.

7. The Future of OBD2 Connections

The future of OBD2 connections is evolving with advancements in automotive technology and the increasing demand for more comprehensive vehicle diagnostics and data access. Several key trends are shaping the future of OBD2:

OBD3 and Remote Diagnostics

OBD3 represents a potential evolution of OBD2, incorporating telematics to enable remote diagnostics and emissions testing. By adding a small radio transponder to vehicles, OBD3 would allow the vehicle identification number (VIN) and DTCs to be sent via Wi-Fi to a central server for checks. While this technology offers convenience and cost savings, it also raises concerns about surveillance and data privacy.

WWH-OBD and OBDonUDS

Modern alternatives like WWH-OBD (World Wide Harmonized OBD) and OBDonUDS (OBD on UDS) are emerging to address the limitations of OBD2 in terms of data richness and lower-layer protocols. These protocols streamline and enhance OBD communication by leveraging the UDS protocol as a basis.

Electric Vehicle Diagnostics

The rise of electric vehicles (EVs) poses a challenge to the traditional OBD2 system, as EVs do not have the same emissions-related diagnostic needs as internal combustion engine vehicles. As a result, many modern EVs do not support standard OBD2 requests. Instead, they often utilize OEM-specific UDS communication, making it difficult to access diagnostic data without specialized tools and knowledge.

Data Security and Access

With the increasing reliance on OBD2 for data access, security concerns are becoming more prevalent. Proposals to “turn off” OBD2 functionality while driving and instead collect data in a central server aim to address security risks but also raise concerns about manufacturers controlling automotive big data.

Integration with Mobile Apps and Cloud Services

The integration of OBD2 with mobile apps and cloud services is becoming increasingly common. This allows car owners to access diagnostic data, track vehicle performance, and receive maintenance alerts through their smartphones. Cloud-based services can also provide advanced analytics and predictive maintenance capabilities.

Alt Text: Illustration showing the removal of the OBD2 connector in electric vehicles, highlighting the shift towards OEM-specific diagnostic solutions.

8. Common OBD2 Issues and Troubleshooting

While OBD2 connections are generally reliable, some common issues can arise that may require troubleshooting.

Communication Errors

Communication errors occur when the diagnostic tool cannot establish a connection with the vehicle’s computer. This can be caused by several factors:

- Faulty Connector: Check the OBD2 connector for damage or corrosion.

- Incorrect Protocol: Ensure the diagnostic tool is using the correct communication protocol for the vehicle.

- Wiring Issues: Inspect the wiring harness for damage or loose connections.

- ECU Problems: In rare cases, the vehicle’s computer (ECU) may be faulty.

Inaccurate Data

Inaccurate data can be caused by faulty sensors or incorrect calibration. To troubleshoot this issue:

- Verify Sensor Readings: Compare the sensor readings with known good values.

- Check Sensor Wiring: Inspect the sensor wiring for damage or loose connections.

- Calibrate Sensors: Some sensors may require calibration to ensure accurate readings.

False DTCs

False DTCs can be triggered by transient issues or software glitches. To address this issue:

- Clear DTCs: Clear the DTCs and see if they reappear.

- Check for TSBs: Review the Technical Service Bulletins (TSBs) for known issues and solutions.

- Update Software: Ensure the vehicle’s computer has the latest software updates.

Tool Malfunctions

Tool malfunctions can occur due to software bugs or hardware failures. To resolve this issue:

- Update Software: Ensure the diagnostic tool has the latest software updates.

- Reboot the Tool: Try rebooting the diagnostic tool.

- Contact Support: Contact the tool manufacturer for technical support.

Seeking Professional Assistance

If you are unable to resolve the OBD2 issue, it’s best to seek professional assistance from a qualified technician. A professional technician has the knowledge, experience, and equipment to diagnose and repair complex OBD2 issues.

9. OBD2 Data Logging – Use Case Examples

OBD2 data logging has various practical applications, ranging from personal vehicle maintenance to commercial fleet management.

Personal Vehicle Maintenance

Logging OBD2 data can help car owners:

- Monitor Vehicle Health: Track key parameters such as engine temperature, fuel consumption, and oxygen sensor readings to identify potential problems early.

- Improve Fuel Efficiency: Analyze fuel trim data to optimize driving habits and identify maintenance needs that can improve fuel economy.

- Diagnose Intermittent Issues: Capture data during specific driving conditions to diagnose problems that only occur sporadically.

Commercial Fleet Management

For businesses operating fleets of vehicles, OBD2 data logging can:

- Optimize Maintenance Schedules: Monitor vehicle health and performance to schedule maintenance proactively, reducing downtime and repair costs.

- Improve Driver Behavior: Track driving habits such as speeding, hard braking, and excessive idling to promote safer and more efficient driving.

- Reduce Fuel Costs: Analyze fuel consumption data to identify inefficiencies and optimize routing and driving practices.

Performance Tuning and Optimization

Enthusiasts and professional tuners can use OBD2 data logging to:

- Monitor Engine Performance: Track key parameters such as RPM, boost pressure, and air-fuel ratio to optimize engine performance.

- Diagnose Performance Issues: Identify bottlenecks and inefficiencies in the engine or drivetrain.

- Validate Tuning Modifications: Verify that tuning modifications are producing the desired results and are not causing any adverse effects.

Insurance and Accident Reconstruction

OBD2 data logging can also be used in insurance and accident reconstruction:

- Verify Claims: Provide data to verify insurance claims and determine the cause of accidents.

- Reconstruct Accidents: Reconstruct the events leading up to an accident based on vehicle speed, braking, and other parameters.

- Assess Vehicle Damage: Evaluate the extent of vehicle damage based on sensor readings and diagnostic trouble codes.

Alt Text: An OBD2 data logger connected to a car, symbolizing on-board diagnostics and vehicle data collection.

10. Frequently Asked Questions About OBD2 Connections

-

Q: What is the OBD2 port used for?

The OBD2 port is used to access your vehicle’s diagnostic system, allowing you to read diagnostic trouble codes (DTCs) and monitor real-time data parameters.

-

Q: Where is the OBD2 port located?

The OBD2 port is typically located under the dashboard on the driver’s side of the vehicle.

-

Q: Can I use any OBD2 scanner with my car?

While the OBD2 connector is standardized, not all scanners are compatible with all vehicles. Ensure that the scanner you choose supports your vehicle’s make, model, and year.

-

Q: Is it safe to leave an OBD2 scanner plugged in all the time?

Leaving an OBD2 scanner plugged in all the time can drain the vehicle’s battery. It’s best to unplug the scanner when not in use.

-

Q: Can OBD2 scanners damage my car?

When used correctly, OBD2 scanners are safe and will not damage your car. However, it’s essential to follow the manufacturer’s instructions and avoid making unauthorized modifications to the vehicle’s computer.

-

Q: How do I clear a check engine light with an OBD2 scanner?

To clear a check engine light, connect the OBD2 scanner to your vehicle, read the DTCs, and then select the option to clear the codes.

-

Q: What does a specific OBD2 code mean?

Each OBD2 code corresponds to a specific fault in the vehicle. You can consult the vehicle’s repair manual or search online databases like RepairPal to determine the meaning of a specific code.

-

Q: Can I diagnose ABS and airbag problems with an OBD2 scanner?

Basic OBD2 scanners may not be able to diagnose ABS and airbag problems. You may need a more advanced scanner that supports these systems.

-

Q: How often should I scan my car with an OBD2 scanner?

You should scan your car with an OBD2 scanner whenever the check engine light comes on or if you suspect a problem with the vehicle’s performance.

-

Q: Are there any apps that can use my phone as an OBD2 scanner?

Yes, there are many mobile apps that can use your phone as an OBD2 scanner. You’ll need to purchase an OBD2 adapter that connects to your phone via Bluetooth or Wi-Fi.

Want to learn more about OBD2 connections and how they can benefit your Mercedes-Benz? Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN today for expert advice and guidance.

Don’t let vehicle issues slow you down. Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN now for expert advice on OBD2 connections, diagnostic tools, and maintenance tips. Reach us at 789 Oak Avenue, Miami, FL 33101, United States, or call us on Whatsapp at +1 (641) 206-8880. Visit our website at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for more information and immediate assistance. Let us help you keep your Mercedes running smoothly and efficiently.