Obd2 Protocols By Vehicle Make And Model are vital for diagnosing car issues, and MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers expert insights. Understanding these protocols ensures accurate diagnostics and efficient repairs. We provide comprehensive guidance, helping you navigate the complexities of vehicle diagnostics.

Contents

- 1. What Are OBD2 Protocols and Why Are They Important?

- 1.1. Understanding the Basics of OBD2

- 1.2. Key Benefits of OBD2 Protocols

- 1.3. History and Evolution of OBD Systems

- 2. Common OBD2 Protocols

- 2.1. J1850 PWM (Pulse Width Modulation)

- 2.2. J1850 VPW (Variable Pulse Width)

- 2.3. ISO9141-2

- 2.4. ISO14230-4 (KWP2000)

- 2.5. ISO15765-4/SAE J2480 (CAN)

- 3. OBD2 Protocols by Vehicle Make

- 3.1. Ford OBD2 Protocols

- 3.2. General Motors OBD2 Protocols

- 3.3. Chrysler OBD2 Protocols

- 3.4. European Makes (Mercedes-Benz, BMW, Audi, Volkswagen) OBD2 Protocols

- 3.5. Asian Makes (Toyota, Honda, Nissan) OBD2 Protocols

- 4. OBD2 Protocols by Vehicle Model

- 4.1. Mercedes-Benz OBD2 Protocols

- 4.2. BMW OBD2 Protocols

- 4.3. Toyota OBD2 Protocols

- 4.4. Honda OBD2 Protocols

- 4.5. Ford OBD2 Protocols

- 5. How to Determine Your Vehicle’s OBD2 Protocol

- 5.1. Checking the Vehicle’s Manual

- 5.2. Inspecting the OBD2 Connector

- 5.3. Using an OBD2 Scanner

- 5.4. Consulting Online Databases

- 6. OBD2 Connector Types and Locations

- 6.1. Type A and Type B Connectors

- 6.2. Standard OBD2 Connector Locations

- 6.3. Common OBD2 Connector Locations in Different Vehicles

- 7. Tools for Reading OBD2 Protocols

- 7.1. Basic OBD2 Code Readers

- 7.2. Advanced Diagnostic Scanners

- 7.3. Smartphone Apps and Adapters

- 7.4. Professional Diagnostic Software

- 8. Diagnosing Common Issues Using OBD2 Protocols

- 8.1. Reading and Interpreting Diagnostic Trouble Codes (DTCs)

- 8.2. Identifying Emission-Related Problems

- 8.3. Detecting Engine Performance Issues

- 8.4. Troubleshooting Transmission Problems

- 8.5. Addressing ABS and Brake System Faults

- 9. Advanced Uses of OBD2 Protocols

- 9.1. Performance Tuning and Customization

- 9.2. Data Logging and Analysis

- 9.3. Monitoring Fuel Efficiency

- 9.4. Unlocking Hidden Features

- 10. Future Trends in OBD Technology

- 10.1. Enhanced Diagnostics and Remote Monitoring

- 10.2. Integration with Telematics Systems

- 10.3. Cybersecurity Considerations

- 10.4. Standardization of OBD-III

- 11. Maintaining and Servicing Your Mercedes-Benz Using OBD2

- 11.1. Regular OBD2 Scans for Preventative Maintenance

- 11.2. Resetting Service Lights and Maintenance Reminders

- 11.3. Verifying Repairs After Maintenance

- 11.4. Long-Term Benefits of Using OBD2 for Vehicle Health

- 12. Common OBD2 Error Codes for Mercedes-Benz Vehicles

- 12.1. P0400 Series: Exhaust Gas Recirculation (EGR) Issues

- 12.2. P0170 and P0173: Fuel Trim Problems

- 12.3. P0300 Series: Misfire Detection

- 12.4. P0420: Catalytic Converter Efficiency Below Threshold

- 12.5. Addressing Specific Mercedes-Benz Error Codes

- 13. Resources for Learning More About OBD2 Protocols

- 13.1. Online Forums and Communities

- 13.2. Training Courses and Workshops

- 13.3. Technical Publications and Manuals

- 13.4. OEM (Original Equipment Manufacturer) Resources

- 14. Legal and Regulatory Aspects of OBD2

- 14.1. EPA Regulations and Compliance

- 14.2. State-Level Emission Testing Programs

- 14.3. Impact on Vehicle Modifications and Tuning

- 14.4. Ensuring Compliance with OBD2 Standards

- 15. Case Studies: Real-World Applications of OBD2 Protocols

- 15.1. Diagnosing Intermittent Misfires in a Mercedes-Benz C-Class

- 15.2. Identifying a Faulty Oxygen Sensor in a BMW 3 Series

- 15.3. Resolving Transmission Issues in a Toyota Camry

- 15.4. Addressing Emission Problems in a Ford F-150

- 16. Choosing the Right OBD2 Tool for Your Needs

- 16.1. Consider Your Vehicle Make and Model

- 16.2. Determine Your Diagnostic Needs

- 16.3. Set a Budget for Your OBD2 Tool

- 16.4. Read Reviews and Compare Features

- 17. Expert Tips for Using OBD2 Scanners Effectively

- 17.1. Always Start with a Full Vehicle Scan

- 17.2. Research DTCs Thoroughly

- 17.3. Monitor Live Sensor Data for Accurate Diagnosis

- 17.4. Perform Actuation Tests to Verify Component Function

- 17.5. Clear DTCs After Repairs and Verify the Fix

- 18. Common Pitfalls to Avoid When Using OBD2

- 18.1. Misinterpreting DTCs Without Proper Research

- 18.2. Relying Solely on DTCs Without Analyzing Sensor Data

- 18.3. Neglecting Basic Mechanical Checks

- 18.4. Overlooking Intermittent Problems

- 19. Ethical Considerations in Using OBD2 Data

- 19.1. Protecting Vehicle Owner Privacy

- 19.2. Ensuring Data Security and Confidentiality

- 19.3. Adhering to Data Protection Regulations

- 19.4. Responsible Use of Vehicle Information

- 20. FAQs About OBD2 Protocols

- 20.1. What is the best OBD2 scanner for Mercedes-Benz vehicles?

- 20.2. How do I find the OBD2 port in my car?

- 20.3. Can I use any OBD2 scanner on any car?

- 20.4. What does a P0420 code mean?

- 20.5. How do I reset the check engine light?

- 20.6. What is the difference between OBD1 and OBD2?

- 20.7. Can OBD2 tools unlock hidden features in my car?

- 20.8. How often should I scan my car with an OBD2 scanner?

- 20.9. Are there any risks associated with using OBD2 scanners?

- 20.10. Where can I find reliable information about OBD2 protocols?

1. What Are OBD2 Protocols and Why Are They Important?

OBD2 protocols are standardized systems that allow diagnostic tools to communicate with a vehicle’s computer. They are important because they enable mechanics and car owners to diagnose problems accurately, ensuring efficient repairs and maintenance. According to the EPA, OBD2 systems help reduce emissions and improve fuel efficiency by monitoring key engine components.

1.1. Understanding the Basics of OBD2

On-Board Diagnostics version 2 (OBD2) is a standardized system used in vehicles to monitor and diagnose engine and emission-related issues. Introduced in the mid-1990s, OBD2 provides a wealth of information about a vehicle’s performance and health. It allows technicians and car owners to access diagnostic trouble codes (DTCs), sensor data, and other critical information. OBD2’s standardization means that any compliant vehicle can be diagnosed using a universal tool, regardless of make or model.

1.2. Key Benefits of OBD2 Protocols

The benefits of OBD2 protocols are numerous:

- Standardization: Ensures compatibility across different vehicle makes and models.

- Emission Control: Helps monitor and reduce vehicle emissions.

- Fault Diagnosis: Quickly identifies issues through diagnostic trouble codes.

- Data Access: Provides real-time sensor data for detailed analysis.

- Cost Savings: Allows for early detection and prevention of costly repairs.

1.3. History and Evolution of OBD Systems

The evolution of On-Board Diagnostics (OBD) systems has been a journey from basic monitoring to sophisticated, standardized diagnostics. OBD systems were first introduced in the late 1960s in response to stricter emission regulations. These early systems were rudimentary, providing limited diagnostic information. In the 1980s, OBD-I systems began to appear, offering more detailed monitoring of engine components. However, OBD-I systems were not standardized, meaning each manufacturer used its own diagnostic methods and connectors.

The standardization of OBD2 in the mid-1990s marked a significant milestone. OBD2 mandated a universal diagnostic connector and a standardized set of diagnostic trouble codes. This allowed any OBD2-compliant vehicle to be diagnosed using a single tool, regardless of its make or model. In the early 2000s, Controller Area Network (CAN) protocols became increasingly prevalent in OBD2 systems, offering faster and more reliable communication between vehicle components.

Today, OBD systems continue to evolve with the advent of advanced technologies such as telematics and cloud-based diagnostics. Modern OBD systems not only monitor engine and emission-related issues but also provide data on various vehicle systems, including transmission, brakes, and safety features.

2. Common OBD2 Protocols

Several communication protocols are used in OBD2 systems, each with its own characteristics and applications. The most common protocols include:

- J1850 PWM (Pulse Width Modulation)

- J1850 VPW (Variable Pulse Width)

- ISO9141-2

- ISO14230-4 (KWP2000)

- ISO15765-4/SAE J2480 (CAN)

2.1. J1850 PWM (Pulse Width Modulation)

J1850 PWM is an OBD2 communication protocol primarily used by Ford. It uses a variable pulse width to transmit data, making it relatively robust against noise and interference. This protocol is characterized by its use of pin 2 and pin 10 on the OBD2 connector for communication.

2.2. J1850 VPW (Variable Pulse Width)

J1850 VPW is another OBD2 communication protocol commonly used by General Motors (GM). Like J1850 PWM, it uses a variable pulse width to transmit data. However, J1850 VPW differs in its voltage levels and timing characteristics. It also uses pin 2 on the OBD2 connector for communication.

2.3. ISO9141-2

ISO9141-2 is an OBD2 communication protocol widely used by European and Asian manufacturers. It is a serial communication protocol that uses pin 7 on the OBD2 connector for the K-line and optionally pin 15 for the L-line. ISO9141-2 is known for its simplicity and reliability.

2.4. ISO14230-4 (KWP2000)

ISO14230-4, also known as Keyword Protocol 2000 (KWP2000), is an OBD2 communication protocol used by many European and Asian manufacturers. It is a more advanced protocol than ISO9141-2, offering faster data transfer rates and more sophisticated diagnostic capabilities. KWP2000 also uses pin 7 on the OBD2 connector for communication.

2.5. ISO15765-4/SAE J2480 (CAN)

ISO15765-4, also known as SAE J2480 and commonly referred to as CAN (Controller Area Network), is the most modern and widely used OBD2 communication protocol. It is used by virtually all vehicle manufacturers since 2008. CAN is a high-speed communication protocol that allows multiple electronic control units (ECUs) in a vehicle to communicate with each other. It uses pins 6 and 14 on the OBD2 connector for communication.

3. OBD2 Protocols by Vehicle Make

Different vehicle manufacturers use different OBD2 protocols based on their engineering preferences and the age of the vehicle. Here’s a breakdown by make:

- Ford: J1850 PWM, CAN

- General Motors: J1850 VPW, CAN

- Chrysler: J1850 VPW, CAN

- European Makes (Mercedes-Benz, BMW, Audi, Volkswagen): ISO9141-2, ISO14230-4 (KWP2000), CAN

- Asian Makes (Toyota, Honda, Nissan): ISO9141-2, ISO14230-4 (KWP2000), CAN

3.1. Ford OBD2 Protocols

Ford vehicles primarily used J1850 PWM until the adoption of CAN. Modern Ford vehicles use the CAN protocol.

3.2. General Motors OBD2 Protocols

General Motors vehicles mainly used J1850 VPW before transitioning to CAN. Current GM vehicles use the CAN protocol.

3.3. Chrysler OBD2 Protocols

Chrysler vehicles also used J1850 VPW in the past but now primarily use CAN.

3.4. European Makes (Mercedes-Benz, BMW, Audi, Volkswagen) OBD2 Protocols

European manufacturers like Mercedes-Benz, BMW, Audi, and Volkswagen have historically used ISO9141-2 and ISO14230-4 (KWP2000) protocols. However, modern models have fully adopted the CAN protocol.

3.5. Asian Makes (Toyota, Honda, Nissan) OBD2 Protocols

Asian manufacturers such as Toyota, Honda, and Nissan also used ISO9141-2 and ISO14230-4 (KWP2000) protocols. Newer models now use the CAN protocol.

4. OBD2 Protocols by Vehicle Model

Identifying OBD2 protocols by vehicle model can be more specific. Here are some examples:

- Mercedes-Benz C-Class (W203): ISO9141-2, ISO14230-4 (KWP2000)

- Mercedes-Benz C-Class (W204): CAN

- BMW 3 Series (E46): ISO9141-2, ISO14230-4 (KWP2000)

- BMW 3 Series (E90): CAN

- Toyota Camry (2000): ISO9141-2

- Toyota Camry (2010): CAN

4.1. Mercedes-Benz OBD2 Protocols

Mercedes-Benz vehicles transitioned from ISO9141-2 and ISO14230-4 to CAN. For example, older C-Class models (W203) use ISO protocols, while newer models (W204 and later) use CAN.

4.2. BMW OBD2 Protocols

BMW vehicles followed a similar transition, with older 3 Series models (E46) using ISO protocols and newer models (E90 and later) using CAN.

4.3. Toyota OBD2 Protocols

Toyota vehicles also moved from ISO9141-2 to CAN. A 2000 Camry uses ISO9141-2, while a 2010 Camry uses CAN.

4.4. Honda OBD2 Protocols

Honda vehicles transitioned similarly to Toyota, with older models using ISO protocols and newer models using CAN.

4.5. Ford OBD2 Protocols

Ford vehicles transitioned from J1850 PWM to CAN. Early 2000s models may use J1850 PWM, while later models use CAN.

5. How to Determine Your Vehicle’s OBD2 Protocol

Determining your vehicle’s OBD2 protocol can be done through several methods:

- Check the Vehicle’s Manual: The owner’s manual often lists the OBD2 protocol used.

- Inspect the OBD2 Connector: Check which pins are present in the OBD2 connector.

- Use an OBD2 Scanner: Some scanners can automatically detect the protocol.

- Consult Online Databases: Online databases provide protocol information based on vehicle make and model.

5.1. Checking the Vehicle’s Manual

The vehicle’s owner manual is a reliable source of information about the OBD2 protocol used in your vehicle. Look for sections related to diagnostics or specifications to find this information.

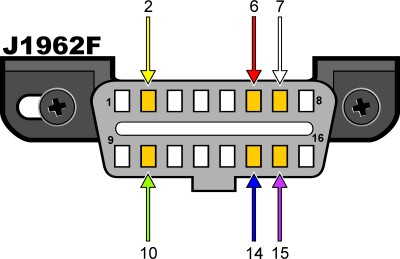

5.2. Inspecting the OBD2 Connector

Inspecting the OBD2 connector can provide clues about the protocol used. Check which pins are present in the connector and compare them to the pinout diagrams for different protocols.

Here’s a quick guide:

- J1850 PWM: Pins 2 and 10 are present.

- J1850 VPW: Pin 2 is present, but not pin 10.

- ISO9141-2/ISO14230-4: Pin 7 is present.

- CAN: Pins 6 and 14 are present.

J1962F OBDII connector pinout

J1962F OBDII connector pinout

5.3. Using an OBD2 Scanner

Some OBD2 scanners have the ability to automatically detect the protocol used by the vehicle. Simply plug the scanner into the OBD2 port and follow the instructions to identify the protocol.

5.4. Consulting Online Databases

Several online databases provide information about OBD2 protocols based on vehicle make, model, and year. These databases can be a valuable resource when you’re unsure about your vehicle’s protocol.

6. OBD2 Connector Types and Locations

The OBD2 connector, also known as the Diagnostic Link Connector (DLC), is a standardized 16-pin connector used to access vehicle diagnostic information. There are two types of DLCs: Type A and Type B.

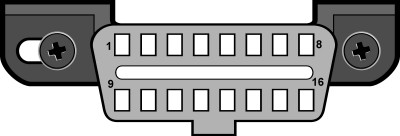

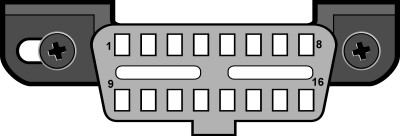

6.1. Type A and Type B Connectors

Type A and Type B connectors differ in the shape of their alignment tab. Type A connectors are more common and are typically found in passenger vehicles. Type B connectors are sometimes used in heavy-duty vehicles.

J1962F, Type A

J1962F, Type A

Fig. 1 – J1962 Vehicle Connector, Type A

J1962F, Type B

J1962F, Type B

Fig. 2 – J1962 Vehicle Connector, Type B

6.2. Standard OBD2 Connector Locations

According to SAE J1962, the OBD2 connector should be located in the passenger or driver’s compartment, easily accessible from the driver’s seat. The preferred location is between the steering column and the vehicle centerline.

6.3. Common OBD2 Connector Locations in Different Vehicles

While the location of the OBD2 connector is standardized, it can vary slightly between different vehicle makes and models. Here are some common locations:

- Mercedes-Benz: Under the dashboard on the driver’s side

- BMW: Under the dashboard on the driver’s side

- Toyota: Under the dashboard on the driver’s side or in the center console

- Honda: Under the dashboard on the driver’s side

- Ford: Under the dashboard on the driver’s side

7. Tools for Reading OBD2 Protocols

Several tools are available for reading OBD2 protocols, ranging from basic code readers to advanced diagnostic scanners.

7.1. Basic OBD2 Code Readers

Basic OBD2 code readers are inexpensive tools that can read diagnostic trouble codes (DTCs) from a vehicle’s computer. They typically display the code and a brief description of the issue.

7.2. Advanced Diagnostic Scanners

Advanced diagnostic scanners offer more comprehensive features, such as the ability to read live sensor data, perform actuation tests, and reset trouble codes. These scanners are used by professional mechanics and serious car enthusiasts.

7.3. Smartphone Apps and Adapters

Smartphone apps and adapters allow you to use your smartphone or tablet as an OBD2 scanner. These adapters plug into the OBD2 port and communicate with your device via Bluetooth or Wi-Fi.

7.4. Professional Diagnostic Software

Professional diagnostic software provides advanced diagnostic capabilities, such as ECU programming, coding, and advanced data analysis. This software is used by specialized repair shops and technicians.

8. Diagnosing Common Issues Using OBD2 Protocols

OBD2 protocols allow you to diagnose a wide range of issues, from engine problems to emission failures. Here are some common issues and how to diagnose them using OBD2:

8.1. Reading and Interpreting Diagnostic Trouble Codes (DTCs)

Diagnostic Trouble Codes (DTCs) are codes stored in a vehicle’s computer that indicate a specific issue or fault. OBD2 scanners can read these codes and provide a description of the problem. Interpreting DTCs correctly is essential for accurate diagnosis and repair.

8.2. Identifying Emission-Related Problems

OBD2 systems are designed to monitor and control vehicle emissions. By reading DTCs related to the emission system, you can identify problems such as catalytic converter failures, oxygen sensor issues, and evaporative emission control system leaks.

8.3. Detecting Engine Performance Issues

OBD2 protocols can help detect engine performance issues such as misfires, lean or rich conditions, and timing problems. By monitoring live sensor data, you can identify the root cause of these issues.

8.4. Troubleshooting Transmission Problems

Some OBD2 scanners can read transmission-related DTCs, allowing you to diagnose transmission problems such as slipping, harsh shifting, and incorrect gear ratios.

8.5. Addressing ABS and Brake System Faults

Advanced OBD2 scanners can also read ABS (Anti-lock Braking System) and brake system DTCs, helping you diagnose issues such as faulty wheel speed sensors, hydraulic control unit problems, and brake pad wear.

9. Advanced Uses of OBD2 Protocols

OBD2 protocols are not just for diagnosing problems; they can also be used for advanced functions such as performance tuning and data logging.

9.1. Performance Tuning and Customization

OBD2 protocols allow you to modify various engine parameters for performance tuning. By adjusting parameters such as fuel injection timing, ignition timing, and boost pressure, you can optimize engine performance for specific applications.

9.2. Data Logging and Analysis

OBD2 scanners can log real-time sensor data, allowing you to analyze vehicle performance under different conditions. This data can be used to identify performance bottlenecks, optimize fuel efficiency, and diagnose intermittent issues.

9.3. Monitoring Fuel Efficiency

OBD2 protocols provide data on fuel consumption, allowing you to monitor fuel efficiency and identify areas for improvement. By tracking fuel consumption over time, you can optimize driving habits and vehicle maintenance for better fuel economy.

9.4. Unlocking Hidden Features

Some advanced OBD2 tools can unlock hidden features in your vehicle, such as enabling daytime running lights, customizing interior lighting, and adjusting vehicle settings.

10. Future Trends in OBD Technology

OBD technology is constantly evolving to meet the demands of modern vehicles. Here are some future trends in OBD technology:

10.1. Enhanced Diagnostics and Remote Monitoring

Future OBD systems will offer enhanced diagnostic capabilities, including predictive maintenance and remote monitoring. These systems will be able to anticipate potential issues before they occur, reducing downtime and repair costs.

10.2. Integration with Telematics Systems

OBD technology will become increasingly integrated with telematics systems, providing real-time vehicle data to fleet managers and insurance companies. This data can be used to improve vehicle maintenance, optimize driving behavior, and reduce insurance costs.

10.3. Cybersecurity Considerations

As OBD systems become more connected, cybersecurity will become a critical concern. Future OBD systems will incorporate advanced security features to protect against hacking and unauthorized access.

10.4. Standardization of OBD-III

OBD-III is a proposed standard that would further enhance the diagnostic capabilities of OBD systems. OBD-III would require vehicles to report emission-related issues in real-time, allowing for faster detection and repair of emission problems.

11. Maintaining and Servicing Your Mercedes-Benz Using OBD2

Maintaining and servicing your Mercedes-Benz using OBD2 can help you keep your vehicle in top condition and prevent costly repairs.

11.1. Regular OBD2 Scans for Preventative Maintenance

Performing regular OBD2 scans can help you identify potential issues before they become major problems. By monitoring DTCs and sensor data, you can detect early signs of engine wear, emission problems, and other issues.

11.2. Resetting Service Lights and Maintenance Reminders

Many Mercedes-Benz vehicles use service lights and maintenance reminders to indicate when it’s time for routine maintenance. OBD2 scanners can be used to reset these lights and reminders after performing the necessary maintenance.

11.3. Verifying Repairs After Maintenance

After performing maintenance or repairs on your Mercedes-Benz, it’s essential to verify that the repairs were successful. OBD2 scanners can be used to monitor sensor data and ensure that all systems are functioning correctly.

11.4. Long-Term Benefits of Using OBD2 for Vehicle Health

Using OBD2 for vehicle health monitoring can provide long-term benefits, such as reduced repair costs, improved fuel efficiency, and extended vehicle life. By proactively addressing potential issues, you can keep your Mercedes-Benz running smoothly for years to come.

12. Common OBD2 Error Codes for Mercedes-Benz Vehicles

Understanding common OBD2 error codes for Mercedes-Benz vehicles can help you quickly identify and address potential issues.

12.1. P0400 Series: Exhaust Gas Recirculation (EGR) Issues

The P0400 series of codes indicates issues with the Exhaust Gas Recirculation (EGR) system. These codes may indicate a faulty EGR valve, clogged EGR passages, or other problems with the EGR system.

12.2. P0170 and P0173: Fuel Trim Problems

P0170 and P0173 codes indicate fuel trim problems, which can be caused by a variety of factors, such as vacuum leaks, faulty oxygen sensors, or fuel injector issues.

12.3. P0300 Series: Misfire Detection

The P0300 series of codes indicates misfire detection, which can be caused by faulty spark plugs, ignition coils, or fuel injectors.

12.4. P0420: Catalytic Converter Efficiency Below Threshold

The P0420 code indicates that the catalytic converter efficiency is below the threshold, which may indicate a failing catalytic converter or other emission-related problems.

12.5. Addressing Specific Mercedes-Benz Error Codes

When addressing specific Mercedes-Benz error codes, it’s essential to consult a repair manual or online database for detailed diagnostic and repair information. Following the recommended diagnostic procedures can help you accurately identify the root cause of the problem and perform the necessary repairs.

13. Resources for Learning More About OBD2 Protocols

Several resources are available for learning more about OBD2 protocols, including online forums, training courses, and technical publications.

13.1. Online Forums and Communities

Online forums and communities provide a valuable resource for sharing information and asking questions about OBD2 protocols. These forums often include experienced technicians and car enthusiasts who can provide helpful advice and guidance.

13.2. Training Courses and Workshops

Training courses and workshops offer in-depth instruction on OBD2 protocols and diagnostic techniques. These courses are often taught by experienced instructors and provide hands-on training with diagnostic tools.

13.3. Technical Publications and Manuals

Technical publications and manuals provide detailed information about OBD2 protocols, diagnostic procedures, and repair techniques. These resources can be invaluable for understanding the intricacies of OBD2 systems and performing accurate diagnostics.

13.4. OEM (Original Equipment Manufacturer) Resources

OEM resources, such as repair manuals and technical service bulletins, provide detailed information about specific vehicle makes and models. These resources can be essential for diagnosing and repairing complex issues.

14. Legal and Regulatory Aspects of OBD2

OBD2 systems are subject to various legal and regulatory requirements, particularly concerning emission control.

14.1. EPA Regulations and Compliance

The Environmental Protection Agency (EPA) regulates OBD2 systems to ensure that vehicles meet emission standards. Manufacturers are required to design and implement OBD2 systems that accurately monitor and control vehicle emissions.

14.2. State-Level Emission Testing Programs

Many states have emission testing programs that require vehicles to pass an OBD2-based emission test. These tests ensure that vehicles meet emission standards and are not contributing to air pollution.

14.3. Impact on Vehicle Modifications and Tuning

Modifying or tuning a vehicle’s OBD2 system can have legal consequences, particularly if it affects the vehicle’s emission control system. It’s essential to comply with all applicable laws and regulations when modifying or tuning a vehicle’s OBD2 system.

14.4. Ensuring Compliance with OBD2 Standards

To ensure compliance with OBD2 standards, it’s essential to use certified diagnostic tools and follow recommended diagnostic procedures. Regular OBD2 scans can help you identify potential issues and address them before they become major problems.

15. Case Studies: Real-World Applications of OBD2 Protocols

Real-world case studies can illustrate the practical applications of OBD2 protocols in diagnosing and repairing vehicle issues.

15.1. Diagnosing Intermittent Misfires in a Mercedes-Benz C-Class

In one case study, a Mercedes-Benz C-Class was experiencing intermittent misfires. By using an OBD2 scanner to monitor live sensor data, the technician identified a faulty ignition coil that was causing the misfires. Replacing the ignition coil resolved the issue.

15.2. Identifying a Faulty Oxygen Sensor in a BMW 3 Series

Another case study involved a BMW 3 Series with poor fuel economy. An OBD2 scan revealed a code indicating a faulty oxygen sensor. Replacing the oxygen sensor improved fuel economy and resolved the issue.

15.3. Resolving Transmission Issues in a Toyota Camry

In a third case study, a Toyota Camry was experiencing harsh shifting. An advanced OBD2 scanner revealed transmission-related DTCs. Further diagnosis identified a faulty transmission solenoid, which was replaced to resolve the issue.

15.4. Addressing Emission Problems in a Ford F-150

A Ford F-150 failed an emission test due to a code indicating a problem with the evaporative emission control system. An OBD2 scan revealed a leak in the fuel vapor recovery system. Repairing the leak allowed the vehicle to pass the emission test.

16. Choosing the Right OBD2 Tool for Your Needs

Choosing the right OBD2 tool depends on your specific needs and budget. Here are some factors to consider:

16.1. Consider Your Vehicle Make and Model

Some OBD2 tools are designed to work with specific vehicle makes and models. Consider your vehicle’s make and model when choosing an OBD2 tool to ensure compatibility.

16.2. Determine Your Diagnostic Needs

Determine your diagnostic needs before choosing an OBD2 tool. If you only need to read basic DTCs, a basic code reader may suffice. If you need more advanced features, such as live sensor data and actuation tests, you’ll need an advanced diagnostic scanner.

16.3. Set a Budget for Your OBD2 Tool

OBD2 tools range in price from inexpensive code readers to high-end diagnostic scanners. Set a budget for your OBD2 tool and choose a tool that meets your needs without breaking the bank.

16.4. Read Reviews and Compare Features

Read reviews and compare features before choosing an OBD2 tool. Look for tools with positive reviews and features that meet your diagnostic needs.

17. Expert Tips for Using OBD2 Scanners Effectively

Using OBD2 scanners effectively requires some knowledge and skill. Here are some expert tips:

17.1. Always Start with a Full Vehicle Scan

Always start with a full vehicle scan to identify all DTCs and potential issues. This will provide a comprehensive overview of the vehicle’s health.

17.2. Research DTCs Thoroughly

Research DTCs thoroughly to understand the potential causes and recommended diagnostic procedures. Use repair manuals, online databases, and technical service bulletins to gather information.

17.3. Monitor Live Sensor Data for Accurate Diagnosis

Monitor live sensor data to identify the root cause of problems. By observing sensor readings under different conditions, you can pinpoint the source of the issue.

17.4. Perform Actuation Tests to Verify Component Function

Perform actuation tests to verify the function of components. Actuation tests allow you to control individual components and observe their response.

17.5. Clear DTCs After Repairs and Verify the Fix

Clear DTCs after performing repairs and verify that the fix was successful. Monitor the vehicle for any recurring codes or issues.

18. Common Pitfalls to Avoid When Using OBD2

Using OBD2 can be a valuable tool for diagnosing and repairing vehicle issues, but it’s essential to avoid common pitfalls.

18.1. Misinterpreting DTCs Without Proper Research

Misinterpreting DTCs without proper research can lead to incorrect diagnoses and unnecessary repairs. Always research DTCs thoroughly before taking action.

18.2. Relying Solely on DTCs Without Analyzing Sensor Data

Relying solely on DTCs without analyzing sensor data can result in incomplete diagnoses. Sensor data provides valuable insights into the vehicle’s performance and can help you identify the root cause of problems.

18.3. Neglecting Basic Mechanical Checks

Neglecting basic mechanical checks can lead to misdiagnoses. Always perform basic mechanical checks, such as inspecting for vacuum leaks and checking fluid levels, before relying on OBD2 data.

18.4. Overlooking Intermittent Problems

Overlooking intermittent problems can make diagnosis difficult. Monitor the vehicle for recurring codes or issues and use data logging to capture intermittent events.

19. Ethical Considerations in Using OBD2 Data

Using OBD2 data raises ethical considerations, particularly concerning privacy and data security.

19.1. Protecting Vehicle Owner Privacy

Protecting vehicle owner privacy is essential when using OBD2 data. Avoid sharing sensitive information without the owner’s consent and implement security measures to protect against unauthorized access.

19.2. Ensuring Data Security and Confidentiality

Ensure data security and confidentiality when using OBD2 data. Use secure communication protocols and encryption to protect against data breaches.

19.3. Adhering to Data Protection Regulations

Adhere to data protection regulations, such as GDPR and CCPA, when using OBD2 data. These regulations require you to obtain consent before collecting and using personal data.

19.4. Responsible Use of Vehicle Information

Use vehicle information responsibly and avoid using it for purposes that could harm or exploit vehicle owners. Always prioritize the safety and well-being of vehicle owners.

20. FAQs About OBD2 Protocols

Here are some frequently asked questions about OBD2 protocols:

20.1. What is the best OBD2 scanner for Mercedes-Benz vehicles?

The best OBD2 scanner for Mercedes-Benz vehicles depends on your specific needs and budget. Some popular options include the Autel MaxiSys, the iCarsoft MB II, and the BlueDriver Bluetooth Professional OBDII Scan Tool.

20.2. How do I find the OBD2 port in my car?

The OBD2 port is typically located under the dashboard on the driver’s side, between the steering column and the vehicle centerline.

20.3. Can I use any OBD2 scanner on any car?

Yes, you can use any OBD2 scanner on any OBD2-compliant car. However, some scanners may offer more features and compatibility for specific vehicle makes and models.

20.4. What does a P0420 code mean?

A P0420 code indicates that the catalytic converter efficiency is below the threshold.

20.5. How do I reset the check engine light?

You can reset the check engine light using an OBD2 scanner. Simply read the DTCs, perform the necessary repairs, and then use the scanner to clear the codes.

20.6. What is the difference between OBD1 and OBD2?

OBD1 is an earlier, non-standardized diagnostic system, while OBD2 is a standardized system that provides more comprehensive diagnostic information.

20.7. Can OBD2 tools unlock hidden features in my car?

Some advanced OBD2 tools can unlock hidden features in your car, such as enabling daytime running lights and customizing interior lighting.

20.8. How often should I scan my car with an OBD2 scanner?

You should scan your car with an OBD2 scanner regularly, especially if you notice any performance issues or warning lights.

20.9. Are there any risks associated with using OBD2 scanners?

There are minimal risks associated with using OBD2 scanners, as long as you follow the instructions and use a certified tool.

20.10. Where can I find reliable information about OBD2 protocols?

You can find reliable information about OBD2 protocols from online forums, training courses, technical publications, and OEM resources.

Understanding OBD2 protocols is essential for diagnosing and repairing modern vehicles, and MERCEDES-DIAGNOSTIC-TOOL.EDU.VN is here to guide you every step of the way. By familiarizing yourself with the different protocols, connector types, and diagnostic tools, you can keep your Mercedes-Benz in top condition and prevent costly repairs.

Ready to take control of your Mercedes-Benz diagnostics? Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN today for expert guidance on OBD2 tools, unlocking hidden features, and comprehensive repair solutions. Visit us at 789 Oak Avenue, Miami, FL 33101, United States, or reach out via Whatsapp at +1 (641) 206-8880. Explore our website at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for more information. Let us help you keep your Mercedes-Benz running smoothly and efficiently!