Typical live data values for Mercedes climate control button parameters usually involve voltage readings, temperature sensors, and switch status indicators. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we provide precise diagnostic tools and expertise to ensure your Mercedes climate control system functions optimally. By understanding these parameters, you can effectively troubleshoot and maintain your vehicle’s climate control system.

Contents

- 1. Understanding Mercedes-Benz Climate Control Systems

- 1.1 Key Components of Mercedes Climate Control Systems

- 1.2 Role of Live Data in Climate Control Diagnostics

- 1.3 Common Issues in Mercedes Climate Control Systems

- 2. Identifying Key Climate Control Button Parameters

- 2.1 Temperature Setting Parameters

- 2.2 Fan Speed Parameters

- 2.3 Air Distribution Mode Parameters

- 2.4 Auxiliary Function Parameters

- 3. Deciphering Live Data Values: What to Look For

- 3.1 Temperature Sensor Readings

- 3.2 Pressure Sensor Readings

- 3.3 Actuator and Motor Values

- 3.4 Diagnostic Trouble Codes (DTCs) and Their Interpretation

- 4. Tools for Reading Mercedes Climate Control Live Data

- 4.1 Professional Diagnostic Scanners

- 4.2 OBD-II Adapters and Smartphone Apps

- 4.3 MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Solutions

- 5. Step-by-Step Guide to Diagnosing Climate Control Issues Using Live Data

- 5.1 Initial Inspection and Symptom Verification

- 5.2 Connecting the Diagnostic Tool and Reading DTCs

- 5.3 Monitoring Live Data Parameters

- 5.4 Analyzing Data and Identifying Discrepancies

- 5.5 Performing Actuator Tests and Component Checks

- 5.6 Verifying Repairs with Live Data

- 6. Typical Live Data Values for Specific Mercedes Models

- 6.1 Mercedes C-Class (W205)

- 6.2 Mercedes E-Class (W213)

- 6.3 Mercedes S-Class (W222)

- 7. Advanced Diagnostics and Coding Options

- 7.1 Recoding Climate Control Modules

- 7.2 Activating Hidden Features

- 7.3 Addressing Software Glitches

- 8. Maintenance Tips for Optimal Climate Control Performance

- 8.1 Regular Refrigerant Checks and Recharging

- 8.2 Cleaning or Replacing Cabin Air Filters

- 8.3 Inspecting and Cleaning Condenser Fins

- 8.4 Checking and Maintaining Belts and Hoses

- 9. Case Studies: Real-World Examples of Live Data Diagnostics

- 9.1 Case Study 1: Lack of Cooling in a C-Class (W205)

- 9.2 Case Study 2: Weak Airflow in an E-Class (W213)

- 9.3 Case Study 3: Incorrect Temperature Control in an S-Class (W222)

- 10. The Future of Climate Control Diagnostics

- 10.1 AI-Powered Diagnostics

- 10.2 Remote Diagnostics and Over-the-Air Updates

- 10.3 Integration with Vehicle Health Monitoring Systems

- FAQ: Frequently Asked Questions

- 1. What is the typical refrigerant pressure for a Mercedes-Benz climate control system?

- 2. How often should I recharge my Mercedes-Benz climate control system?

- 3. What are the common causes of a Mercedes-Benz climate control system not cooling?

- 4. Can I diagnose climate control issues with a basic OBD-II scanner?

- 5. How do I check the cabin air filter in my Mercedes-Benz?

- 6. What is the purpose of the evaporator temperature sensor?

- 7. How do I know if my blower motor resistor is faulty?

- 8. Can I add refrigerant to my climate control system myself?

- 9. What is the role of the climate control module?

- 10. How can I improve the efficiency of my Mercedes-Benz climate control system?

Navigating Mercedes climate control systems requires understanding live data values for parameters. This article dives deep into typical values for Mercedes climate control button parameters, enhanced diagnostic tools, and maintenance strategies. We’ll explore how to use real-time data to diagnose issues, optimize performance, and maintain the comfort of your ride. Let’s discuss Mercedes climate control diagnostics, climate control parameters, Mercedes climate control repair, Mercedes diagnostics.

1. Understanding Mercedes-Benz Climate Control Systems

Mercedes-Benz climate control systems are sophisticated, integrating numerous sensors, actuators, and control modules to maintain cabin comfort. These systems rely on real-time data from various parameters to function efficiently. Knowing typical live data values is essential for diagnosing issues and ensuring optimal performance.

1.1 Key Components of Mercedes Climate Control Systems

The Mercedes climate control system comprises several key components working in harmony. These include:

- Compressor: Circulates refrigerant.

- Condenser: Dissipates heat from the refrigerant.

- Evaporator: Absorbs heat from the cabin air.

- Expansion Valve: Controls refrigerant flow.

- Blower Motor: Circulates air through the system.

- Temperature Sensors: Monitor temperature at various points.

- Control Module: Manages the system based on sensor inputs and user settings.

Understanding these components provides a foundation for interpreting live data values accurately.

1.2 Role of Live Data in Climate Control Diagnostics

Live data provides real-time information about the operating conditions of the climate control system. This data includes temperature readings, pressure values, actuator positions, and switch statuses. By monitoring these parameters, technicians can identify anomalies that indicate potential issues. Live data helps in:

- Pinpointing Faults: Identifying components that are not functioning correctly.

- Verifying Repairs: Ensuring that repairs have resolved the underlying problem.

- Optimizing Performance: Adjusting system settings for maximum efficiency.

- Preventative Maintenance: Detecting early signs of wear or failure.

Real-time data analysis is crucial for effective diagnostics and maintenance.

1.3 Common Issues in Mercedes Climate Control Systems

Several common issues can affect Mercedes climate control systems. These include:

- Refrigerant Leaks: Resulting in reduced cooling capacity.

- Compressor Failure: Leading to no cooling.

- Blower Motor Issues: Causing weak or no airflow.

- Sensor Malfunctions: Providing incorrect temperature readings.

- Actuator Problems: Affecting air distribution.

Recognizing these common problems helps in focusing diagnostic efforts on the most likely causes.

2. Identifying Key Climate Control Button Parameters

Climate control buttons on a Mercedes-Benz provide user input that dictates the system’s operation. Each button corresponds to specific parameters that can be monitored through live data. Key parameters include temperature settings, fan speed, air distribution modes, and auxiliary functions like defrost and recirculation.

2.1 Temperature Setting Parameters

Temperature setting parameters reflect the desired cabin temperature. These parameters are typically measured in degrees Celsius or Fahrenheit and are set by the user through the climate control interface. Live data monitoring can reveal if the system is accurately responding to these settings.

- Set Point Temperature: The target temperature set by the user.

- Actual Temperature: The temperature measured by sensors in the cabin.

- Temperature Difference: The deviation between the set point and actual temperatures.

Monitoring these parameters helps diagnose issues related to temperature regulation.

2.2 Fan Speed Parameters

Fan speed parameters control the rate at which air is circulated through the cabin. These parameters are usually represented as a percentage or a numerical value corresponding to different fan speed levels. Live data can indicate whether the blower motor is responding correctly to fan speed adjustments.

- Requested Fan Speed: The fan speed level selected by the user.

- Actual Fan Speed: The measured speed of the blower motor.

- Blower Motor Voltage: The voltage supplied to the blower motor, which correlates with fan speed.

Analyzing these parameters can help identify blower motor or control module issues.

2.3 Air Distribution Mode Parameters

Air distribution mode parameters determine where air is directed within the cabin, such as to the face, feet, or windshield. These parameters are controlled by actuators that adjust the position of air vents. Live data can show the status of these actuators and confirm that they are functioning correctly.

- Selected Air Distribution Mode: The mode chosen by the user (e.g., face, feet, defrost).

- Actuator Positions: The positions of the actuators controlling air vent direction.

- Feedback Signals: Signals from the actuators confirming their positions.

Monitoring these parameters can help diagnose problems with air distribution and actuator functionality.

2.4 Auxiliary Function Parameters

Auxiliary function parameters include settings for defrost, recirculation, and other special features. These parameters can be monitored to ensure that these functions are operating as intended. Live data can show the status of these functions and related components.

- Defrost Status: Indicates whether the defrost function is active.

- Recirculation Status: Shows whether the cabin air is being recirculated.

- Compressor Engagement: Confirms whether the compressor is engaged for cooling.

Checking these parameters can help diagnose issues with auxiliary functions and their associated components.

3. Deciphering Live Data Values: What to Look For

Interpreting live data values requires understanding the expected ranges for various parameters. Deviations from these ranges can indicate specific problems within the climate control system.

3.1 Temperature Sensor Readings

Temperature sensors provide critical data for the climate control system. Typical values vary depending on the sensor’s location and the ambient conditions.

- Ambient Temperature Sensor: Measures the outside air temperature. Expected values should correlate with the actual outdoor temperature.

- Cabin Temperature Sensor: Measures the air temperature inside the cabin. Values should reflect the set point temperature and the system’s ability to maintain it.

- Evaporator Temperature Sensor: Monitors the temperature of the evaporator core. Readings that are too high or too low can indicate refrigerant issues or sensor malfunctions.

- Coolant Temperature Sensor: Measures the engine coolant temperature. This affects the climate control system’s ability to provide heat.

Monitoring these sensor readings is crucial for diagnosing temperature-related issues.

3.2 Pressure Sensor Readings

Pressure sensors monitor the refrigerant pressure within the climate control system. Typical values depend on the system’s operating state and ambient temperature.

- High-Side Pressure Sensor: Measures the pressure on the discharge side of the compressor. High readings can indicate a blockage, while low readings may suggest a refrigerant leak.

- Low-Side Pressure Sensor: Measures the pressure on the suction side of the compressor. Low readings can indicate a refrigerant leak or a faulty compressor.

Analyzing these pressure readings helps diagnose refrigerant and compressor-related problems.

3.3 Actuator and Motor Values

Actuators and motors control various components within the climate control system, such as air distribution flaps and the blower motor. Live data values include voltage, current, and position feedback.

- Air Distribution Actuators: Voltage and position feedback signals indicate whether the actuators are moving to the correct positions.

- Blower Motor Voltage: The voltage supplied to the blower motor determines the fan speed. Deviations from expected values can indicate a motor or control module issue.

- Compressor Clutch Engagement: A signal indicating whether the compressor clutch is engaged. Lack of engagement can prevent cooling.

Monitoring these values helps diagnose issues with actuators, motors, and their control circuits.

3.4 Diagnostic Trouble Codes (DTCs) and Their Interpretation

Diagnostic Trouble Codes (DTCs) are codes stored in the vehicle’s computer system when a fault is detected. These codes can provide valuable information about the nature and location of the problem. Common DTCs related to climate control systems include:

- B1000-B1999: Body-related codes, often associated with climate control issues.

- P05xx: Codes related to air conditioning compressor clutch circuit malfunctions.

- P06xx: Codes associated with blower motor control circuit problems.

Understanding these codes helps narrow down the possible causes of climate control issues.

4. Tools for Reading Mercedes Climate Control Live Data

Several tools are available for reading live data from Mercedes climate control systems. These range from professional-grade diagnostic scanners to smartphone-based OBD-II adapters.

4.1 Professional Diagnostic Scanners

Professional diagnostic scanners provide comprehensive access to vehicle systems, including climate control. These tools offer advanced features such as:

- Real-Time Data Streaming: Displaying live data from multiple sensors and actuators.

- DTC Reading and Clearing: Retrieving and clearing diagnostic trouble codes.

- Actuator Testing: Commanding actuators to perform specific actions for testing purposes.

- System Programming: Updating software and configuring system settings.

Examples of professional diagnostic scanners include the Mercedes-Benz Star Diagnosis system, Autel MaxiSys, and Snap-on Modis.

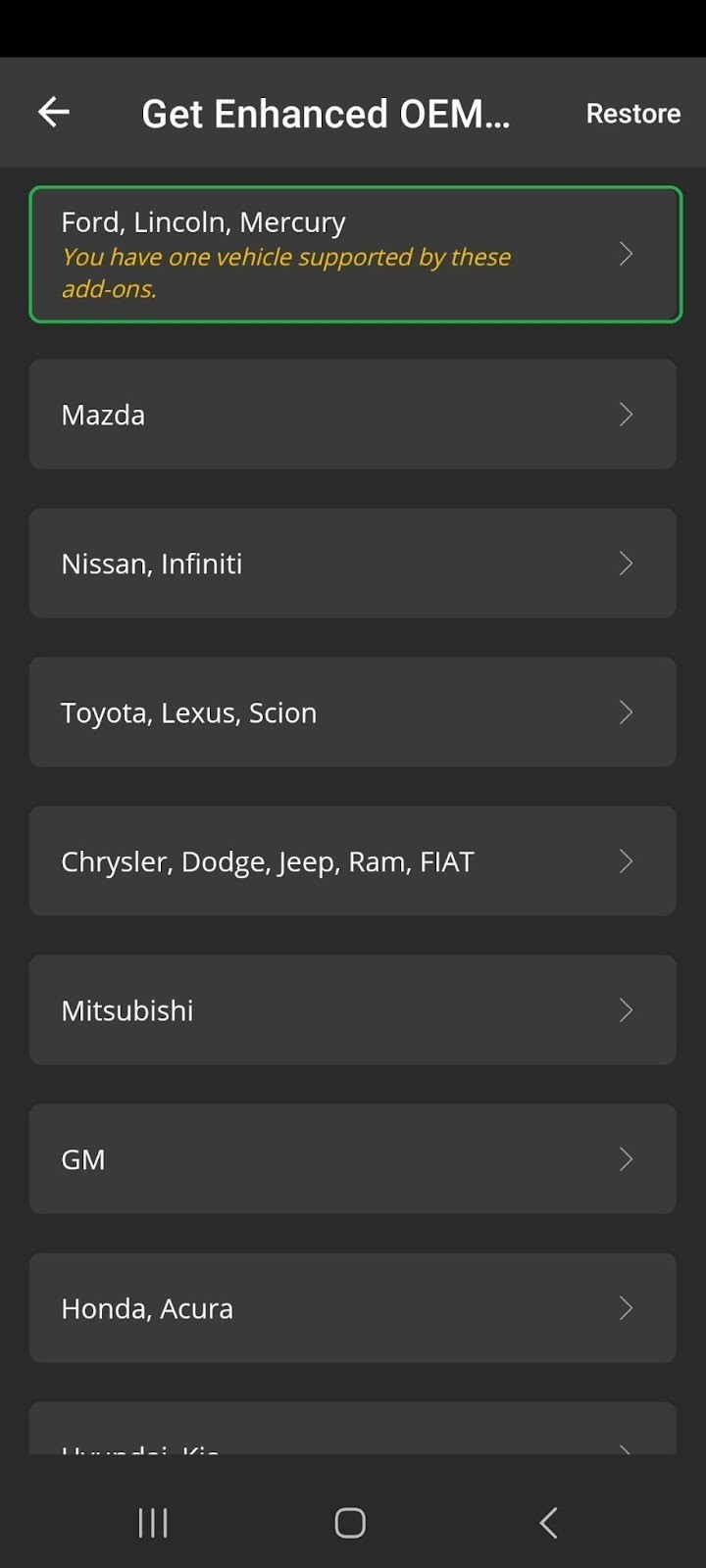

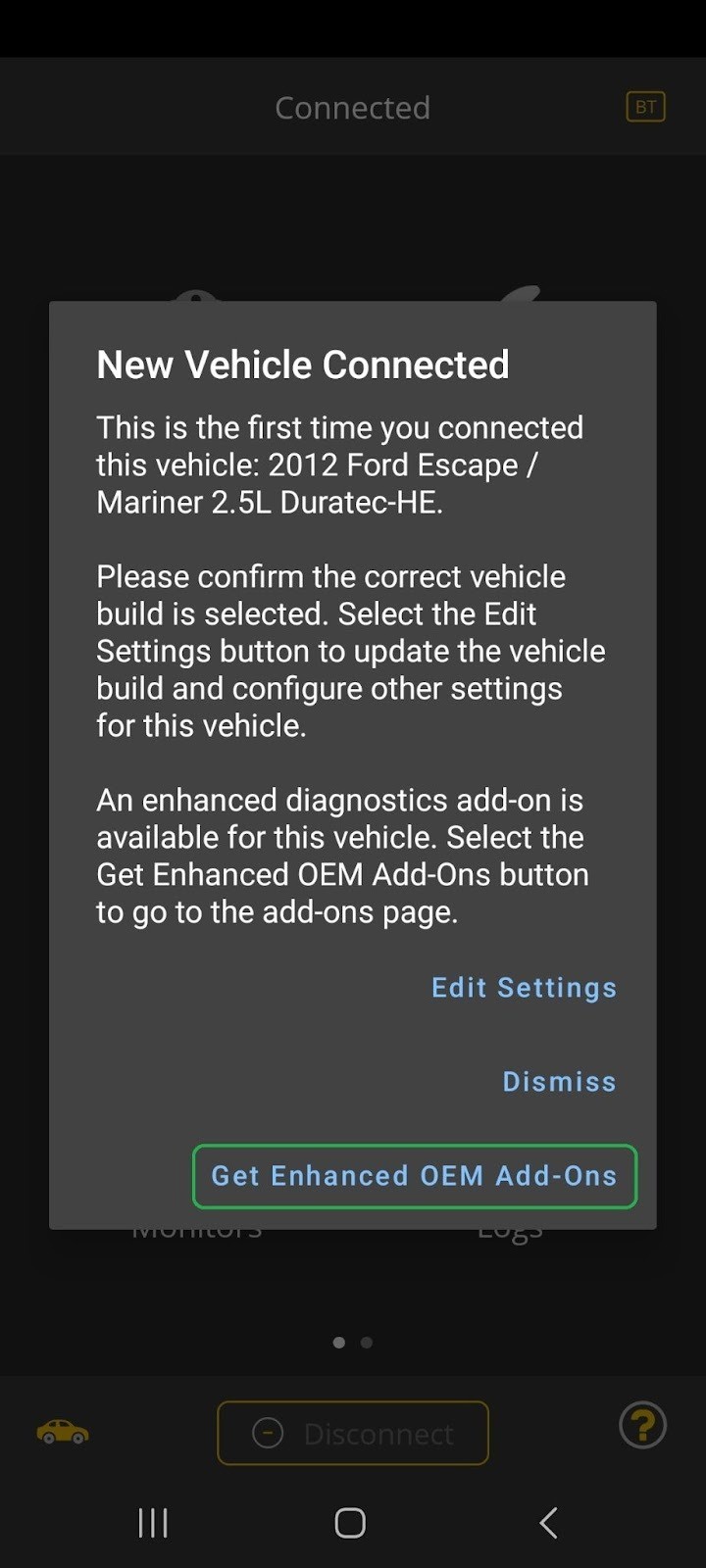

4.2 OBD-II Adapters and Smartphone Apps

OBD-II adapters connect to the vehicle’s diagnostic port and communicate with a smartphone or tablet via Bluetooth or Wi-Fi. These adapters, combined with diagnostic apps, can provide access to live data and DTCs.

- OBDLink MX+: A popular OBD-II adapter that supports enhanced diagnostics for Mercedes-Benz vehicles.

- Carly for Mercedes: A smartphone app that offers advanced diagnostic and coding features for Mercedes-Benz vehicles.

- Torque Pro: A customizable OBD-II app that can display live data and read DTCs from various vehicle systems.

These tools offer a cost-effective way to access valuable diagnostic information.

4.3 MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Solutions

At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we offer a range of diagnostic tools and services specifically tailored for Mercedes-Benz vehicles. Our solutions include:

- Diagnostic Software: Advanced software that provides in-depth access to vehicle systems and live data.

- OBD-II Adapters: High-quality adapters designed for reliable communication with Mercedes-Benz vehicles.

- Remote Diagnostic Services: Expert technicians who can remotely diagnose and troubleshoot issues with your vehicle’s climate control system.

- Training and Support: Comprehensive training materials and support to help you effectively use our diagnostic tools and interpret live data.

Our solutions are designed to empower Mercedes-Benz owners and technicians with the tools and knowledge they need to maintain and repair their vehicles. For expert assistance, contact us at 789 Oak Avenue, Miami, FL 33101, United States, or WhatsApp at +1 (641) 206-8880. Visit our website at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for more information.

5. Step-by-Step Guide to Diagnosing Climate Control Issues Using Live Data

Diagnosing climate control issues using live data involves a systematic approach. Follow these steps to effectively troubleshoot problems and identify the root cause.

5.1 Initial Inspection and Symptom Verification

Begin by performing a visual inspection of the climate control system. Check for obvious signs of damage, such as leaks or broken components. Verify the symptoms reported by the user, such as lack of cooling, weak airflow, or incorrect temperature.

5.2 Connecting the Diagnostic Tool and Reading DTCs

Connect the diagnostic tool to the vehicle’s OBD-II port and read any stored Diagnostic Trouble Codes (DTCs). Record these codes and research their possible causes. Clear the codes and recheck after a test drive to see if any codes reappear.

5.3 Monitoring Live Data Parameters

Select the relevant live data parameters to monitor, such as temperature sensor readings, pressure sensor values, actuator positions, and blower motor voltage. Observe these parameters while operating the climate control system under different conditions.

5.4 Analyzing Data and Identifying Discrepancies

Compare the live data values with the expected ranges. Look for discrepancies that indicate potential problems. For example, a temperature sensor reading that is significantly different from the actual temperature could indicate a sensor malfunction.

5.5 Performing Actuator Tests and Component Checks

Use the diagnostic tool to perform actuator tests. This involves commanding actuators to move to specific positions and verifying that they respond correctly. Check the operation of other components, such as the blower motor and compressor clutch, using appropriate testing methods.

5.6 Verifying Repairs with Live Data

After performing repairs, use live data to verify that the issues have been resolved. Monitor the relevant parameters to ensure that they are now within the expected ranges. Clear any remaining DTCs and recheck after a test drive.

6. Typical Live Data Values for Specific Mercedes Models

While general guidelines apply to all Mercedes-Benz climate control systems, specific models may have unique characteristics and expected data ranges. Here are some examples:

6.1 Mercedes C-Class (W205)

- Evaporator Temperature: 2-8°C (35-46°F) during cooling operation.

- High-Side Pressure: 1500-2500 kPa (220-360 psi) depending on ambient temperature.

- Low-Side Pressure: 200-400 kPa (30-60 psi).

- Blower Motor Voltage: Varies with fan speed setting, typically 6-14V.

6.2 Mercedes E-Class (W213)

- Cabin Temperature Sensor: Should match set point temperature ±2°C (±4°F).

- High-Side Pressure: 1600-2600 kPa (230-380 psi).

- Low-Side Pressure: 250-450 kPa (35-65 psi).

- Air Distribution Actuators: Position feedback signals should indicate correct vent positions.

6.3 Mercedes S-Class (W222)

- Evaporator Temperature: 3-9°C (37-48°F).

- High-Side Pressure: 1700-2700 kPa (250-390 psi).

- Low-Side Pressure: 300-500 kPa (40-70 psi).

- Compressor Clutch Engagement: Should engage when cooling is requested.

Note: These values are approximate and can vary depending on ambient conditions and system configuration. Always consult the vehicle’s service manual for specific data ranges.

7. Advanced Diagnostics and Coding Options

In addition to basic live data monitoring, advanced diagnostic tools offer coding and programming options that can enhance the functionality of the climate control system.

7.1 Recoding Climate Control Modules

Recoding climate control modules can allow for customization of certain features, such as adjusting the sensitivity of temperature sensors or modifying the behavior of air distribution actuators. This requires specialized software and expertise.

7.2 Activating Hidden Features

Some Mercedes-Benz models have hidden features that can be activated through coding. These may include enhanced air filtration modes, automatic recirculation based on air quality, or customized fan speed settings.

7.3 Addressing Software Glitches

Software glitches can sometimes cause climate control issues. Updating the software in the climate control module can resolve these problems and improve system performance.

Warning: Coding and programming should only be performed by qualified technicians with the necessary tools and knowledge. Incorrect coding can cause serious problems with the climate control system and other vehicle functions.

8. Maintenance Tips for Optimal Climate Control Performance

Regular maintenance is essential for ensuring optimal performance and longevity of the Mercedes-Benz climate control system.

8.1 Regular Refrigerant Checks and Recharging

Refrigerant levels should be checked periodically and recharged as needed. Low refrigerant levels can reduce cooling capacity and cause damage to the compressor.

8.2 Cleaning or Replacing Cabin Air Filters

Cabin air filters should be cleaned or replaced regularly to maintain good air quality inside the vehicle. Clogged filters can reduce airflow and cause musty odors.

8.3 Inspecting and Cleaning Condenser Fins

The condenser fins should be inspected and cleaned to ensure efficient heat transfer. Dirt and debris can reduce the condenser’s ability to dissipate heat, leading to reduced cooling performance.

8.4 Checking and Maintaining Belts and Hoses

Belts and hoses should be checked for wear and damage. Worn or damaged belts can cause the compressor to malfunction, while leaking hoses can result in refrigerant loss.

9. Case Studies: Real-World Examples of Live Data Diagnostics

Here are some real-world examples of how live data can be used to diagnose climate control issues:

9.1 Case Study 1: Lack of Cooling in a C-Class (W205)

- Symptom: Lack of cooling despite the compressor running.

- DTCs: None.

- Live Data Analysis: Low-side pressure was significantly lower than expected.

- Diagnosis: Refrigerant leak.

- Solution: Repaired the leak and recharged the system.

9.2 Case Study 2: Weak Airflow in an E-Class (W213)

- Symptom: Weak airflow from the vents.

- DTCs: B1023 – Blower motor fault.

- Live Data Analysis: Blower motor voltage was lower than expected.

- Diagnosis: Faulty blower motor resistor.

- Solution: Replaced the blower motor resistor.

9.3 Case Study 3: Incorrect Temperature Control in an S-Class (W222)

- Symptom: The cabin temperature did not match the set point.

- DTCs: None.

- Live Data Analysis: Cabin temperature sensor reading was inaccurate.

- Diagnosis: Faulty cabin temperature sensor.

- Solution: Replaced the cabin temperature sensor.

10. The Future of Climate Control Diagnostics

The future of climate control diagnostics will likely involve more advanced technologies and data analysis methods.

10.1 AI-Powered Diagnostics

Artificial intelligence (AI) could be used to analyze live data and identify potential issues more quickly and accurately. AI algorithms could learn from historical data and recognize patterns that indicate specific problems.

10.2 Remote Diagnostics and Over-the-Air Updates

Remote diagnostics will become more common, allowing technicians to diagnose and troubleshoot climate control issues remotely. Over-the-air software updates could be used to address software glitches and improve system performance.

10.3 Integration with Vehicle Health Monitoring Systems

Climate control diagnostics will be integrated with vehicle health monitoring systems, providing real-time information about the system’s performance. This will allow for proactive maintenance and early detection of potential issues.

FAQ: Frequently Asked Questions

1. What is the typical refrigerant pressure for a Mercedes-Benz climate control system?

Typical refrigerant pressures vary depending on the model and operating conditions, but generally, the high-side pressure should be between 1500-2700 kPa (220-390 psi), and the low-side pressure should be between 200-500 kPa (30-70 psi).

2. How often should I recharge my Mercedes-Benz climate control system?

It is generally recommended to check the refrigerant level every 2-3 years and recharge as needed.

3. What are the common causes of a Mercedes-Benz climate control system not cooling?

Common causes include refrigerant leaks, compressor failure, faulty sensors, and blocked condenser fins.

4. Can I diagnose climate control issues with a basic OBD-II scanner?

A basic OBD-II scanner can read some DTCs related to the climate control system, but advanced diagnostic tools are needed to monitor live data and perform actuator tests.

5. How do I check the cabin air filter in my Mercedes-Benz?

The location of the cabin air filter varies depending on the model, but it is typically located behind the glove box or under the hood near the windshield. Refer to your vehicle’s owner’s manual for specific instructions.

6. What is the purpose of the evaporator temperature sensor?

The evaporator temperature sensor monitors the temperature of the evaporator core to prevent it from freezing.

7. How do I know if my blower motor resistor is faulty?

Symptoms of a faulty blower motor resistor include the blower motor only working on certain speeds or not working at all.

8. Can I add refrigerant to my climate control system myself?

It is generally recommended to have a qualified technician recharge the system, as overcharging or using the wrong type of refrigerant can damage the system.

9. What is the role of the climate control module?

The climate control module manages the operation of the entire climate control system based on sensor inputs and user settings.

10. How can I improve the efficiency of my Mercedes-Benz climate control system?

Regular maintenance, such as checking refrigerant levels, cleaning condenser fins, and replacing cabin air filters, can help improve efficiency.

Understanding typical live data values for Mercedes climate control button parameters is crucial for effective diagnostics and maintenance. By using the right tools and following a systematic approach, you can identify issues, optimize performance, and ensure the comfort of your ride.

Need expert assistance with your Mercedes-Benz climate control system? Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN at 789 Oak Avenue, Miami, FL 33101, United States, or WhatsApp at +1 (641) 206-8880. Visit our website at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for more information.

Mercedes-Benz climate control panel

Mercedes-Benz climate control panel

OBDLink MX+ adapter connected to a Mercedes-Benz

OBDLink MX+ adapter connected to a Mercedes-Benz

Ready to optimize your Mercedes climate control system? Contact us at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for expert diagnostics and support. Reach us at 789 Oak Avenue, Miami, FL 33101, United States, or WhatsApp at +1 (641) 206-8880. Let us help you maintain your vehicle’s comfort and performance.