Diagnostic Trouble Codes (DTCs) decoding can be achieved in more detail by leveraging specialized tools and resources like those offered by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, which provides in-depth insights and tools for interpreting complex diagnostic data. By understanding UDS protocols and accessing comprehensive databases, you can unlock enhanced diagnostic capabilities, ensuring precise vehicle maintenance and issue resolution. This approach helps you stay ahead with advanced fault code analysis and efficient automotive repairs.

Contents

- 1. What is the UDS Protocol and How Does It Help Decode DTCs?

- 2. How Does UDS Relate to CAN Bus and the OSI Model in Decoding DTCs?

- 3. What are the Key UDS Standards and Concepts for Detailed DTC Decoding?

- 4. What is UDSonCAN and DoCAN, and How Do They Impact DTC Interpretation?

- 5. Does UDS Specify a Standard Connector for DTC Decoding?

- 6. What is the Structure of a UDS Message Frame and How Does It Aid DTC Decoding?

- 7. How Do Positive and Negative UDS Responses Affect DTC Decoding?

- 8. What is CAN ISO-TP and How Does It Facilitate Detailed DTC Communication?

- 9. What are the Differences Between UDS, OBD2, WWH-OBD, and OBDonUDS in Terms of DTC Decoding?

- 10. What is WWH-OBD (ISO 27145) and How Does It Improve DTC Decoding?

- 11. What is OBDonUDS (SAE J1979-2) and Why is It Important for DTC Decoding in the US?

- 12. How Can You Request and Record UDS Data for Effective DTC Analysis?

- 13. What are the Common Use Cases for Recording UDS Data to Better Understand DTCs?

- 14. Why is UDS Considered a Manufacturer-Specific Diagnostic Protocol for DTCs?

- 15. How Does UDS Data Logging Benefit Automotive Engineers in Decoding DTCs Effectively?

- 16. Is UDS Data Logging Relevant for Aftermarket Users in Decoding DTCs?

- 17. When Should UDS Be Used Instead of Raw CAN Data for DTC Decoding?

- 18. Can Most Vehicles Be Assumed to Support UDS Communication for DTC Decoding?

- 19. Will UDS Replace OBD2 for DTC Decoding in the Future?

- 20. How Can UDS Be Used to Record Single Frame Data for Speed via WWH-OBD for DTC Decoding?

- 21. How Can UDS Be Used to Record Multi-Frame Data for EV State of Charge (SoC%) for Enhanced DTC Decoding?

- 22. What is the Process for Decoding Multi-Frame UDS Data for DTC Analysis?

- 23. How Can the Vehicle Identification Number (VIN) Be Recorded via UDS for Vehicle Diagnostics and DTC Correlation?

- 24. How Can Diagnostic Trouble Codes (DTCs) Be Recorded via WWH-OBD for Advanced Vehicle Analysis?

- 25. What Are Some Practical Applications of UDS Data Logging in Decoding DTCs?

- 26. What Tools and Resources Does MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Offer for Decoding DTCs in Detail?

- 27. How Can Detailed DTC Decoding Improve Vehicle Maintenance and Repair?

- 28. What Steps Can Individuals Take to Learn More About Detailed DTC Decoding Techniques?

- 29. What are the Benefits of Staying Updated on the Latest Advancements in DTC Decoding?

- 30. How Does MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Support the Automotive Community in Mastering Detailed DTC Decoding?

1. What is the UDS Protocol and How Does It Help Decode DTCs?

The Unified Diagnostic Services (UDS) protocol is a communication protocol used in automotive Electronic Control Units (ECUs) to enable diagnostics, firmware updates, and routine testing. It helps decode DTCs by providing a standardized way to request and receive diagnostic information from vehicle ECUs. The UDS protocol (ISO 14229) is standardized across both manufacturers and standards, such as CAN, KWP 2000, Ethernet, and LIN, and is used in ECUs across all tier 1 Original Equipment Manufacturers (OEMs). UDS facilitates the extraction of parameter data values, such as temperatures, state of charge, and VIN, which are essential for comprehensive vehicle diagnostics and maintenance.

2. How Does UDS Relate to CAN Bus and the OSI Model in Decoding DTCs?

UDS relates to CAN bus and the OSI model by utilizing the Controller Area Network (CAN) as a basis for communication. CAN is described by a data-link layer and physical layer in the OSI model (as per ISO 11898). UDS (ISO 14229) is a higher-layer protocol that utilizes both the session layer (5th) and application layer (7th) in the OSI model. This integration allows for structured communication between diagnostic tools and vehicle ECUs, enabling the retrieval and interpretation of DTCs. Multiple standards other than CAN may be used as the basis for UDS communication, including FlexRay, Ethernet, LIN bus, and K-line, but CAN is the most common lower-layer protocol.

3. What are the Key UDS Standards and Concepts for Detailed DTC Decoding?

Key UDS standards and concepts include ISO 14229-1 (application layer requirements), ISO 14229-3 (UDS on CAN implementation), ISO 14229-2 (session layer), and ISO 15765-2 (transport protocol for CAN). ISO 14229-1 outlines client-server communication flows, UDS services, positive responses, negative response codes (NRCs), and definitions for DTCs and parameter data identifiers (DIDs). ISO 14229-3 focuses on implementing UDS on Controller Area Networks (CAN), also known as UDSonCAN, detailing the application layer requirements and CAN-specific requirements for UDS services like ResponseOnEvent and ReadDataByPeriodicIdentifier. These standards ensure that diagnostic information, including DTCs, is communicated and interpreted accurately, leading to more detailed and effective decoding.

4. What is UDSonCAN and DoCAN, and How Do They Impact DTC Interpretation?

UDSonCAN (UDS on CAN bus) refers to ISO 14229-3, while DoCAN (Diagnostics on CAN bus) refers to ISO 15765-2, also known as ISO-TP. These terms are crucial for understanding how diagnostics are performed over CAN networks. UDSonCAN specifies the application layer requirements for UDS implemented on CAN, outlining CAN-specific requirements for certain UDS services. DoCAN, as described in ISO 15765-2, details how to communicate diagnostic requests and responses, especially for multi-frame payloads, which is vital for transmitting larger DTC data. Understanding the distinctions and interactions between UDSonCAN and DoCAN helps ensure accurate and efficient DTC interpretation in vehicle diagnostics.

5. Does UDS Specify a Standard Connector for DTC Decoding?

Unlike other higher-layer CAN protocols like OBD2, J1939, and ISOBUS, UDS does not specify a standard connector to be used for connecting external diagnostic equipment. However, in practice, the OBD2 connector (SAE J1962) is used in most vehicles. Electric vehicles from Nissan, Hyundai, and VW may support limited or no OBD2 communication but do respond to UDS requests via the OBD2 connector. This widespread use of the OBD2 connector for UDS communication simplifies the process of accessing and decoding DTCs across various vehicle makes and models.

6. What is the Structure of a UDS Message Frame and How Does It Aid DTC Decoding?

A UDS message frame contains fields such as the Protocol Control Information (PCI), UDS Service ID (SID), UDS Sub Function Byte, and UDS Request Data Parameters, including the Data Identifier (DID). The PCI field is required for diagnostic UDS requests on CAN bus and is related to ISO-TP (ISO 15765-2). The UDS Service Identifier (SID) specifies the UDS service being utilized, while the sub-function byte is used in some UDS request frames to control report types or suppress responses. The Data Identifier (DID) is a 2-byte value used to identify specific parameters. Understanding these fields helps in constructing and interpreting UDS messages, which is essential for accurately decoding DTCs and other diagnostic information.

7. How Do Positive and Negative UDS Responses Affect DTC Decoding?

Positive UDS responses indicate that a request was successful, and the response frame contains the requested data. For example, a positive response to a service 0x22 request will contain the response SID 0x62 (0x22 + 0x40) and the 2-byte DID, followed by the actual data payload for the requested DID. Negative UDS responses, indicated by the Negative Response Code SID 0x7F, provide information regarding the cause of the rejection, such as an invalid message format or length. These responses are structured with the PCI field, the negative response code SID, the SID of the rejected request, and the Negative Response Code (NRC). Understanding these responses helps diagnose issues and ensure accurate DTC decoding.

8. What is CAN ISO-TP and How Does It Facilitate Detailed DTC Communication?

CAN ISO-TP (ISO 15765-2) is a transport protocol that solves the challenge of large payloads in CAN-based vehicle diagnostics by enabling communication of data payloads up to 4095 bytes through segmentation, flow control, and reassembly. It specifies CAN frames for single-frame and multi-frame communication. For example, when the payload exceeds 7 bytes, ISO-TP splits the data across multiple CAN frames. The ECU sends a First Frame (FF) with the total packet length and the initial data chunk, and the tester sends a Flow Control (FC) frame to manage the data transfer. This protocol is crucial for detailed DTC communication, as it allows the transmission of extensive diagnostic data that exceeds the standard CAN frame size.

9. What are the Differences Between UDS, OBD2, WWH-OBD, and OBDonUDS in Terms of DTC Decoding?

OBD (On-Board Diagnostics) is implemented differently across countries and vehicles. ISO OBD (or EOBD) refers to the OBD protocol specification for EU cars, while SAE OBD is for US cars. HD OBD (SAE J1939) is for heavy-duty vehicles. UDS (ISO 14229) provides richer diagnostics beyond the limits of emissions-focused OBD protocols. WWH-OBD (ISO 27145) is a global standard based on UDS. OBDonUDS (SAE J1979-2) is being adopted in the US as an update to SAE J1979. UDS enables extensive control over vehicle ECUs, while OBD2 is limited to emissions-related diagnostics. WWH-OBD and OBDonUDS are based on UDS to provide a single, future-proof alternative to existing OBD protocols, enhancing DTC data richness and classification.

10. What is WWH-OBD (ISO 27145) and How Does It Improve DTC Decoding?

WWH-OBD is a global standard for vehicle diagnostics developed by the UN under the Global Technical Regulations (GTR) mandate. It aims to provide a single, future-proof alternative to existing OBD protocols (ISO OBD, SAE OBD, HD OBD) and is based on UDS. This transition from OBD2 to WWH-OBD increases data richness by using 2-byte UDS data identifiers (DIDs), allowing 65535 parameters compared to the 1-byte limit of OBD2 parameter identifiers (PIDs). WWH-OBD allows for ‘extended DTCs’ of 3 bytes, enabling grouping DTCs by 2-byte types and using the 3rd byte as a failure mode indicator. It also classifies DTCs based on the severity of the issue regarding exhaust emissions quality. This results in more detailed and accurate DTC decoding, facilitating better diagnostics and repairs.

11. What is OBDonUDS (SAE J1979-2) and Why is It Important for DTC Decoding in the US?

OBDonUDS (SAE J1979-2) serves as an update to the SAE J1979 standard and is being adopted in the US. Similar to how OBD2 has been split into SAE OBD for the US and ISO OBD for the EU, the next generation of OBD2 may again be regionally split. WWH-OBD has been adopted in the EU for heavy-duty vehicles, but not yet in the US. The new SAE J1979-2 standard, also referred to as OBDonUDS, initiates a transition phase starting in 2023 where ECUs are allowed to support either OBD2 or OBDonUDS. From 2027, OBDonUDS will be mandatory for all vehicles produced in the US. OBDonUDS is important because it will facilitate simplified ECU programming as emissions-related diagnostics can be implemented within the same UDS-based structure as the manufacturer-specific enhanced diagnostics, leading to improved DTC decoding capabilities.

12. How Can You Request and Record UDS Data for Effective DTC Analysis?

UDS data can be requested and recorded using tools like the CANedge, which can be configured to transmit up to 64 custom CAN frames as periodic or single-shot frames. For single-frame UDS communication, you configure the CANedge with the request frame, which triggers a single response frame from the ECU. For multi-frame communication, you configure the CANedge with a request frame and add the Flow Control frame as a separate frame to be transmitted X milliseconds after the request frame. The CANedge records the UDS responses as raw CAN frames, which can then be processed and decoded using software such as Vector tools, Python, or MF4 decoders. This allows for the acquisition of diagnostic trouble code values and other sensor data for effective DTC analysis.

13. What are the Common Use Cases for Recording UDS Data to Better Understand DTCs?

Common use cases for recording UDS data include acquiring diagnostic trouble code values for diagnosing issues, extracting the current value of various sensors related to each ECU (such as speed, RPM, state of charge, and temperatures), and low-level control of ECUs for resets and firmware flashing. OEM engineers, vehicle fleet managers, and researchers can use UDS to collect data of interest from the vehicle, assuming they know how to request and decode the data. For example, vehicle fleet managers can record DTCs to track vehicle health and schedule maintenance, and OEM engineers can collect sensor data to analyze vehicle performance and identify potential issues.

14. Why is UDS Considered a Manufacturer-Specific Diagnostic Protocol for DTCs?

UDS is considered a manufacturer-specific diagnostic protocol because the actual content of the communication remains proprietary and is typically only known to the manufacturer of a specific vehicle/ECU. While UDS provides a standardized structure for diagnostic communication, the actual identifiers, parameters, and interpretation rules are not standardized across all vehicles. Vehicles supporting WWH-OBD or OBDonUDS may support some of the usual OBD2 PIDs, but proprietary parameters require manufacturer-specific knowledge to request and interpret. This proprietary nature makes UDS most relevant to automotive engineers working at OEMs or aftermarket users who can identify the reverse-engineered information required to request and decode UDS parameters.

15. How Does UDS Data Logging Benefit Automotive Engineers in Decoding DTCs Effectively?

Tools like the CANedge CAN bus data logger allow automotive engineers to record raw CAN traffic from a vehicle while simultaneously requesting diagnostic trouble codes and specific parameter values via UDS. This enables engineers to collect comprehensive data logs that can be used to diagnose issues, analyze vehicle performance, and develop new diagnostic strategies. By combining raw CAN traffic with UDS data, engineers can gain a deeper understanding of vehicle behavior and more effectively decode DTCs. The CANedge allows customization of CAN frames to send, including custom UDS requests and flow control frames, and data can be processed via free software/API tools.

16. Is UDS Data Logging Relevant for Aftermarket Users in Decoding DTCs?

Some aftermarket users, such as vehicle fleet managers and private persons, can benefit from UDS data logging if they can identify the reverse-engineered information required to request and decode the UDS parameters of interest. While UDS communication is primarily manufacturer-specific, public information and DBC files may be available where others have reverse-engineered the information. Logging UDS data will also become increasingly relevant as WWH-OBD gets rolled out, as WWH-OBD is already used in EU heavy-duty vehicles produced after 2014. This means UDS communication will be relevant for use cases related to on-board diagnostics in these vehicles.

17. When Should UDS Be Used Instead of Raw CAN Data for DTC Decoding?

UDS is frequently used for extracting sensor values and diagnostic information, even though the data may already be communicated between ECUs on the CAN bus, due to gateways that block access to raw CAN bus data via the OBD2 connector. An increasing share of modern cars, particularly German vehicles and electric vehicles, have started to block access to the raw CAN bus data via the OBD2 connector. In contrast, the OBD2 connector gateways typically still allow for UDS communication, including sensor value communication. This makes UDS a valuable tool for accessing diagnostic information in these vehicles.

18. Can Most Vehicles Be Assumed to Support UDS Communication for DTC Decoding?

Since most ECUs today support UDS communication, the answer is generally yes. If you’re the vehicle manufacturer, you will typically have the information required to construct UDS requests for whatever data you need, and you’ll also know how to decode it. For the specific case of recording WWH-OBD data in EU trucks, standardized DID information can be recorded by both OEMs and aftermarket users, similar to how you can record public OBD2 PIDs from cars/trucks. However, if you are in the aftermarket and wish to record proprietary UDS information from a car/truck, it will be difficult without contacting the OEM or identifying the request/decoding information through reverse engineering.

19. Will UDS Replace OBD2 for DTC Decoding in the Future?

The availability of OBD2 data is expected to decrease over time for multiple reasons. WWH-OBD (based on UDS) or OBDonUDS are expected to gradually replace OBD2 as the de facto standard for vehicle diagnostics. Additionally, with the rise of electric vehicles, legislated OBD2 is not necessarily supported at all. Even if an EV supports some OBD2 PIDs, some of the most relevant EV parameters, like State of Charge (SoC) and State of Health (SoH), are not available via OBD2. In contrast, UDS remains supported in most EVs and will provide access to a far broader range of data, making UDS communication increasingly relevant for DTC decoding in the future.

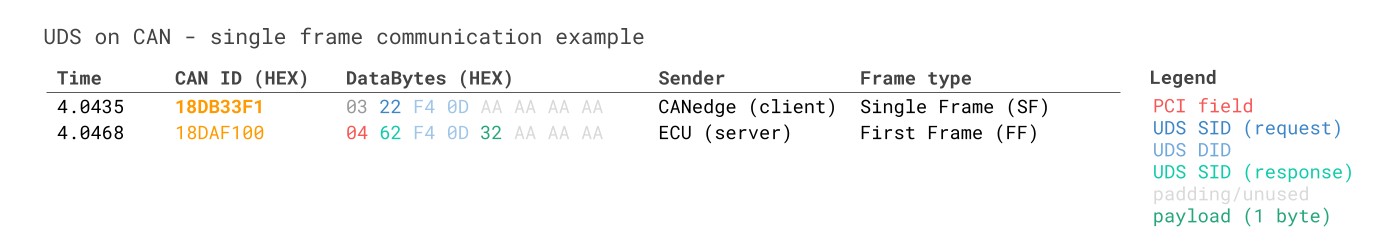

20. How Can UDS Be Used to Record Single Frame Data for Speed via WWH-OBD for DTC Decoding?

To request speed via WWH-OBD, the UDS SID 0x22 (Read Data by Identifier) and the DID 0xF40D are used. The CANedge3 can be used to send/receive CAN frames, and the resulting payload can be decoded as per the OBD2 intro, resulting in a vehicle speed value. The request is sent with CAN ID 0x18DB33F1, the same 29-bit CAN ID used to perform a functionally addressed OBD2 PID request in heavy-duty vehicles. The response has CAN ID 0x18DAF100, an example of a physical response ID matching the IDs you’d see in regular OBD2 responses from heavy-duty vehicles. This process provides a clear example of how single-frame UDS communication works in the context of WWH-OBD.

WWH-OBD Request Response Speed Example

WWH-OBD Request Response Speed Example

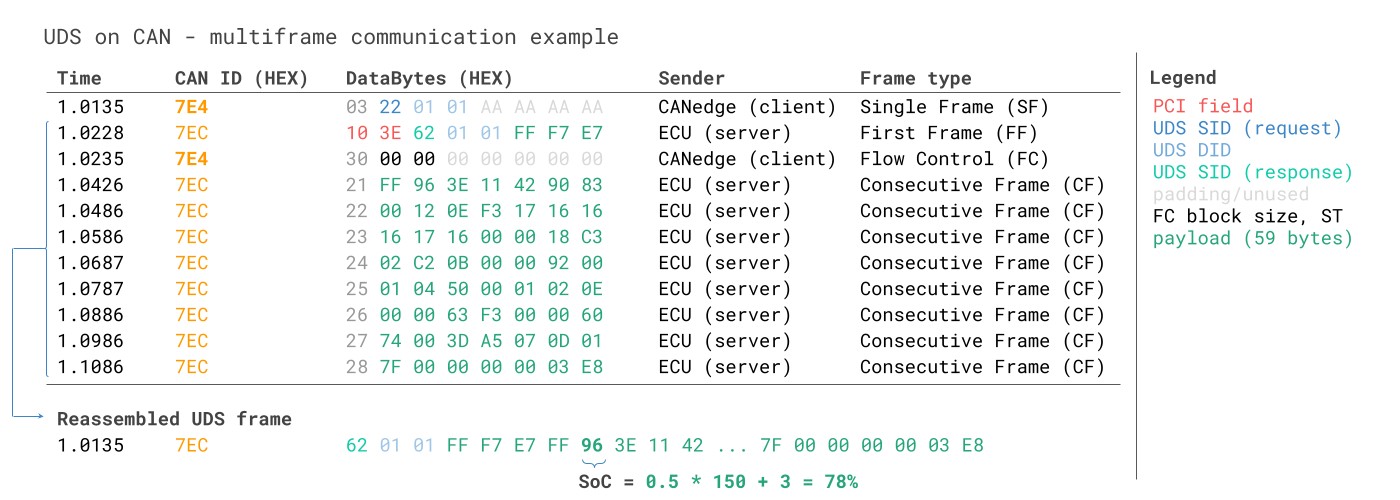

21. How Can UDS Be Used to Record Multi-Frame Data for EV State of Charge (SoC%) for Enhanced DTC Decoding?

Multi-frame UDS communication can be used to record the current value of State of Charge (SoC%) from an electric vehicle, like the Kia EV6. The CANedge can be configured to send a Single Frame (SF) request with the UDS SID 0x22 and the DID 0x0101. In response, the targeted ECU sends a First Frame (FF) response with the data payload size, response SID, and DID. The tester tool then sends a Flow Control (FC) frame, and the ECU sends the remaining Consecutive Frames (CF) with the rest of the payload. Decoding the multi-frame UDS data involves reassembling the segmented CAN frames and using a DBC file to extract physical values, providing a method for enhanced DTC decoding in EVs.

UDS ISO-TP Multi Frame Request Response Electric Vehicle SoC

UDS ISO-TP Multi Frame Request Response Electric Vehicle SoC

22. What is the Process for Decoding Multi-Frame UDS Data for DTC Analysis?

To decode multi-frame UDS data, you must first reassemble the segmented CAN frames. This involves identifying the First Frame (FF), Flow Control (FC), and Consecutive Frames (CF) and combining the data payloads from the CFs into a single, complete message. Software/API tools that support ISO-TP and DBC decoding are used for this process. For example, the Kia EV6 DBC specifies that SoC is found in the 8th byte and should be decoded with a scaling factor of 0.5 and an offset of 3. After reassembly, the DBC file is used to decode the raw CAN frames into physical values, enabling detailed DTC analysis.

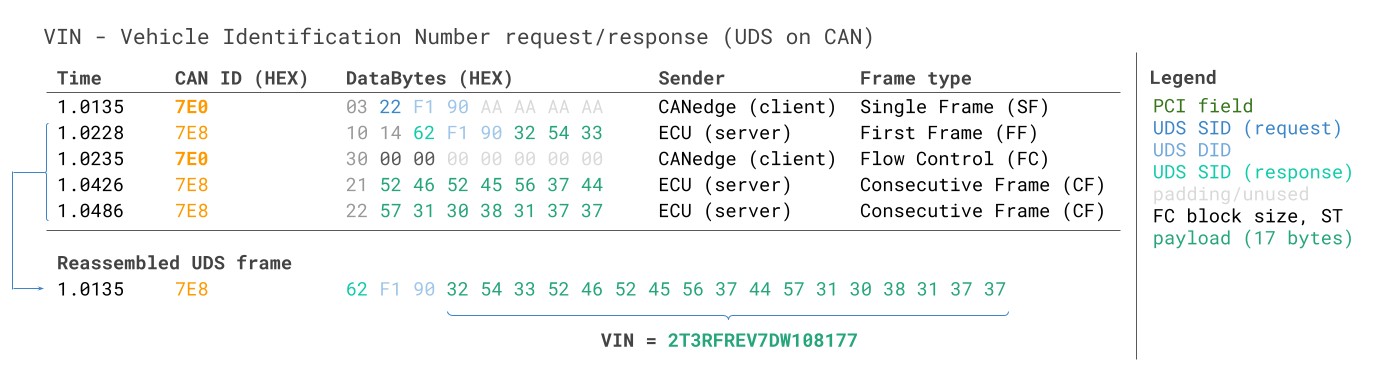

23. How Can the Vehicle Identification Number (VIN) Be Recorded via UDS for Vehicle Diagnostics and DTC Correlation?

The Vehicle Identification Number (VIN) can be recorded via UDS using UDS SID 0x22 and DID 0xF190. The VIN consists of 17 ASCII characters and is extracted via a multi-frame diagnostic request/response. The request/response communication flow is similar to the OBD2 case, but uses the UDS service and DID. The UDS response frame does not include the Number of Data Items (NODI) field after the DID, in contrast to the OBD2 case. Recording the VIN is useful in data logging or telematics use cases where a unique identifier is required for association with CAN bus log files and can improve vehicle diagnostics and DTC correlation.

VIN Vehicle Identification Number UDS Unified Diagnostic Services

VIN Vehicle Identification Number UDS Unified Diagnostic Services

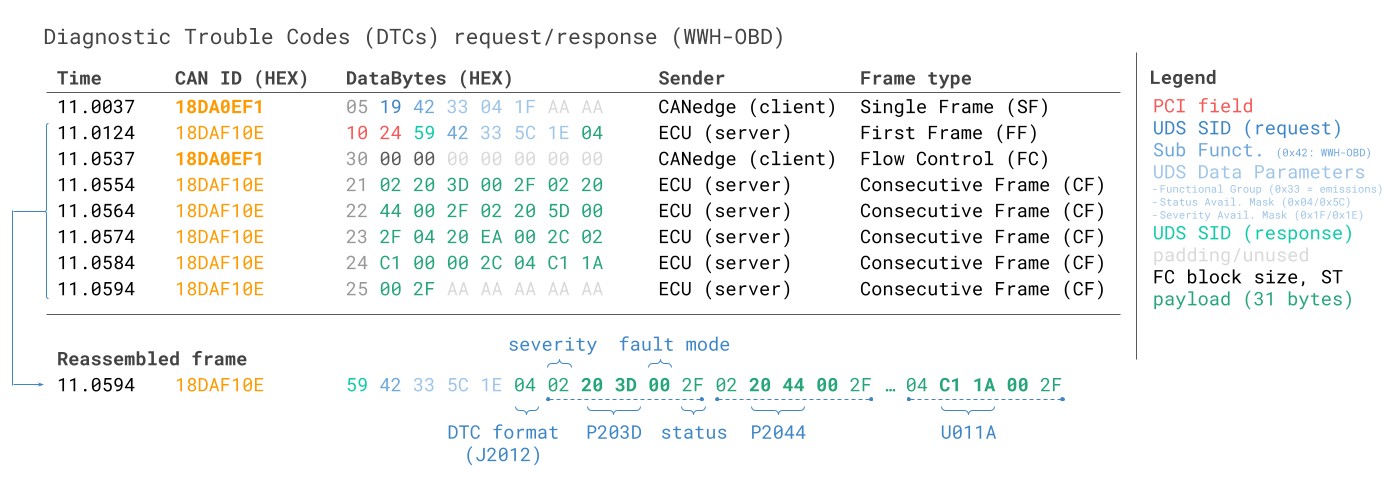

24. How Can Diagnostic Trouble Codes (DTCs) Be Recorded via WWH-OBD for Advanced Vehicle Analysis?

To record Diagnostic Trouble Codes (DTCs) via WWH-OBD, you use service 0x19 and sub-function byte 0x42. This corresponds to requesting Diagnostic Trouble Codes via UDS, specifically for WWH-OBD. The remaining 3 bytes in the request message are UDS data parameters specifying further configuration details of the request. In the response message, the format identifier 0x04 implies that the DTCs should be interpreted as per SAE J2012. The response includes 5 bytes for each DTC, with the middle 3 bytes equaling the actual DTC. The 1st byte reflects the severity of the DTC, and the next two data bytes reflect the fault code. This allows for advanced vehicle analysis using detailed DTC information.

WWH-OBD Diagnostic Trouble Codes DTC ISO TP

WWH-OBD Diagnostic Trouble Codes DTC ISO TP

25. What Are Some Practical Applications of UDS Data Logging in Decoding DTCs?

Practical applications of UDS data logging include UDS telematics for prototype electric vehicles, where the CANedge3 is deployed to request data on state of charge, state of health, and temperatures. Another application is training a predictive maintenance model across fleets of heavy-duty vehicles by periodically requesting diagnostic trouble codes, providing log files that combine sensor data and classification results. These applications illustrate how UDS data logging can be used to improve vehicle diagnostics, predict maintenance needs, and enhance vehicle performance analysis.

26. What Tools and Resources Does MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Offer for Decoding DTCs in Detail?

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers a variety of tools and resources for decoding DTCs in detail, including comprehensive databases, diagnostic tools, step-by-step guides, and expert support. By leveraging these resources, users can gain access to in-depth insights into UDS protocols, standardized identifiers, and proprietary parameters. The website provides tailored solutions for both automotive engineers and aftermarket users, enabling them to accurately interpret DTCs and optimize vehicle maintenance.

27. How Can Detailed DTC Decoding Improve Vehicle Maintenance and Repair?

Detailed DTC decoding enables precise vehicle maintenance and repair by providing specific information about the nature and location of faults. By understanding the root cause of issues, technicians can perform targeted repairs, reducing downtime and costs. Detailed DTC decoding also helps in identifying potential problems before they escalate, allowing for proactive maintenance. Furthermore, it enhances the accuracy of diagnostic procedures, leading to more effective troubleshooting and resolution.

28. What Steps Can Individuals Take to Learn More About Detailed DTC Decoding Techniques?

Individuals can take several steps to learn more about detailed DTC decoding techniques, including researching online resources, enrolling in specialized courses, and engaging with industry experts. Online resources such as forums, technical articles, and manufacturer websites provide valuable information. Specialized courses offer structured learning on diagnostic protocols and decoding techniques. Additionally, networking with industry professionals provides opportunities to gain practical insights and stay updated on the latest advancements.

29. What are the Benefits of Staying Updated on the Latest Advancements in DTC Decoding?

Staying updated on the latest advancements in DTC decoding offers numerous benefits, including improved diagnostic accuracy, enhanced repair efficiency, and increased customer satisfaction. New decoding techniques provide more detailed information about faults, enabling technicians to perform more effective repairs. Staying updated also ensures compliance with industry standards and regulations. Moreover, it enhances professional credibility and opens up opportunities for career advancement.

30. How Does MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Support the Automotive Community in Mastering Detailed DTC Decoding?

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN supports the automotive community in mastering detailed DTC decoding by providing access to cutting-edge tools, comprehensive resources, and expert guidance. The website offers a user-friendly platform for accessing diagnostic information, troubleshooting issues, and optimizing vehicle performance. Additionally, MERCEDES-DIAGNOSTIC-TOOL.EDU.VN fosters a collaborative environment where users can share knowledge, exchange ideas, and contribute to the advancement of automotive diagnostics. This holistic approach empowers automotive professionals to excel in their field and deliver superior service to their customers.

Ready to elevate your Mercedes-Benz diagnostic capabilities? Contact us today at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for expert guidance on diagnostic tools, unlocking hidden features, and accessing comprehensive repair and maintenance information. Let us help you keep your Mercedes-Benz running at its best.

Address: 789 Oak Avenue, Miami, FL 33101, United States

WhatsApp: +1 (641) 206-8880

Website: MERCEDES-DIAGNOSTIC-TOOL.EDU.VN