The CAN (Controller Area Network) bus is a vital communication system that allows ECUs (Electronic Control Units) within vehicles to communicate without a central computer, and it plays a crucial role in automotive coding. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides comprehensive resources to understand and leverage CAN bus technology, offering solutions for diagnostics, customization, and repair. Dive in to discover how this technology is revolutionizing vehicle maintenance and performance, enhanced by automotive networking, ECU programming and vehicle diagnostics.

Contents

- 1. Understanding the CAN Bus

- 1.1 What is an ECU?

- 1.2 Variants of CAN Bus

- 1.3 Alternative Automotive Networks

- 2. Benefits of the CAN Bus System

- 2.1 Simplicity and Cost-Effectiveness

- 2.2 Easy Accessibility

- 2.3 Robustness

- 2.4 Efficiency

- 3. A Brief History of the CAN Bus

- 4. The Future of the CAN Bus

- 5. CAN Physical & Data Link Layer

- 5.1 Physical Layer (ISO 11898-2)

- 5.2 Data Link Layer (ISO 11898-1)

- 6. Understanding the CAN Frame

- 7. Higher-Layer CAN Protocols

- 7.1 OBD2 (On-Board Diagnostics)

- 7.2 UDS (Unified Diagnostic Services)

- 7.3 CCP/XCP (CAN Calibration Protocol/Universal Measurement and Calibration Protocol)

- 7.4 CANopen

- 7.5 SAE J1939

- 7.6 NMEA 2000

- 7.7 ISOBUS (ISO 11783)

- 7.8 Other Protocols

- 8. Relation to Coding and Vehicle Customization

- 8.1 ECU Programming

- 8.2 Customization and Retrofitting

- 8.3 Diagnostic and Repair

- 8.4 Tools and Interfaces

- 8.5 The Role of MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

- 9. How to Log CAN Bus Data

- 9.1 Select the Right Hardware

- 9.2 Identify the Adapter Cable

- 9.3 Configure and Connect Your Device

- 9.4 Review Raw CAN Data

- 10. Decoding Raw CAN Data to Physical Values

- 10.1 Understand CAN Signal Extraction

- 10.2 Get the Relevant DBC File

- 10.3 Use a Software/API Tool

- 11. Example Use Cases for Logging CAN Data

- 11.1 Logging/Streaming Data from Cars

- 11.2 Heavy-Duty Fleet Telematics

- 11.3 Predictive Maintenance

- 11.4 Vehicle/Machine Black Box

- 12. Navigating CAN Bus Coding with MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

- 12.1 Challenges in Understanding CAN Bus

- 12.2 Services Offered by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

- 12.3 Benefits of Using MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

- 13. Frequently Asked Questions (FAQ)

1. Understanding the CAN Bus

The CAN bus is like the nervous system of a car, facilitating communication between different ECUs. These ECUs control various functions such as the engine, brakes, and transmission. By using a two-wire system (CAN high and CAN low), the CAN bus enables efficient and reliable data sharing throughout the vehicle.

1.1 What is an ECU?

Electronic Control Units (ECUs) are specialized components that manage specific functionalities in a vehicle. A modern car can have over 70 ECUs, each responsible for tasks ranging from engine control to managing the vehicle’s temperature. ECUs consist of a microcontroller (the brain), a CAN controller (manages communication), and a CAN transceiver (connects to the physical CAN wires).

1.2 Variants of CAN Bus

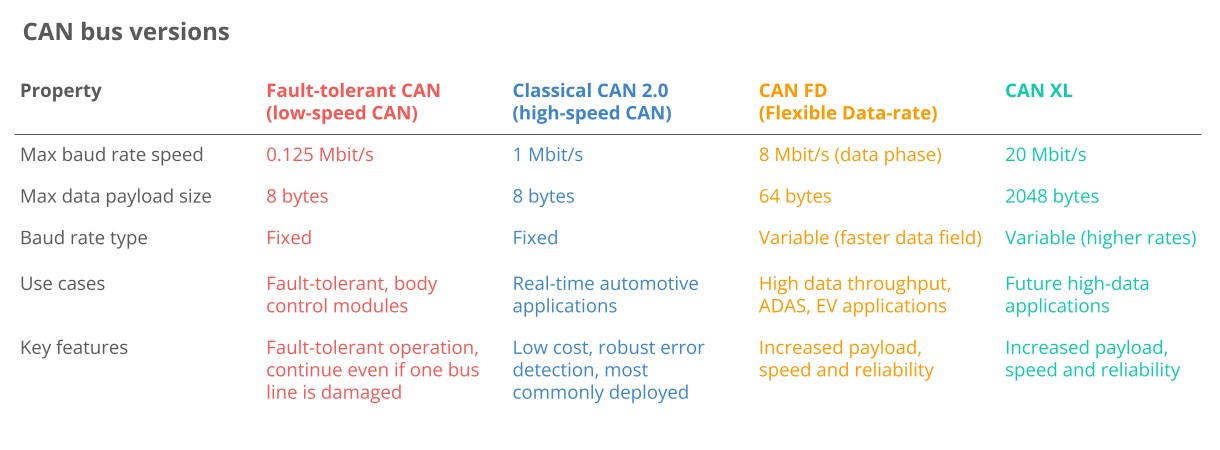

Several variants of CAN exist, each designed for specific applications:

- Low-Speed CAN: Ideal for fault-tolerant applications, though increasingly replaced by LIN bus.

- High-Speed CAN: The most common variant in automotive and machinery.

- CAN FD (Flexible Data-Rate): Offers faster speeds and longer payloads. More details can be found at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

- CAN XL: Provides even greater speed and payload capacity, bridging the gap between CAN and Automotive Ethernet.

Classical CAN FD XL Variants Canbus

Classical CAN FD XL Variants Canbus

1.3 Alternative Automotive Networks

In addition to CAN, other networks are used in vehicles:

- LIN Bus: A low-cost alternative for non-critical functions like air conditioning.

- FlexRay: Offers high speed and fault tolerance but is more expensive.

- Automotive Ethernet: Supports high bandwidth needs for ADAS and infotainment systems.

2. Benefits of the CAN Bus System

The CAN bus offers several advantages, making it a standard in modern vehicles and machinery. These benefits translate to increased efficiency and cost savings in vehicle maintenance.

2.1 Simplicity and Cost-Effectiveness

The CAN bus simplifies wiring by allowing ECUs to communicate via a single system, reducing complexity and costs. This is particularly noticeable when compared to older point-to-point wiring systems.

- Reduced Wiring Complexity: Simplifies connections and reduces potential points of failure.

- Weight Reduction: Can reduce the weight of wiring harnesses by up to 20 kg, improving fuel efficiency.

- Scalability: The widespread adoption of CAN has reduced the cost of components like controllers and transceivers.

2.2 Easy Accessibility

The CAN bus provides a single access point to communicate with all ECUs, enabling centralized diagnostics, data logging, and configuration. This is invaluable for vehicle maintenance and performance tuning.

- Centralized Diagnostics: Simplifies troubleshooting by providing access to all network traffic from a single point.

- Silent CAN Logging: Allows data logging without affecting the CAN bus, critical for accurate diagnostics.

- ECU Flashing: Enables firmware and configuration updates to any ECU via the CAN bus.

- Standardization: Higher-layer protocols are standardized across manufacturers, improving the interoperability of hardware and software tools.

2.3 Robustness

The CAN bus is highly resistant to electrical disturbances and electromagnetic interference, making it ideal for safety-critical applications.

- Differential Signaling: Minimizes the impact of electromagnetic interference.

- Error Handling: Ensures data integrity through extensive error detection, including bit errors and CRC errors.

- Confinement: Nodes can disconnect from the bus if they exceed error thresholds, preventing further issues.

2.4 Efficiency

CAN frames are prioritized by ID, ensuring that critical data gets immediate bus access without interrupting other frames.

- Arbitration: Prioritizes messages, ensuring that high-priority data is transmitted first.

- Utilization: Maximizes bandwidth by efficiently filling gaps between critical messages.

- Speed: Offers sufficient speed for most automotive and industrial applications.

3. A Brief History of the CAN Bus

The CAN bus has evolved significantly since its inception, becoming a cornerstone of modern vehicle technology. Understanding its history provides context for its current applications and future developments.

- Pre CAN: ECUs relied on complex point-to-point wiring.

- 1986: Bosch developed the CAN protocol.

- 1991: Bosch published CAN 2.0 (CAN 2.0A: 11 bit, 2.0B: 29 bit).

- 1993: CAN became an international standard (ISO 11898).

- 2003: ISO 11898 became a standard series.

- 2012: Bosch released CAN FD 1.0.

- 2015: The CAN FD protocol was standardized (ISO 11898-1).

- 2016: The physical CAN layer for data-rates up to 5 Mbit/s was standardized in ISO 11898-2.

- 2018: CiA started development of CAN XL.

- 2024: CAN XL standardized (ISO 11898-1:2024, 11898-2:2024)

Today, CAN is standard in automobiles, trucks, ships, airplanes, and machinery.

4. The Future of the CAN Bus

The CAN bus protocol will remain relevant, influenced by trends such as the need for speed, connected vehicles, and open-source initiatives.

- Need for Speed: May drive transition towards CAN FD, CAN XL, or Automotive Ethernet.

- Connected Vehicles: Rise of cloud computing may enable predictive maintenance and remote troubleshooting but also cybersecurity risks.

- Open vs. Closed: A push towards Open Source may face off vs. OEM-driven demand for proprietary data.

5. CAN Physical & Data Link Layer

The CAN bus is described by a data link layer and physical layer. For high-speed CAN, ISO 11898-1 describes the data link layer, while ISO 11898-2 describes the physical layer. In the context of a 7 layer OSI model, CAN thus represents the two lowest layers.

5.1 Physical Layer (ISO 11898-2)

The physical layer defines cable types, electrical signal levels, node requirements, and cable impedance. It specifies parameters like baud rate (up to 1 Mbit/s for Classical CAN, 8 Mbit/s for CAN FD), cable length (500 meters at 125 kbit/s to 40 meters at 1 Mbit/s), and termination (120 Ohm resistor at each end of the bus).

5.2 Data Link Layer (ISO 11898-1)

The data link layer defines frame formats, error handling, and data transmission. It specifies frame types (data frames, remote frames, error frames, overload frames) and error handling methods (CRC, acknowledgement slots, error counters).

6. Understanding the CAN Frame

Communication over the CAN bus occurs via CAN frames. A standard CAN data frame includes:

- SOF (Start of Frame): Indicates the beginning of a transmission.

- ID: The frame identifier, with lower values having higher priority.

- RTR (Remote Transmission Request): Indicates whether a node sends data or requests data.

- Control: Contains the Identifier Extension Bit (IDE) and Data Length Code (DLC).

- Data: Contains the data bytes or payload.

- CRC (Cyclic Redundancy Check): Ensures data integrity.

- ACK (Acknowledge): Indicates successful data reception.

- EOF (End of Frame): Marks the end of the CAN frame.

7. Higher-Layer CAN Protocols

CAN provides a basis for communication, but higher-layer protocols detail how data is communicated. Common protocols include OBD2, UDS, CCP/XCP, CANopen, SAE J1939, NMEA 2000, and ISOBUS. These protocols define how messages larger than 8 bytes are handled and how raw data is decoded, and often include specific parameters for vehicle health and performance monitoring.

7.1 OBD2 (On-Board Diagnostics)

Used in cars and trucks for diagnostics, maintenance, and emissions tests, specifying diagnostic trouble codes (DTCs) and real-time data.

7.2 UDS (Unified Diagnostic Services)

A communication protocol used in automotive ECUs for diagnostics, firmware updates, and routine testing.

7.3 CCP/XCP (CAN Calibration Protocol/Universal Measurement and Calibration Protocol)

Enable read/write ECU access for calibration, measurement, and flashing.

7.4 CANopen

Used in embedded control applications, including industrial automation, to enable interoperability between CAN nodes.

7.5 SAE J1939

Used in heavy-duty vehicles, identifying parameters like speed with suspect parameter numbers (SPN) and parameter group numbers (PGN).

7.6 NMEA 2000

Used in the maritime industry for connecting engines, instruments, and sensors on boats.

7.7 ISOBUS (ISO 11783)

Used in agriculture and forestry machinery, enabling integration between vehicles and implements.

7.8 Other Protocols

Other protocols include ARINC (aerospace), UAVCAN (drones), DeviceNet (industrial automation), SafetyBUS p (safety-critical industrial automation), MilCAN (military vehicles), and HVAC CAN (HVAC systems).

8. Relation to Coding and Vehicle Customization

Coding, in the context of automotive systems, involves modifying the software and parameters within the ECUs to alter vehicle behavior. The CAN bus provides the communication pathway for these modifications.

8.1 ECU Programming

Through coding, technicians can reprogram ECUs to optimize performance, enable new features, or adapt to different hardware configurations. The CAN bus allows these programming changes to be transmitted to the relevant ECUs efficiently.

8.2 Customization and Retrofitting

Many vehicle owners seek to customize their cars by enabling features that were originally disabled or retrofitting new components. Coding via the CAN bus is often necessary to activate these features or ensure compatibility with the new hardware.

8.3 Diagnostic and Repair

Coding is also essential in diagnostic and repair scenarios. When replacing an ECU, it often needs to be coded to match the vehicle’s specific configuration. Additionally, coding can be used to clear fault codes and reset systems after repairs.

8.4 Tools and Interfaces

Several tools and interfaces are available for coding and interacting with the CAN bus. These include specialized diagnostic tools, software platforms, and programming interfaces that allow technicians to read, write, and modify ECU data. Examples include Mercedes-Benz Star Diagnosis, Autel MaxiSys, and Vector Informatik tools.

8.5 The Role of MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN plays a critical role in providing the tools, information, and expertise needed to navigate the complexities of CAN bus coding. The website offers:

- Diagnostic Tools: Information on selecting the appropriate diagnostic tools for Mercedes-Benz vehicles.

- Step-by-Step Guides: Detailed instructions on unlocking hidden features and performing various coding procedures.

- Troubleshooting Tips: Solutions to common problems encountered during coding and repair.

- Expert Support: Access to knowledgeable professionals who can provide guidance and assistance.

9. How to Log CAN Bus Data

Logging CAN bus data involves several critical steps to capture and analyze vehicle communication effectively.

9.1 Select the Right Hardware

Decide how you want to collect the CAN data. Options include data loggers, interfaces, and adapters.

9.2 Identify the Adapter Cable

Determine the appropriate adapter for your application, such as OBD2, J1939, or M12 adapters.

On Board Diagnostic OBD2 Connector Adapter

On Board Diagnostic OBD2 Connector Adapter

- Cars: An OBD2 adapter is typically used to request OBD2/UDS data or access proprietary CAN data.

- Heavy-Duty Vehicles: A J1939 adapter is commonly used, but other connectors may be necessary.

- Maritime Vessels: An M12 connector provides access to NMEA 2000 data.

- Industrial Machinery: An M12 adapter or standard DB9 connector is often used.

9.3 Configure and Connect Your Device

Ensure your device baud rate matches the CAN bus and configure it to transmit relevant request messages.

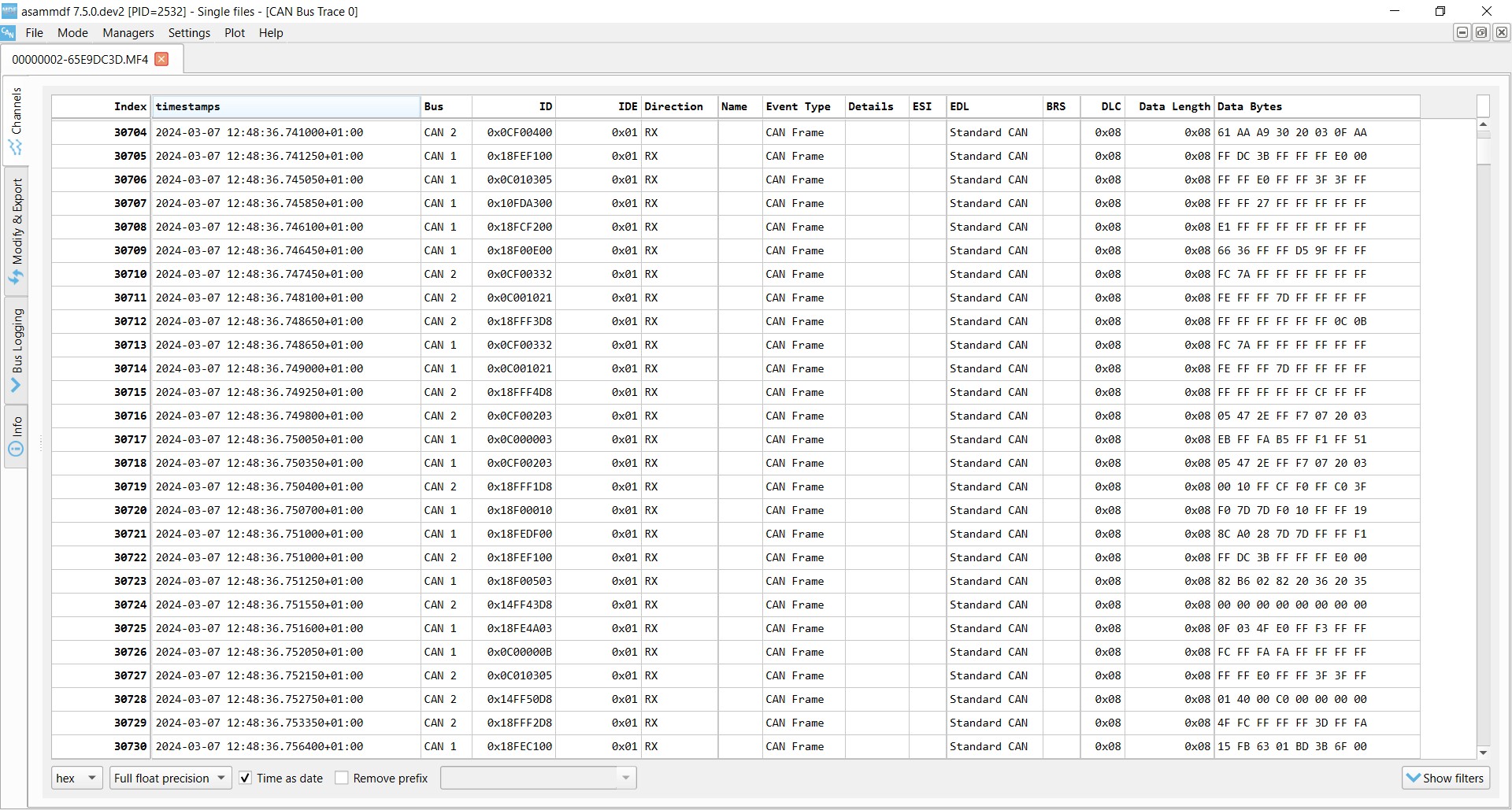

9.4 Review Raw CAN Data

Review the resulting log file, noting that raw CAN bus data is not human-readable and requires decoding.

Raw CAN Bus Data Example Asammdf J1939

Raw CAN Bus Data Example Asammdf J1939

10. Decoding Raw CAN Data to Physical Values

Decoding raw CAN data involves interpreting CAN frames into scaled engineering values, requiring a DBC file and software tool.

10.1 Understand CAN Signal Extraction

Each CAN frame contains CAN signals in the data payload. Extracting physical values requires information about byte order, bit start, bit length, offset, and scale.

10.2 Get the Relevant DBC File

A CAN DBC file contains information for decoding raw CAN data. DBC files are application-specific and often proprietary.

- OEM Engineers: Typically have the DBC or information to create one.

- Non-OEMs: May need to find a standard DBC or reverse engineer the CAN bus to create one.

10.3 Use a Software/API Tool

Use software/API tools that support your log file format and DBC files, such as asammdf GUI, Grafana dashboards, MATLAB, or Python.

11. Example Use Cases for Logging CAN Data

Common use cases for recording CAN bus data include logging data from cars, heavy-duty fleet telematics, predictive maintenance, and vehicle/machine black box applications.

11.1 Logging/Streaming Data from Cars

OBD2 data can be used to reduce fuel costs, improve driving, test prototype parts, and for insurance purposes.

11.2 Heavy-Duty Fleet Telematics

J1939 data from trucks, buses, and tractors can be used in fleet management to reduce costs or improve safety.

11.3 Predictive Maintenance

Vehicles and machinery can be monitored via IoT CAN loggers to predict and avoid breakdowns.

11.4 Vehicle/Machine Black Box

A CAN logger can serve as a black box for vehicles or equipment, providing data for disputes or diagnostics.

12. Navigating CAN Bus Coding with MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

Understanding the CAN bus is crucial for anyone involved in modern vehicle diagnostics, repair, and customization. With the right tools and knowledge, enthusiasts and professionals can unlock the full potential of their vehicles.

12.1 Challenges in Understanding CAN Bus

Many face challenges in understanding the CAN bus, including the complexity of the system, the need for specialized tools, and the difficulty of obtaining accurate information.

12.2 Services Offered by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers a range of services to help overcome these challenges:

- Detailed Guides and Tutorials: Comprehensive resources to understand CAN bus technology.

- Tool Recommendations: Expert advice on selecting the right diagnostic and coding tools.

- Remote Support: Professional assistance with coding, diagnostics, and troubleshooting.

- Community Forum: A platform for sharing knowledge and experiences with other enthusiasts and professionals.

12.3 Benefits of Using MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

By using MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, users can:

- Save Time and Money: Accurate diagnostics and coding can prevent costly repairs and unnecessary dealer visits.

- Unlock Hidden Features: Customize their vehicles to their preferences by enabling hidden functionalities.

- Improve Vehicle Performance: Optimize engine parameters and other settings for enhanced performance and efficiency.

- Gain Confidence: Develop a deeper understanding of their vehicle’s systems and capabilities.

13. Frequently Asked Questions (FAQ)

Here are some frequently asked questions about the CAN bus and its relation to coding:

- What is the best diagnostic tool for Mercedes-Benz vehicles? The best tool depends on your specific needs, but options include Mercedes-Benz Star Diagnosis, Autel MaxiSys, and iCarsoft MB II. Consult MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for detailed recommendations.

- How do I unlock hidden features on my Mercedes-Benz? Unlocking hidden features requires coding and may vary depending on the vehicle model. Consult MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for step-by-step guides.

- How often should I service my Mercedes-Benz? Service intervals vary, but typically range from 10,000 to 15,000 miles. Consult your vehicle’s manual and MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for specific recommendations.

- What is a CAN bus? The CAN bus (Controller Area Network) is a communication system used in vehicles to enable ECUs (Electronic Control Units) to communicate with each other without a host computer.

- Why is the CAN bus important for coding? The CAN bus provides the communication pathway for modifying the software and parameters within the ECUs, enabling vehicle customization, retrofitting, and diagnostic repairs.

- What are the different types of CAN bus? The primary types are Low-Speed CAN, High-Speed CAN, CAN FD (Flexible Data-Rate), and CAN XL, each designed for specific applications.

- What is a DBC file? A CAN DBC file (CAN database) is a text file that contains information for decoding raw CAN data, essential for interpreting CAN bus communications.

- How do I log CAN bus data? Logging CAN bus data involves selecting the right hardware, identifying the appropriate adapter cable, configuring your device, and reviewing the raw data.

- What is ECU programming? ECU programming involves modifying the software and parameters within the ECUs to alter vehicle behavior, optimize performance, or enable new features.

- What tools do I need for CAN bus coding? You typically need a diagnostic tool, software platform, and programming interface, such as Mercedes-Benz Star Diagnosis or Autel MaxiSys.

Want to explore the full potential of your Mercedes-Benz? Whether you’re looking to diagnose issues, unlock hidden features, or customize your vehicle, MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers the expertise and tools you need. Our detailed guides and expert support ensure you can confidently navigate the complexities of CAN bus technology.

Contact us today for personalized assistance.

Address: 789 Oak Avenue, Miami, FL 33101, United States

WhatsApp: +1 (641) 206-8880

Website: MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

Let MERCEDES-DIAGNOSTIC-TOOL.EDU.VN be your trusted partner in mastering Mercedes-Benz diagnostics and coding, unlocking the full capabilities of your vehicle.