How do you interpret ABS (C-prefix) codes related to wheel speed sensors? Understanding these codes is essential for diagnosing and repairing your Mercedes-Benz’s anti-lock braking system (ABS). At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we provide the tools and expertise to help you accurately interpret these codes, ensuring your vehicle’s safety and performance. Dive into this comprehensive guide to learn about erratic signals, missing signals, and comparison faults, and discover how our resources can streamline your diagnostic process. Optimize your vehicle’s ABS with accurate diagnostics and sensor maintenance, ensuring optimal braking performance and driver safety.

Contents

- 1. Understanding ABS (C-Prefix) Codes for Wheel Speed Sensors

- 1.1. Defining ABS and Wheel Speed Sensors

- 1.2. The Significance of C-Prefix Codes

- 1.3. The Role of Wheel Speed Sensors in ABS Functionality

- 2. Common ABS Codes Related to Wheel Speed Sensors

- 2.1. Erratic Signal Codes

- 2.2. Missing Signal Codes

- 2.3. Comparison Fault Codes

- 3. Interpreting Erratic Signal Codes

- 3.1. Common Causes of Erratic Signals

- 3.2. Diagnostic Steps for Erratic Signals

- 3.3. Using Diagnostic Tools to Analyze Signals

- 4. Interpreting Missing Signal Codes

- 4.1. Common Causes of Missing Signals

- 4.2. Diagnostic Steps for Missing Signals

- 4.3. Using Multimeters to Check Continuity

- 5. Interpreting Comparison Fault Codes

- 5.1. Common Causes of Comparison Faults

- 5.2. Diagnostic Steps for Comparison Faults

- 5.3. Verifying Sensor Accuracy

- 6. Advanced Diagnostic Techniques

- 6.1. Using Oscilloscopes for Signal Analysis

- 6.2. Dynamic Testing Techniques

- 6.3. Advanced Diagnostic Scanners

- 7. Practical Tips for Repairing Wheel Speed Sensors

- 7.1. Selecting Quality Replacement Parts

- 7.2. Proper Cleaning and Installation

- 7.3. Wiring and Connection Best Practices

- 8. Preventative Maintenance for Wheel Speed Sensors

- 8.1. Regular Inspection of Sensors and Wiring

- 8.2. Cleaning Procedures

- 8.3. Protecting Wiring from Damage

- 9. Case Studies: Real-World Examples of ABS Diagnostic and Repair

- 9.1. Case Study 1: Erratic Signal on a Mercedes-Benz C-Class

- 9.2. Case Study 2: Missing Signal on a Mercedes-Benz E-Class

- 9.3. Case Study 3: Comparison Fault on a Mercedes-Benz S-Class

- 10. Leveraging MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for ABS Diagnostics

- 10.1. Accessing Diagnostic Guides and Resources

- 10.2. Tool Recommendations

- 10.3. Expert Support and Consultation

1. Understanding ABS (C-Prefix) Codes for Wheel Speed Sensors

What are ABS (C-prefix) codes and why are they important? ABS (Anti-lock Braking System) codes with a “C” prefix indicate issues within the chassis system of your vehicle, often related to braking components. Wheel speed sensors are crucial for the ABS to function correctly, and any faults in these sensors can trigger a C-prefix code, which can prevent the ABS from functioning as intended, impacting safety and vehicle control. Addressing these codes promptly ensures your ABS functions correctly, maintaining optimal braking performance and safety.

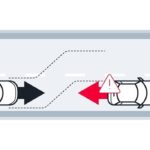

1.1. Defining ABS and Wheel Speed Sensors

What do ABS and wheel speed sensors do in a Mercedes-Benz? The Anti-lock Braking System (ABS) is a safety feature that prevents the wheels from locking up during braking, allowing the driver to maintain steering control. Wheel speed sensors (WSS) measure the rotational speed of each wheel and transmit this data to the ABS control module. This information helps the ABS determine if a wheel is about to lock up, at which point it modulates the brake pressure to that wheel. Proper functioning of both ABS and WSS ensures stable braking and steering, especially in emergency situations.

1.2. The Significance of C-Prefix Codes

Why are C-prefix codes specifically important for chassis-related issues? C-prefix codes are specifically designated for the chassis system, which includes components like the braking system, suspension, and steering. When a C-prefix code appears, it indicates a problem within one of these systems, often requiring immediate attention. Because the braking system is a critical safety component, C-prefix codes related to ABS and wheel speed sensors should be addressed promptly to prevent accidents. Ignoring these codes can lead to reduced braking efficiency and compromised safety.

1.3. The Role of Wheel Speed Sensors in ABS Functionality

How do wheel speed sensors contribute to the overall effectiveness of the ABS? Wheel speed sensors are the primary source of information for the ABS control module. By constantly monitoring the speed of each wheel, the sensors provide real-time data that allows the ABS to detect wheel lock-up. If a sensor fails or provides inaccurate data, the ABS may not function correctly, leading to longer stopping distances or loss of control during braking. Accurate and reliable wheel speed sensor data is vital for the ABS to perform its function effectively.

2. Common ABS Codes Related to Wheel Speed Sensors

What are the common ABS codes that relate to wheel speed sensors? Several ABS codes are commonly associated with wheel speed sensor issues, including codes indicating erratic signals, missing signals, and comparison faults. These codes can help pinpoint specific problems with the sensors or the circuits they are connected to. Understanding these codes is the first step in diagnosing and repairing ABS issues effectively.

2.1. Erratic Signal Codes

What does an erratic signal code mean for a wheel speed sensor? An erratic signal code indicates that the signal from the wheel speed sensor is unstable or inconsistent. This could be due to a damaged sensor, a loose connection, or interference from other electrical components. The ABS control module relies on a consistent signal to accurately determine wheel speed, so an erratic signal can prevent the ABS from functioning correctly. Addressing erratic signal codes promptly is crucial to restoring proper ABS functionality.

2.2. Missing Signal Codes

What does a missing signal code indicate about a wheel speed sensor? A missing signal code means that the ABS control module is not receiving any signal from the wheel speed sensor. This can be caused by a broken sensor, a disconnected wire, or a fault in the ABS control module itself. Without a signal from the sensor, the ABS cannot determine the wheel’s speed and may disable the ABS function for that wheel. Identifying and fixing the cause of a missing signal is essential for maintaining ABS performance.

2.3. Comparison Fault Codes

What does a comparison fault code signify regarding wheel speed sensors? A comparison fault code arises when the ABS control module detects a significant difference in speed between two or more wheels. This can happen if one wheel speed sensor is providing inaccurate data, or if there is a mechanical issue, such as a stuck brake or a faulty differential. The ABS relies on accurate wheel speed comparisons to function correctly, so a comparison fault can lead to ABS malfunction. Investigating and resolving comparison fault codes ensures accurate ABS operation.

3. Interpreting Erratic Signal Codes

How do you diagnose and interpret erratic signal codes from wheel speed sensors? Interpreting erratic signal codes involves checking the sensor for physical damage, inspecting the wiring for loose connections or corrosion, and testing the sensor’s output with a multimeter or oscilloscope. Understanding the potential causes of an erratic signal helps in accurately diagnosing the issue and implementing the necessary repairs. By thoroughly investigating the sensor and its connections, you can pinpoint the source of the problem and restore stable ABS functionality.

3.1. Common Causes of Erratic Signals

What are the common reasons for wheel speed sensors to send erratic signals? Several factors can cause wheel speed sensors to send erratic signals. These include:

- Sensor Damage: Physical damage to the sensor can disrupt its ability to accurately measure wheel speed.

- Loose Connections: Loose or corroded wiring connections can cause intermittent signal disruptions.

- Contamination: Debris or contaminants on the sensor can interfere with its readings.

- Electromagnetic Interference (EMI): Interference from other electrical components can distort the sensor’s signal.

- Faulty Wiring: Damaged or degraded wiring can lead to unstable signal transmission.

Addressing these potential causes is crucial for resolving erratic signal issues.

3.2. Diagnostic Steps for Erratic Signals

What steps should you take to diagnose erratic signals from wheel speed sensors? Diagnosing erratic signals from wheel speed sensors involves a systematic approach:

- Visual Inspection: Check the sensor for any visible damage or contamination.

- Wiring Inspection: Inspect the wiring and connectors for looseness, corrosion, or damage.

- Sensor Testing: Use a multimeter or oscilloscope to test the sensor’s output signal.

- Signal Analysis: Analyze the signal pattern to identify any anomalies or inconsistencies.

- Component Isolation: Disconnect other electrical components to rule out EMI as a cause.

Following these steps helps pinpoint the source of the erratic signal and guide the repair process.

3.3. Using Diagnostic Tools to Analyze Signals

How can diagnostic tools assist in analyzing erratic signals from wheel speed sensors? Diagnostic tools like multimeters and oscilloscopes are essential for analyzing erratic signals. A multimeter can measure the sensor’s voltage and resistance, while an oscilloscope can display the signal waveform, allowing you to identify any irregularities or distortions. Advanced diagnostic scanners can also provide real-time data and graphical representations of the sensor’s output, making it easier to detect intermittent issues. Leveraging these tools ensures accurate and efficient signal analysis.

4. Interpreting Missing Signal Codes

What are the diagnostic procedures for interpreting missing signal codes from wheel speed sensors? Interpreting missing signal codes requires checking the sensor for continuity, inspecting the wiring for breaks or disconnections, and verifying the power supply to the sensor. Addressing a missing signal code involves a methodical approach to ensure all potential causes are investigated and resolved, restoring ABS functionality.

4.1. Common Causes of Missing Signals

What are the typical reasons for a wheel speed sensor to lose signal? Several factors can lead to a missing signal from a wheel speed sensor:

- Broken Sensor: Physical damage to the sensor can prevent it from generating a signal.

- Disconnected Wiring: A disconnected or broken wire can interrupt the signal path.

- Corroded Connections: Corrosion on the sensor or wiring connections can block signal transmission.

- Faulty ABS Control Module: A problem with the ABS control module can prevent it from receiving the sensor signal.

- Power Supply Issues: A lack of power to the sensor can prevent it from functioning.

Identifying these potential causes is crucial for resolving missing signal issues.

4.2. Diagnostic Steps for Missing Signals

What steps should be followed to diagnose a missing signal from a wheel speed sensor? Diagnosing a missing signal from a wheel speed sensor involves a structured approach:

- Continuity Test: Use a multimeter to check the continuity of the sensor and its wiring.

- Wiring Inspection: Inspect the wiring for breaks, disconnections, or damage.

- Power Supply Verification: Verify that the sensor is receiving the correct voltage.

- ABS Control Module Check: Test the ABS control module to ensure it is functioning correctly.

- Sensor Replacement: If the sensor is faulty, replace it with a new one.

Following these steps helps pinpoint the cause of the missing signal and guide the repair process.

4.3. Using Multimeters to Check Continuity

How can a multimeter be used to check the continuity of a wheel speed sensor circuit? A multimeter is an essential tool for checking the continuity of a wheel speed sensor circuit. Set the multimeter to the continuity setting and connect the probes to both ends of the sensor wiring. If the multimeter indicates continuity, the circuit is intact. If there is no continuity, there is a break in the circuit, which needs to be located and repaired. Checking continuity ensures that the signal can travel from the sensor to the ABS control module.

5. Interpreting Comparison Fault Codes

How do you approach the diagnosis of comparison fault codes from wheel speed sensors? Interpreting comparison fault codes involves checking the sensors for consistent readings, verifying the accuracy of the sensor signals, and inspecting the mechanical components for issues that could affect wheel speed. Addressing comparison fault codes requires a comprehensive approach to ensure all potential causes are investigated and resolved, restoring proper ABS functionality.

5.1. Common Causes of Comparison Faults

What are the common reasons for wheel speed sensors to show comparison faults? Several factors can cause wheel speed sensors to show comparison faults:

- Inaccurate Sensor Readings: A faulty sensor may provide inaccurate speed readings, leading to a comparison fault.

- Mechanical Issues: Problems like a stuck brake caliper or a faulty differential can cause differences in wheel speed.

- Tire Issues: Uneven tire wear or mismatched tire sizes can affect wheel speed and trigger a comparison fault.

- Wiring Problems: Damaged or corroded wiring can cause inaccurate signal transmission.

- ABS Control Module Fault: A problem with the ABS control module can lead to incorrect wheel speed comparisons.

Identifying these potential causes is crucial for resolving comparison fault issues.

5.2. Diagnostic Steps for Comparison Faults

What steps should you take to diagnose comparison faults in wheel speed sensors? Diagnosing comparison faults in wheel speed sensors involves a detailed process:

- Sensor Reading Verification: Compare the speed readings from each sensor using a diagnostic scanner.

- Mechanical Inspection: Inspect the brakes, differential, and tires for any mechanical issues.

- Tire Condition Assessment: Check the tires for uneven wear or mismatched sizes.

- Wiring Inspection: Examine the wiring for damage, corrosion, or loose connections.

- ABS Control Module Testing: Test the ABS control module to ensure it is functioning correctly.

Following these steps helps identify the cause of the comparison fault and guide the repair process.

5.3. Verifying Sensor Accuracy

How can you verify the accuracy of wheel speed sensors when diagnosing comparison faults? Verifying the accuracy of wheel speed sensors is essential for diagnosing comparison faults. Use a diagnostic scanner to monitor the real-time speed readings from each sensor while driving the vehicle. Compare the readings to ensure they are consistent and accurate. If one sensor consistently shows a different speed than the others, it may be faulty and need to be replaced. Accurate sensor readings are vital for resolving comparison faults and restoring proper ABS function.

6. Advanced Diagnostic Techniques

What advanced techniques can be used for diagnosing wheel speed sensor issues? Advanced diagnostic techniques for wheel speed sensors include using oscilloscopes to analyze signal patterns, performing dynamic testing to identify intermittent faults, and employing advanced diagnostic scanners to access detailed ABS system data. These techniques provide a deeper understanding of sensor performance and help pinpoint elusive issues.

6.1. Using Oscilloscopes for Signal Analysis

How can an oscilloscope help in analyzing wheel speed sensor signals? An oscilloscope is a valuable tool for analyzing wheel speed sensor signals because it displays the signal waveform in real-time. This allows you to identify subtle issues like signal noise, dropouts, or distortions that may not be detectable with a multimeter. By examining the waveform, you can assess the sensor’s output quality and identify any anomalies that could be causing ABS problems. Oscilloscope analysis provides a more detailed and accurate assessment of sensor performance.

6.2. Dynamic Testing Techniques

What dynamic testing techniques can be applied to diagnose wheel speed sensor issues? Dynamic testing involves evaluating wheel speed sensors under real-world driving conditions to identify intermittent faults. This can include monitoring sensor signals while accelerating, braking, and turning. By observing the sensor behavior during different driving maneuvers, you can uncover issues that may not be apparent during static testing. Dynamic testing provides a more comprehensive assessment of sensor performance and helps identify elusive problems.

6.3. Advanced Diagnostic Scanners

What advantages do advanced diagnostic scanners offer for diagnosing ABS and wheel speed sensor issues? Advanced diagnostic scanners offer several advantages for diagnosing ABS and wheel speed sensor issues. These scanners can access detailed ABS system data, including real-time sensor readings, fault codes, and system parameters. They also provide advanced diagnostic functions like sensor calibration, system reset, and component testing. With their comprehensive capabilities, advanced diagnostic scanners enable more accurate and efficient troubleshooting of ABS and wheel speed sensor problems.

7. Practical Tips for Repairing Wheel Speed Sensors

What practical tips can improve the process of repairing wheel speed sensors? Practical tips for repairing wheel speed sensors include using high-quality replacement parts, properly cleaning sensor mounting surfaces, and carefully routing wiring to prevent damage or interference. These tips ensure that the repair is done correctly and that the new sensor functions reliably.

7.1. Selecting Quality Replacement Parts

Why is it important to select high-quality replacement parts for wheel speed sensors? Selecting high-quality replacement parts is crucial for ensuring the reliability and performance of wheel speed sensors. Inferior parts may not meet the required specifications, leading to inaccurate readings or premature failure. Using high-quality sensors from reputable manufacturers ensures that the ABS functions correctly and that the replacement part lasts. Investing in quality replacement parts is a cost-effective way to maintain the safety and performance of your vehicle.

7.2. Proper Cleaning and Installation

What are the key steps for properly cleaning and installing wheel speed sensors? Proper cleaning and installation are essential for ensuring the accurate and reliable operation of wheel speed sensors. Start by cleaning the sensor mounting surface to remove any debris or corrosion. When installing the new sensor, ensure it is properly aligned and securely fastened. Carefully route the wiring to prevent damage or interference. Following these steps helps ensure that the sensor functions correctly and that the ABS performs as intended.

7.3. Wiring and Connection Best Practices

What best practices should be followed for wiring and connections when repairing wheel speed sensors? Following best practices for wiring and connections is essential for ensuring reliable signal transmission from wheel speed sensors. Inspect the wiring for damage, corrosion, or loose connections. Use appropriate connectors and terminals to ensure secure and weather-tight connections. Route the wiring carefully to prevent chafing or interference from other components. Properly securing and protecting the wiring helps prevent future problems and ensures consistent sensor performance.

8. Preventative Maintenance for Wheel Speed Sensors

How can preventative maintenance help in ensuring the longevity and reliability of wheel speed sensors? Preventative maintenance for wheel speed sensors includes regular inspection of the sensors and wiring, cleaning the sensors to remove debris, and protecting the wiring from damage. These measures help ensure that the sensors continue to function accurately and reliably, preventing ABS issues and maintaining vehicle safety.

8.1. Regular Inspection of Sensors and Wiring

Why is regular inspection important for maintaining wheel speed sensors and their wiring? Regular inspection of wheel speed sensors and their wiring is crucial for identifying potential problems before they lead to ABS malfunctions. Check the sensors for physical damage, contamination, or corrosion. Inspect the wiring for wear, cracks, or loose connections. Early detection of these issues allows for timely repairs, preventing more significant problems and maintaining ABS performance.

8.2. Cleaning Procedures

What are the recommended cleaning procedures for wheel speed sensors? Cleaning wheel speed sensors helps remove debris and contaminants that can interfere with their readings. Use a soft brush or cloth to gently clean the sensor surface. Avoid using harsh chemicals or abrasive materials that could damage the sensor. Ensure the sensor is dry before reinstalling it. Regular cleaning helps maintain accurate sensor readings and prevents ABS issues.

8.3. Protecting Wiring from Damage

How can wiring be protected to avoid damage and ensure consistent wheel speed sensor performance? Protecting the wiring from damage is essential for ensuring consistent wheel speed sensor performance. Route the wiring carefully to avoid chafing or contact with sharp edges. Use protective sleeves or conduits to shield the wiring from harsh environmental conditions. Secure the wiring to prevent it from dangling or rubbing against other components. Taking these precautions helps prevent wiring damage and maintains reliable sensor operation.

9. Case Studies: Real-World Examples of ABS Diagnostic and Repair

How can real-world case studies illustrate the practical application of ABS diagnostic and repair techniques? Real-world case studies provide valuable insights into the practical application of ABS diagnostic and repair techniques. These examples demonstrate how to troubleshoot common ABS problems, interpret diagnostic codes, and implement effective repair strategies. By examining these cases, technicians and vehicle owners can gain a better understanding of ABS systems and improve their diagnostic skills.

9.1. Case Study 1: Erratic Signal on a Mercedes-Benz C-Class

What steps were taken to diagnose and resolve an erratic signal issue on a Mercedes-Benz C-Class? In this case study, a Mercedes-Benz C-Class exhibited an erratic signal code related to the front right wheel speed sensor. The diagnostic process involved:

- Visual Inspection: The sensor was inspected for physical damage and contamination.

- Wiring Inspection: The wiring and connectors were checked for looseness and corrosion.

- Signal Analysis: An oscilloscope was used to analyze the sensor’s signal waveform.

The analysis revealed signal noise caused by a corroded wiring connection. The connection was cleaned and repaired, resolving the erratic signal issue and restoring proper ABS function.

9.2. Case Study 2: Missing Signal on a Mercedes-Benz E-Class

How was a missing signal issue addressed on a Mercedes-Benz E-Class? A Mercedes-Benz E-Class presented a missing signal code for the rear left wheel speed sensor. The diagnostic steps included:

- Continuity Test: A multimeter was used to check the continuity of the sensor and its wiring.

- Wiring Inspection: The wiring was inspected for breaks and disconnections.

- Power Supply Verification: The power supply to the sensor was verified.

The investigation revealed a broken wire near the sensor connector. The wire was repaired, restoring the signal and resolving the ABS issue.

9.3. Case Study 3: Comparison Fault on a Mercedes-Benz S-Class

What was the approach to diagnosing and repairing a comparison fault on a Mercedes-Benz S-Class? A Mercedes-Benz S-Class displayed a comparison fault code between the front wheel speed sensors. The diagnostic process involved:

- Sensor Reading Verification: The speed readings from each sensor were compared using a diagnostic scanner.

- Mechanical Inspection: The brakes, differential, and tires were inspected for mechanical issues.

- Tire Condition Assessment: The tires were checked for uneven wear.

The investigation revealed that one tire had significantly more wear than the others. Replacing the worn tire resolved the comparison fault and restored proper ABS function.

10. Leveraging MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for ABS Diagnostics

How can MERCEDES-DIAGNOSTIC-TOOL.EDU.VN assist with diagnosing ABS issues in Mercedes-Benz vehicles? MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides comprehensive resources for diagnosing ABS issues, including detailed diagnostic guides, troubleshooting tips, and access to advanced diagnostic tools. Our platform helps you accurately interpret ABS codes, identify potential problems, and implement effective repair strategies, ensuring your Mercedes-Benz’s braking system functions optimally.

10.1. Accessing Diagnostic Guides and Resources

What types of diagnostic guides and resources are available on MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for ABS diagnostics? MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers a variety of diagnostic guides and resources for ABS diagnostics, including:

- Detailed Diagnostic Guides: Step-by-step instructions for diagnosing common ABS issues.

- Troubleshooting Tips: Practical advice for resolving ABS problems quickly and efficiently.

- Code Interpretation Guides: Explanations of ABS codes and their potential causes.

- Technical Articles: In-depth articles on ABS systems and components.

These resources provide the information you need to accurately diagnose and repair ABS issues in your Mercedes-Benz.

10.2. Tool Recommendations

What diagnostic tools does MERCEDES-DIAGNOSTIC-TOOL.EDU.VN recommend for diagnosing ABS and wheel speed sensor issues? MERCEDES-DIAGNOSTIC-TOOL.EDU.VN recommends several diagnostic tools for ABS and wheel speed sensor issues, including:

- Diagnostic Scanners: Advanced scanners that can read ABS codes, access system data, and perform component testing.

- Multimeters: Essential tools for checking continuity, voltage, and resistance in sensor circuits.

- Oscilloscopes: Advanced instruments for analyzing sensor signal waveforms and identifying anomalies.

These tools provide the capabilities needed to accurately diagnose and repair ABS problems.

10.3. Expert Support and Consultation

How can I get expert support and consultation from MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for complex ABS diagnostic issues? MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers expert support and consultation for complex ABS diagnostic issues. Contact our team of experienced technicians for personalized assistance with diagnosing and repairing your Mercedes-Benz’s ABS system. We provide the expertise and support you need to resolve even the most challenging ABS problems.

Understanding and addressing ABS (C-prefix) codes related to wheel speed sensors is essential for maintaining the safety and performance of your Mercedes-Benz. Whether you’re dealing with erratic signals, missing signals, or comparison faults, MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides the resources, tools, and expertise to help you diagnose and repair these issues effectively. Don’t compromise on safety – ensure your ABS system functions optimally with the help of our comprehensive diagnostic solutions.

Ready to take control of your Mercedes-Benz’s ABS diagnostics? Contact us today via WhatsApp at +1 (641) 206-8880 or visit our website at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, located at 789 Oak Avenue, Miami, FL 33101, United States, to learn more about our diagnostic tools and expert support services. Our team is ready to help you accurately diagnose and repair ABS issues, ensuring your vehicle’s safety and performance.

Understanding Mercedes-Benz ABS Sensor functions

FAQ Section

1. What does an ABS C-prefix code indicate?

An ABS C-prefix code indicates an issue within the chassis system of your vehicle, often related to braking components, such as wheel speed sensors. These codes require prompt attention to ensure the ABS functions correctly, maintaining optimal braking performance and safety.

2. How do wheel speed sensors contribute to ABS functionality?

Wheel speed sensors measure the rotational speed of each wheel and transmit this data to the ABS control module. This information helps the ABS determine if a wheel is about to lock up, allowing it to modulate brake pressure and maintain steering control.

3. What are common causes of erratic signals from wheel speed sensors?

Common causes of erratic signals include sensor damage, loose connections, contamination, electromagnetic interference (EMI), and faulty wiring. Addressing these potential causes is crucial for resolving erratic signal issues.

4. What steps should I take to diagnose a missing signal from a wheel speed sensor?

Diagnosing a missing signal involves checking the sensor for continuity, inspecting the wiring for breaks or disconnections, verifying the power supply to the sensor, and testing the ABS control module.

5. What does a comparison fault code signify regarding wheel speed sensors?

A comparison fault code arises when the ABS control module detects a significant difference in speed between two or more wheels. This can be due to inaccurate sensor readings, mechanical issues, or wiring problems.

6. How can a multimeter be used to check the continuity of a wheel speed sensor circuit?

Set the multimeter to the continuity setting and connect the probes to both ends of the sensor wiring. If the multimeter indicates continuity, the circuit is intact. If there is no continuity, there is a break in the circuit.

7. Why is it important to select high-quality replacement parts for wheel speed sensors?

Selecting high-quality replacement parts ensures the reliability and performance of wheel speed sensors. Inferior parts may not meet the required specifications, leading to inaccurate readings or premature failure.

8. How can preventative maintenance help ensure the longevity of wheel speed sensors?

Preventative maintenance includes regular inspection of the sensors and wiring, cleaning the sensors to remove debris, and protecting the wiring from damage. These measures help ensure that the sensors continue to function accurately and reliably.

9. What types of diagnostic guides and resources are available on MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for ABS diagnostics?

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers detailed diagnostic guides, troubleshooting tips, code interpretation guides, and technical articles on ABS systems and components.

10. How can I get expert support from MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for complex ABS diagnostic issues?

Contact our team of experienced technicians for personalized assistance with diagnosing and repairing your Mercedes-Benz’s ABS system. We provide the expertise and support you need to resolve even the most challenging ABS problems.

Potential wiring and connection problems of Mercedes-Benz wheel speed sensors