The scan tool identifies the communication protocol to use by analyzing the OBD-II port’s pin configuration and the data received from the vehicle, ensuring accurate diagnostics, and at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we equip you with the knowledge and tools to navigate this process effectively. This guarantees seamless communication between the diagnostic device and the vehicle’s computer. Enhance your understanding with our expert guidance on Mercedes diagnostics, ECU programming, and automotive repairs.

Contents

- 1. Understanding OBD-II Protocols

- 1.1. What is OBD-II?

- 1.2. Why are OBD-II Protocols Important?

- 1.3. Key OBD-II Protocols

- 2. How Scan Tools Detect Protocols

- 2.1. Automatic Protocol Detection

- 2.2. Pin Configuration Analysis

- 2.3. Data Exchange and Handshaking

- 2.4. Error Handling and Protocol Switching

- 2.5. Role of the Diagnostic Link Connector (DLC)

- 3. Identifying Protocols Manually

- 3.1. Examining the DLC Pinout

- 3.2. Interpreting Pin Combinations

- 3.3. Using Vehicle Documentation

- 3.4. Online Resources and Databases

- 4. The Role of Scan Tools in Mercedes-Benz Diagnostics

- 4.1. Mercedes-Benz Diagnostic Challenges

- 4.2. Importance of Protocol Compatibility in Mercedes-Benz

- 4.3. Recommended Scan Tools for Mercedes-Benz

- 4.4. Advantages of Using Specialized Tools

- 5. Step-by-Step Protocol Identification Guide

- 5.1. Preparation and Safety Measures

- 5.2. Locating the DLC

- 5.3. Visual Inspection of the DLC

- 5.4. Connecting the Scan Tool

- 5.5. Automatic Protocol Detection Process

- 5.6. Manual Protocol Selection (If Necessary)

- 5.7. Verifying the Connection

- 6. Common Issues and Troubleshooting

- 6.1. Scan Tool Compatibility Issues

- 6.2. Connection Problems

- 6.3. Protocol Mismatch

- 6.4. ECU Communication Errors

- 6.5. Software and Firmware Updates

- 7. Advanced Diagnostic Techniques for Mercedes-Benz

- 7.1. Reading and Interpreting Diagnostic Trouble Codes (DTCs)

- 7.2. Live Data Analysis

- 7.3. Actuation Tests

- 7.4. ECU Programming and Coding

- 7.5. Accessing Mercedes-Benz Specific Diagnostic Functions

- 8. Staying Updated with OBD-II Standards and Technologies

- 8.1. Monitoring SAE and ISO Updates

- 8.2. Attending Industry Training and Workshops

- 8.3. Subscribing to Industry Publications and Forums

- 8.4. Utilizing Online Resources and Databases

- 9. Practical Tips for Efficient Diagnostics

- 9.1. Thorough Vehicle Inspection

- 9.2. Documenting Diagnostic Findings

- 9.3. Verifying Repairs

- 9.4. Using a Systematic Approach

- 9.5. Seeking Expert Assistance When Needed

- 10. Real-World Examples of Protocol Identification

- 10.1. Case Study 1: Diagnosing a 2005 Mercedes-Benz C-Class

- 10.2. Case Study 2: Identifying Protocol on a 2000 Ford Explorer

- 10.3. Case Study 3: Troubleshooting a 2010 Toyota Camry

- 11. The Future of OBD-II and Vehicle Diagnostics

- 11.1. Advancements in OBD-III and Beyond

- 11.2. Integration with Telematics and Cloud Services

- 11.3. Role of Artificial Intelligence (AI) in Diagnostics

- 11.4. Enhanced Cybersecurity Measures

- 12. Frequently Asked Questions (FAQs)

- 12.1. What is the best scan tool for Mercedes-Benz vehicles?

- 12.2. How do I know if my vehicle is OBD-II compliant?

- 12.3. Can I use a generic scan tool on my Mercedes-Benz?

- 12.4. What are common OBD-II diagnostic trouble codes?

- 12.5. How often should I run diagnostics on my vehicle?

- 12.6. What is the DLC and where is it located?

- 12.7. What does it mean when my scan tool says “no communication”?

- 12.8. How do I update my scan tool’s software?

- 12.9. What is ECU programming and when is it necessary?

- 12.10. Where can I find more information about Mercedes-Benz specific diagnostics?

- Conclusion

1. Understanding OBD-II Protocols

1.1. What is OBD-II?

OBD-II, or On-Board Diagnostics II, is a standardized system used in vehicles to monitor and diagnose various engine and vehicle parameters. Required for all cars and light trucks sold in the United States after 1996, and with similar mandates in the European Union, OBD-II ensures that vehicles can be easily diagnosed using a universal set of diagnostic trouble codes (DTCs) and communication protocols. According to the Environmental Protection Agency (EPA), this standardization helps reduce emissions and improves vehicle performance.

1.2. Why are OBD-II Protocols Important?

OBD-II protocols are vital because they dictate how diagnostic tools communicate with a vehicle’s engine control unit (ECU). Without a standardized protocol, diagnostic tools would be incompatible with different vehicle makes and models, making it difficult to read diagnostic data and troubleshoot issues. These protocols ensure that any compliant scan tool can access the necessary information to diagnose problems accurately.

1.3. Key OBD-II Protocols

Several communication protocols are used in OBD-II compliant vehicles. Understanding these protocols is essential for technicians and vehicle owners to effectively use scan tools. These include:

- J1850 PWM (Pulse Width Modulation): Primarily used by Ford.

- J1850 VPW (Variable Pulse Width): Predominantly used by General Motors.

- ISO9141-2: Used by Chrysler, European, and Asian vehicles.

- ISO14230-4 (Keyword Protocol 2000): Also used by Chrysler, European, and Asian vehicles.

- ISO15765-4/SAE J2480 (CAN – Controller Area Network): The modern standard used in all vehicles since 2008.

2. How Scan Tools Detect Protocols

2.1. Automatic Protocol Detection

Modern scan tools are designed to automatically detect the OBD-II protocol used by a vehicle. This feature simplifies the diagnostic process, allowing users to quickly connect to the vehicle’s ECU without manually configuring the protocol settings. This automatic detection is typically achieved through a combination of hardware and software algorithms.

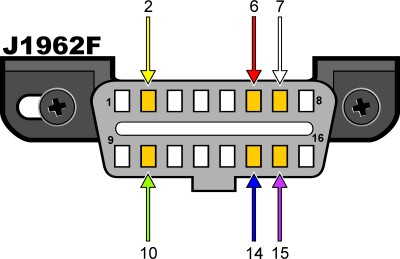

2.2. Pin Configuration Analysis

Scan tools analyze the pin configuration of the vehicle’s Diagnostic Link Connector (DLC) to identify the protocol being used. The DLC, standardized by SAE J1962, has specific pins designated for different protocols. By checking which pins are active, the scan tool can narrow down the possibilities and determine the correct protocol.

2.3. Data Exchange and Handshaking

Once the physical connection is established, the scan tool initiates a data exchange process with the vehicle’s ECU. This process, often referred to as “handshaking,” involves sending specific requests and analyzing the responses to confirm the protocol. The scan tool sends a series of standardized messages and evaluates the format and content of the replies from the ECU.

2.4. Error Handling and Protocol Switching

If the scan tool initially guesses the wrong protocol, it will receive an error message or no response at all. In such cases, the tool will automatically switch to another protocol and repeat the handshaking process until a successful connection is established. This iterative process ensures that the correct protocol is identified, regardless of the vehicle’s make, model, or year.

J1962F OBDII connector pinout

J1962F OBDII connector pinout

2.5. Role of the Diagnostic Link Connector (DLC)

The DLC, also known as the OBD-II port, is the physical interface between the scan tool and the vehicle’s computer system. Standardized by SAE J1962, the DLC ensures that all vehicles have a consistent connection point for diagnostic equipment. The DLC typically has 16 pins, each assigned to specific functions or protocols.

3. Identifying Protocols Manually

3.1. Examining the DLC Pinout

Even with automatic detection, understanding how to manually identify OBD-II protocols can be beneficial. The most straightforward method is to examine the DLC pinout. By identifying which pins are populated, you can determine the protocol used by the vehicle.

- Pin 2: J1850 PWM and J1850 VPW

- Pin 6: CAN (ISO15765-4)

- Pin 7: ISO9141-2 and ISO14230-4

- Pin 10: J1850 PWM

- Pin 14: CAN (ISO15765-4)

- Pin 15: ISO9141-2 and ISO14230-4 (optional)

3.2. Interpreting Pin Combinations

Specific combinations of active pins indicate the protocol in use. For example:

- J1850 PWM: Pins 2, 4, 5, 10, and 16 must be present.

- J1850 VPW: Pins 2, 4, 5, and 16 must be present, but not pin 10.

- ISO9141/14230: Pins 4, 5, 7, and 16 must be present. Pin 15 may or may not be present.

- CAN (ISO15765-4): Pins 4, 5, 6, 14, and 16 must be present.

3.3. Using Vehicle Documentation

Vehicle manufacturers typically provide documentation that specifies the OBD-II protocol used in their vehicles. Consulting the owner’s manual or service documentation can provide definitive information about the protocol, making the diagnostic process more efficient.

3.4. Online Resources and Databases

Several online resources and databases compile information about OBD-II protocols for various vehicle makes and models. These resources can be valuable for technicians and vehicle owners looking to identify the correct protocol for their specific vehicle. Websites like the OBD Resource Center offer extensive lists and guides.

4. The Role of Scan Tools in Mercedes-Benz Diagnostics

4.1. Mercedes-Benz Diagnostic Challenges

Mercedes-Benz vehicles, known for their advanced technology and complex systems, present unique diagnostic challenges. These vehicles often incorporate proprietary systems and require specialized diagnostic tools to accurately read and interpret diagnostic data. Using generic scan tools may not provide comprehensive access to all vehicle systems, potentially leading to inaccurate diagnoses.

4.2. Importance of Protocol Compatibility in Mercedes-Benz

Ensuring protocol compatibility is crucial when diagnosing Mercedes-Benz vehicles. Mercedes-Benz vehicles primarily use the ISO15765-4 (CAN) protocol, especially in newer models. However, older models might use ISO9141-2 or ISO14230-4. Using a scan tool that supports these protocols ensures seamless communication with the vehicle’s ECU, allowing technicians to access all available diagnostic information.

4.3. Recommended Scan Tools for Mercedes-Benz

For Mercedes-Benz vehicles, it is recommended to use scan tools specifically designed for these cars. These tools provide deeper access to the vehicle’s systems and support proprietary diagnostic functions. Some recommended scan tools include:

- Mercedes-Benz Star Diagnosis: The official diagnostic tool used by Mercedes-Benz dealerships.

- iCarsoft MB II: A popular aftermarket scan tool that offers comprehensive diagnostic capabilities for Mercedes-Benz vehicles.

- Autel MaxiSYS Pro: A professional-grade scan tool that supports a wide range of diagnostic functions, including ECU programming and advanced diagnostics.

4.4. Advantages of Using Specialized Tools

Specialized scan tools offer several advantages when diagnosing Mercedes-Benz vehicles:

- Comprehensive System Access: Access to all vehicle systems, including engine, transmission, ABS, SRS, and more.

- Proprietary Diagnostic Functions: Support for proprietary diagnostic functions specific to Mercedes-Benz vehicles.

- Accurate Data Interpretation: Accurate interpretation of diagnostic data, including fault codes and live data parameters.

- ECU Programming Capabilities: Ability to perform ECU programming and coding, allowing for software updates and customization.

5. Step-by-Step Protocol Identification Guide

5.1. Preparation and Safety Measures

Before starting the protocol identification process, ensure you have the necessary tools and equipment. This includes a scan tool, a vehicle diagnostic manual, and appropriate safety gear. Park the vehicle in a well-ventilated area and turn off the ignition.

5.2. Locating the DLC

The DLC is typically located under the dashboard on the driver’s side of the vehicle. Refer to the vehicle’s owner’s manual for the exact location if needed. Ensure the DLC is easily accessible and free from obstructions.

5.3. Visual Inspection of the DLC

Inspect the DLC for any signs of damage or corrosion. Clean the connector if necessary to ensure a good connection with the scan tool. Check the pin configuration to see which pins are populated.

5.4. Connecting the Scan Tool

Connect the scan tool to the DLC. Ensure the connection is secure and that the scan tool is powered on. Follow the scan tool’s instructions for initial setup and configuration.

5.5. Automatic Protocol Detection Process

Most modern scan tools will automatically attempt to detect the protocol. Follow the scan tool’s prompts to initiate the automatic detection process. The scan tool will cycle through different protocols until it finds the correct one.

5.6. Manual Protocol Selection (If Necessary)

If the automatic detection fails, you may need to manually select the protocol. Refer to the vehicle’s documentation or online resources to determine the correct protocol. Select the protocol from the scan tool’s menu and attempt to connect to the vehicle’s ECU.

5.7. Verifying the Connection

Once the connection is established, verify that the scan tool is receiving data from the vehicle’s ECU. Check for live data parameters, such as engine speed, coolant temperature, and throttle position. If the data appears accurate and consistent, the connection is successful.

6. Common Issues and Troubleshooting

6.1. Scan Tool Compatibility Issues

One of the most common issues is scan tool incompatibility. Not all scan tools support all OBD-II protocols, and some may not be compatible with specific vehicle makes and models. Before purchasing or using a scan tool, verify that it supports the protocols used by your vehicle.

6.2. Connection Problems

Connection problems can occur due to damaged or corroded DLC connectors, faulty scan tool cables, or loose connections. Inspect the DLC and scan tool cables for any signs of damage. Ensure all connections are secure and free from obstructions.

6.3. Protocol Mismatch

If the scan tool attempts to use the wrong protocol, it will not be able to communicate with the vehicle’s ECU. Manually select the correct protocol if automatic detection fails. Refer to the vehicle’s documentation or online resources for the correct protocol information.

6.4. ECU Communication Errors

ECU communication errors can occur due to various factors, including a faulty ECU, wiring issues, or software glitches. Check the vehicle’s wiring and connections to the ECU. Consult a qualified technician for further diagnosis and repair if necessary.

6.5. Software and Firmware Updates

Ensure that your scan tool has the latest software and firmware updates. These updates often include improved protocol support, bug fixes, and enhanced diagnostic capabilities. Check the scan tool manufacturer’s website for available updates and follow the instructions for installation.

7. Advanced Diagnostic Techniques for Mercedes-Benz

7.1. Reading and Interpreting Diagnostic Trouble Codes (DTCs)

Diagnostic Trouble Codes (DTCs) are codes stored in the vehicle’s ECU that indicate specific issues or malfunctions. Scan tools are used to read these codes, providing valuable information for diagnosing problems. Understanding how to interpret DTCs is essential for effective troubleshooting.

7.2. Live Data Analysis

Live data analysis involves monitoring real-time data parameters from the vehicle’s sensors and systems. This technique allows technicians to identify abnormal readings and pinpoint the source of problems. Scan tools display live data in various formats, including graphs and charts, making it easier to analyze.

7.3. Actuation Tests

Actuation tests involve using the scan tool to activate specific components or systems in the vehicle. This allows technicians to verify the functionality of these components and identify any issues. For example, you can use an actuation test to activate the fuel pump or cycle the ABS system.

7.4. ECU Programming and Coding

ECU programming and coding involve modifying the software in the vehicle’s ECU to change its behavior or enable new features. This technique is often used to install software updates, customize vehicle settings, or replace a faulty ECU. Specialized scan tools are required for ECU programming and coding.

7.5. Accessing Mercedes-Benz Specific Diagnostic Functions

Mercedes-Benz vehicles often have specific diagnostic functions that are not available on other vehicles. These functions may include accessing proprietary diagnostic codes, performing advanced system tests, or calibrating sensors. Using a scan tool designed for Mercedes-Benz vehicles is essential to access these functions.

8. Staying Updated with OBD-II Standards and Technologies

8.1. Monitoring SAE and ISO Updates

The Society of Automotive Engineers (SAE) and the International Organization for Standardization (ISO) are responsible for developing and maintaining OBD-II standards. Staying informed about updates and changes to these standards is crucial for technicians and vehicle owners. Monitor the SAE and ISO websites for the latest information.

8.2. Attending Industry Training and Workshops

Attending industry training and workshops is an excellent way to stay updated with the latest OBD-II technologies and diagnostic techniques. These events provide hands-on training and insights from industry experts, helping you improve your diagnostic skills.

8.3. Subscribing to Industry Publications and Forums

Subscribing to industry publications and participating in online forums can provide valuable information and insights about OBD-II technologies. These resources often feature articles, tutorials, and discussions about the latest diagnostic tools, techniques, and standards.

8.4. Utilizing Online Resources and Databases

Numerous online resources and databases offer information about OBD-II protocols, diagnostic trouble codes, and troubleshooting tips. Websites like MERCEDES-DIAGNOSTIC-TOOL.EDU.VN are great resources for Mercedes-Benz specific diagnostics and repairs, providing extensive guides and support.

9. Practical Tips for Efficient Diagnostics

9.1. Thorough Vehicle Inspection

Before connecting the scan tool, perform a thorough visual inspection of the vehicle. Check for any obvious signs of damage, such as broken wires, loose connections, or fluid leaks. Addressing these issues before running diagnostics can save time and prevent further complications.

9.2. Documenting Diagnostic Findings

Keep detailed records of your diagnostic findings, including DTCs, live data parameters, and test results. This documentation can be valuable for tracking down intermittent problems, identifying patterns, and sharing information with other technicians.

9.3. Verifying Repairs

After performing repairs, verify that the problem has been resolved by running diagnostics again. Clear any stored DTCs and monitor live data parameters to ensure that the vehicle is operating correctly.

9.4. Using a Systematic Approach

Follow a systematic approach to diagnostics, starting with the most likely causes and working your way through the possible solutions. This approach can help you avoid wasting time and resources on unnecessary repairs.

9.5. Seeking Expert Assistance When Needed

Don’t hesitate to seek expert assistance when needed. If you encounter a complex diagnostic problem that you cannot resolve on your own, consult a qualified technician or refer to the vehicle manufacturer’s service documentation.

10. Real-World Examples of Protocol Identification

10.1. Case Study 1: Diagnosing a 2005 Mercedes-Benz C-Class

A technician was tasked with diagnosing an engine performance issue on a 2005 Mercedes-Benz C-Class. The technician connected a generic scan tool to the vehicle’s DLC, but the tool failed to automatically detect the protocol. By examining the DLC pinout, the technician identified that pins 4, 5, 6, 14, and 16 were populated, indicating the ISO15765-4 (CAN) protocol. After manually selecting this protocol on the scan tool, the technician was able to successfully connect to the vehicle’s ECU and read diagnostic trouble codes.

10.2. Case Study 2: Identifying Protocol on a 2000 Ford Explorer

A vehicle owner was trying to diagnose a check engine light on a 2000 Ford Explorer. The owner connected a scan tool to the vehicle’s DLC, but the tool gave a connection error. Referring to online resources, the owner learned that 2000 Ford Explorers typically use the J1850 PWM protocol. By examining the DLC, the owner confirmed that pins 2, 4, 5, 10, and 16 were present. The owner then manually selected the J1850 PWM protocol on the scan tool and successfully connected to the vehicle’s ECU.

10.3. Case Study 3: Troubleshooting a 2010 Toyota Camry

A mechanic was diagnosing an ABS issue on a 2010 Toyota Camry. The mechanic’s scan tool automatically detected the ISO15765-4 (CAN) protocol, but the connection was intermittent. After inspecting the DLC, the mechanic found corrosion on several pins. Cleaning the pins with a contact cleaner resolved the connection issue, allowing the mechanic to access the vehicle’s ABS system and diagnose the problem.

11. The Future of OBD-II and Vehicle Diagnostics

11.1. Advancements in OBD-III and Beyond

While OBD-II remains the current standard, advancements in vehicle technology are driving the development of future diagnostic systems. OBD-III and beyond promise to offer more comprehensive monitoring, advanced diagnostic capabilities, and improved data access.

11.2. Integration with Telematics and Cloud Services

The integration of OBD-II with telematics and cloud services is transforming vehicle diagnostics. Telematics systems can transmit real-time vehicle data to cloud-based platforms, allowing for remote diagnostics, predictive maintenance, and over-the-air software updates.

11.3. Role of Artificial Intelligence (AI) in Diagnostics

Artificial intelligence (AI) is playing an increasingly important role in vehicle diagnostics. AI-powered diagnostic tools can analyze vast amounts of data to identify patterns, predict failures, and provide automated troubleshooting guidance.

11.4. Enhanced Cybersecurity Measures

As vehicles become more connected, cybersecurity is becoming a critical concern. Future diagnostic systems will need to incorporate enhanced security measures to protect against unauthorized access and prevent malicious attacks.

12. Frequently Asked Questions (FAQs)

12.1. What is the best scan tool for Mercedes-Benz vehicles?

The best scan tool for Mercedes-Benz vehicles is often the Mercedes-Benz Star Diagnosis system, as it provides the most comprehensive access to vehicle systems and supports proprietary diagnostic functions. However, aftermarket tools like the iCarsoft MB II and Autel MaxiSYS Pro also offer excellent capabilities.

12.2. How do I know if my vehicle is OBD-II compliant?

All cars and light trucks sold in the United States after 1996 are required to be OBD-II compliant. You can also check the vehicle’s owner’s manual or look for an OBD-II port under the dashboard.

12.3. Can I use a generic scan tool on my Mercedes-Benz?

While you can use a generic scan tool on your Mercedes-Benz, it may not provide access to all vehicle systems or support proprietary diagnostic functions. Using a scan tool specifically designed for Mercedes-Benz vehicles is recommended.

12.4. What are common OBD-II diagnostic trouble codes?

Common OBD-II diagnostic trouble codes include P0300 (Random/Multiple Cylinder Misfire Detected), P0171 (System Too Lean Bank 1), and P0420 (Catalyst System Efficiency Below Threshold Bank 1).

12.5. How often should I run diagnostics on my vehicle?

You should run diagnostics on your vehicle whenever you notice any performance issues or when the check engine light comes on. Regular diagnostic checks can help identify potential problems early and prevent costly repairs.

12.6. What is the DLC and where is it located?

The DLC (Diagnostic Link Connector), also known as the OBD-II port, is the physical interface between the scan tool and the vehicle’s computer system. It is typically located under the dashboard on the driver’s side of the vehicle.

12.7. What does it mean when my scan tool says “no communication”?

“No communication” typically means that the scan tool is unable to establish a connection with the vehicle’s ECU. This can be due to a faulty connection, incorrect protocol selection, or a problem with the ECU itself.

12.8. How do I update my scan tool’s software?

Refer to the scan tool manufacturer’s website for instructions on how to update the software. Typically, you will need to connect the scan tool to a computer and download the latest software from the manufacturer’s website.

12.9. What is ECU programming and when is it necessary?

ECU programming involves modifying the software in the vehicle’s ECU to change its behavior or enable new features. It is necessary when installing software updates, customizing vehicle settings, or replacing a faulty ECU.

12.10. Where can I find more information about Mercedes-Benz specific diagnostics?

You can find more information about Mercedes-Benz specific diagnostics on websites like MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, which offers extensive guides and support for Mercedes-Benz diagnostics and repairs.

Conclusion

Understanding how a scan tool identifies the correct OBD-II protocol is crucial for effective vehicle diagnostics, especially for complex vehicles like Mercedes-Benz. By combining automatic protocol detection with manual verification techniques, technicians and vehicle owners can ensure accurate communication with the vehicle’s ECU. Utilizing specialized scan tools, staying updated with the latest standards, and following practical diagnostic tips can further enhance the diagnostic process.

Ready to take your Mercedes-Benz diagnostics to the next level? Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN today for expert advice on choosing the right diagnostic tools, unlocking hidden features, and accessing comprehensive repair and maintenance guides. Visit us at 789 Oak Avenue, Miami, FL 33101, United States, or reach out via WhatsApp at +1 (641) 206-8880. Let us help you keep your Mercedes-Benz running smoothly and efficiently.