Manufacturer-specific training courses for DTC diagnostics provide in-depth knowledge, specialized skills, and proprietary information essential for accurately diagnosing and repairing Mercedes-Benz vehicles, which can be easily accessible at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN. These courses enhance diagnostic accuracy, reduce repair times, and improve customer satisfaction, contributing to increased efficiency and profitability for automotive technicians and service centers. They offer the expertise needed to excel in Mercedes-Benz diagnostics, especially with advanced diagnostic equipment and procedures.

Contents

- 2. The Foundation of DTC Diagnostics

- 2.1. What are DTCs?

- 2.2. The Role of the On-Board Diagnostic (OBD) System

- 2.3. OBD-I vs. OBD-II: A Historical Perspective

- 2.4. OBD-II and J1939: Key Standards for Vehicle Diagnostics

- 2.5. Manufacturer-Specific DTCs: The Need for Specialized Knowledge

- 3. Decoding DTCs: A Step-by-Step Guide

- 3.1. Understanding the Structure of an OBD-II DTC

- 3.2. Common DTCs and Their Meanings

- 3.3. Interpreting J1939 DTCs

- 3.4. The Importance of Manufacturer-Specific Training for Accurate Interpretation

- 4. The Value of Manufacturer-Specific Training Courses

- 4.1. Enhanced Diagnostic Accuracy

- 4.2. Reduced Repair Times

- 4.3. Improved Customer Satisfaction

- 4.4. Access to Proprietary Information

- 4.5. Keeping Up with Technological Advancements

- 5. Key Benefits of Choosing MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

- 5.1. Comprehensive Curriculum

- 5.2. Expert Instructors

- 5.3. Hands-On Training

- 5.4. State-of-the-Art Facilities

- 5.5. Career Advancement Opportunities

- 6. Real-World Applications: Case Studies and Examples

- 6.1. Case Study 1: Diagnosing a Complex Electrical Issue

- 6.2. Case Study 2: Resolving an Intermittent Engine Misfire

- 6.3. Example: Utilizing Technical Service Bulletins (TSBs)

- 7. Essential Diagnostic Tools and Equipment

- 7.1. Mercedes-Benz Diagnostic Scanners

- 7.2. Oscilloscopes

- 7.3. Multimeters

- 7.4. Smoke Machines

- 7.5. Pressure Testers

- 8. The Future of Automotive Diagnostics

- 8.1. The Rise of Telematics and Remote Diagnostics

- 8.2. The Integration of Artificial Intelligence (AI)

- 8.3. The Importance of Continuous Learning

- 9. Investing in Your Future: Why Choose Manufacturer-Specific Training?

- 9.1. Increased Earning Potential

- 9.2. Enhanced Job Security

- 9.3. Greater Job Satisfaction

- 10. Getting Started with MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

- 10.1. Exploring Course Offerings

- 10.2. Contacting Admissions

- 10.3. Visiting the Campus

- FAQ: Your Questions About Manufacturer-Specific Training Answered

- What are the benefits of manufacturer-specific training for DTC diagnostics?

- How do manufacturer-specific training courses enhance diagnostic accuracy?

- Can manufacturer-specific training courses reduce repair times?

- Why is access to proprietary information important in manufacturer-specific training?

- How do these training courses help technicians keep up with technological advancements?

- What career opportunities are available after completing manufacturer-specific training?

- What essential diagnostic tools and equipment are covered in these training courses?

- How is artificial intelligence (AI) impacting automotive diagnostics?

- How does manufacturer-specific training enhance job security for technicians?

- What makes MERCEDES-DIAGNOSTIC-TOOL.EDU.VN stand out for manufacturer-specific training?

1. Understanding Diagnostic Trouble Codes (DTCs) and Mercedes-Benz

Diagnostic Trouble Codes (DTCs) are the language your Mercedes-Benz uses to communicate when something isn’t quite right. Think of them as the car’s way of saying, “Hey, there’s an issue here!” While generic DTCs offer a basic understanding, manufacturer-specific training courses, like those offered by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, unlock a deeper level of understanding. These courses provide in-depth knowledge of Mercedes-Benz diagnostic systems, helping technicians pinpoint problems quickly and accurately, ultimately saving time and money. These training courses offered by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN cover advanced diagnostics, repair procedures, and specialized tools.

2. The Foundation of DTC Diagnostics

2.1. What are DTCs?

Diagnostic Trouble Codes (DTCs) are codes generated by a vehicle’s on-board diagnostic (OBD) system. When a fault is detected, the OBD system illuminates the malfunction indicator lamp (MIL), commonly known as the check engine light, and stores a corresponding DTC. These codes provide valuable information about the nature and location of the problem, enabling technicians to diagnose and repair the issue effectively.

2.2. The Role of the On-Board Diagnostic (OBD) System

The On-Board Diagnostic (OBD) system is a computer system in your vehicle that monitors the performance of various components and systems. It plays a critical role in detecting malfunctions and alerting the driver through the check engine light. The OBD system also allows external devices, such as diagnostic scanners, to interact with the vehicle’s computer system and retrieve DTCs.

2.3. OBD-I vs. OBD-II: A Historical Perspective

Over the years, various versions of OBD interfaces have been used. Early interfaces, classified as OBD-I, largely varied from manufacturer to manufacturer. The introduction of OBD-II brought standardization to DTCs, with a common list of codes adopted by all cars following the OBD-II standard. However, manufacturer-specific DTCs still exist to address unique issues in specific car makes and models.

2.4. OBD-II and J1939: Key Standards for Vehicle Diagnostics

Today, two main standards are used to read DTCs: OBD-II and J1939. OBD-II is best suited for light- and medium-duty vehicles, while J1939 is ideal for heavy-duty vehicles and heavy equipment. Cars and light trucks built and sold in the United States after January 1, 1996, are required to be OBD-II equipped. Most diesel engine manufactured vehicles or equipment are J1939 compliant.

2.5. Manufacturer-Specific DTCs: The Need for Specialized Knowledge

While OBD-II provides a standardized set of DTCs, manufacturers like Mercedes-Benz may create their own DTCs to supplement the universal codes. These manufacturer-specific codes address unique systems and components in their vehicles. Interpreting these codes often requires specialized knowledge and training, making manufacturer-specific training courses essential for accurate diagnostics and repairs.

Automobile Engine Control Unit

Automobile Engine Control Unit

3. Decoding DTCs: A Step-by-Step Guide

3.1. Understanding the Structure of an OBD-II DTC

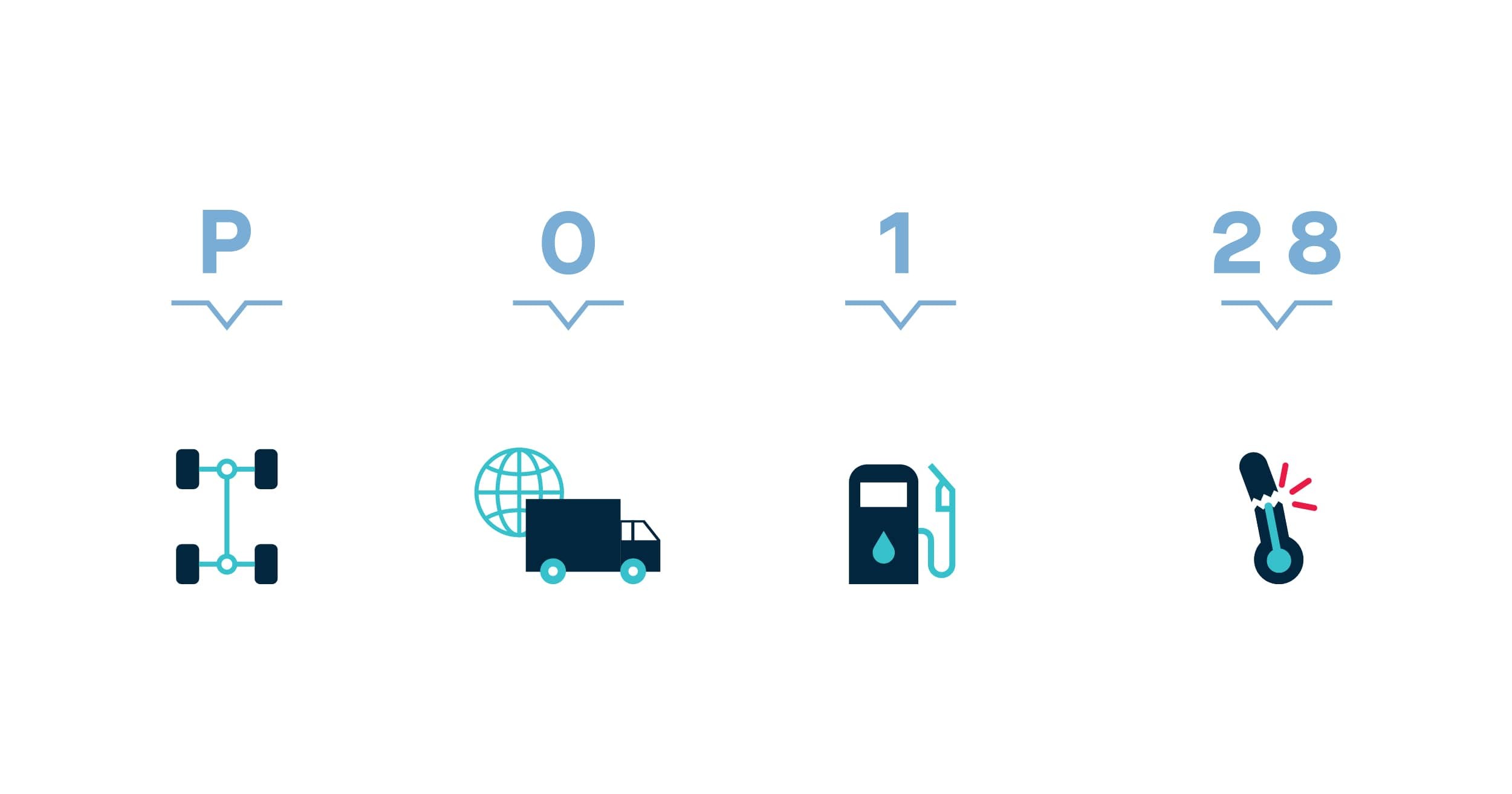

OBD-II DTCs consist of five characters, each providing specific information about the vehicle’s problem. The first character indicates the control system with an issue, with possible values including P (powertrain), C (chassis), B (body), and U (network). The second character indicates whether the code is generic (0) or manufacturer-specific (1). The third character reveals the subsystem at fault, ranging from 1 to 8. The fourth and fifth characters form a two-digit number between 0 and 99, identifying the exact issue.

3.2. Common DTCs and Their Meanings

Certain DTCs are more common than others. Examples include P0442 (small system leak in the evaporative emission control system), P0606 (malfunction in the powertrain control module), P0101 (fault in the mass air flow sensor), P0110 (malfunction in the intake air temperature sensor circuit), P0500 (vehicle speed sensor malfunction), and P0706 (fault in the transmission range sensor circuit range). While DTCs are useful for identifying malfunctions, they do not reveal the underlying cause, requiring further diagnosis by a mechanic.

3.3. Interpreting J1939 DTCs

J1939 DTCs contain four fields: Suspect Parameter Number (SPN), Failure Mode Identifier (FMI), Occurrence Counter (OC), and SPN Conversion Method (CM). The SPN represents the parameter with an error, while the FMI indicates the nature and type of error. The OC counts the occurrences of the error condition, and the CM defines the byte alignment within the DTC.

3.4. The Importance of Manufacturer-Specific Training for Accurate Interpretation

While general knowledge of DTC structures is helpful, manufacturer-specific training is crucial for accurately interpreting DTCs in Mercedes-Benz vehicles. These courses provide detailed information on the specific systems and components used by Mercedes-Benz, enabling technicians to understand the nuances of manufacturer-specific DTCs and diagnose issues with greater precision.

4. The Value of Manufacturer-Specific Training Courses

4.1. Enhanced Diagnostic Accuracy

Manufacturer-specific training courses provide technicians with in-depth knowledge of Mercedes-Benz diagnostic systems, including the intricacies of manufacturer-specific DTCs. This specialized knowledge enables technicians to diagnose issues more accurately, reducing the risk of misdiagnosis and unnecessary repairs.

4.2. Reduced Repair Times

By providing technicians with a deeper understanding of Mercedes-Benz diagnostic systems, manufacturer-specific training courses can significantly reduce repair times. Technicians can quickly pinpoint the source of the problem and implement the appropriate repairs, minimizing downtime and maximizing productivity.

4.3. Improved Customer Satisfaction

Accurate diagnostics and efficient repairs lead to improved customer satisfaction. When technicians can resolve issues quickly and effectively, customers are more likely to be satisfied with the service they receive. Manufacturer-specific training courses empower technicians to deliver exceptional service, enhancing customer loyalty and positive word-of-mouth referrals.

4.4. Access to Proprietary Information

Manufacturer-specific training courses often provide access to proprietary information that is not readily available through other sources. This information may include detailed diagnostic procedures, technical service bulletins, and software updates. Access to this proprietary information can give technicians a significant advantage in diagnosing and repairing Mercedes-Benz vehicles.

4.5. Keeping Up with Technological Advancements

The automotive industry is constantly evolving, with new technologies and systems being introduced on a regular basis. Manufacturer-specific training courses help technicians stay up-to-date with these advancements, ensuring that they have the knowledge and skills necessary to diagnose and repair the latest Mercedes-Benz models.

5. Key Benefits of Choosing MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

5.1. Comprehensive Curriculum

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers a comprehensive curriculum that covers all aspects of Mercedes-Benz diagnostics, from basic principles to advanced techniques. The courses are designed to provide technicians with a thorough understanding of Mercedes-Benz diagnostic systems, enabling them to diagnose and repair a wide range of issues.

5.2. Expert Instructors

The instructors at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN are experienced professionals with extensive knowledge of Mercedes-Benz diagnostics. They are passionate about sharing their expertise and helping technicians develop the skills they need to succeed. The instructors provide personalized attention and guidance, ensuring that each student receives the support they need to master the material.

5.3. Hands-On Training

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN emphasizes hands-on training, providing students with ample opportunities to apply their knowledge in a real-world setting. The courses include practical exercises and case studies that simulate common diagnostic scenarios. This hands-on experience helps technicians develop the skills and confidence they need to diagnose and repair Mercedes-Benz vehicles effectively.

5.4. State-of-the-Art Facilities

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN boasts state-of-the-art facilities equipped with the latest diagnostic tools and equipment. Students have access to the same tools and equipment used by Mercedes-Benz dealerships, ensuring that they are well-prepared for the challenges of the modern automotive repair shop.

5.5. Career Advancement Opportunities

Completing manufacturer-specific training courses at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN can open up a wide range of career advancement opportunities. Technicians with specialized knowledge of Mercedes-Benz diagnostics are in high demand, and they can command higher salaries and more prestigious positions. These courses can also provide a pathway to becoming a certified Mercedes-Benz technician, further enhancing career prospects.

6. Real-World Applications: Case Studies and Examples

6.1. Case Study 1: Diagnosing a Complex Electrical Issue

A Mercedes-Benz vehicle exhibits a complex electrical issue, with multiple warning lights illuminated on the dashboard. A technician without manufacturer-specific training may struggle to pinpoint the source of the problem, potentially leading to misdiagnosis and unnecessary repairs. However, a technician who has completed manufacturer-specific training at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN can leverage their knowledge of Mercedes-Benz electrical systems and diagnostic procedures to quickly identify the root cause of the issue and implement the appropriate repairs.

6.2. Case Study 2: Resolving an Intermittent Engine Misfire

A Mercedes-Benz vehicle experiences an intermittent engine misfire, which is difficult to diagnose using conventional methods. A technician with manufacturer-specific training can utilize advanced diagnostic tools and techniques, such as oscilloscope analysis and fuel trim monitoring, to identify the underlying cause of the misfire and resolve the issue effectively.

6.3. Example: Utilizing Technical Service Bulletins (TSBs)

Technical Service Bulletins (TSBs) provide valuable information on common issues and repair procedures for specific Mercedes-Benz models. Manufacturer-specific training courses often include access to TSBs, enabling technicians to stay up-to-date on the latest repair recommendations and best practices.

7. Essential Diagnostic Tools and Equipment

7.1. Mercedes-Benz Diagnostic Scanners

Mercedes-Benz diagnostic scanners are essential tools for retrieving DTCs and performing advanced diagnostic functions. These scanners provide access to a wide range of diagnostic information, including live data, freeze frame data, and actuation tests.

7.2. Oscilloscopes

Oscilloscopes are used to analyze electrical signals and waveforms, providing valuable insights into the performance of various components and systems. They can be particularly useful for diagnosing intermittent issues and identifying faulty sensors or actuators.

7.3. Multimeters

Multimeters are versatile tools used to measure voltage, current, and resistance. They are essential for troubleshooting electrical circuits and identifying shorts, opens, and other electrical faults.

7.4. Smoke Machines

Smoke machines are used to detect leaks in the intake and exhaust systems. They can be particularly useful for diagnosing vacuum leaks and identifying issues with the evaporative emission control system.

7.5. Pressure Testers

Pressure testers are used to measure pressure in various systems, such as the fuel system, cooling system, and oil system. They can be helpful for diagnosing pressure-related issues, such as fuel pressure problems or coolant leaks.

8. The Future of Automotive Diagnostics

8.1. The Rise of Telematics and Remote Diagnostics

Telematics and remote diagnostics are playing an increasingly important role in the automotive industry. Telematics systems collect data from the vehicle and transmit it to a remote server, enabling technicians to monitor vehicle performance and diagnose issues remotely.

8.2. The Integration of Artificial Intelligence (AI)

Artificial intelligence (AI) is being integrated into diagnostic tools and systems, enabling technicians to diagnose issues more quickly and accurately. AI-powered diagnostic systems can analyze vast amounts of data and identify patterns that would be difficult for humans to detect.

8.3. The Importance of Continuous Learning

As automotive technology continues to evolve, it is essential for technicians to engage in continuous learning. Manufacturer-specific training courses provide a valuable opportunity for technicians to stay up-to-date on the latest advancements and develop the skills they need to succeed in the future.

9. Investing in Your Future: Why Choose Manufacturer-Specific Training?

9.1. Increased Earning Potential

Technicians with manufacturer-specific training are in high demand and can command higher salaries. Their specialized knowledge and skills make them valuable assets to automotive repair shops and dealerships.

9.2. Enhanced Job Security

The automotive industry is constantly evolving, and technicians who are willing to invest in their education and training are more likely to remain employed. Manufacturer-specific training courses demonstrate a commitment to professional development, making technicians more attractive to employers.

9.3. Greater Job Satisfaction

Technicians who are confident in their ability to diagnose and repair complex issues are more likely to experience job satisfaction. Manufacturer-specific training courses empower technicians to excel in their careers and take pride in their work.

10. Getting Started with MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

10.1. Exploring Course Offerings

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers a wide range of courses to meet the needs of technicians at all skill levels. Whether you are a beginner or an experienced professional, you can find a course that will help you enhance your knowledge and skills.

10.2. Contacting Admissions

The admissions team at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN is available to answer any questions you may have about the courses, tuition fees, and enrollment process. Contact them today to learn more about how you can take your career to the next level.

10.3. Visiting the Campus

If possible, consider visiting the MERCEDES-DIAGNOSTIC-TOOL.EDU.VN campus to see the facilities and meet the instructors. This will give you a better sense of the learning environment and help you decide if the program is the right fit for you.

Don’t let Diagnostic Trouble Codes (DTCs) leave you in the dark. Equip yourself with the expert knowledge to confidently diagnose and repair Mercedes-Benz vehicles.

Ready to unlock the full potential of your diagnostic skills?

Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN today for a consultation on the perfect training program for your needs.

Address: 789 Oak Avenue, Miami, FL 33101, United States

Whatsapp: +1 (641) 206-8880

Website: MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

Let MERCEDES-DIAGNOSTIC-TOOL.EDU.VN be your trusted partner in mastering Mercedes-Benz diagnostics!

FAQ: Your Questions About Manufacturer-Specific Training Answered

What are the benefits of manufacturer-specific training for DTC diagnostics?

Manufacturer-specific training offers enhanced diagnostic accuracy, reduced repair times, access to proprietary information, and keeps you updated with technological advancements, improving overall customer satisfaction.

How do manufacturer-specific training courses enhance diagnostic accuracy?

These courses provide in-depth knowledge of specific vehicle systems, manufacturer-specific DTCs, and advanced diagnostic procedures, leading to more accurate diagnoses.

Can manufacturer-specific training courses reduce repair times?

Yes, by providing technicians with a deeper understanding of the diagnostic systems, these courses enable faster identification of issues and more efficient repairs.

Why is access to proprietary information important in manufacturer-specific training?

Proprietary information, such as technical service bulletins and software updates, gives technicians a significant advantage in diagnosing and repairing vehicles accurately.

How do these training courses help technicians keep up with technological advancements?

The automotive industry evolves rapidly, and manufacturer-specific training courses ensure technicians are up-to-date with the latest technologies and systems.

What career opportunities are available after completing manufacturer-specific training?

Completing these courses can lead to higher salaries, more prestigious positions, and certification as a specialist technician.

What essential diagnostic tools and equipment are covered in these training courses?

These courses cover Mercedes-Benz diagnostic scanners, oscilloscopes, multimeters, smoke machines, pressure testers, and other specialized tools.

How is artificial intelligence (AI) impacting automotive diagnostics?

AI is being integrated into diagnostic tools to analyze data and identify patterns, making diagnostics faster and more accurate.

How does manufacturer-specific training enhance job security for technicians?

By demonstrating a commitment to professional development, technicians become more attractive to employers, ensuring job security in a competitive industry.

What makes MERCEDES-DIAGNOSTIC-TOOL.EDU.VN stand out for manufacturer-specific training?

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers a comprehensive curriculum, expert instructors, hands-on training, state-of-the-art facilities, and career advancement opportunities.