The Cat Catalyst Monitor Obd2 is an essential system in your Mercedes for ensuring optimal emissions control, and at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we provide comprehensive insights and solutions to keep it running smoothly. This article delves into how it works, why it’s important, and how to troubleshoot common issues, offering clear guidance and practical tips for Mercedes owners and technicians alike. Trust MERCEDES-DIAGNOSTIC-TOOL.EDU.VN to help you navigate the complexities of your Mercedes’ onboard diagnostics, ensuring your vehicle meets emission standards while maintaining peak performance.

Contents

- 1. What is the Cat Catalyst Monitor OBD2 and Why Is It Important?

- 1.1. Defining the Cat Catalyst Monitor

- 1.2. Purpose and Functionality

- 1.3. Why Is It Important?

- 1.4. Role of Oxygen Sensors

- 1.5. Common Issues Detected

- 2. Understanding OBD2 Monitors and Readiness

- 2.1. What are OBD2 Monitors?

- 2.2. Importance of Monitor Readiness

- 2.3. Factors Affecting Monitor Readiness

- 2.4. How to Check Monitor Status

- 2.5. Common Monitors and Their Requirements

- 3. Common Reasons Why the Catalyst Monitor Won’t Run

- 3.1. Sensor Issues

- 3.2. Exhaust Leaks

- 3.3. Specific Driving Conditions Not Met

- 3.4. Engine Performance Issues

- 3.5. Software Issues

- 4. Step-by-Step Guide to Running the Catalyst Monitor

- 4.1. Preliminary Checks and Preparations

- 4.2. Understanding the Drive Cycle

- 4.3. Performing the Drive Cycle

- 4.4. Monitoring the Catalyst Monitor Status

- 4.5. Troubleshooting Tips

- 5. The Role of Mercedes Diagnostic Tools

- 5.1. Types of Diagnostic Tools

- 5.2. Capabilities and Features

- 5.3. How Diagnostic Tools Aid in Catalyst Monitor Diagnosis

- 5.4. Benefits of Using Mercedes Diagnostic Tools

- 6. Resetting the OBD2 System After Repairs

- 6.1. Why Reset the OBD2 System?

- 6.2. Methods for Resetting the OBD2 System

- 6.3. Precautions and Considerations

- 6.4. Driving the Vehicle to Reset Monitors

- 7. Tips for Maintaining a Healthy Catalyst System

- 7.1. Regular Maintenance

- 7.2. Using Quality Fuel

- 7.3. Addressing Engine Issues Promptly

- 7.4. Avoiding Short Trips

- 7.5. Monitoring Engine Performance

- 7.6. Professional Inspections

- 8. Common Diagnostic Trouble Codes (DTCs) Related to the Catalyst Monitor

- 8.1. P0420 – Catalyst System Efficiency Below Threshold (Bank 1)

- 8.2. P0430 – Catalyst System Efficiency Below Threshold (Bank 2)

- 8.3. P0130 – O2 Sensor Circuit Malfunction (Bank 1, Sensor 1)

- 8.4. P0133 – O2 Sensor Circuit Slow Response (Bank 1, Sensor 1)

- 8.5. P0136 – O2 Sensor Circuit Malfunction (Bank 1, Sensor 2)

- 8.6. P0139 – O2 Sensor Circuit Slow Response (Bank 1, Sensor 2)

- 8.7. P0140 – O2 Sensor Circuit No Activity Detected (Bank 1, Sensor 2)

- 8.8. P0400 – Exhaust Gas Recirculation Flow Malfunction

- 9. The Impact of Aftermarket Parts on the Catalyst Monitor

- 9.1. Quality and Compatibility Issues

- 9.2. Oxygen Sensor Issues

- 9.3. Catalytic Converter Issues

- 9.4. Exhaust Leak Issues

- 9.5. Software Issues

- 9.6. Benefits of Using OEM Parts

1. What is the Cat Catalyst Monitor OBD2 and Why Is It Important?

The cat catalyst monitor OBD2 is an onboard diagnostic system that assesses the performance of your Mercedes’ catalytic converter, an essential component in reducing harmful emissions; its proper function is vital for both environmental compliance and vehicle performance.

The catalyst monitor is like the health inspector of your car’s exhaust system. According to the EPA, catalytic converters reduce harmful emissions such as hydrocarbons, carbon monoxide, and nitrogen oxides by converting them into less harmful substances. When the catalyst monitor OBD2 is functioning correctly, it ensures that the catalytic converter is efficiently reducing these pollutants. This not only helps your car pass emissions tests but also contributes to cleaner air. Failing to address issues with the catalyst monitor can lead to increased emissions, decreased fuel efficiency, and potential damage to other engine components. Understanding the importance of this system is the first step in maintaining your Mercedes in optimal condition.

1.1. Defining the Cat Catalyst Monitor

The cat catalyst monitor is an integral part of the On-Board Diagnostics II (OBD2) system in modern vehicles, including Mercedes-Benz models. According to research from the California Air Resources Board (CARB), the OBD2 system was mandated in 1996 to monitor vehicle emissions and ensure compliance with environmental regulations. The catalyst monitor specifically evaluates the efficiency of the catalytic converter by measuring the oxygen levels before and after the converter. This data helps the vehicle’s Engine Control Module (ECM) determine if the catalytic converter is effectively reducing pollutants.

1.2. Purpose and Functionality

The primary purpose of the cat catalyst monitor is to ensure that the catalytic converter is functioning within acceptable parameters. The ECM uses data from oxygen sensors (O2 sensors) placed before and after the catalytic converter to perform this evaluation. As stated by Bosch in their automotive handbook, the upstream O2 sensor measures the oxygen content in the exhaust gas entering the converter, while the downstream O2 sensor measures the oxygen content after the converter. The difference in oxygen levels indicates the converter’s efficiency. If the ECM detects that the catalytic converter is not performing efficiently, it will trigger the check engine light and store a diagnostic trouble code (DTC) in the OBD2 system.

1.3. Why Is It Important?

The cat catalyst monitor is crucial for several reasons:

- Environmental Compliance: Ensuring that your Mercedes-Benz meets emission standards is essential for legal compliance and environmental protection.

- Vehicle Performance: A properly functioning catalytic converter ensures optimal engine performance and fuel efficiency.

- Early Detection of Issues: The catalyst monitor can detect potential problems with the catalytic converter before they lead to more significant and costly repairs.

- Smog Check Requirements: In many states, including California, a vehicle must have all OBD2 monitors in a “ready” state to pass a smog check, as highlighted by the Bureau of Automotive Repair.

1.4. Role of Oxygen Sensors

Oxygen sensors play a vital role in the operation of the catalyst monitor. According to a study by Delphi Automotive, the O2 sensors provide the ECM with the necessary data to assess the catalytic converter’s efficiency. The upstream O2 sensor measures the air-fuel ratio of the exhaust gas, while the downstream O2 sensor measures the oxygen content after the catalytic converter has done its job. By comparing the signals from both sensors, the ECM can determine if the converter is functioning correctly. If the downstream sensor shows similar readings to the upstream sensor, it indicates that the catalytic converter is not efficiently reducing pollutants, triggering the catalyst monitor to report a failure.

1.5. Common Issues Detected

The cat catalyst monitor can detect several common issues related to the catalytic converter, including:

- Catalytic Converter Efficiency Below Threshold: This is the most common issue, indicating that the converter is not effectively reducing pollutants.

- Oxygen Sensor Malfunctions: Faulty or degraded O2 sensors can provide inaccurate data, leading to false readings and incorrect diagnoses.

- Exhaust Leaks: Leaks in the exhaust system can affect the readings of the O2 sensors and the overall efficiency of the catalytic converter.

- Engine Performance Issues: Problems such as misfires, lean or rich fuel conditions, and vacuum leaks can affect the performance of the catalytic converter and trigger the catalyst monitor.

2. Understanding OBD2 Monitors and Readiness

OBD2 monitors are diagnostic programs within your Mercedes’ computer that continuously check various systems; monitor readiness indicates whether these tests have been completed, which is crucial for passing emissions tests.

Understanding OBD2 monitors and their readiness status is vital for any Mercedes-Benz owner. These monitors are like internal quality control checks that your car performs on itself. As detailed by the Society of Automotive Engineers (SAE), OBD2 monitors continuously test various systems, including the catalytic converter, oxygen sensors, evaporative emissions system, and more. When these monitors are in a “ready” state, it means they have completed their tests and verified that the systems are functioning correctly. This is especially important for passing emissions tests, where all or most monitors must be ready to ensure compliance.

2.1. What are OBD2 Monitors?

OBD2 monitors are diagnostic routines that run in the background to check the functionality of various emission-related components and systems in your Mercedes-Benz. These monitors are designed to detect malfunctions that could lead to increased emissions. According to the EPA, the OBD2 system includes monitors for:

- Catalyst Monitor: Checks the efficiency of the catalytic converter.

- Oxygen Sensor Monitor: Verifies the performance of the oxygen sensors.

- Evaporative System Monitor: Detects leaks in the fuel vapor recovery system.

- Secondary Air System Monitor: Checks the operation of the secondary air injection system.

- Misfire Monitor: Detects engine misfires that could damage the catalytic converter.

- Fuel System Monitor: Monitors the fuel delivery system for proper operation.

2.2. Importance of Monitor Readiness

Monitor readiness refers to the status of these diagnostic tests. When a monitor is “ready,” it means the test has been completed, and the system has been verified as functioning correctly. If a monitor is “not ready,” it means the test has not been completed or a fault has been detected. As explained by the California Bureau of Automotive Repair, vehicles in California must have all or most monitors in a “ready” state to pass a smog check. The specific requirements vary depending on the model year of the vehicle.

2.3. Factors Affecting Monitor Readiness

Several factors can affect the readiness status of OBD2 monitors in your Mercedes-Benz:

- Recent Battery Disconnection: Disconnecting the battery can reset the OBD2 system, causing all monitors to be set to “not ready.”

- Clearing Diagnostic Trouble Codes (DTCs): Using a scan tool to clear DTCs also resets the monitors.

- Engine Performance Issues: Problems such as misfires, vacuum leaks, or faulty sensors can prevent monitors from running.

- Specific Driving Conditions: Some monitors require specific driving conditions to run, such as sustained highway speeds or a cold start.

2.4. How to Check Monitor Status

You can check the status of the OBD2 monitors using a scan tool. Many affordable OBD2 scanners are available that can plug into your Mercedes-Benz’s OBD2 port and display the readiness status of each monitor. Some advanced scan tools can also provide detailed information about the conditions required to run each monitor. Additionally, some Mercedes-Benz models have a built-in function to display monitor status through the instrument cluster.

2.5. Common Monitors and Their Requirements

Each OBD2 monitor has specific requirements to run and achieve a “ready” status. Here are some common monitors and their typical requirements:

- Catalyst Monitor: Requires a stable engine temperature, steady highway speeds, and a certain amount of drive time.

- Oxygen Sensor Monitor: Needs the engine to reach operating temperature and cycle through various load conditions.

- Evaporative System Monitor: Often requires a cold start and a specific fuel level in the gas tank.

- Misfire Monitor: Continuously runs during normal driving conditions.

To ensure your Mercedes-Benz passes an emissions test, it’s essential to understand the status of your OBD2 monitors and take the necessary steps to get them into a “ready” state. If you’re having trouble getting a specific monitor to run, consult with a qualified technician or refer to the factory service manual for your vehicle.

3. Common Reasons Why the Catalyst Monitor Won’t Run

Several factors can prevent the catalyst monitor from running, including sensor issues, exhaust leaks, and specific driving conditions not being met; addressing these can help resolve the problem.

There are several reasons why the catalyst monitor on your Mercedes-Benz might not run, leaving you frustrated and potentially unable to pass an emissions test. Understanding these common issues is the first step in diagnosing and resolving the problem. According to automotive diagnostic experts at AESwave, the catalyst monitor requires very specific conditions to run, and any deviation from these conditions can prevent the monitor from completing its test.

3.1. Sensor Issues

One of the most common reasons for the catalyst monitor not running is related to faulty or degraded sensors. The catalyst monitor relies heavily on the data from the oxygen sensors (O2 sensors) to assess the efficiency of the catalytic converter. If these sensors are not functioning correctly, the ECM may not be able to accurately evaluate the converter’s performance, preventing the monitor from running. Common sensor-related issues include:

- Faulty O2 Sensors: Damaged or malfunctioning O2 sensors can provide inaccurate readings, leading to false diagnoses.

- Degraded O2 Sensors: Over time, O2 sensors can become less sensitive and provide slow or inaccurate readings, even if they are not completely failing.

- Wiring Issues: Damaged or corroded wiring to the O2 sensors can disrupt the signal and prevent the monitor from running.

3.2. Exhaust Leaks

Exhaust leaks can also prevent the catalyst monitor from running properly. Leaks in the exhaust system can allow outside air to enter, affecting the readings of the O2 sensors. This can disrupt the monitor’s ability to accurately assess the catalytic converter’s efficiency. Exhaust leaks can occur at various points in the exhaust system, including:

- Exhaust Manifold: Leaks at the exhaust manifold gasket or cracks in the manifold itself.

- Exhaust Pipes: Corrosion or damage to the exhaust pipes can create leaks.

- Catalytic Converter: Leaks at the inlet or outlet flanges of the catalytic converter.

- O2 Sensor Bungs: Leaks around the O2 sensor bungs can also affect sensor readings.

3.3. Specific Driving Conditions Not Met

The catalyst monitor often requires specific driving conditions to run. These conditions can include:

- Engine Temperature: The engine must reach and maintain a certain operating temperature.

- Vehicle Speed: The vehicle must be driven at a steady speed, often on the highway.

- Load Conditions: The engine may need to operate under specific load conditions, such as a steady throttle position.

- Drive Time: The monitor may require a certain amount of drive time to complete its test.

If these conditions are not met, the catalyst monitor may not run. For example, if you primarily drive in stop-and-go traffic, the catalyst monitor may never have the opportunity to complete its test.

3.4. Engine Performance Issues

Underlying engine performance issues can also prevent the catalyst monitor from running. Problems such as misfires, vacuum leaks, or fuel system issues can affect the overall performance of the catalytic converter and prevent the monitor from completing its test. Common engine performance issues include:

- Misfires: Engine misfires can damage the catalytic converter and prevent the monitor from running.

- Vacuum Leaks: Vacuum leaks can disrupt the air-fuel mixture and affect the performance of the catalytic converter.

- Fuel System Issues: Problems such as a faulty fuel injector or a malfunctioning fuel pump can also affect the catalyst monitor.

3.5. Software Issues

In some cases, software issues within the vehicle’s Engine Control Module (ECM) can prevent the catalyst monitor from running. These issues can include:

- Software Glitches: Occasionally, glitches in the ECM software can prevent the monitor from running.

- Outdated Software: In some cases, updating the ECM software can resolve issues with the catalyst monitor.

- Incorrect Programming: If the ECM has been incorrectly programmed, it can affect the operation of the catalyst monitor.

Addressing these common reasons can significantly improve your chances of getting the catalyst monitor to run and ensuring your Mercedes-Benz passes its emissions test. If you’re unsure how to diagnose and resolve these issues, consulting with a qualified technician at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN is always a good idea.

4. Step-by-Step Guide to Running the Catalyst Monitor

To run the catalyst monitor, ensure your Mercedes is in good condition, follow a specific drive cycle, and monitor the progress using an OBD2 scanner; precise execution is key to success.

Running the catalyst monitor on your Mercedes-Benz can be a challenging but achievable task. Following a step-by-step guide can significantly increase your chances of success. According to information from Mercedes-Benz’s official service manuals, a specific drive cycle must be followed to allow the catalyst monitor to run. This guide will walk you through the necessary steps to get your catalyst monitor into a “ready” state.

4.1. Preliminary Checks and Preparations

Before attempting to run the catalyst monitor, it’s essential to ensure that your Mercedes-Benz is in good working condition. This includes:

- Check Engine Light: Ensure that the check engine light is not illuminated. If it is, address any stored diagnostic trouble codes (DTCs) before proceeding.

- Maintenance: Perform any necessary maintenance, such as oil changes, spark plug replacements, and air filter replacements.

- Fuel Level: Ensure that your fuel tank is between 1/4 and 3/4 full. Some monitors, especially the evaporative system monitor, require a specific fuel level to run.

- OBD2 Scanner: Have an OBD2 scanner ready to monitor the progress of the catalyst monitor.

4.2. Understanding the Drive Cycle

The drive cycle is a specific set of driving conditions that must be met to allow the catalyst monitor to run. The exact drive cycle can vary depending on the model year and engine type of your Mercedes-Benz. However, a typical drive cycle for the catalyst monitor includes the following steps:

- Cold Start: Start the engine and allow it to idle for approximately two minutes. This allows the engine to reach its initial operating temperature.

- Acceleration: Accelerate to a steady speed of 45-55 mph (72-88 km/h) on a level highway.

- Cruising: Maintain this steady speed for at least five minutes. Avoid sudden acceleration or deceleration.

- Deceleration: Slowly release the accelerator and allow the vehicle to coast down to 20 mph (32 km/h) without using the brakes.

- Repeat: Repeat steps 2-4 several times, as needed.

4.3. Performing the Drive Cycle

When performing the drive cycle, keep the following tips in mind:

- Safety First: Choose a safe location, such as a lightly trafficked highway, to perform the drive cycle.

- Steady Speeds: Maintain steady speeds and avoid sudden changes in acceleration or deceleration.

- Monitor Progress: Use your OBD2 scanner to monitor the progress of the catalyst monitor. The scanner will indicate whether the monitor is running and whether it has completed its test.

- Patience: The catalyst monitor may take several drive cycles to complete its test. Be patient and continue to follow the drive cycle instructions.

4.4. Monitoring the Catalyst Monitor Status

Using your OBD2 scanner, you can monitor the status of the catalyst monitor in real-time. The scanner will typically display the monitor status as either “complete” or “incomplete.” Once the catalyst monitor has completed its test, the status will change to “complete.”

4.5. Troubleshooting Tips

If the catalyst monitor does not run after several attempts, consider the following troubleshooting tips:

- Check for DTCs: Ensure that there are no stored DTCs that could be preventing the monitor from running.

- Verify Sensor Operation: Use the OBD2 scanner to check the operation of the oxygen sensors. Ensure that they are providing accurate readings.

- Inspect for Exhaust Leaks: Check for any exhaust leaks that could be affecting the monitor’s ability to run.

- Consult a Technician: If you’re unable to resolve the issue on your own, consult with a qualified technician at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for further diagnosis and repair.

By following these steps and tips, you can increase your chances of successfully running the catalyst monitor on your Mercedes-Benz and ensuring that it is ready for an emissions test. Remember, patience and attention to detail are key to success.

5. The Role of Mercedes Diagnostic Tools

Mercedes diagnostic tools provide in-depth analysis and pinpoint accuracy in identifying issues with the catalyst monitor; these tools save time and ensure accurate repairs.

Mercedes diagnostic tools play a crucial role in diagnosing and resolving issues related to the catalyst monitor. These tools provide in-depth analysis and pinpoint accuracy in identifying problems that might not be apparent through visual inspection or generic OBD2 scanners. According to Mercedes-Benz’s official documentation, specialized diagnostic equipment is often necessary to fully evaluate the complex systems within their vehicles.

5.1. Types of Diagnostic Tools

There are several types of diagnostic tools available for Mercedes-Benz vehicles, each with its own capabilities and features:

- Mercedes-Benz Star Diagnosis: This is the factory-level diagnostic tool used by Mercedes-Benz dealerships and authorized service centers. It provides comprehensive diagnostic capabilities, including the ability to read and clear DTCs, perform advanced system tests, and reprogram control units.

- Autel MaxiSys: This is a popular aftermarket diagnostic tool that offers similar capabilities to the Mercedes-Benz Star Diagnosis. It supports a wide range of Mercedes-Benz models and provides in-depth diagnostic information.

- iCarsoft MB II: This is a more affordable option that is specifically designed for Mercedes-Benz vehicles. It can read and clear DTCs, perform basic system tests, and reset service reminders.

- Generic OBD2 Scanners: While generic OBD2 scanners can read basic DTCs related to the catalyst monitor, they typically do not provide the in-depth diagnostic information needed to accurately diagnose and resolve complex issues.

5.2. Capabilities and Features

Mercedes diagnostic tools offer a wide range of capabilities and features that are essential for diagnosing catalyst monitor issues:

- Reading and Clearing DTCs: These tools can read and clear diagnostic trouble codes (DTCs) related to the catalyst monitor and other emission-related systems.

- Live Data Streaming: They can display live data from the oxygen sensors, catalytic converter, and other related components, allowing technicians to monitor their performance in real-time.

- Actuator Testing: Diagnostic tools can perform actuator tests to verify the operation of various components, such as the oxygen sensor heaters and the secondary air injection system.

- System Programming and Reprogramming: Some advanced diagnostic tools can reprogram control units, such as the Engine Control Module (ECM), to address software issues that may be affecting the catalyst monitor.

- Freeze Frame Data: These tools can capture freeze frame data, which provides a snapshot of the vehicle’s operating conditions at the time a DTC was set.

5.3. How Diagnostic Tools Aid in Catalyst Monitor Diagnosis

Mercedes diagnostic tools can aid in catalyst monitor diagnosis in several ways:

- Pinpointing the Root Cause: By providing in-depth diagnostic information, these tools can help technicians pinpoint the root cause of the catalyst monitor issue, whether it’s a faulty sensor, an exhaust leak, or an engine performance problem.

- Verifying Sensor Operation: Diagnostic tools can be used to verify the operation of the oxygen sensors and ensure that they are providing accurate readings.

- Identifying Exhaust Leaks: Some diagnostic tools can perform tests to identify exhaust leaks that may be affecting the catalyst monitor.

- Evaluating Engine Performance: These tools can be used to evaluate engine performance and identify issues such as misfires or vacuum leaks that may be contributing to the catalyst monitor problem.

- Confirming Repairs: After performing repairs, diagnostic tools can be used to confirm that the issue has been resolved and that the catalyst monitor is now running correctly.

5.4. Benefits of Using Mercedes Diagnostic Tools

There are several benefits to using Mercedes diagnostic tools for catalyst monitor diagnosis and repair:

- Accuracy: These tools provide accurate and reliable diagnostic information, reducing the risk of misdiagnosis and unnecessary repairs.

- Efficiency: By pinpointing the root cause of the issue quickly, diagnostic tools can save time and labor costs.

- Comprehensive Analysis: These tools offer a comprehensive analysis of the vehicle’s systems, allowing technicians to identify potential problems before they become major issues.

- Access to Factory Information: Some diagnostic tools provide access to factory service information, including wiring diagrams, technical service bulletins, and repair procedures.

Investing in a Mercedes diagnostic tool or seeking the assistance of a technician who has access to one can greatly improve your ability to diagnose and resolve catalyst monitor issues. With the right tool and knowledge, you can keep your Mercedes-Benz running smoothly and ensure that it passes its emissions tests.

6. Resetting the OBD2 System After Repairs

After completing repairs, resetting the OBD2 system allows the monitors to run again, ensuring the effectiveness of the fix; however, it’s essential to drive the vehicle to allow the monitors to reset properly.

Resetting the OBD2 system after completing repairs is an essential step to ensure that the catalyst monitor and other emission-related systems are functioning correctly. Resetting the system clears any stored diagnostic trouble codes (DTCs) and allows the monitors to run again, verifying the effectiveness of the repair. According to automotive repair experts, it’s crucial to follow the proper procedure for resetting the OBD2 system to avoid potential problems.

6.1. Why Reset the OBD2 System?

There are several reasons why you should reset the OBD2 system after completing repairs:

- Clear Stored DTCs: Resetting the system clears any stored DTCs that may be related to the catalyst monitor or other emission-related systems.

- Allow Monitors to Run: Resetting the system allows the monitors to run again and verify that the repairs have been effective.

- Ensure Proper Operation: Resetting the system ensures that the vehicle’s computer is operating with the latest information and that all systems are functioning correctly.

- Prepare for Emissions Testing: In many states, vehicles must have all OBD2 monitors in a “ready” state to pass an emissions test. Resetting the system and allowing the monitors to run is essential for preparing your vehicle for testing.

6.2. Methods for Resetting the OBD2 System

There are several methods for resetting the OBD2 system on your Mercedes-Benz:

- Using an OBD2 Scanner: The most common method for resetting the OBD2 system is to use an OBD2 scanner. Simply plug the scanner into the OBD2 port, select the “clear codes” or “reset” function, and follow the prompts.

- Disconnecting the Battery: Disconnecting the battery for a period of time can also reset the OBD2 system. However, this method may also reset other electronic systems in the vehicle, such as the radio and the navigation system.

- Driving the Vehicle: In some cases, simply driving the vehicle for a period of time can reset the OBD2 system. The vehicle’s computer will automatically run the monitors and clear any stored DTCs if the underlying issues have been resolved.

6.3. Precautions and Considerations

Before resetting the OBD2 system, consider the following precautions and considerations:

- Verify Repairs: Ensure that all necessary repairs have been completed before resetting the system. Resetting the system without addressing the underlying issues will only result in the DTCs returning.

- Record DTCs: Before resetting the system, record any stored DTCs. This will help you track the effectiveness of the repairs and identify any new issues that may arise.

- Allow Monitors to Run: After resetting the system, allow the monitors to run before attempting to pass an emissions test. This may require driving the vehicle for a period of time and under specific conditions.

- Consult a Technician: If you’re unsure how to reset the OBD2 system or if you have any concerns, consult with a qualified technician at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for assistance.

6.4. Driving the Vehicle to Reset Monitors

After resetting the OBD2 system, it’s essential to drive the vehicle to allow the monitors to run and verify that the repairs have been effective. The specific driving conditions required to run the monitors can vary depending on the model year and engine type of your Mercedes-Benz. However, a typical drive cycle includes the following:

- Cold Start: Start the engine and allow it to idle for approximately two minutes.

- Acceleration: Accelerate to a steady speed of 45-55 mph (72-88 km/h) on a level highway.

- Cruising: Maintain this steady speed for at least five minutes.

- Deceleration: Slowly release the accelerator and allow the vehicle to coast down to 20 mph (32 km/h) without using the brakes.

- Repeat: Repeat steps 2-4 several times, as needed.

Monitoring the status of the monitors using an OBD2 scanner can help you determine when they have completed their tests and are in a “ready” state.

7. Tips for Maintaining a Healthy Catalyst System

Maintaining a healthy catalyst system involves regular maintenance, using quality fuel, and addressing engine issues promptly; these practices extend the life of the catalytic converter and ensure optimal performance.

Maintaining a healthy catalyst system in your Mercedes-Benz is essential for ensuring optimal emissions control, fuel efficiency, and engine performance. The catalytic converter is a critical component of the exhaust system, and taking proactive steps to maintain its health can extend its lifespan and prevent costly repairs. According to the EPA, proper maintenance and care can significantly improve the performance and longevity of the catalyst system.

7.1. Regular Maintenance

Regular maintenance is key to keeping your catalyst system in good condition. This includes:

- Oil Changes: Perform regular oil changes according to the manufacturer’s recommendations. Dirty or contaminated oil can damage the catalytic converter.

- Spark Plug Replacement: Replace spark plugs at the recommended intervals. Misfiring spark plugs can cause raw fuel to enter the exhaust system, damaging the catalytic converter.

- Air Filter Replacement: Replace the air filter regularly. A dirty air filter can restrict airflow to the engine, causing it to run rich and potentially damage the catalytic converter.

- Fuel Filter Replacement: Replace the fuel filter at the recommended intervals. A clogged fuel filter can restrict fuel flow to the engine, causing it to run lean and potentially damage the catalytic converter.

7.2. Using Quality Fuel

Using quality fuel can also help maintain a healthy catalyst system. Low-quality fuel may contain additives that can damage the catalytic converter. Using premium fuel that meets the manufacturer’s specifications can help prevent damage and extend the lifespan of the converter.

7.3. Addressing Engine Issues Promptly

Addressing engine issues promptly can also help maintain a healthy catalyst system. Problems such as misfires, vacuum leaks, or fuel system issues can affect the performance of the catalytic converter and potentially damage it. Addressing these issues as soon as they arise can help prevent further damage and extend the lifespan of the converter.

7.4. Avoiding Short Trips

Avoiding short trips can also help maintain a healthy catalyst system. Short trips can prevent the catalytic converter from reaching its optimal operating temperature, which can reduce its efficiency and potentially damage it over time. Taking longer trips allows the converter to reach its optimal operating temperature and function properly.

7.5. Monitoring Engine Performance

Monitoring engine performance can also help you identify potential problems with the catalyst system. Keep an eye out for warning signs such as:

- Check Engine Light: A illuminated check engine light can indicate a problem with the catalyst system or other emission-related systems.

- Decreased Fuel Efficiency: A sudden decrease in fuel efficiency can indicate a problem with the catalytic converter.

- Rough Running Engine: A rough running engine can indicate a problem with the catalyst system or other engine components.

- Unusual Odors: Unusual odors from the exhaust system can indicate a problem with the catalytic converter.

7.6. Professional Inspections

Finally, consider having your catalyst system inspected by a qualified technician at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN on a regular basis. A professional inspection can help identify potential problems early on and prevent costly repairs down the road.

By following these tips, you can help maintain a healthy catalyst system in your Mercedes-Benz and ensure that it continues to provide optimal emissions control, fuel efficiency, and engine performance for years to come.

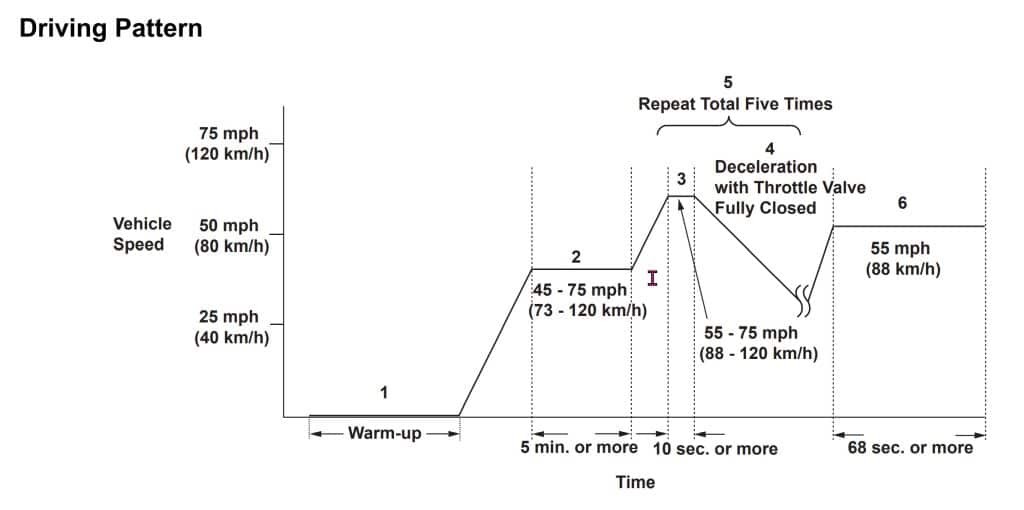

Catalyst drive cycle graph with speed and time plotted. (Honda version)

Catalyst drive cycle graph with speed and time plotted. (Honda version)

8. Common Diagnostic Trouble Codes (DTCs) Related to the Catalyst Monitor

Various DTCs can indicate catalyst monitor issues, each requiring specific diagnostic steps; understanding these codes helps in efficient troubleshooting.

Several diagnostic trouble codes (DTCs) can be triggered by issues related to the catalyst monitor in your Mercedes-Benz. Understanding these common DTCs and their potential causes can help you troubleshoot and resolve catalyst monitor problems more efficiently. According to the Society of Automotive Engineers (SAE), DTCs are standardized codes that provide information about the nature and location of a fault within a vehicle’s systems.

8.1. P0420 – Catalyst System Efficiency Below Threshold (Bank 1)

This is one of the most common DTCs associated with the catalyst monitor. It indicates that the catalytic converter on Bank 1 is not operating at its required efficiency level. Potential causes include:

- Faulty Catalytic Converter: The catalytic converter itself may be worn out or damaged.

- Faulty Oxygen Sensors: The oxygen sensors upstream or downstream of the catalytic converter may be providing inaccurate readings.

- Exhaust Leaks: Exhaust leaks near the catalytic converter or oxygen sensors can affect the readings and trigger the code.

- Engine Performance Issues: Problems such as misfires, vacuum leaks, or fuel system issues can affect the performance of the catalytic converter.

8.2. P0430 – Catalyst System Efficiency Below Threshold (Bank 2)

This DTC is similar to P0420 but applies to the catalytic converter on Bank 2. The potential causes are the same as those for P0420.

8.3. P0130 – O2 Sensor Circuit Malfunction (Bank 1, Sensor 1)

This DTC indicates a malfunction in the oxygen sensor circuit on Bank 1, Sensor 1 (upstream sensor). Potential causes include:

- Faulty Oxygen Sensor: The oxygen sensor itself may be damaged or malfunctioning.

- Wiring Issues: Damaged or corroded wiring to the oxygen sensor can disrupt the signal.

- Connector Issues: A loose or corroded connector can also cause this code.

- ECM Issues: In rare cases, a problem with the Engine Control Module (ECM) can trigger this code.

8.4. P0133 – O2 Sensor Circuit Slow Response (Bank 1, Sensor 1)

This DTC indicates that the oxygen sensor on Bank 1, Sensor 1 is responding slowly to changes in the exhaust gas composition. Potential causes include:

- Degraded Oxygen Sensor: The oxygen sensor may be old or worn out and not responding quickly enough.

- Exhaust Leaks: Exhaust leaks near the oxygen sensor can affect its readings.

- Wiring Issues: Damaged or corroded wiring to the oxygen sensor can slow down its response time.

8.5. P0136 – O2 Sensor Circuit Malfunction (Bank 1, Sensor 2)

This DTC indicates a malfunction in the oxygen sensor circuit on Bank 1, Sensor 2 (downstream sensor). The potential causes are the same as those for P0130.

8.6. P0139 – O2 Sensor Circuit Slow Response (Bank 1, Sensor 2)

This DTC indicates that the oxygen sensor on Bank 1, Sensor 2 is responding slowly to changes in the exhaust gas composition. The potential causes are the same as those for P0133.

8.7. P0140 – O2 Sensor Circuit No Activity Detected (Bank 1, Sensor 2)

This DTC indicates that there is no activity detected from the oxygen sensor on Bank 1, Sensor 2. This could be due to a faulty sensor, wiring issues, or a problem with the ECM.

8.8. P0400 – Exhaust Gas Recirculation Flow Malfunction

While not directly related to the catalyst monitor, this DTC can affect the performance of the catalytic converter. It indicates a problem with the Exhaust Gas Recirculation (EGR) system, which can affect the air-fuel mixture and potentially damage the catalytic converter.

When troubleshooting catalyst monitor issues, it’s essential to start by reading the DTCs stored in the vehicle’s computer. This will provide valuable information about the nature and location of the fault. From there, you can use diagnostic tools and procedures to pinpoint the root cause of the problem and perform the necessary repairs. If you’re unsure how to proceed, consult with a qualified technician at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for assistance.

9. The Impact of Aftermarket Parts on the Catalyst Monitor

Using non-OEM parts can affect the catalyst monitor’s performance, potentially leading to inaccurate readings or failure to run; OEM parts ensure compatibility and reliability.

The impact of aftermarket parts on the catalyst monitor can be significant. While aftermarket parts may seem like a cost-effective alternative to OEM (Original Equipment Manufacturer) parts, they can sometimes affect the performance of the catalyst monitor and other emission-related systems. According to automotive experts, using non-OEM parts can lead to inaccurate readings, failure to run, and other issues that can prevent your Mercedes-Benz from passing an emissions test.

9.1. Quality and Compatibility Issues

One of the main concerns with aftermarket parts is their quality and compatibility. OEM parts are designed and manufactured to meet the specific requirements of your Mercedes-Benz. They are tested and validated to ensure that they will function correctly and reliably. Aftermarket parts, on the other hand, may not always meet the same standards. They may be made from lower-quality materials, have different specifications, or not be fully compatible with your vehicle’s systems.

9.2. Oxygen Sensor Issues

Oxygen sensors are critical to the operation of the catalyst monitor. Aftermarket oxygen sensors may not provide the same level of accuracy and reliability as OEM sensors. This can lead to inaccurate readings, which can prevent the catalyst monitor from running or cause it to trigger false DTCs.

9.3. Catalytic Converter Issues

Aftermarket catalytic converters may not meet the same efficiency standards as OEM converters. This can result in the catalyst monitor detecting that the converter is not operating at its required efficiency level, triggering a P0420 or P0430 DTC.

9.4. Exhaust Leak Issues

Aftermarket exhaust components, such as exhaust pipes and mufflers, may not fit as precisely as OEM components. This can lead to exhaust leaks, which can affect the readings of the oxygen sensors and prevent the catalyst monitor from running.

9.5. Software Issues

In some cases, using aftermarket parts can cause software issues that affect the catalyst monitor. For example, some aftermarket performance chips or tuners can alter the vehicle’s programming in a way that prevents the catalyst monitor from running.

9.6. Benefits of Using OEM Parts

There are several benefits to using OEM parts for your Mercedes-Benz:

- Quality and Reliability: OEM parts are designed and manufactured to meet the highest standards of quality and reliability.

- Compatibility: OEM parts are designed to be fully compatible with your vehicle’s systems.

- Warranty: OEM parts typically come with a warranty, providing you with added peace of mind.

- Performance: OEM parts are designed to provide optimal performance and efficiency.

- Emissions Compliance: OEM parts are designed to meet all applicable emissions standards.

While aftermarket parts may seem like a more affordable option, the potential risks and drawbacks can outweigh the cost savings. Using OEM parts can help ensure that your Mercedes-Benz is running at its best and that it will pass its emissions tests without any problems.