Decoding Obd2 Responses involves interpreting the data received from a vehicle’s On-Board Diagnostics system, allowing users to understand the vehicle’s health and performance and MERCEDES-DIAGNOSTIC-TOOL.EDU.VN can assist you with that. This process translates raw data into meaningful information, enabling informed decisions about maintenance and repairs, ultimately saving time and money with the right diagnostic tools and expertise. Understanding diagnostic trouble codes (DTCs), accessing real-time data, and vehicle communication protocols are key in decoding OBD2 responses effectively.

Contents

- 1. Understanding the Basics of OBD2

- 1.1. What is the Purpose of OBD2?

- 1.2. A Brief History of OBD2

- 1.3. Why is OBD2 Important for Modern Vehicles?

- 2. Essential Components for Decoding OBD2 Responses

- 2.1. Understanding OBD2 Scanners

- 2.2. Selecting the Right Software for OBD2 Decoding

- 2.3. The Role of the OBD2 Connector

- 3. Understanding Common OBD2 Protocols

- 3.1. CAN Bus (Controller Area Network)

- 3.2. ISO 9141-2

- 3.3. SAE J1850 (VPW and PWM)

- 4. Decoding Diagnostic Trouble Codes (DTCs)

- 4.1. Understanding the Structure of DTCs

- 4.2. Common DTCs and Their Meanings

- 4.3. Using DTCs for Effective Diagnostics

- 5. Accessing and Interpreting Real-Time Data

- 5.1. Identifying Key PIDs for Diagnosis

- 5.2. Interpreting Real-Time Data Values

- 5.3. Using Graphs and Data Logging for Analysis

- 6. Advanced Techniques in Decoding OBD2 Responses

- 6.1. Performing Advanced Diagnostic Procedures

- 6.2. Working with OEM-Specific Data

- 6.3. Utilizing Bi-Directional Controls

- 7. Common Challenges and Solutions in OBD2 Decoding

- 7.1. Addressing Communication Errors

- 7.2. Dealing with Inaccurate Data

- 7.3. Managing Complex Vehicle Systems

- 8. The Future of OBD and Vehicle Diagnostics

- 8.1. OBD3 and Remote Diagnostics

- 8.2. Integration with Telematics and IoT

- 8.3. The Role of AI and Machine Learning

- 9. Practical Applications and Use Cases

- 9.1. Personal Vehicle Maintenance

- 9.2. Fleet Management

- 9.3. Automotive Research and Development

- 10. Frequently Asked Questions (FAQs)

1. Understanding the Basics of OBD2

The On-Board Diagnostics II (OBD2) system is standardized across the automotive industry. It serves as a crucial tool for monitoring a vehicle’s performance and diagnosing potential issues. This section delves into the core aspects of OBD2, including its functions, history, and significance in modern vehicle maintenance.

1.1. What is the Purpose of OBD2?

OBD2 is designed to provide vehicle owners and technicians with access to the health information of a car. According to the Environmental Protection Agency (EPA), OBD2 systems monitor the performance of major engine components, including those responsible for controlling emissions. This monitoring helps ensure that vehicles operate within regulatory standards and reduces environmental impact. The OBD2 system achieves this by:

- Monitoring Emissions: Keeping track of emission levels to ensure compliance with environmental regulations.

- Diagnosing Problems: Identifying malfunctions within the engine and related systems.

- Providing Data: Offering real-time data on vehicle performance metrics to aid in troubleshooting.

1.2. A Brief History of OBD2

The evolution of OBD2 is rooted in the need for standardized vehicle diagnostics. The journey began in California with the California Air Resources Board (CARB) mandating OBD systems in new cars from 1991 onward for emission control. This requirement set the stage for broader adoption and standardization. Key milestones in OBD2 history include:

- 1996: OBD2 became mandatory in the United States for all cars and light trucks, standardizing diagnostic trouble codes (DTCs) and the OBD connector, as outlined by the Society of Automotive Engineers (SAE).

- 2001: The European Union required OBD compliance for gasoline cars.

- 2003: OBD compliance extended to diesel cars in the European Union (EOBD).

- 2008: CAN bus (ISO 15765-4) was mandated as the basis for OBD2 in US cars.

- 2010: OBD2 requirements expanded to include heavy-duty vehicles in the United States.

1.3. Why is OBD2 Important for Modern Vehicles?

OBD2 is vital for maintaining modern vehicles due to its capacity to offer detailed insights into vehicle operations. Its importance is underscored by:

- Early Problem Detection: OBD2 enables early detection of potential issues, preventing costly repairs down the line.

- Standardized Diagnostics: The standardization of OBD2 ensures that any compliant scan tool can communicate with any vehicle, streamlining the diagnostic process.

- Emission Control: By monitoring emissions, OBD2 helps vehicles remain environmentally compliant, reducing pollution.

2. Essential Components for Decoding OBD2 Responses

To effectively decode OBD2 responses, understanding the necessary tools and components is critical. This section outlines the key elements required for this process, including OBD2 scanners, software, and the OBD2 connector itself.

2.1. Understanding OBD2 Scanners

An OBD2 scanner is a diagnostic tool used to retrieve data from a vehicle’s OBD2 system. These scanners range from basic code readers to advanced diagnostic platforms. According to a study by Grand View Research, the global automotive diagnostic scan tools market is expected to grow, highlighting the increasing reliance on these tools for vehicle maintenance. Key features of OBD2 scanners include:

- Reading DTCs: Retrieving diagnostic trouble codes that indicate specific problems.

- Clearing DTCs: Resetting the check engine light after repairs are made.

- Viewing Real-Time Data: Displaying live data from sensors and systems within the vehicle.

2.2. Selecting the Right Software for OBD2 Decoding

Software plays a crucial role in decoding OBD2 responses, translating raw data into actionable information. Various software options are available, each offering different features and capabilities. Important software features include:

- Compatibility: Ensuring the software is compatible with your OBD2 scanner and vehicle.

- Data Interpretation: Translating raw OBD2 data into understandable formats.

- Advanced Diagnostics: Providing advanced diagnostic features such as graphing, data logging, and custom reports.

2.3. The Role of the OBD2 Connector

The OBD2 connector, or Data Link Connector (DLC), is a standardized 16-pin interface that provides access to the vehicle’s diagnostic data. As specified in SAE J1962, the connector is typically located within reach of the driver, though its exact location may vary by vehicle. Key aspects of the OBD2 connector include:

- Standardization: Ensuring universal compatibility between vehicles and diagnostic tools.

- Pin Configuration: Providing specific pins for power, ground, and communication protocols.

- Data Access: Allowing scanners to communicate with the vehicle’s electronic control units (ECUs) to retrieve diagnostic information.

3. Understanding Common OBD2 Protocols

OBD2 communication relies on several protocols, each dictating how data is transmitted and interpreted. This section examines the primary protocols used in OBD2 systems, including CAN bus, ISO 9141-2, and SAE J1850, highlighting their importance and application.

3.1. CAN Bus (Controller Area Network)

CAN bus (Controller Area Network) is the predominant protocol used in modern OBD2 systems. Since 2008, it has been mandatory in all cars sold in the US, as per ISO 15765. The CAN bus protocol allows different electronic control units (ECUs) within the vehicle to communicate with each other without a host computer. Key features of CAN bus in OBD2 include:

- High-Speed Communication: Enabling rapid data exchange between ECUs.

- Error Detection: Providing robust error detection and correction mechanisms.

- Standardization: Ensuring consistent communication across different vehicle systems.

3.2. ISO 9141-2

ISO 9141-2 is an older protocol used in OBD2 systems, primarily in European, Chrysler, and Asian cars from 2000 to 2004. While less common in newer vehicles, understanding ISO 9141-2 is essential for diagnosing older models. Key aspects of ISO 9141-2 include:

- K-Line Communication: Using a K-line for serial data transmission.

- Low-Speed Communication: Offering slower data transfer rates compared to CAN bus.

- Diagnostic Capabilities: Providing essential diagnostic information for engine and emission-related issues.

3.3. SAE J1850 (VPW and PWM)

SAE J1850 is another legacy protocol used in older OBD2 systems, mainly in General Motors (VPW) and Ford (PWM) vehicles. Though largely replaced by CAN bus, familiarity with SAE J1850 is helpful for servicing classic cars. Key characteristics of SAE J1850 include:

- Variable Pulse Width (VPW): Used by GM for data transmission.

- Pulse Width Modulation (PWM): Used by Ford for data transmission.

- Diagnostic Data: Providing access to diagnostic information, including DTCs and real-time sensor data.

4. Decoding Diagnostic Trouble Codes (DTCs)

Diagnostic Trouble Codes (DTCs) are a fundamental aspect of OBD2, providing specific information about vehicle malfunctions. This section details how to interpret DTCs, understand their structure, and utilize them for effective vehicle diagnostics.

4.1. Understanding the Structure of DTCs

DTCs are standardized codes that help identify the source of a problem within a vehicle’s systems. These codes consist of five characters: a letter followed by four digits. The letter indicates the system involved, while the digits specify the exact fault. According to the SAE J2012 standard, the first character categories of DTCs are:

- P (Powertrain): Relates to the engine, transmission, and associated components.

- B (Body): Concerns systems such as airbags, power windows, and central locking.

- C (Chassis): Pertains to the braking system, suspension, and steering.

- U (Network): Indicates issues with the vehicle’s communication network.

4.2. Common DTCs and Their Meanings

Certain DTCs are more frequently encountered than others, and understanding these common codes can expedite the diagnostic process. Examples of common DTCs include:

- P0300: Random/Multiple Cylinder Misfire Detected, indicating potential issues with ignition, fuel delivery, or compression.

- P0171: System Too Lean (Bank 1), suggesting a vacuum leak, faulty oxygen sensor, or fuel delivery problem.

- P0420: Catalyst System Efficiency Below Threshold (Bank 1), indicating a potential issue with the catalytic converter.

4.3. Using DTCs for Effective Diagnostics

To effectively utilize DTCs, follow these steps:

- Retrieve the DTC: Use an OBD2 scanner to read the DTC from the vehicle’s computer.

- Research the DTC: Consult repair manuals, online databases, or professional diagnostic tools to understand the code’s meaning and potential causes.

- Verify the Problem: Perform tests and inspections to confirm the issue indicated by the DTC.

- Repair the Problem: Address the root cause of the problem, which may involve replacing faulty parts or repairing damaged components.

- Clear the DTC: After completing the repair, clear the DTC and monitor the vehicle to ensure the problem is resolved.

5. Accessing and Interpreting Real-Time Data

Real-time data, also known as live data or parameter identification (PID) data, provides a dynamic view of a vehicle’s operating conditions. This section explores how to access and interpret real-time data, highlighting its role in diagnosing complex issues and monitoring vehicle performance.

5.1. Identifying Key PIDs for Diagnosis

Parameter Identification (PID) data includes a wide array of sensor readings and system statuses. Identifying key PIDs is essential for targeted diagnostics. According to the OBD2 PID standard, common PIDs include:

- Engine Speed (RPM): Indicates the rotational speed of the engine.

- Vehicle Speed: Shows the current speed of the vehicle.

- Engine Coolant Temperature: Monitors the temperature of the engine coolant.

- Oxygen Sensor Readings: Provides data on the oxygen content in the exhaust gases.

- Fuel Trim Values: Indicates adjustments made to the fuel delivery system.

5.2. Interpreting Real-Time Data Values

Interpreting real-time data involves comparing the values against expected ranges and looking for anomalies that indicate potential problems. For example:

- Unstable RPM at Idle: May indicate a vacuum leak, faulty idle air control valve, or other engine-related issues.

- Abnormal Oxygen Sensor Readings: Could suggest a faulty sensor, exhaust leak, or catalytic converter problem.

- High Coolant Temperature: May indicate a cooling system issue, such as a failing thermostat or radiator.

5.3. Using Graphs and Data Logging for Analysis

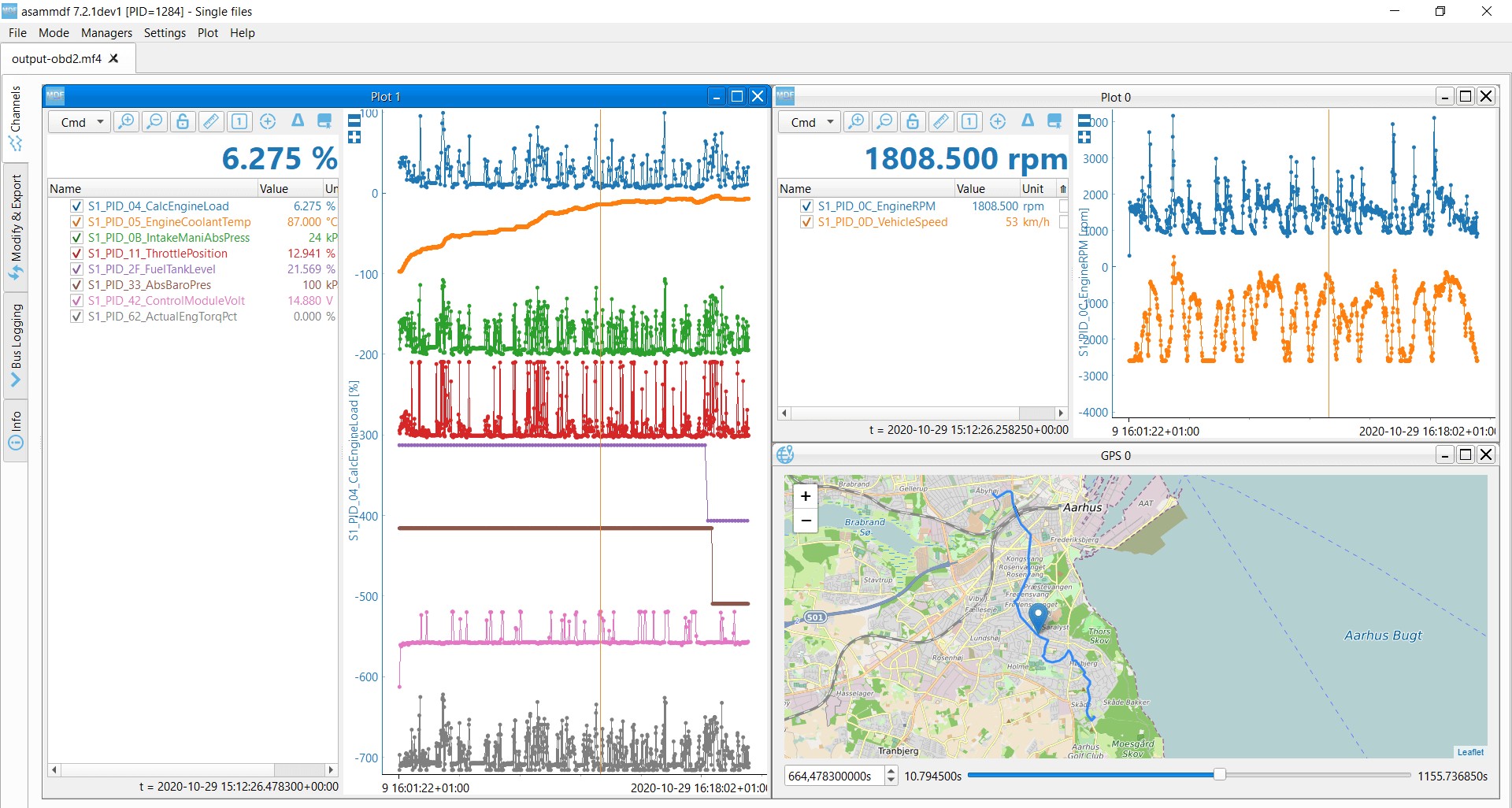

Graphs and data logging are powerful tools for analyzing real-time data. By plotting data over time, technicians can identify trends and patterns that may not be apparent from static readings. Data logging allows for the recording of multiple PIDs simultaneously, providing a comprehensive view of vehicle performance under different operating conditions.

- Graphing: Helps visualize changes in PID values, making it easier to spot irregularities.

- Data Logging: Enables the recording of data for later analysis, useful for diagnosing intermittent problems or evaluating the effectiveness of repairs.

6. Advanced Techniques in Decoding OBD2 Responses

Advanced techniques in decoding OBD2 responses involve a deeper understanding of vehicle communication protocols and diagnostic strategies. This section discusses advanced diagnostic procedures, working with OEM-specific data, and using bi-directional controls.

6.1. Performing Advanced Diagnostic Procedures

Advanced diagnostic procedures go beyond basic code reading and data analysis, incorporating techniques such as:

- Voltage Drop Testing: Measuring voltage drops in electrical circuits to identify shorts or high resistance.

- Compression Testing: Assessing the compression in each cylinder to identify engine-related issues.

- Fuel System Testing: Evaluating the fuel pump pressure, injector performance, and fuel trim values to diagnose fuel delivery problems.

6.2. Working with OEM-Specific Data

While OBD2 provides standardized data, Original Equipment Manufacturers (OEMs) often include proprietary data and diagnostic capabilities. Accessing and interpreting OEM-specific data can offer deeper insights into vehicle systems. Key considerations include:

- OEM Diagnostic Tools: Using diagnostic tools designed by the vehicle manufacturer to access proprietary data.

- Subscription Services: Subscribing to OEM diagnostic databases for access to technical information and repair procedures.

- Reverse Engineering: Analyzing CAN bus data to reverse engineer proprietary protocols and signals.

6.3. Utilizing Bi-Directional Controls

Bi-directional controls allow technicians to send commands to the vehicle’s ECUs, activating or deactivating specific components for testing purposes. This capability is essential for diagnosing complex issues. Common bi-directional controls include:

- Activating Fuel Injectors: Testing injector performance and identifying faulty injectors.

- Controlling Cooling Fans: Verifying the operation of cooling fans and diagnosing cooling system issues.

- Operating ABS Modules: Testing the anti-lock braking system and diagnosing ABS-related problems.

OBD2 data decoded visual plot asammdf CAN bus DBC file

OBD2 data decoded visual plot asammdf CAN bus DBC file

7. Common Challenges and Solutions in OBD2 Decoding

Decoding OBD2 responses can present various challenges, including communication errors, inaccurate data, and dealing with complex vehicle systems. This section addresses these common challenges and provides practical solutions.

7.1. Addressing Communication Errors

Communication errors can occur between the OBD2 scanner and the vehicle’s ECUs, preventing data retrieval. Common causes include:

- Faulty Connector: Inspect the OBD2 connector for damaged pins or loose connections.

- Incorrect Protocol: Ensure the scanner is using the correct communication protocol for the vehicle.

- ECU Issues: Investigate potential problems with the vehicle’s ECUs, such as power supply or internal faults.

7.2. Dealing with Inaccurate Data

Inaccurate data can lead to misdiagnosis and incorrect repairs. To address this, consider:

- Sensor Calibration: Verify the calibration of sensors and replace any that are out of specification.

- Wiring Issues: Check for damaged or corroded wiring that may affect sensor readings.

- Software Updates: Ensure the diagnostic software is up-to-date with the latest vehicle information.

7.3. Managing Complex Vehicle Systems

Modern vehicles feature increasingly complex systems, making diagnostics more challenging. Strategies for managing this complexity include:

- Comprehensive Training: Invest in ongoing training to stay current with new vehicle technologies.

- Diagnostic Tools: Utilize advanced diagnostic tools with comprehensive system coverage and diagnostic capabilities.

- Technical Resources: Consult technical service bulletins, repair manuals, and online forums for guidance and support.

8. The Future of OBD and Vehicle Diagnostics

The future of OBD and vehicle diagnostics is evolving with advancements in technology, connectivity, and data analytics. This section explores emerging trends and innovations shaping the future of OBD systems.

8.1. OBD3 and Remote Diagnostics

OBD3 is an emerging standard that aims to enhance vehicle diagnostics through remote monitoring and data transmission. The concept involves equipping vehicles with a transponder to transmit VIN and DTCs to a central server via WiFi. Key aspects of OBD3 include:

- Remote Monitoring: Enabling continuous monitoring of vehicle health and emissions.

- Real-Time Alerts: Providing immediate alerts for detected issues, allowing for proactive maintenance.

- Data Analytics: Leveraging data analytics to identify trends, predict failures, and improve vehicle performance.

8.2. Integration with Telematics and IoT

The integration of OBD with telematics and the Internet of Things (IoT) is expanding the capabilities of vehicle diagnostics. Telematics systems can collect and transmit a wide range of vehicle data, enabling:

- Predictive Maintenance: Anticipating maintenance needs based on real-time data analysis.

- Fleet Management: Optimizing fleet operations through data-driven insights.

- Usage-Based Insurance: Offering insurance premiums based on actual driving behavior and vehicle usage.

8.3. The Role of AI and Machine Learning

Artificial Intelligence (AI) and machine learning are poised to revolutionize vehicle diagnostics by:

- Automated Diagnostics: Automating the diagnostic process, reducing the need for manual analysis.

- Predictive Modeling: Developing predictive models to anticipate potential failures and optimize maintenance schedules.

- Personalized Recommendations: Providing personalized recommendations for vehicle maintenance and repair based on individual driving habits and vehicle conditions.

9. Practical Applications and Use Cases

OBD2 data logging has various practical applications across different sectors, from personal vehicle maintenance to fleet management and automotive research. This section explores real-world use cases that highlight the value of OBD2 data.

9.1. Personal Vehicle Maintenance

For individual vehicle owners, OBD2 data logging can:

- Reduce Fuel Costs: By monitoring fuel consumption and identifying inefficient driving habits.

- Improve Driving: By providing insights into driving behavior and identifying areas for improvement.

- Prevent Costly Repairs: By detecting potential issues early and addressing them before they escalate.

9.2. Fleet Management

In fleet management, OBD2 data logging enables:

- Real-Time Monitoring: Tracking the location, performance, and health of fleet vehicles in real-time.

- Preventive Maintenance: Scheduling maintenance based on actual vehicle usage and condition, reducing downtime.

- Driver Safety: Monitoring driver behavior, such as speeding and harsh braking, to improve safety and reduce accident rates.

9.3. Automotive Research and Development

Automotive researchers and engineers use OBD2 data for:

- Performance Testing: Evaluating the performance of new components and systems under real-world conditions.

- Emissions Monitoring: Measuring vehicle emissions and ensuring compliance with regulatory standards.

- Data Analysis: Analyzing vehicle data to identify areas for improvement in design and engineering.

10. Frequently Asked Questions (FAQs)

Here are some frequently asked questions about decoding OBD2 responses:

1. What is OBD2 and why is it important?

OBD2 is an on-board diagnostics system that monitors vehicle performance and helps identify issues, ensuring compliance with emissions standards and enabling early detection of problems.

2. Which OBD2 scanner should I choose?

The choice depends on your needs; basic code readers are suitable for simple diagnostics, while advanced scanners offer more comprehensive features like real-time data and bi-directional controls.

3. How do I interpret a DTC?

DTCs are five-character codes; the first letter indicates the system (e.g., P for Powertrain), and the digits specify the exact fault. Consult repair manuals or online databases for detailed information.

4. What is the CAN bus protocol?

CAN bus (Controller Area Network) is the primary protocol used in modern OBD2 systems for high-speed communication between a vehicle’s electronic control units (ECUs).

5. What is real-time data, and how is it useful?

Real-time data includes live readings from various sensors, providing a dynamic view of a vehicle’s operating conditions for targeted diagnostics.

6. How can I use graphs and data logging for OBD2 analysis?

Graphs help visualize changes in PID values over time, while data logging allows you to record multiple PIDs simultaneously for comprehensive analysis.

7. What are bi-directional controls?

Bi-directional controls allow you to send commands to the vehicle’s ECUs to activate or deactivate specific components for testing purposes.

8. What are common challenges in decoding OBD2 responses?

Common challenges include communication errors, inaccurate data, and managing the complexity of modern vehicle systems.

9. What is OBD3, and how does it differ from OBD2?

OBD3 is an emerging standard that enhances vehicle diagnostics through remote monitoring and real-time data transmission for proactive maintenance.

10. How is AI impacting vehicle diagnostics?

AI is revolutionizing vehicle diagnostics through automated diagnostics, predictive modeling, and personalized maintenance recommendations.

For personalized assistance with decoding OBD2 responses and selecting the right tools and services, contact us at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN. Our team is ready to help you unlock the full potential of your Mercedes-Benz.

Contact Information:

- Address: 789 Oak Avenue, Miami, FL 33101, United States

- WhatsApp: +1 (641) 206-8880

- Website: MERCEDES-DIAGNOSTIC-TOOL.EDU.VN