What does PID mean in OBD2? In On-Board Diagnostics II (OBD2), PID stands for Parameter Identification. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers you a complete guide on understanding and utilizing PIDs for vehicle diagnostics, helping you efficiently monitor your Mercedes-Benz. Explore the specifics of OBD2 parameter IDs, their importance in diagnosing vehicle issues, and how to use them effectively.

Contents

- 1. Understanding OBD2 and Its Components

- 1.1. What is OBD2?

- 1.2. Key Components of OBD2

- 1.3. Why is OBD2 Important?

- 2. What Does PID Mean in OBD2?

- 2.1. Definition of PID

- 2.2. Role of PIDs in Vehicle Diagnostics

- 2.3. Examples of Common PIDs

- 3. How OBD2 PIDs Work

- 3.1. Request and Response Mechanism

- 3.2. Interpreting PID Data

- 3.3. Standardized vs. Manufacturer-Specific PIDs

- 4. Using OBD2 PIDs for Diagnostics

- 4.1. Connecting an OBD2 Scan Tool

- 4.2. Requesting and Reading PIDs

- 4.3. Interpreting Real-Time Data

- 4.4. Identifying Potential Issues

- 5. OBD2 PID Table: Common Parameters and Their Meanings

- 5.1. Comprehensive List of Common PIDs

- 5.2. Understanding PID Descriptions

- 5.3. Interpreting Units and Scaling

- 6. Advanced OBD2 PID Techniques

- 6.1. Using Mode 0x01 PID 0x00 for Compatibility Testing

- 6.2. Understanding and Utilizing Proprietary PIDs

- 6.3. Addressing Common Issues with OBD2 PIDs

- 7. OBD2 PID Data Logging and Analysis

- 7.1. Setting Up Data Logging

- 7.2. Choosing the Right Data Logging Tools

- 7.3. Analyzing Logged Data

- 7.4. Identifying Trends and Anomalies

- 8. Practical Examples of OBD2 PID Diagnostics

- 8.1. Diagnosing Engine Misfires

- 8.2. Identifying Fuel System Issues

- 8.3. Troubleshooting Emissions Problems

- 9. Future Trends in OBD and PIDs

- 9.1. Integration with Telematics

- 9.2. Enhanced Diagnostic Capabilities

- 9.3. Wireless Communication and Remote Diagnostics

- 10. Common Mistakes to Avoid When Using OBD2 PIDs

- 10.1. Incorrect PID Selection

- 10.2. Misinterpreting Data

- 10.3. Ignoring Contextual Information

- FAQ: Understanding OBD2 PIDs

- What is the difference between a PID and a DTC?

- Can I use any OBD2 scan tool with any car?

- How do I find the right PID for a specific parameter?

- What does it mean if a PID returns no data?

- Are OBD2 PIDs the same for all car manufacturers?

- Can I damage my car by using an OBD2 scan tool?

- How often should I check my car’s OBD2 system?

- What are the limitations of using OBD2 PIDs for diagnostics?

- How do I update my OBD2 scan tool?

- What is the role of the ECU in OBD2 PID diagnostics?

1. Understanding OBD2 and Its Components

OBD2, or On-Board Diagnostics II, is a standardized system used in vehicles to monitor and report on various engine and vehicle parameters. It’s like a health checkup for your car, providing valuable insights into its performance and potential issues.

1.1. What is OBD2?

OBD2 is a self-diagnostic system present in most vehicles manufactured after 1996. It monitors various engine and vehicle parameters, allowing you to extract diagnostic trouble codes (DTCs) and real-time data through the OBD2 connector. This system helps mechanics and car owners alike diagnose issues more efficiently.

1.2. Key Components of OBD2

The main components of an OBD2 system include:

- OBD2 Connector: A 16-pin connector used to interface with the vehicle’s diagnostic system.

- Diagnostic Trouble Codes (DTCs): Codes that indicate specific issues or malfunctions detected by the system.

- Parameter Identification (PIDs): Codes used to request and receive real-time data about specific parameters.

- Scan Tool: A device used to read DTCs and PIDs from the OBD2 system.

1.3. Why is OBD2 Important?

OBD2 is essential for several reasons:

- Emission Control: It helps monitor and control vehicle emissions, ensuring compliance with environmental regulations. According to the California Air Resources Board (CARB), OBD systems were initially mandated for emission control purposes in California in 1991.

- Early Problem Detection: It allows for early detection of potential issues, preventing costly repairs down the road.

- Diagnostic Efficiency: It provides standardized data, making it easier for mechanics to diagnose and repair vehicles.

2. What Does PID Mean in OBD2?

PID, or Parameter Identification, is a crucial element within the OBD2 framework. It refers to the codes used to request specific pieces of real-time data from a vehicle’s electronic control units (ECUs).

2.1. Definition of PID

In OBD2, PID stands for Parameter Identification. These are codes used to request specific data parameters from the vehicle’s computer.

2.2. Role of PIDs in Vehicle Diagnostics

PIDs play a pivotal role in vehicle diagnostics by enabling users to access real-time data. This data can include engine speed (RPM), vehicle speed, coolant temperature, and many other parameters. By monitoring these parameters, technicians and car owners can identify anomalies and potential issues.

2.3. Examples of Common PIDs

Some common PIDs include:

- 0x0C: Engine RPM

- 0x0D: Vehicle Speed

- 0x05: Coolant Temperature

- 0x0B: Intake Manifold Absolute Pressure

Each PID corresponds to a specific data point, allowing for precise monitoring and diagnostics.

3. How OBD2 PIDs Work

Understanding how OBD2 PIDs work involves looking at the request and response mechanism, data interpretation, and the standardization of PIDs.

3.1. Request and Response Mechanism

The OBD2 communication process involves a request-response mechanism. A scan tool sends a request to the vehicle’s ECU using a specific PID. The ECU then responds with the data corresponding to that PID.

3.2. Interpreting PID Data

The data returned by the ECU needs to be interpreted to be meaningful. This often involves converting raw hexadecimal values into physical units, such as kilometers per hour (km/h) or degrees Celsius (°C).

3.3. Standardized vs. Manufacturer-Specific PIDs

While many PIDs are standardized across all OBD2-compliant vehicles, some manufacturers use proprietary PIDs to access additional data specific to their vehicles. Standardized PIDs are defined by SAE J1979 and ISO 15031-5, ensuring uniformity across different makes and models.

4. Using OBD2 PIDs for Diagnostics

Using OBD2 PIDs for diagnostics involves several steps, from connecting the scan tool to interpreting the data.

4.1. Connecting an OBD2 Scan Tool

The first step is to connect an OBD2 scan tool to the OBD2 connector in your vehicle. The connector is typically located under the dashboard, near the steering wheel.

4.2. Requesting and Reading PIDs

Once connected, use the scan tool to request specific PIDs. The tool will display the data returned by the ECU in real-time.

4.3. Interpreting Real-Time Data

Interpreting real-time data involves understanding the normal ranges for each parameter and identifying any deviations that may indicate a problem. For example, an unusually high coolant temperature could indicate a cooling system issue.

4.4. Identifying Potential Issues

By monitoring PIDs, you can identify potential issues such as:

- Engine Performance Problems: Irregularities in engine RPM or intake manifold pressure.

- Emissions Issues: Abnormal readings from oxygen sensors or catalytic converters.

- Cooling System Problems: High coolant temperatures.

5. OBD2 PID Table: Common Parameters and Their Meanings

A comprehensive OBD2 PID table provides a detailed list of common parameters, their PIDs, descriptions, and scaling information.

5.1. Comprehensive List of Common PIDs

Here is a table of common OBD2 PIDs:

| PID (Hex) | Parameter | Description | Units |

|---|---|---|---|

| 0x00 | Supported PIDs [01-20] | Indicates which PIDs are supported in the range 0x01 to 0x20 | – |

| 0x01 | Monitor Status Since DTCs Cleared | Indicates the status of OBD2 monitors since the last DTC clear | – |

| 0x03 | Fuel System Status | Indicates the status of the fuel system | – |

| 0x04 | Calculated Engine Load Value | Indicates the percentage of engine load relative to its maximum | % |

| 0x05 | Engine Coolant Temperature | Indicates the temperature of the engine coolant | Degrees C |

| 0x06 | Short Term Fuel Trim Bank 1 | Indicates the short-term adjustment to the fuel mixture | % |

| 0x07 | Long Term Fuel Trim Bank 1 | Indicates the long-term adjustment to the fuel mixture | % |

| 0x08 | Short Term Fuel Trim Bank 2 | Indicates the short-term adjustment to the fuel mixture | % |

| 0x09 | Long Term Fuel Trim Bank 2 | Indicates the long-term adjustment to the fuel mixture | % |

| 0x0A | Fuel Pressure | Indicates the fuel pressure in the fuel rail | kPa |

| 0x0B | Intake Manifold Absolute Pressure | Indicates the pressure in the intake manifold | kPa |

| 0x0C | Engine RPM | Indicates the rotational speed of the engine | RPM |

| 0x0D | Vehicle Speed | Indicates the speed of the vehicle | km/h |

| 0x0E | Timing Advance | Indicates the timing advance for the ignition system | Degrees |

| 0x0F | Intake Air Temperature | Indicates the temperature of the air entering the engine | Degrees C |

| 0x10 | Mass Air Flow Rate | Indicates the mass of air flowing into the engine | g/s |

| 0x11 | Throttle Position | Indicates the position of the throttle valve | % |

| 0x1F | Run Time Since Engine Start | Indicates the time since the engine was started | Seconds |

5.2. Understanding PID Descriptions

Each PID description provides information about the parameter being measured, its units, and how it relates to vehicle performance.

5.3. Interpreting Units and Scaling

Understanding the units and scaling is crucial for converting raw PID data into meaningful values. The scaling information specifies how to convert the hexadecimal value returned by the ECU into a physical unit. For example, the formula for converting coolant temperature (PID 0x05) is:

Temperature (°C) = A - 40

Where A is the hexadecimal value returned by the ECU.

6. Advanced OBD2 PID Techniques

Advanced techniques include using mode 0x01 PID 0x00 for compatibility testing, understanding proprietary PIDs, and addressing common issues.

6.1. Using Mode 0x01 PID 0x00 for Compatibility Testing

Mode 0x01 PID 0x00 is a fundamental compatibility test. If an emissions-related ECU supports any OBD2 services, it must support this PID. Responding to this PID, the vehicle ECU informs whether it supports PIDs 0x01-0x20.

6.2. Understanding and Utilizing Proprietary PIDs

Some manufacturers use proprietary PIDs to access additional data specific to their vehicles. These PIDs are not standardized and require specific knowledge or documentation from the manufacturer.

6.3. Addressing Common Issues with OBD2 PIDs

Common issues include incorrect data readings, unsupported PIDs, and communication errors. Ensuring your scan tool is compatible with your vehicle and that you are using the correct PIDs can help resolve these issues.

7. OBD2 PID Data Logging and Analysis

Data logging and analysis involves recording PID data over time and using software tools to visualize and analyze the data.

7.1. Setting Up Data Logging

Data logging involves configuring a scan tool to record PID data over a specified period. This can be useful for diagnosing intermittent issues or monitoring vehicle performance under different conditions.

7.2. Choosing the Right Data Logging Tools

Various data logging tools are available, ranging from simple handheld devices to sophisticated software applications. Choose a tool that meets your specific needs and budget.

7.3. Analyzing Logged Data

Analyzing logged data involves using software tools to visualize and interpret the data. This can help identify trends, anomalies, and potential issues.

7.4. Identifying Trends and Anomalies

By analyzing logged data, you can identify trends such as gradual performance degradation or anomalies such as sudden spikes in temperature or pressure.

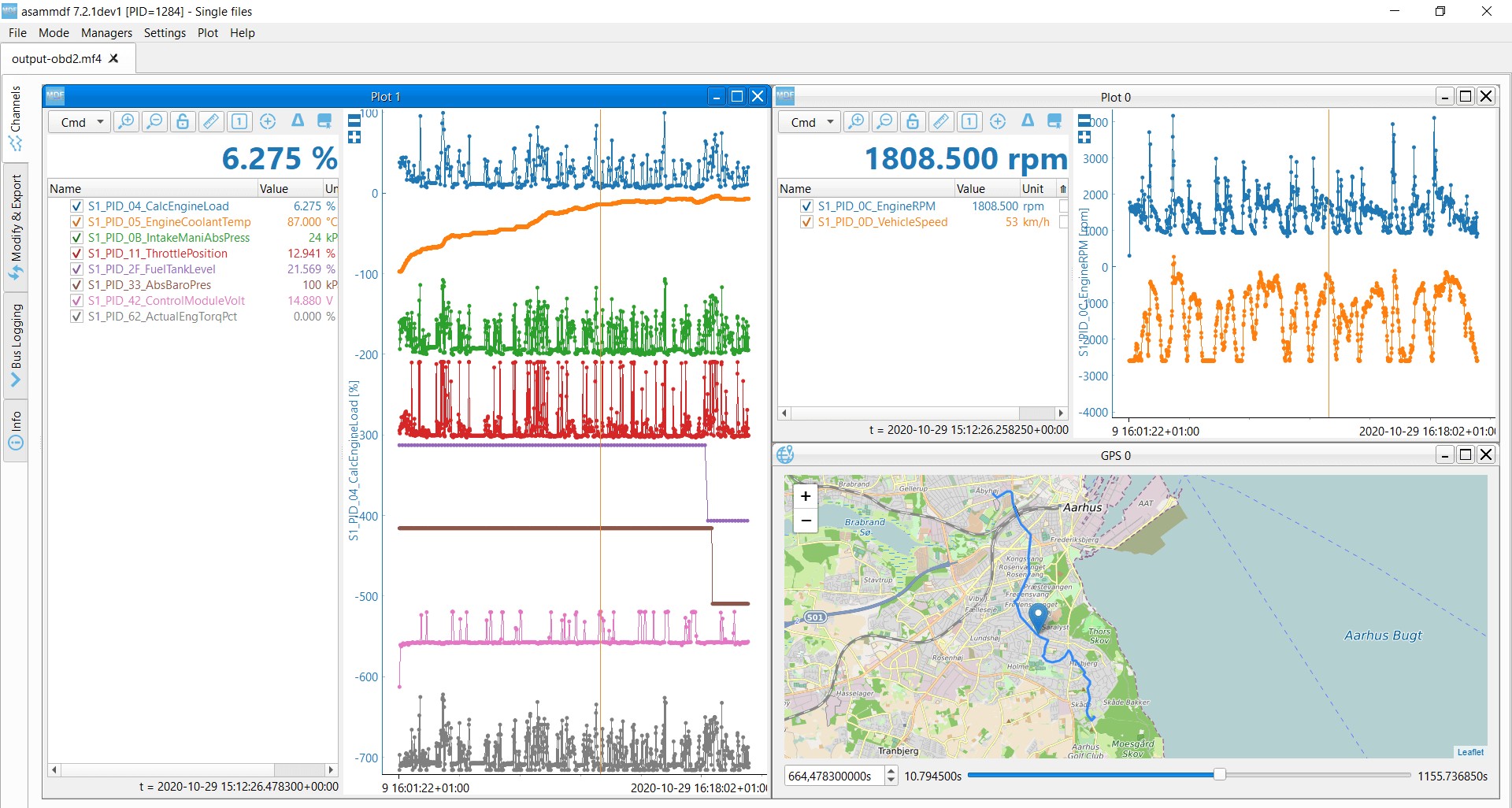

OBD2 data decoded visual plot asammdf CAN bus DBC file

OBD2 data decoded visual plot asammdf CAN bus DBC file

8. Practical Examples of OBD2 PID Diagnostics

Practical examples include diagnosing engine misfires, fuel system issues, and emissions problems using OBD2 PIDs.

8.1. Diagnosing Engine Misfires

Engine misfires can be diagnosed by monitoring PIDs such as engine RPM, misfire counters, and fuel trim values. Irregularities in these parameters can indicate a misfire.

8.2. Identifying Fuel System Issues

Fuel system issues can be identified by monitoring PIDs such as fuel pressure, fuel trim values, and oxygen sensor readings. Abnormal readings can indicate problems with the fuel pump, injectors, or oxygen sensors.

8.3. Troubleshooting Emissions Problems

Emissions problems can be troubleshooted by monitoring PIDs such as oxygen sensor readings, catalytic converter temperature, and exhaust gas recirculation (EGR) flow. Abnormal readings can indicate issues with the catalytic converter, oxygen sensors, or EGR system.

9. Future Trends in OBD and PIDs

Future trends in OBD and PIDs include the integration of telematics, enhanced diagnostic capabilities, and the use of wireless communication.

9.1. Integration with Telematics

The integration of OBD2 with telematics systems allows for remote monitoring of vehicle health and performance. This can enable predictive maintenance and proactive diagnostics.

9.2. Enhanced Diagnostic Capabilities

Future OBD systems are expected to offer enhanced diagnostic capabilities, including more detailed data and more sophisticated algorithms for identifying potential issues.

9.3. Wireless Communication and Remote Diagnostics

Wireless communication technologies such as Bluetooth and Wi-Fi enable remote diagnostics, allowing technicians to access vehicle data from anywhere.

10. Common Mistakes to Avoid When Using OBD2 PIDs

Avoiding common mistakes can help ensure accurate and reliable diagnostics.

10.1. Incorrect PID Selection

Selecting the wrong PID can result in inaccurate or misleading data. Always refer to the vehicle’s service manual or a comprehensive PID table to ensure you are using the correct PID.

10.2. Misinterpreting Data

Misinterpreting data can lead to incorrect diagnoses. Understand the units, scaling, and normal ranges for each parameter to avoid misinterpretations.

10.3. Ignoring Contextual Information

Ignoring contextual information such as driving conditions, engine temperature, and recent maintenance can lead to incomplete or inaccurate diagnoses.

FAQ: Understanding OBD2 PIDs

What is the difference between a PID and a DTC?

A Diagnostic Trouble Code (DTC) indicates a specific problem detected by the vehicle’s computer, while a Parameter Identification (PID) is a code used to request real-time data about a specific parameter. DTCs point to issues, while PIDs provide data for analysis.

Can I use any OBD2 scan tool with any car?

Most OBD2 scan tools are compatible with any OBD2-compliant vehicle (typically those manufactured after 1996). However, some advanced features or proprietary PIDs may only be accessible with specific scan tools.

How do I find the right PID for a specific parameter?

Refer to the vehicle’s service manual or a comprehensive OBD2 PID table to find the correct PID for the parameter you want to monitor.

What does it mean if a PID returns no data?

If a PID returns no data, it could mean that the vehicle does not support that PID, there is a communication error, or the parameter is not currently being measured.

Are OBD2 PIDs the same for all car manufacturers?

While many PIDs are standardized, some manufacturers use proprietary PIDs to access additional data specific to their vehicles.

Can I damage my car by using an OBD2 scan tool?

Using an OBD2 scan tool is generally safe, but it is essential to use a tool that is compatible with your vehicle and to follow the manufacturer’s instructions.

How often should I check my car’s OBD2 system?

You should check your car’s OBD2 system whenever you notice a warning light or suspect a problem. Regular checks can also help identify potential issues early.

What are the limitations of using OBD2 PIDs for diagnostics?

Limitations include the availability of proprietary PIDs, the complexity of data interpretation, and the potential for communication errors.

How do I update my OBD2 scan tool?

Refer to the scan tool’s manufacturer instructions for updating the tool’s software and PID database. Regular updates can ensure compatibility with new vehicles and access to the latest features.

What is the role of the ECU in OBD2 PID diagnostics?

The Electronic Control Unit (ECU) is the central computer in the vehicle that monitors and controls various systems. In OBD2 PID diagnostics, the ECU provides the data requested by the scan tool based on the specified PIDs.

Understanding what PID means in OBD2 is critical for effective vehicle diagnostics. By leveraging PIDs, you can gain valuable insights into your vehicle’s performance and identify potential issues before they become major problems.

Are you seeking to master your Mercedes-Benz diagnostics? Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN today for expert consultation on OBD2 tools, unlocking hidden features, and step-by-step repair guidance. Our team is ready to provide immediate support for your diagnostic needs. Reach us at 789 Oak Avenue, Miami, FL 33101, United States or via Whatsapp at +1 (641) 206-8880. For more information, visit our website at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN. Let us help you keep your Mercedes-Benz running smoothly and efficiently.