OBD2 communication protocols are the standardized languages that vehicle diagnostic tools use to communicate with a car’s computer. Understanding these protocols is vital for anyone involved in vehicle diagnostics and repair, and MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides the expertise to navigate these systems effectively. Mastering these protocols unlocks advanced vehicle diagnostics, facilitates efficient repairs, and enables customized vehicle enhancements, improving diagnostic tools and automotive repairs.

Contents

- 1. Why Should You Learn About OBD2 Communication Protocols?

- 1.1. What is the Significance of OBD2 Protocols?

- 1.2. Who Benefits from Knowing About OBD2 Protocols?

- 1.3. What Are the Key Benefits of Understanding OBD2 Protocols?

- 1.4. What Makes MERCEDES-DIAGNOSTIC-TOOL.EDU.VN the Right Resource?

- 2. Exploring the Five Main OBD2 Communication Protocols

- 2.1. What Are The Different Types of OBD2 Protocols?

- 2.2. SAE J1850 VPW (Variable Pulse Width)

- 2.2.1. How Does SAE J1850 VPW Work?

- 2.2.2. What Are the Key Features of SAE J1850 VPW?

- 2.2.3. What Are the Advantages and Disadvantages of SAE J1850 VPW?

- 2.3. SAE J1850 PWM (Pulse Width Modulation)

- 2.3.1. How Does SAE J1850 PWM Work?

- 2.3.2. What Are the Key Features of SAE J1850 PWM?

- 2.3.3. What Are the Advantages and Disadvantages of SAE J1850 PWM?

- 2.4. ISO 9141-2

- 2.4.1. How Does ISO 9141-2 Work?

- 2.4.2. What Are the Key Features of ISO 9141-2?

- 2.4.3. What Are the Advantages and Disadvantages of ISO 9141-2?

- 2.5. ISO 14230-4 (KWP2000)

- 2.5.1. How Does ISO 14230-4 (KWP2000) Work?

- 2.5.2. What Are the Key Features of ISO 14230-4 (KWP2000)?

- 2.5.3. What Are the Advantages and Disadvantages of ISO 14230-4 (KWP2000)?

- 2.6. ISO 15765-4 (CAN)

- 2.6.1. How Does ISO 15765-4 (CAN) Work?

- 2.6.2. What Are the Key Features of ISO 15765-4 (CAN)?

- 2.6.3. What Are the Advantages and Disadvantages of ISO 15765-4 (CAN)?

- 2.7. OBD2 Protocol Comparison Table

- 3. Diagnosing Protocol Issues

- 3.1. What Are the Common Issues with OBD2 Protocols?

- 3.2. How to Identify the Protocol Used by a Vehicle

- 3.3. Step-by-Step Guide to Diagnosing Protocol Issues

- 3.4. Tools and Equipment Needed for Diagnosing Protocol Issues

- 3.5. Case Studies of Common Protocol Issues and Their Solutions

- 3.5.1. Case Study 1: No Communication with ECU

- 3.5.2. Case Study 2: Incorrect Protocol Detection

- 3.5.3. Case Study 3: Intermittent Communication Issues

- 3.6. Resources at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Protocol Diagnosis

- 4. How OBD2 Protocols Affect Mercedes-Benz Vehicles

- 4.1. What OBD2 Protocols Do Mercedes-Benz Vehicles Use?

- 4.2. Common Diagnostic Trouble Codes (DTCs) in Mercedes-Benz Vehicles

- 4.3. Using Diagnostic Tools on Mercedes-Benz Vehicles

- 4.4. Challenges When Diagnosing Mercedes-Benz Vehicles

- 4.5. Tips for Effective Diagnostics on Mercedes-Benz Vehicles

- 4.6. Resources at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Mercedes-Benz Diagnostics

- 5. Advanced Diagnostic Techniques Using OBD2 Protocols

- 5.1. Live Data Streaming and Analysis

- 5.2. Component Testing and Activation

- 5.3. System Simulations and Modeling

- 5.4. Reading and Interpreting Freeze Frame Data

- 5.5. Using OBD2 Data for Performance Tuning

- 5.6. Ethical Considerations When Using Advanced Diagnostic Techniques

- 5.7. Resources at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Advanced Diagnostics

- 6. Future Trends in OBD2 Communication Protocols

- 6.1. Increased Use of CAN FD (Flexible Data-Rate)

- 6.2. Adoption of Ethernet-Based Communication

- 6.3. Wireless OBD2 Communication

- 6.4. Cybersecurity Considerations

- 6.5. Remote Diagnostics and Over-the-Air Updates

- 6.6. Integration with Cloud-Based Services

- 6.7. The Role of Artificial Intelligence (AI) in Diagnostics

- 6.8. Resources at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Future Trends

- 7. OBD2 Communication Protocols FAQs

- 7.1. What is the Difference Between OBD1 and OBD2?

- 7.2. How Do I Find the OBD2 Port in My Car?

- 7.3. Can I Use Any OBD2 Scanner on Any Car?

- 7.4. What Does a Diagnostic Trouble Code (DTC) Mean?

- 7.5. Can I Clear DTCs Myself?

- 7.6. What is the Difference Between a Generic OBD2 Scanner and a Manufacturer-Specific Scanner?

- 7.7. How Often Should I Scan My Car for DTCs?

- 7.8. What is the Role of the ECU in OBD2 Communication?

- 7.9. How Do I Update the Software on My OBD2 Scanner?

- 7.10. What is the Best OBD2 Scanner for Mercedes-Benz Vehicles?

- 8. Take the Next Step with MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

1. Why Should You Learn About OBD2 Communication Protocols?

Understanding OBD2 communication protocols is essential for effective vehicle diagnostics and repair. If you’re looking to enhance your expertise, it’s important to know that these protocols enable communication with a vehicle’s computer to read diagnostic data, clear trouble codes, and monitor performance parameters. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN supports you in mastering these systems, ensuring accurate and efficient vehicle maintenance and customization.

OBD2 (On-Board Diagnostics II) protocols are the standardized methods that vehicles use to transmit diagnostic data. Since 1996, OBD2 has been mandatory in all cars sold in the United States, and it has been widely adopted in other countries as well. These protocols allow diagnostic tools to communicate with a vehicle’s engine control unit (ECU) and other control modules.

1.1. What is the Significance of OBD2 Protocols?

OBD2 protocols are like the common language that diagnostic tools use to speak to your car’s computer. Without understanding these protocols, it’s like trying to understand someone speaking a foreign language. The significance lies in the ability to accurately read and interpret data from the vehicle’s computer, enabling effective diagnostics and repairs.

According to the Society of Automotive Engineers (SAE), standardizing these protocols ensures that any compliant diagnostic tool can communicate with any compliant vehicle, regardless of manufacturer. This standardization has revolutionized the automotive repair industry, making diagnostics more accessible and efficient.

1.2. Who Benefits from Knowing About OBD2 Protocols?

- Car Owners: Being familiar with OBD2 protocols allows car owners to perform basic diagnostics themselves, saving money on simple issues and making informed decisions about repairs.

- Automotive Technicians: A deep understanding of these protocols is crucial for technicians to accurately diagnose complex issues and perform effective repairs. It also enables them to use advanced diagnostic tools and software.

- DIY Enthusiasts: For those who enjoy working on their cars, knowing about OBD2 protocols opens up a world of possibilities for performance tuning, customization, and advanced diagnostics.

- Fleet Managers: Understanding OBD2 protocols can help fleet managers monitor vehicle health, optimize maintenance schedules, and reduce downtime.

1.3. What Are the Key Benefits of Understanding OBD2 Protocols?

| Benefit | Description |

|---|---|

| Accurate Diagnostics | Allows for precise identification of issues, reducing guesswork and saving time. |

| Cost Savings | Enables informed decisions about repairs, preventing unnecessary services and expenses. |

| Performance Tuning | Facilitates the optimization of engine performance for better fuel efficiency and power. |

| Preventative Maintenance | Helps monitor vehicle health and identify potential problems before they become major issues. |

| Customization | Opens up possibilities for customizing vehicle settings and features. |

1.4. What Makes MERCEDES-DIAGNOSTIC-TOOL.EDU.VN the Right Resource?

At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we specialize in providing comprehensive resources and training on OBD2 protocols and vehicle diagnostics. We offer in-depth guides, tutorials, and expert support to help you master these complex systems. Whether you’re a seasoned technician or a car owner just starting, our resources are designed to empower you with the knowledge and skills you need.

Our expertise is particularly valuable for Mercedes-Benz owners and technicians. Mercedes-Benz vehicles often have unique diagnostic requirements and features, and our resources are tailored to address these specific needs. With MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, you can be confident that you’re getting the most accurate and up-to-date information available.

2. Exploring the Five Main OBD2 Communication Protocols

The OBD2 standard includes five main communication protocols, each with its own characteristics and applications. Understanding these protocols is essential for selecting the right diagnostic tools and interpreting the data they provide. These protocols vary in their voltage levels, data transmission rates, and error-checking mechanisms. Each protocol has its own strengths and weaknesses, making it suitable for different vehicle applications.

2.1. What Are The Different Types of OBD2 Protocols?

The five main OBD2 communication protocols are:

- SAE J1850 VPW (Variable Pulse Width)

- SAE J1850 PWM (Pulse Width Modulation)

- ISO 9141-2

- ISO 14230-4 (KWP2000)

- ISO 15765-4 (CAN)

2.2. SAE J1850 VPW (Variable Pulse Width)

SAE J1850 VPW is a protocol primarily used by General Motors (GM) vehicles. It communicates using a single-wire bus with a voltage of around 7 volts. The data is transmitted using variable pulse widths to represent different binary values. This protocol is relatively slow compared to newer protocols.

2.2.1. How Does SAE J1850 VPW Work?

SAE J1850 VPW uses a variable pulse width to encode data. A short pulse represents a binary 0, while a long pulse represents a binary 1. The timing of these pulses is critical for accurate data transmission. The protocol also includes error-checking mechanisms to ensure data integrity.

2.2.2. What Are the Key Features of SAE J1850 VPW?

- Single-wire communication

- Variable pulse width encoding

- Voltage level of approximately 7 volts

- Primarily used by GM vehicles

2.2.3. What Are the Advantages and Disadvantages of SAE J1850 VPW?

| Advantage | Disadvantage |

|---|---|

| Simple implementation | Slower data transmission rate |

| Robust against electrical noise | Limited diagnostic capabilities compared to newer protocols |

| Widely supported by older GM vehicles | Less efficient use of bandwidth |

SAE J1850 VPW Protocol

SAE J1850 VPW Protocol

2.3. SAE J1850 PWM (Pulse Width Modulation)

SAE J1850 PWM is another protocol developed by the Society of Automotive Engineers (SAE). It is primarily used by Ford vehicles. PWM uses two wires for communication and a voltage of around 5 volts. Data is transmitted by varying the width of the pulses. This protocol is faster than VPW but still slower than newer protocols like CAN.

2.3.1. How Does SAE J1850 PWM Work?

SAE J1850 PWM modulates the width of the pulses to represent different data values. The duty cycle of the pulse (the percentage of time the pulse is high) determines the value of the data bit. This protocol also includes error-checking mechanisms to ensure data integrity.

2.3.2. What Are the Key Features of SAE J1850 PWM?

- Two-wire communication

- Pulse width modulation encoding

- Voltage level of approximately 5 volts

- Primarily used by Ford vehicles

2.3.3. What Are the Advantages and Disadvantages of SAE J1850 PWM?

| Advantage | Disadvantage |

|---|---|

| Faster data transmission than VPW | Slower data transmission rate compared to CAN |

| Robust against electrical noise | More complex implementation than VPW |

| Widely supported by older Ford vehicles | Less efficient use of bandwidth |

SAE J1850 PWM Protocol

SAE J1850 PWM Protocol

2.4. ISO 9141-2

ISO 9141-2 is a protocol used by many European and Asian vehicles, including some Chrysler models. It uses an asynchronous serial communication with a data rate of 10.4 kbps. This protocol requires the use of a K-line for communication and an optional L-line for wake-up.

2.4.1. How Does ISO 9141-2 Work?

ISO 9141-2 uses a serial communication protocol where data bits are transmitted sequentially over a single wire (K-line). The L-line can be used to initiate communication with the ECU. The protocol also includes error-checking mechanisms to ensure data integrity.

2.4.2. What Are the Key Features of ISO 9141-2?

- Asynchronous serial communication

- Data rate of 10.4 kbps

- Uses K-line for communication

- Optional L-line for wake-up

- Used by many European and Asian vehicles

2.4.3. What Are the Advantages and Disadvantages of ISO 9141-2?

| Advantage | Disadvantage |

|---|---|

| Widely supported by European and Asian vehicles | Slower data transmission rate compared to CAN |

| Relatively simple implementation | Requires additional hardware for L-line wake-up |

| Robust against electrical noise | Less efficient use of bandwidth |

ISO 9141 Protocol

ISO 9141 Protocol

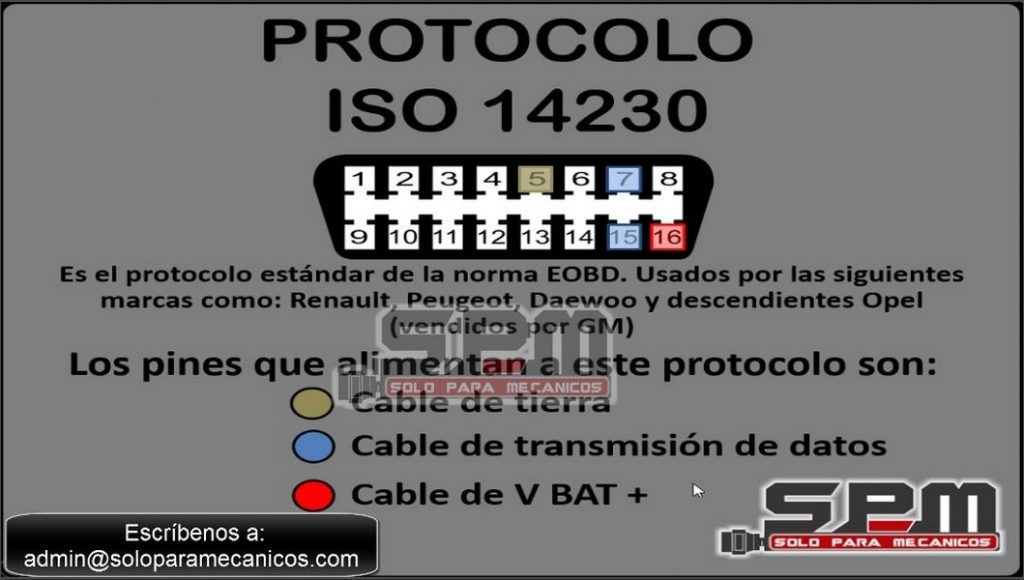

2.5. ISO 14230-4 (KWP2000)

ISO 14230-4, also known as KWP2000 (Keyword Protocol 2000), is an updated version of ISO 9141-2. It offers faster data rates and improved error-checking. KWP2000 is used by many European and Asian vehicles, including BMW, Mercedes-Benz, and Volkswagen.

2.5.1. How Does ISO 14230-4 (KWP2000) Work?

KWP2000 uses a keyword-based communication system where specific keywords are used to initiate and manage communication with the ECU. It supports both 5-baud initialization and fast initialization methods. The protocol also includes advanced error-checking mechanisms to ensure data integrity.

2.5.2. What Are the Key Features of ISO 14230-4 (KWP2000)?

- Keyword-based communication

- Faster data rates than ISO 9141-2

- Supports 5-baud and fast initialization

- Used by many European and Asian vehicles

2.5.3. What Are the Advantages and Disadvantages of ISO 14230-4 (KWP2000)?

| Advantage | Disadvantage |

|---|---|

| Faster data transmission than ISO 9141-2 | More complex implementation than ISO 9141-2 |

| Improved error-checking | Requires more processing power |

| Widely supported by European and Asian vehicles | Less efficient use of bandwidth |

ISO 14230 Protocol

ISO 14230 Protocol

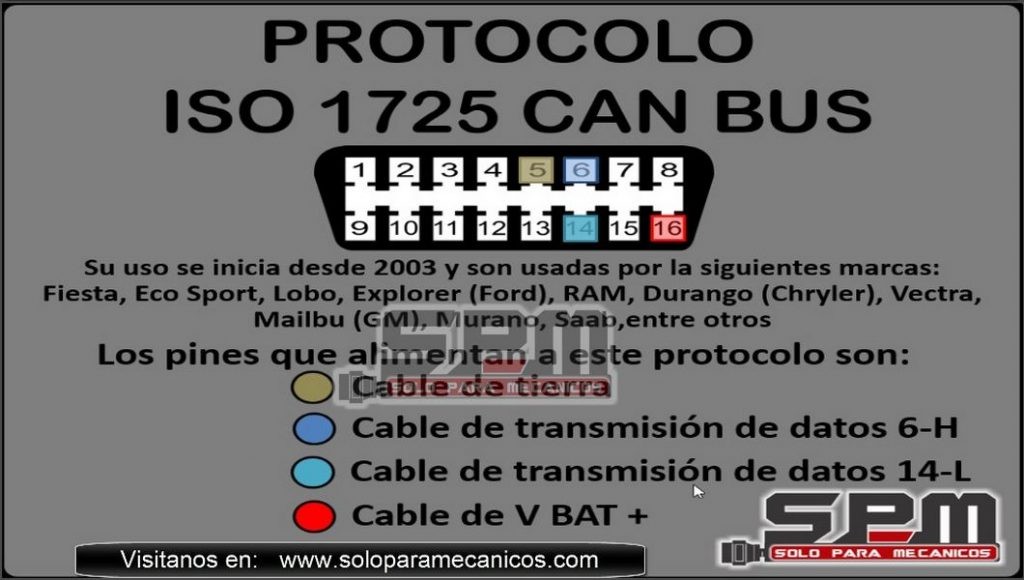

2.6. ISO 15765-4 (CAN)

ISO 15765-4, also known as CAN (Controller Area Network), is the most modern and widely used OBD2 protocol. It is mandatory in all vehicles sold in the United States since 2008. CAN uses a two-wire bus with high-speed data transmission rates. It also includes advanced error-checking and message prioritization features.

2.6.1. How Does ISO 15765-4 (CAN) Work?

CAN uses a message-based communication system where data is transmitted in the form of messages. Each message includes an identifier that indicates the priority and type of data being transmitted. The protocol also includes advanced error-checking mechanisms to ensure data integrity.

2.6.2. What Are the Key Features of ISO 15765-4 (CAN)?

- Message-based communication

- High-speed data transmission rates

- Advanced error-checking

- Message prioritization

- Mandatory in all vehicles sold in the US since 2008

2.6.3. What Are the Advantages and Disadvantages of ISO 15765-4 (CAN)?

| Advantage | Disadvantage |

|---|---|

| Fastest data transmission rate | More complex implementation than older protocols |

| Most efficient use of bandwidth | Requires more processing power |

| Advanced error-checking and message prioritization | Higher cost of implementation |

| Widely supported by modern vehicles |

ISO 15765 Protocol

ISO 15765 Protocol

2.7. OBD2 Protocol Comparison Table

| Protocol | Primary Use | Data Rate | Voltage | Wires | Advantages | Disadvantages |

|---|---|---|---|---|---|---|

| SAE J1850 VPW | General Motors (GM) | Low | 7V | 1 | Simple implementation, robust against electrical noise | Slower data transmission, limited diagnostic capabilities |

| SAE J1850 PWM | Ford | Medium | 5V | 2 | Faster than VPW, robust against electrical noise | Slower than CAN, more complex than VPW |

| ISO 9141-2 | European and Asian vehicles | Low | 12V | 1 | Widely supported, relatively simple implementation | Slower data transmission, requires additional hardware for L-line wake-up |

| ISO 14230-4 (KWP2000) | European and Asian vehicles | Medium | 12V | 1 | Faster than ISO 9141-2, improved error-checking | More complex than ISO 9141-2, requires more processing power |

| ISO 15765-4 (CAN) | Modern vehicles | High | 2.5V | 2 | Fastest data transmission, efficient bandwidth, advanced error-checking | More complex, requires more processing power, higher implementation cost |

3. Diagnosing Protocol Issues

Diagnosing protocol issues involves a systematic approach to identify and resolve communication problems between the diagnostic tool and the vehicle’s computer. These issues can arise from various sources, including faulty connectors, wiring problems, or incompatible diagnostic tools. Effective diagnosis requires a solid understanding of OBD2 protocols and the ability to use diagnostic equipment.

3.1. What Are the Common Issues with OBD2 Protocols?

Common issues with OBD2 protocols include:

- Incompatible Diagnostic Tools: Using a diagnostic tool that does not support the vehicle’s protocol.

- Faulty Connectors: Damaged or corroded OBD2 connectors.

- Wiring Problems: Broken or shorted wires in the OBD2 circuit.

- ECU Issues: Problems with the vehicle’s engine control unit (ECU).

- Software Glitches: Errors in the diagnostic tool’s software.

3.2. How to Identify the Protocol Used by a Vehicle

Identifying the protocol used by a vehicle can be done by:

- Checking the Vehicle’s Manual: The vehicle’s manual often specifies the OBD2 protocol used.

- Using a Protocol Detector: Some diagnostic tools have a protocol detection feature that automatically identifies the protocol.

- Inspecting the OBD2 Connector: Examining the pins on the OBD2 connector can provide clues about the protocol used.

- Consulting Online Resources: Online databases and forums can provide information about the protocols used by specific vehicle makes and models.

3.3. Step-by-Step Guide to Diagnosing Protocol Issues

- Verify the Diagnostic Tool’s Compatibility: Ensure that the diagnostic tool supports the vehicle’s OBD2 protocol.

- Inspect the OBD2 Connector: Check for damage, corrosion, or loose pins. Clean or replace the connector if necessary.

- Check the Wiring: Use a multimeter to check for continuity and shorts in the OBD2 wiring. Repair or replace any damaged wires.

- Test the ECU: If possible, test the ECU to ensure it is functioning correctly. This may require specialized equipment.

- Update the Diagnostic Tool’s Software: Ensure that the diagnostic tool has the latest software updates installed.

- Try a Different Diagnostic Tool: If the issue persists, try using a different diagnostic tool to rule out a problem with the tool itself.

3.4. Tools and Equipment Needed for Diagnosing Protocol Issues

- OBD2 Diagnostic Tool: A tool that supports multiple OBD2 protocols.

- Multimeter: For checking voltage, continuity, and resistance in the wiring.

- OBD2 Connector Tester: For testing the functionality of the OBD2 connector.

- Wiring Diagram: For identifying the correct wiring connections.

- Cleaning Supplies: For cleaning corroded connectors.

3.5. Case Studies of Common Protocol Issues and Their Solutions

3.5.1. Case Study 1: No Communication with ECU

- Problem: A technician was unable to establish communication with the ECU of a 2005 Ford F-150.

- Diagnosis: The technician used a multimeter to check the OBD2 connector and found that there was no power on pin 16.

- Solution: The technician traced the wiring and found a broken wire in the power supply circuit. After repairing the wire, the diagnostic tool was able to communicate with the ECU.

3.5.2. Case Study 2: Incorrect Protocol Detection

- Problem: A car owner was using a diagnostic tool that incorrectly identified the OBD2 protocol of their 2008 Honda Civic.

- Diagnosis: The car owner consulted the vehicle’s manual and confirmed that the correct protocol was ISO 15765-4 (CAN).

- Solution: The car owner updated the diagnostic tool’s software, which corrected the protocol detection issue.

3.5.3. Case Study 3: Intermittent Communication Issues

- Problem: A fleet manager was experiencing intermittent communication issues with the ECUs of several vehicles in their fleet.

- Diagnosis: The fleet manager inspected the OBD2 connectors and found that they were corroded.

- Solution: The fleet manager cleaned the connectors with a contact cleaner and applied a dielectric grease to prevent future corrosion. This resolved the communication issues.

3.6. Resources at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Protocol Diagnosis

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides detailed guides, tutorials, and expert support to help you diagnose and resolve protocol issues. Our resources include:

- Troubleshooting Guides: Step-by-step guides for diagnosing common protocol issues.

- Wiring Diagrams: Detailed wiring diagrams for various vehicle makes and models.

- Video Tutorials: Visual demonstrations of diagnostic procedures.

- Expert Support: Access to experienced technicians who can provide personalized assistance.

By leveraging these resources, you can quickly and effectively diagnose and resolve protocol issues, ensuring that your diagnostic tools are always functioning correctly.

4. How OBD2 Protocols Affect Mercedes-Benz Vehicles

Mercedes-Benz vehicles, known for their advanced technology and sophisticated engineering, utilize OBD2 protocols for diagnostics and maintenance. Understanding how these protocols are implemented in Mercedes-Benz vehicles is crucial for both technicians and owners. These protocols allow for the retrieval of diagnostic trouble codes (DTCs), live data monitoring, and component testing, enabling efficient and accurate repairs.

4.1. What OBD2 Protocols Do Mercedes-Benz Vehicles Use?

Mercedes-Benz vehicles primarily use the ISO 15765-4 (CAN) protocol, which is the most modern and widely used OBD2 protocol. However, older models may also use ISO 14230-4 (KWP2000) or ISO 9141-2. The specific protocol used depends on the vehicle’s model year and configuration.

4.2. Common Diagnostic Trouble Codes (DTCs) in Mercedes-Benz Vehicles

Common DTCs in Mercedes-Benz vehicles include:

- P0171 and P0174: System Too Lean (Bank 1 and Bank 2)

- P0300: Random Misfire Detected

- P0400: Exhaust Gas Recirculation (EGR) Flow Malfunction

- P0420: Catalyst System Efficiency Below Threshold (Bank 1)

- P0715: Input/Turbine Speed Sensor Circuit Malfunction

These codes can indicate a variety of issues, ranging from faulty sensors to vacuum leaks to catalytic converter problems. Accurate diagnosis requires a thorough understanding of the vehicle’s systems and the ability to interpret the data provided by the diagnostic tool.

4.3. Using Diagnostic Tools on Mercedes-Benz Vehicles

Using diagnostic tools on Mercedes-Benz vehicles requires a tool that is compatible with the vehicle’s OBD2 protocol and supports Mercedes-Benz specific diagnostic functions. Some diagnostic tools are designed specifically for Mercedes-Benz vehicles and offer advanced features such as:

- ECU Programming: Allows for reprogramming of the vehicle’s engine control unit (ECU).

- Adaptation Resets: Allows for resetting of adaptive values in the ECU.

- Component Testing: Allows for testing of individual components such as sensors and actuators.

- Activating hidden features: Allows the owner to customize certain features of the vehicle like ambient lighting, auto folding mirrors, etc.

4.4. Challenges When Diagnosing Mercedes-Benz Vehicles

Diagnosing Mercedes-Benz vehicles can be challenging due to their complex systems and advanced technology. Some common challenges include:

- Proprietary Diagnostic Codes: Mercedes-Benz vehicles may use proprietary diagnostic codes that are not recognized by generic OBD2 tools.

- Complex Wiring Systems: Mercedes-Benz vehicles have complex wiring systems that can be difficult to troubleshoot.

- Location of the OBD2 Port: In some models, the OBD2 port may be difficult to access.

4.5. Tips for Effective Diagnostics on Mercedes-Benz Vehicles

- Use a Mercedes-Benz Specific Diagnostic Tool: These tools are designed to communicate with Mercedes-Benz vehicles and provide access to advanced diagnostic functions.

- Consult the Vehicle’s Service Manual: The service manual provides detailed information about the vehicle’s systems and diagnostic procedures.

- Check for Technical Service Bulletins (TSBs): TSBs provide information about common issues and recommended solutions.

- Use a Multimeter to Check Wiring: A multimeter can be used to check for continuity and shorts in the wiring.

- Be Methodical: Follow a systematic approach to diagnosis to avoid overlooking potential issues.

4.6. Resources at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Mercedes-Benz Diagnostics

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers a wide range of resources to help you diagnose and repair Mercedes-Benz vehicles. Our resources include:

- Mercedes-Benz Specific Diagnostic Tools: We offer a selection of diagnostic tools designed specifically for Mercedes-Benz vehicles.

- Diagnostic Guides: Step-by-step guides for diagnosing common issues in Mercedes-Benz vehicles.

- Wiring Diagrams: Detailed wiring diagrams for various Mercedes-Benz models.

- Video Tutorials: Visual demonstrations of diagnostic procedures.

- Expert Support: Access to experienced technicians who can provide personalized assistance.

By leveraging these resources, you can confidently diagnose and repair Mercedes-Benz vehicles, ensuring that they continue to perform at their best.

5. Advanced Diagnostic Techniques Using OBD2 Protocols

Advanced diagnostic techniques using OBD2 protocols involve leveraging the full capabilities of diagnostic tools and understanding the intricacies of vehicle systems. These techniques go beyond basic code reading and involve in-depth data analysis, component testing, and system simulations. Mastering these techniques enables technicians to diagnose complex issues and perform advanced repairs.

5.1. Live Data Streaming and Analysis

Live data streaming involves monitoring real-time data from the vehicle’s sensors and systems. This data can be analyzed to identify performance issues, diagnose intermittent problems, and verify the effectiveness of repairs. Key parameters to monitor include:

- Engine Speed (RPM): Indicates the speed of the engine.

- Engine Load: Indicates the amount of load on the engine.

- Coolant Temperature: Indicates the temperature of the engine coolant.

- Oxygen Sensor Readings: Indicates the oxygen content in the exhaust.

- Fuel Trim: Indicates the adjustments made to the fuel mixture by the ECU.

By monitoring these parameters, technicians can identify issues such as:

- Misfires: Irregularities in the engine’s firing pattern.

- Vacuum Leaks: Unmetered air entering the engine.

- Sensor Failures: Malfunctioning sensors providing inaccurate data.

- Fuel Delivery Problems: Issues with the fuel injectors or fuel pump.

5.2. Component Testing and Activation

Component testing involves using the diagnostic tool to activate or test individual components in the vehicle’s systems. This can be used to verify the functionality of sensors, actuators, and other components. Common component tests include:

- Fuel Injector Test: Activating the fuel injectors to check for proper operation.

- EGR Valve Test: Activating the EGR valve to check for proper flow.

- Oxygen Sensor Test: Monitoring the oxygen sensor readings while varying the engine conditions.

- ABS Motor Test: Activating the ABS motor to check for proper operation.

5.3. System Simulations and Modeling

System simulations involve using the diagnostic tool to simulate different operating conditions and monitor the response of the vehicle’s systems. This can be used to diagnose issues that only occur under specific conditions. For example, a technician may simulate a high-speed driving condition to diagnose a problem with the vehicle’s turbocharger.

5.4. Reading and Interpreting Freeze Frame Data

Freeze frame data is a snapshot of the vehicle’s operating conditions at the time a diagnostic trouble code (DTC) was set. This data can provide valuable clues about the cause of the problem. Key parameters in freeze frame data include:

- Engine Speed (RPM): The speed of the engine at the time the DTC was set.

- Engine Load: The amount of load on the engine at the time the DTC was set.

- Coolant Temperature: The temperature of the engine coolant at the time the DTC was set.

- Fuel Trim: The adjustments made to the fuel mixture by the ECU at the time the DTC was set.

5.5. Using OBD2 Data for Performance Tuning

OBD2 data can be used for performance tuning by monitoring the vehicle’s performance parameters and making adjustments to optimize engine performance. This may involve adjusting the fuel mixture, ignition timing, and other parameters. Performance tuning should only be performed by experienced technicians with a thorough understanding of vehicle systems.

5.6. Ethical Considerations When Using Advanced Diagnostic Techniques

When using advanced diagnostic techniques, it is important to consider the ethical implications of your actions. This includes:

- Respecting Vehicle Owners’ Privacy: Avoid accessing or sharing personal information stored in the vehicle’s computer.

- Following Legal Regulations: Comply with all applicable laws and regulations regarding vehicle modifications and emissions.

- Avoiding Harmful Modifications: Avoid making modifications that could damage the vehicle or compromise its safety.

5.7. Resources at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Advanced Diagnostics

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides advanced resources and training to help you master advanced diagnostic techniques. Our resources include:

- Advanced Diagnostic Guides: Step-by-step guides for performing advanced diagnostic procedures.

- Video Tutorials: Visual demonstrations of advanced diagnostic techniques.

- Expert Support: Access to experienced technicians who can provide personalized assistance.

- Online Courses: Comprehensive online courses covering advanced diagnostic topics.

By leveraging these resources, you can develop the skills and knowledge needed to diagnose and repair even the most complex vehicle issues.

6. Future Trends in OBD2 Communication Protocols

The field of OBD2 communication protocols is constantly evolving to meet the demands of modern vehicles. As vehicles become more complex and connected, the need for faster, more reliable, and more secure communication protocols is increasing. Several trends are shaping the future of OBD2 communication protocols.

6.1. Increased Use of CAN FD (Flexible Data-Rate)

CAN FD (Flexible Data-Rate) is an extension of the CAN protocol that allows for faster data transmission rates and larger data payloads. CAN FD is becoming increasingly common in modern vehicles and is expected to eventually replace the original CAN protocol.

6.2. Adoption of Ethernet-Based Communication

Ethernet-based communication is being adopted in some vehicles for high-bandwidth applications such as advanced driver-assistance systems (ADAS) and infotainment systems. Ethernet offers significantly faster data transmission rates than CAN and CAN FD.

6.3. Wireless OBD2 Communication

Wireless OBD2 communication is becoming more common with the advent of Bluetooth and Wi-Fi enabled diagnostic tools. Wireless communication allows for greater flexibility and convenience when diagnosing vehicles.

6.4. Cybersecurity Considerations

As vehicles become more connected, cybersecurity is becoming an increasingly important consideration. Future OBD2 communication protocols will need to incorporate security features to protect against unauthorized access and cyberattacks.

6.5. Remote Diagnostics and Over-the-Air Updates

Remote diagnostics and over-the-air (OTA) updates are becoming more common in modern vehicles. These technologies allow technicians to diagnose and repair vehicles remotely and to update vehicle software without requiring a visit to the dealership.

6.6. Integration with Cloud-Based Services

Future OBD2 communication protocols will likely be integrated with cloud-based services to provide access to real-time data, advanced analytics, and remote diagnostics. This will enable more proactive and predictive maintenance.

6.7. The Role of Artificial Intelligence (AI) in Diagnostics

Artificial intelligence (AI) is playing an increasingly important role in vehicle diagnostics. AI-powered diagnostic tools can analyze OBD2 data to identify patterns, predict failures, and recommend repairs.

6.8. Resources at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Future Trends

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN is committed to staying at the forefront of OBD2 technology. We provide resources and training on the latest trends and developments in OBD2 communication protocols. Our resources include:

- Articles and Blog Posts: Covering the latest trends in OBD2 technology.

- Webinars and Online Courses: Providing in-depth training on new protocols and technologies.

- Product Reviews: Evaluating the latest diagnostic tools and equipment.

- Expert Insights: Sharing insights from industry experts on the future of OBD2 technology.

By staying informed about these trends and leveraging our resources, you can ensure that you are well-prepared for the future of OBD2 communication protocols.

7. OBD2 Communication Protocols FAQs

Understanding OBD2 communication protocols can be complex, so here are some frequently asked questions to help clarify key concepts:

7.1. What is the Difference Between OBD1 and OBD2?

OBD1 was a non-standardized system used in vehicles before 1996. OBD2 is a standardized system that has been mandatory in all cars sold in the United States since 1996. OBD2 provides more comprehensive diagnostic information and uses a standardized connector and communication protocols.

7.2. How Do I Find the OBD2 Port in My Car?

The OBD2 port is typically located under the dashboard on the driver’s side of the vehicle. It is a 16-pin connector.

7.3. Can I Use Any OBD2 Scanner on Any Car?

While OBD2 is a standardized system, not all scanners are compatible with all vehicles. It is important to check the scanner’s compatibility list before using it on a vehicle.

7.4. What Does a Diagnostic Trouble Code (DTC) Mean?

A diagnostic trouble code (DTC) is a code that is stored in the vehicle’s computer when a problem is detected. The DTC provides information about the nature of the problem and can be used to diagnose the issue.

7.5. Can I Clear DTCs Myself?

Yes, you can clear DTCs using an OBD2 scanner. However, it is important to understand the cause of the DTC before clearing it. Clearing a DTC without fixing the underlying problem may result in the code reappearing.

7.6. What is the Difference Between a Generic OBD2 Scanner and a Manufacturer-Specific Scanner?

A generic OBD2 scanner can read and clear generic DTCs that are common to all vehicles. A manufacturer-specific scanner can also read and clear manufacturer-specific DTCs and perform advanced diagnostic functions that are specific to a particular vehicle make.

7.7. How Often Should I Scan My Car for DTCs?

You should scan your car for DTCs whenever you notice a problem or when the check engine light comes on. Regular scanning can help identify potential problems before they become major issues.

7.8. What is the Role of the ECU in OBD2 Communication?

The ECU (Engine Control Unit) is the central computer in the vehicle that controls the engine and other systems. The ECU communicates with the diagnostic tool using the OBD2 communication protocols to provide diagnostic information and receive commands.

7.9. How Do I Update the Software on My OBD2 Scanner?

The process for updating the software on your OBD2 scanner varies depending on the manufacturer and model. Refer to the scanner’s manual for instructions.

7.10. What is the Best OBD2 Scanner for Mercedes-Benz Vehicles?

The best OBD2 scanner for Mercedes-Benz vehicles is one that is compatible with the vehicle’s OBD2 protocol and supports Mercedes-Benz specific diagnostic functions. Some popular options include the iCarsoft MB II, the Autel MaxiCOM MK808, and the Launch X431.

8. Take the Next Step with MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

Ready to deepen your knowledge of OBD2 communication protocols and enhance your diagnostic skills? MERCEDES-DIAGNOSTIC-TOOL.EDU.VN is your premier resource for comprehensive information, expert guidance, and top-quality diagnostic tools.

Whether you’re a car owner aiming to understand your vehicle better, a technician seeking to refine your diagnostic capabilities, or a fleet manager focused on optimizing vehicle maintenance, we have the solutions you need.

Here’s how MERCEDES-DIAGNOSTIC-TOOL.EDU.VN can assist you:

- Extensive Diagnostic Tools: Explore our selection of OBD2 scanners and diagnostic equipment tailored for Mercedes-Benz vehicles.

- In-Depth Guides and Tutorials: Access our library of step-by-step guides, troubleshooting tips, and expert advice to master OBD2 protocols.

- Personalized Support: Get your questions answered and receive customized recommendations from our experienced team of technicians.

Don’t let complex diagnostic challenges slow you down. Contact us today to discover how MERCEDES-DIAGNOSTIC-TOOL.EDU.VN can transform your approach to vehicle diagnostics and maintenance.

Contact Information: