Are you seeking a deeper insight into your Mercedes-Benz’s performance and health? Understanding Obd2 Data is crucial, and MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers a comprehensive guide to help you unlock this valuable information. This knowledge empowers you to diagnose issues, optimize performance, and potentially save on costly repairs, ultimately enhancing your Mercedes-Benz ownership experience. Delve into vehicle diagnostics, diagnostic trouble codes (DTCs), and real-time data analysis to elevate your understanding.

Contents

- 1. What is OBD2 and Why is it Important for Your Mercedes-Benz?

- 1.1 The Role of the Malfunction Indicator Light (MIL)

- 1.2 How OBD2 Scanners Work

- 2. Is My Mercedes-Benz OBD2 Compliant?

- 2.1 OBD2 Compliance Timeline

- 2.2 Verifying OBD2 Compliance

- 3. A Brief History of OBD2 Development

- 4. The Future of OBD2: Trends and Innovations

- 4.1 OBD3 and Telematics

- 4.2 The German Automotive Industry’s Stance on OBD2 Access

- 4.3 Alternatives to Traditional OBD2: WWH-OBD and OBDonUDS

- 5. Understanding OBD2 Standards: A Technical Overview

- 5.1 The OSI Model and OBD2 Standards

- 6. The OBD2 Connector: SAE J1962

- 6.1 Key Features of the OBD2 Connector

- 6.2 Type A vs. Type B OBD2 Connectors

- 7. OBD2 and CAN Bus: ISO 15765-4

- 7.1 Key Aspects of ISO 15765-4

- 7.2 OBD2 CAN Identifiers

- 7.3 OBD2 vs. Proprietary CAN Protocols

- 7.4 Bit-Rate and ID Validation

- 8. Transporting OBD2 Messages via ISO-TP: ISO 15765-2

- 8.1 Single Frame (SF) Communication

- 9. The OBD2 Diagnostic Message: SAE J1979, ISO 15031-5

- 9.1 Example: Requesting Vehicle Speed

- 9.2 The 10 OBD2 Services (Modes)

- 9.3 OBD2 Parameter IDs (PIDs)

- 10. Logging and Decoding OBD2 Data: A Practical Example

- 10.1 Step 1: Test Bit-Rate, IDs, and Supported PIDs

- 10.2 Step 2: Configure OBD2 PID Requests

- 10.3 Step 3: DBC Decode Raw OBD2 Data

- 11. OBD2 Multi-Frame Examples: ISO-TP

- 11.1 Example 1: Vehicle Identification Number (VIN)

- 11.2 Example 2: Multi-PID Request (6x)

- 11.3 Example 3: Diagnostic Trouble Codes (DTCs)

- 12. OBD2 Data Logging: Use Case Examples

- 13. How Can MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Help You?

- 14. Ready to Take Control of Your Mercedes-Benz’s Health?

- 15. Frequently Asked Questions (FAQ) About Understanding OBD2 Data

- 15.1 What is the best OBD2 scanner for a Mercedes-Benz?

- 15.2 How do I find the OBD2 port in my Mercedes-Benz?

- 15.3 Can I use any OBD2 scanner on my Mercedes-Benz?

- 15.4 What do OBD2 codes mean?

- 15.5 How do I clear OBD2 codes from my Mercedes-Benz?

- 15.6 Will clearing OBD2 codes affect my Mercedes-Benz’s performance?

- 15.7 What is the difference between OBD1 and OBD2?

- 15.8 Can I use OBD2 data to improve my Mercedes-Benz’s fuel efficiency?

- 15.9 Are there any risks associated with using an OBD2 scanner?

- 15.10 How often should I scan my Mercedes-Benz for OBD2 codes?

1. What is OBD2 and Why is it Important for Your Mercedes-Benz?

OBD2, or On-Board Diagnostics II, is a standardized system that provides access to your vehicle’s self-diagnostic data. It’s essentially your Mercedes-Benz’s built-in health monitor, crucial for identifying potential issues and ensuring optimal performance. It allows you to retrieve diagnostic trouble codes (DTCs) and real-time data via the OBD2 port.

1.1 The Role of the Malfunction Indicator Light (MIL)

Have you ever noticed the malfunction indicator light (MIL), also known as the check engine light, on your Mercedes-Benz’s dashboard? This light signals that the vehicle’s computer has detected a problem. An OBD2 scanner allows you to decipher the issues.

1.2 How OBD2 Scanners Work

Mechanics use OBD2 scanners to diagnose car problems. The OBD2 reader connects to the 16-pin OBD2 connector, typically located near the steering wheel. The tool transmits OBD2 requests, and the car responds with data like speed, fuel level, and DTCs. This facilitates faster troubleshooting and repair.

The OBD2 port is commonly located under the dashboard on the driver’s side.

2. Is My Mercedes-Benz OBD2 Compliant?

Most modern Mercedes-Benz vehicles support OBD2. Compliance depends on the vehicle’s manufacturing date and the region where it was sold.

2.1 OBD2 Compliance Timeline

- 1996: OBD2 became mandatory in the USA for cars and light trucks.

- 2001: Required in the EU for gasoline cars.

- 2003: Required in the EU for diesel cars (EOBD).

- 2005: OBD2 required in the US for medium-duty vehicles.

- 2008: US cars required to use ISO 15765-4 (CAN) as the OBD2 basis.

- 2010: OBD2 required in US heavy-duty vehicles.

2.2 Verifying OBD2 Compliance

Even if your older Mercedes-Benz has a 16-pin OBD2 connector, it might not fully support the protocol. To confirm, check your vehicle’s documentation or consult with a Mercedes-Benz technician.

3. A Brief History of OBD2 Development

OBD2 originated in California, driven by the California Air Resources Board (CARB) in 1991 to monitor and control vehicle emissions. The Society of Automotive Engineers (SAE) standardized DTCs and the OBD connector (SAE J1962), leading to widespread adoption.

The evolution of OBD2 standards has significantly improved vehicle diagnostics and emission control.

4. The Future of OBD2: Trends and Innovations

OBD2 is evolving with new technologies and regulations. Here are some key trends shaping its future:

4.1 OBD3 and Telematics

OBD3 envisions adding telematics to all cars, incorporating a small radio transponder to transmit Vehicle Identification Numbers (VIN) and DTCs via WiFi to a central server. While convenient, this raises privacy concerns.

4.2 The German Automotive Industry’s Stance on OBD2 Access

Some manufacturers aim to restrict third-party access to OBD2 data, proposing to collect data centrally. This could impact aftermarket OBD2 services. According to Christoph Grote, SVP Electronics, BMW (2017):

“OBD has been designed to service cars in repair shops. In no way has it been intended to allow third parties to build a form of data-driven economy on the access through this interface.”

4.3 Alternatives to Traditional OBD2: WWH-OBD and OBDonUDS

Modern alternatives like WWH-OBD (World Wide Harmonized OBD) and OBDonUDS (OBD on UDS) streamline OBD communication using the UDS protocol.

5. Understanding OBD2 Standards: A Technical Overview

OBD2 functions as a higher-layer protocol, similar to a language, while CAN (Controller Area Network) serves as the communication method. OBD2 standards define the connector, lower-layer protocols, and Parameter IDs (PIDs).

5.1 The OSI Model and OBD2 Standards

The OBD2 standards can be visualized using the 7-layer OSI model, illustrating the different layers involved in communication.

The OSI model provides a structured view of the OBD2 communication stack.

6. The OBD2 Connector: SAE J1962

The 16-pin OBD2 connector, defined by SAE J1962 / ISO 15031-3, enables easy access to your Mercedes-Benz’s data.

6.1 Key Features of the OBD2 Connector

- Located near the steering wheel.

- Pin 16 provides battery power.

- Pinout depends on the communication protocol.

- CAN bus uses pins 6 (CAN-H) and 14 (CAN-L).

6.2 Type A vs. Type B OBD2 Connectors

Type A connectors are typical in cars (12V), while Type B are used in medium and heavy-duty vehicles (24V).

Understanding the differences between Type A and Type B OBD2 connectors is essential for compatibility.

7. OBD2 and CAN Bus: ISO 15765-4

Since 2008, CAN bus has been mandatory for OBD2 in US cars, as per ISO 15765.

7.1 Key Aspects of ISO 15765-4

- CAN bus bit-rate: 250K or 500K.

- CAN IDs: 11-bit or 29-bit.

- Specific CAN IDs for OBD requests/responses.

- Data length: 8 bytes.

- Adapter cable length: max 5 meters.

7.2 OBD2 CAN Identifiers

OBD2 communication involves request/response messages. 11-bit CAN IDs are common, with 0x7DF for ‘Functional Addressing’ and 0x7E0-0x7E7 for ‘Physical Addressing’. Responses typically use IDs 0x7E8-0x7EF.

7.3 OBD2 vs. Proprietary CAN Protocols

Mercedes-Benz ECUs rely on proprietary CAN protocols, separate from OBD2. OBD2 is an additional layer in parallel to the OEM-specific protocol.

OBD2 provides standardized data access, while proprietary protocols manage vehicle functions.

7.4 Bit-Rate and ID Validation

ISO 15765-4 recommends a systematic initialization sequence to determine the correct bit-rate and CAN ID length.

8. Transporting OBD2 Messages via ISO-TP: ISO 15765-2

ISO-TP (ISO 15765-2) is the transport protocol for OBD2 data on the CAN bus, enabling communication of payloads larger than 8 bytes for data like VIN and DTCs.

8.1 Single Frame (SF) Communication

If the OBD2 data fits in a single CAN frame, ISO 15765-2 uses a ‘Single Frame’ (SF), with the first byte indicating the payload length.

9. The OBD2 Diagnostic Message: SAE J1979, ISO 15031-5

An OBD2 message comprises an identifier, data length, and data (Mode, PID, and data bytes).

9.1 Example: Requesting Vehicle Speed

To request vehicle speed, send a request message with Mode 0x01 and PID 0x0D. The car responds with the speed value.

This diagram illustrates a typical OBD2 request and response sequence for vehicle speed.

9.2 The 10 OBD2 Services (Modes)

There are 10 diagnostic services (modes), including real-time data (0x01) and DTC handling. Vehicles aren’t required to support all modes. In responses, 0x40 is added to the mode value.

9.3 OBD2 Parameter IDs (PIDs)

Each OBD2 mode contains PIDs. Mode 0x01 has ~200 standardized PIDs for real-time data. PID 0x00 in mode 0x01 is crucial for determining supported PIDs.

10. Logging and Decoding OBD2 Data: A Practical Example

You can log OBD2 data using tools like the CANedge CAN bus data logger. Connect it to your Mercedes-Benz via an OBD2-DB9 adapter cable.

10.1 Step 1: Test Bit-Rate, IDs, and Supported PIDs

Verify the bit-rate (250K or 500K) and CAN IDs. Send ‘Supported PIDs’ requests to identify the PIDs your vehicle supports.

10.2 Step 2: Configure OBD2 PID Requests

Configure your transmit list with desired PIDs, using ‘Physical Addressing’ request IDs. Add spacing between requests and use triggers to prevent battery drain.

10.3 Step 3: DBC Decode Raw OBD2 Data

Decode the raw OBD2 data into physical values using an OBD2 DBC file. This file helps translate the data into human-readable formats.

11. OBD2 Multi-Frame Examples: ISO-TP

Multi-frame communication requires flow control frames. Here are some examples:

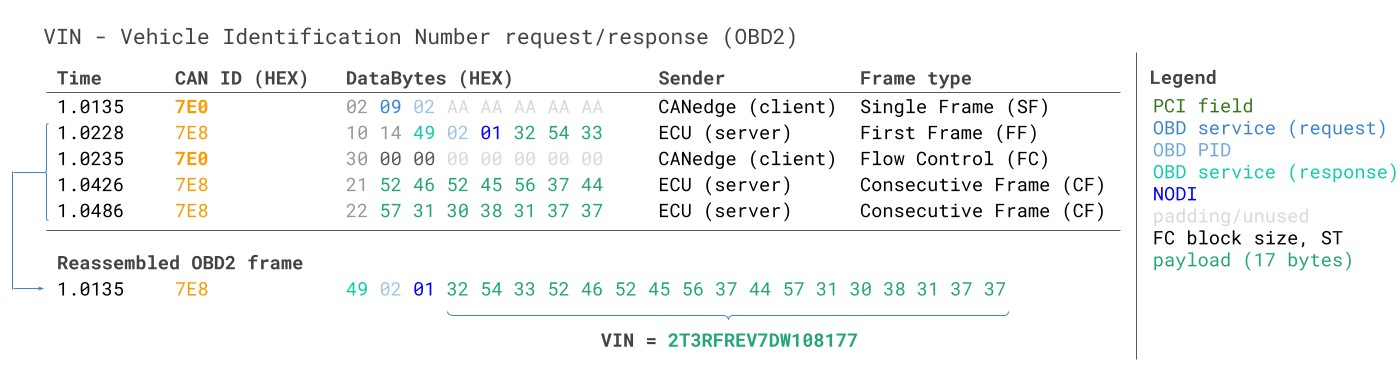

11.1 Example 1: Vehicle Identification Number (VIN)

Extract the VIN using mode 0x09 and PID 0x02.

VIN Vehicle Identification Number OBD2 Example multi-frame

VIN Vehicle Identification Number OBD2 Example multi-frame

11.2 Example 2: Multi-PID Request (6x)

Request up to 6 mode 0x01 PIDs in a single request frame.

11.3 Example 3: Diagnostic Trouble Codes (DTCs)

Request emissions-related DTCs using mode 0x03.

Understanding DTCs is crucial for diagnosing and addressing vehicle issues.

12. OBD2 Data Logging: Use Case Examples

OBD2 data can be used for various purposes:

- Logging data from cars: Reduce fuel costs, improve driving habits, and test prototype parts.

- Real-time car diagnostics: Stream OBD2 data for diagnosing vehicle issues in real-time.

- Predictive maintenance: Monitor vehicles to predict and avoid breakdowns.

- Vehicle blackbox logger: Serve as a ‘blackbox’ for vehicles, providing data for disputes or diagnostics.

13. How Can MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Help You?

At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we understand the importance of having the right tools and knowledge to effectively diagnose and maintain your Mercedes-Benz. That’s why we offer:

- Expert Guidance: Our team of experienced Mercedes-Benz technicians can provide personalized advice on selecting the best OBD2 tools and interpreting the data they provide.

- Step-by-Step Tutorials: We offer comprehensive guides and tutorials on using OBD2 scanners, accessing hidden features, and performing basic repairs.

- Troubleshooting Support: Facing a specific issue with your Mercedes-Benz? Contact us for expert troubleshooting assistance and guidance on resolving common problems.

14. Ready to Take Control of Your Mercedes-Benz’s Health?

Don’t let complex diagnostic data intimidate you. Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN today and let our experts guide you through the process of understanding and utilizing OBD2 data for your Mercedes-Benz.

Contact us now for a consultation:

- Address: 789 Oak Avenue, Miami, FL 33101, United States

- WhatsApp: +1 (641) 206-8880

- Website: MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

15. Frequently Asked Questions (FAQ) About Understanding OBD2 Data

15.1 What is the best OBD2 scanner for a Mercedes-Benz?

The best OBD2 scanner depends on your needs and budget. Options range from basic code readers to advanced professional-grade tools.

15.2 How do I find the OBD2 port in my Mercedes-Benz?

The OBD2 port is typically located under the dashboard on the driver’s side. Refer to your vehicle’s manual for the exact location.

15.3 Can I use any OBD2 scanner on my Mercedes-Benz?

While most OBD2 scanners are compatible, some advanced features may require a Mercedes-Benz specific scanner.

15.4 What do OBD2 codes mean?

OBD2 codes are diagnostic trouble codes (DTCs) that indicate specific problems in your vehicle. Use an OBD2 scanner to read the codes and consult a repair manual or online database for their meanings.

15.5 How do I clear OBD2 codes from my Mercedes-Benz?

You can clear OBD2 codes using an OBD2 scanner. However, it’s essential to address the underlying issue first.

15.6 Will clearing OBD2 codes affect my Mercedes-Benz’s performance?

Clearing codes without fixing the problem will only temporarily turn off the check engine light. The light will return if the issue persists.

15.7 What is the difference between OBD1 and OBD2?

OBD2 is a standardized system, while OBD1 was manufacturer-specific. OBD2 provides more comprehensive diagnostic information.

15.8 Can I use OBD2 data to improve my Mercedes-Benz’s fuel efficiency?

Yes, monitoring parameters like fuel trim, O2 sensor readings, and engine load can help you identify issues affecting fuel economy.

15.9 Are there any risks associated with using an OBD2 scanner?

Using a low-quality or malfunctioning scanner can potentially interfere with your vehicle’s electronics. Always use reputable and reliable tools.

15.10 How often should I scan my Mercedes-Benz for OBD2 codes?

Scan your vehicle whenever the check engine light comes on or if you notice any unusual performance issues. Regular scanning can help identify potential problems early.