When retrofitting a digital instrument cluster, coding is essential to ensure proper functionality and integration with your vehicle’s systems; MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides the diagnostic tools and expertise needed for seamless retrofitting. Proper coding ensures accurate data display, compatibility with vehicle features, and avoidance of error messages.

Contents

- 1. Understanding the Basics of Digital Instrument Cluster Retrofitting

- 1.1. What is a Digital Instrument Cluster?

- 1.2. Benefits of Retrofitting a Digital Instrument Cluster

- 1.3. Preliminary Steps Before Retrofitting

- 2. Essential Coding Requirements for Digital Instrument Cluster Retrofitting

- 2.1. Identifying Necessary Coding Parameters

- 2.2. Software and Hardware Requirements

- 2.3. Step-by-Step Coding Process

- 3. Detailed Coding Procedures for Different Vehicle Brands

- 3.1. BMW Coding Procedures

- 3.1.1. Using E-SYS for BMW Coding

- 3.1.2. Common BMW Coding Issues and Solutions

- 3.2. Mercedes-Benz Coding Procedures

- 3.2.1. Using XENTRY for Mercedes-Benz Coding

- 3.2.2. Common Mercedes-Benz Coding Issues and Solutions

- 4. Addressing Common Coding Challenges and Errors

- 4.1. Compatibility Issues

- 4.1.1. Verifying Compatibility Before Installation

- 4.1.2. Resolving Incompatibility Issues

- 4.2. Software Glitches

- 4.2.1. Identifying Software Glitches

- 4.2.2. Troubleshooting Software Glitches

- 4.3. Data Loss

- 4.3.1. Preventing Data Loss

- 4.3.2. Recovering Lost Data

- 5. Advanced Coding Techniques and Customization

- 5.1. Enabling Hidden Features

- 5.1.1. Identifying Hidden Features

- 5.1.2. Coding Hidden Features

- 5.2. Customizing Display Settings

- 5.2.1. Accessing Display Settings

- 5.2.2. Modifying Display Settings

- 6. Maintaining and Updating Your Digital Instrument Cluster

- 6.1. Software Updates

- 6.1.1. Checking for Updates

- 6.1.2. Installing Updates

- 6.2. Regular Diagnostics

- 6.2.1. Performing Diagnostics

- 6.2.2. Addressing Issues

- 7. Legal and Ethical Considerations

- 7.1. Compliance with Regulations

- 7.1.1. Understanding Regulations

- 7.1.2. Ensuring Compliance

- 7.2. Ethical Considerations

- 7.2.1. Disclosure to Buyers

- 7.2.2. Accurate Mileage Reporting

- 8. Case Studies: Successful Digital Instrument Cluster Retrofits

- 8.1. BMW 5 Series Retrofit

- 8.1.1. Challenges Faced

- 8.1.2. Solutions Implemented

- 8.1.3. Results Achieved

- 8.2. Mercedes-Benz C-Class Retrofit

- 8.2.1. Challenges Faced

- 8.2.2. Solutions Implemented

- 8.2.3. Results Achieved

- 9. Future Trends in Digital Instrument Cluster Technology

- 9.1. Augmented Reality Integration

- 9.1.1. Benefits of AR Integration

- 9.1.2. Examples of AR Integration

- 9.2. Artificial Intelligence (AI) Integration

- 9.2.1. Benefits of AI Integration

- 9.2.2. Examples of AI Integration

- 10. Expert Tips for a Successful Retrofit

- 10.1. Thorough Research

- 10.1.1. Gather Information

- 10.1.2. Consult Experts

- 10.2. Careful Planning

- 10.2.1. Create a Plan

- 10.2.2. Gather Tools

- 10.3. Professional Assistance

- 10.3.1. Benefits of Professional Assistance

- 10.3.2. Finding Professionals

- 11. Frequently Asked Questions (FAQ)

- 11.1. What Coding Is Required When Retrofitting a Digital Instrument Cluster?

- 11.2. Which Diagnostic Tool Is Best for Mercedes-Benz Coding?

- 11.3. How Do I Update My BMW’s Software for Digital Instrument Cluster Compatibility?

- 11.4. Can I Enable Hidden Features on My Digital Instrument Cluster?

- 11.5. What Are the Legal Considerations for Retrofitting a Digital Instrument Cluster?

- 11.6. How Often Should I Update the Software on My Digital Instrument Cluster?

- 11.7. What Do I Do If I Encounter a CAFD File Error During BMW Coding?

- 11.8. How Can I Customize the Display Settings on My Digital Instrument Cluster?

- 11.9. Is It Possible to Retrofit a Digital Instrument Cluster on Older Vehicle Models?

- 11.10. Where Can I Find Professional Assistance for Digital Instrument Cluster Retrofitting?

- 12. Conclusion: Embracing the Future of Automotive Technology

1. Understanding the Basics of Digital Instrument Cluster Retrofitting

Retrofitting a digital instrument cluster involves replacing the original instrument panel with a modern, digital display. This upgrade enhances the vehicle’s aesthetics and provides advanced features such as customizable displays, navigation integration, and detailed vehicle information.

1.1. What is a Digital Instrument Cluster?

A digital instrument cluster, also known as a virtual cockpit or digital dashboard, is a display screen that replaces traditional analog gauges. According to a study by Cox Automotive, 63% of new car buyers prefer digital displays for their advanced features and modern look.

1.2. Benefits of Retrofitting a Digital Instrument Cluster

Retrofitting offers several advantages:

- Enhanced Aesthetics: Modernizes the vehicle’s interior.

- Customizable Displays: Allows drivers to personalize the information displayed.

- Advanced Features: Includes navigation, media, and vehicle data integration.

1.3. Preliminary Steps Before Retrofitting

Before starting the retrofit, consider these steps:

- Compatibility Check: Ensure the digital instrument cluster is compatible with your vehicle’s make, model, and year.

- Gather Necessary Tools: Acquire diagnostic tools, coding software, and any required hardware.

- Backup Vehicle Data: Back up your vehicle’s existing data to prevent data loss during the retrofit process.

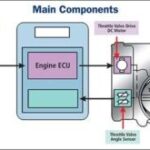

2. Essential Coding Requirements for Digital Instrument Cluster Retrofitting

Coding is a crucial step in the retrofitting process, ensuring the digital instrument cluster communicates correctly with the vehicle’s electronic control units (ECUs).

2.1. Identifying Necessary Coding Parameters

Determine the specific coding parameters required for your vehicle and the new digital instrument cluster. This information is often available from the manufacturer or online forums.

2.2. Software and Hardware Requirements

Ensure you have the necessary software and hardware:

- Diagnostic Software: Such as BMW ISTA, Mercedes XENTRY, or similar tools.

- Interface Cable: An OBD-II cable to connect your computer to the vehicle.

- Power Supply: A stable power supply to prevent interruptions during coding.

2.3. Step-by-Step Coding Process

Follow these steps for coding:

- Connect Diagnostic Tool: Connect your diagnostic tool to the vehicle’s OBD-II port.

- Read ECU Data: Use the diagnostic software to read the existing ECU data.

- Enter Coding Parameters: Input the necessary coding parameters for the new digital instrument cluster.

- Write Coding Data: Write the new coding data to the relevant ECUs.

- Verify Functionality: Test the digital instrument cluster to ensure all features are working correctly.

3. Detailed Coding Procedures for Different Vehicle Brands

The coding process can vary depending on the vehicle brand. Here are detailed procedures for BMW and Mercedes-Benz vehicles.

3.1. BMW Coding Procedures

For BMW vehicles, coding typically involves using E-SYS or ISTA software.

3.1.1. Using E-SYS for BMW Coding

E-SYS is a popular tool for coding BMW vehicles.

- Connect to Vehicle: Connect your computer to the vehicle using an ENET cable.

- Launch E-SYS: Open the E-SYS software and connect to the vehicle.

- Read FA: Read the vehicle’s FA (Fahrzeugauftrag) or vehicle order.

- Edit FA: Add the option code for the digital instrument cluster (e.g., 6WB for the 6WB digital cluster).

- Calculate FP: Calculate the FP (Fahrzeugprofil) or vehicle profile.

- Write FA: Write the modified FA to the vehicle.

- Code ECUs: Code the relevant ECUs (e.g., DKOMBI2, HU-NBT) with the new FA.

3.1.2. Common BMW Coding Issues and Solutions

- CAFD File Not Found: This error occurs when the CAFD file for the ECU is missing or incorrect. Solution: Update your PSdZData files to the latest version.

- Incorrect Coding Parameters: Ensure you are using the correct coding parameters for your vehicle and the digital instrument cluster. Solution: Consult online forums or a BMW specialist.

3.2. Mercedes-Benz Coding Procedures

For Mercedes-Benz vehicles, coding typically involves using XENTRY or Vediamo software. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers specialized tools and support for Mercedes-Benz coding.

3.2.1. Using XENTRY for Mercedes-Benz Coding

XENTRY is the official diagnostic software for Mercedes-Benz vehicles.

- Connect to Vehicle: Connect your computer to the vehicle using a Mercedes-Benz diagnostic interface.

- Launch XENTRY: Open the XENTRY software and connect to the vehicle.

- Identify Control Units: Allow XENTRY to identify the installed control units.

- Perform SCN Coding: Use SCN (Software Calibration Number) coding to program the digital instrument cluster.

- Variant Coding: Perform variant coding to customize the settings of the digital instrument cluster.

3.2.2. Common Mercedes-Benz Coding Issues and Solutions

- SCN Coding Errors: SCN coding requires a valid SCN account and access to the Mercedes-Benz server. Solution: Ensure you have a valid SCN account and a stable internet connection.

- Incorrect Variant Coding: Incorrect variant coding can lead to malfunctioning features. Solution: Double-check the coding parameters and consult a Mercedes-Benz specialist.

4. Addressing Common Coding Challenges and Errors

Coding can present various challenges. Understanding these issues and their solutions is crucial for a successful retrofit.

4.1. Compatibility Issues

Ensure the digital instrument cluster is compatible with your vehicle.

4.1.1. Verifying Compatibility Before Installation

- Check Part Numbers: Verify the part number of the digital instrument cluster matches your vehicle’s specifications.

- Consult Online Forums: Research compatibility information on online forums and communities.

- Contact Specialists: Consult with specialists at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for expert advice.

4.1.2. Resolving Incompatibility Issues

- Software Updates: Ensure your vehicle’s software is up to date.

- Hardware Modifications: In some cases, hardware modifications may be necessary.

- Recoding: Recode the digital instrument cluster to match your vehicle’s specifications.

4.2. Software Glitches

Software glitches can occur during coding.

4.2.1. Identifying Software Glitches

- Error Messages: Pay attention to any error messages displayed during coding.

- Functionality Issues: Check for any malfunctioning features after coding.

4.2.2. Troubleshooting Software Glitches

- Restart Coding Process: Restart the coding process from the beginning.

- Update Software: Ensure your diagnostic software is up to date.

- Consult Experts: Seek assistance from experts at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for troubleshooting.

4.3. Data Loss

Data loss can occur during the coding process.

4.3.1. Preventing Data Loss

- Backup Vehicle Data: Always back up your vehicle’s data before coding.

- Stable Power Supply: Use a stable power supply to prevent interruptions during coding.

4.3.2. Recovering Lost Data

- Restore from Backup: Restore the data from your backup.

- Consult Specialists: Seek assistance from data recovery specialists.

5. Advanced Coding Techniques and Customization

Advanced coding techniques can unlock additional features and customization options.

5.1. Enabling Hidden Features

Digital instrument clusters often have hidden features that can be enabled through coding.

5.1.1. Identifying Hidden Features

- Online Forums: Research hidden features on online forums and communities.

- Coding Guides: Consult coding guides for your vehicle model.

5.1.2. Coding Hidden Features

- Access Coding Parameters: Access the coding parameters for the relevant ECUs.

- Modify Coding Values: Modify the coding values to enable the hidden features.

- Test Functionality: Test the functionality of the enabled features.

5.2. Customizing Display Settings

Customize the display settings of the digital instrument cluster to suit your preferences.

5.2.1. Accessing Display Settings

- Diagnostic Software: Use diagnostic software to access the display settings.

- Vehicle Menu: Access display settings through the vehicle’s menu system.

5.2.2. Modifying Display Settings

- Adjust Brightness: Adjust the brightness of the display.

- Customize Layout: Customize the layout of the display.

- Change Color Schemes: Change the color schemes of the display.

6. Maintaining and Updating Your Digital Instrument Cluster

Regular maintenance and updates are essential to keep your digital instrument cluster functioning correctly.

6.1. Software Updates

Keep the software of your digital instrument cluster up to date.

6.1.1. Checking for Updates

- Vehicle Manufacturer: Check the vehicle manufacturer’s website for updates.

- Diagnostic Software: Use diagnostic software to check for updates.

6.1.2. Installing Updates

- Follow Instructions: Follow the instructions provided by the vehicle manufacturer or diagnostic software.

- Stable Power Supply: Ensure a stable power supply during the update process.

6.2. Regular Diagnostics

Perform regular diagnostics to identify and address any potential issues.

6.2.1. Performing Diagnostics

- Diagnostic Software: Use diagnostic software to perform diagnostics.

- Check for Error Codes: Check for any error codes stored in the vehicle’s ECUs.

6.2.2. Addressing Issues

- Troubleshoot Error Codes: Troubleshoot any error codes to identify the underlying issues.

- Consult Specialists: Consult with specialists at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for expert assistance.

7. Legal and Ethical Considerations

Be aware of the legal and ethical considerations when retrofitting a digital instrument cluster.

7.1. Compliance with Regulations

Ensure the retrofit complies with all relevant regulations.

7.1.1. Understanding Regulations

- Vehicle Safety Standards: Understand the vehicle safety standards in your region.

- Emissions Regulations: Understand the emissions regulations in your region.

7.1.2. Ensuring Compliance

- Consult Experts: Consult with experts at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN to ensure compliance.

- Use Certified Parts: Use certified parts and components for the retrofit.

7.2. Ethical Considerations

Consider the ethical implications of retrofitting a digital instrument cluster.

7.2.1. Disclosure to Buyers

- Inform Potential Buyers: Inform potential buyers about the retrofit if you sell the vehicle.

- Provide Documentation: Provide documentation about the retrofit to potential buyers.

7.2.2. Accurate Mileage Reporting

- Ensure Accurate Mileage: Ensure the mileage displayed on the digital instrument cluster is accurate.

- Disclose Mileage Discrepancies: Disclose any mileage discrepancies to potential buyers.

8. Case Studies: Successful Digital Instrument Cluster Retrofits

Explore real-world examples of successful digital instrument cluster retrofits.

8.1. BMW 5 Series Retrofit

A BMW 5 Series owner successfully retrofitted a 6WB digital instrument cluster.

8.1.1. Challenges Faced

- CAFD File Issues: Encountered CAFD file issues during coding.

- Compatibility Concerns: Had concerns about compatibility with the vehicle’s systems.

8.1.2. Solutions Implemented

- Updated PSdZData: Updated the PSdZData files to the latest version.

- Consulted Experts: Consulted with BMW coding experts for assistance.

8.1.3. Results Achieved

- Seamless Integration: Achieved seamless integration of the digital instrument cluster.

- Enhanced Functionality: Enjoyed enhanced functionality and customization options.

8.2. Mercedes-Benz C-Class Retrofit

A Mercedes-Benz C-Class owner successfully retrofitted a digital instrument cluster.

8.2.1. Challenges Faced

- SCN Coding Errors: Encountered SCN coding errors during the process.

- Variant Coding Issues: Faced issues with variant coding and customization.

8.2.2. Solutions Implemented

- Valid SCN Account: Obtained a valid SCN account and access to the Mercedes-Benz server.

- Double-Checked Parameters: Double-checked the coding parameters and consulted with Mercedes-Benz specialists.

8.2.3. Results Achieved

- Successful Coding: Successfully coded the digital instrument cluster.

- Customized Display: Customized the display settings to suit their preferences.

9. Future Trends in Digital Instrument Cluster Technology

Stay informed about the future trends in digital instrument cluster technology.

9.1. Augmented Reality Integration

Augmented reality (AR) integration is becoming increasingly common in digital instrument clusters.

9.1.1. Benefits of AR Integration

- Enhanced Navigation: Provides enhanced navigation with AR overlays.

- Real-Time Information: Displays real-time information about the surroundings.

9.1.2. Examples of AR Integration

- Mercedes-Benz MBUX: Mercedes-Benz MBUX system offers AR-enhanced navigation.

- Audi Virtual Cockpit: Audi Virtual Cockpit integrates AR elements for improved driver assistance.

9.2. Artificial Intelligence (AI) Integration

Artificial intelligence (AI) integration is enhancing the capabilities of digital instrument clusters.

9.2.1. Benefits of AI Integration

- Personalized Recommendations: Provides personalized recommendations based on driving habits.

- Predictive Maintenance: Predicts maintenance needs based on vehicle data.

9.2.2. Examples of AI Integration

- BMW Intelligent Personal Assistant: BMW Intelligent Personal Assistant learns driver preferences and provides personalized assistance.

- Tesla Autopilot: Tesla Autopilot uses AI to provide advanced driver assistance features.

10. Expert Tips for a Successful Retrofit

Follow these expert tips for a smooth and successful digital instrument cluster retrofit.

10.1. Thorough Research

Conduct thorough research before starting the retrofit.

10.1.1. Gather Information

- Online Forums: Explore online forums and communities for information and tips.

- Coding Guides: Consult coding guides and tutorials for your vehicle model.

10.1.2. Consult Experts

- MERCEDES-DIAGNOSTIC-TOOL.EDU.VN: Consult with experts at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for expert advice.

- Vehicle Specialists: Seek advice from vehicle specialists and mechanics.

10.2. Careful Planning

Plan the retrofit carefully before starting.

10.2.1. Create a Plan

- Step-by-Step Guide: Create a step-by-step guide for the retrofit process.

- Timeline: Set a timeline for the retrofit.

10.2.2. Gather Tools

- Diagnostic Tools: Ensure you have the necessary diagnostic tools and software.

- Hardware: Gather all required hardware components.

10.3. Professional Assistance

Consider seeking professional assistance for the retrofit.

10.3.1. Benefits of Professional Assistance

- Expertise: Access to expert knowledge and experience.

- Time Savings: Saves time and effort.

- Reduced Risk: Reduces the risk of errors and complications.

10.3.2. Finding Professionals

- MERCEDES-DIAGNOSTIC-TOOL.EDU.VN: Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for professional assistance.

- Certified Technicians: Find certified technicians and mechanics in your area.

11. Frequently Asked Questions (FAQ)

11.1. What Coding Is Required When Retrofitting a Digital Instrument Cluster?

Coding is essential to ensure the digital instrument cluster communicates correctly with the vehicle’s ECUs, displaying accurate data and enabling features. Proper coding involves modifying the vehicle’s FA, coding the relevant ECUs, and customizing display settings.

11.2. Which Diagnostic Tool Is Best for Mercedes-Benz Coding?

XENTRY is the official diagnostic software for Mercedes-Benz vehicles, providing comprehensive coding and diagnostic capabilities. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers specialized tools and support for Mercedes-Benz coding with XENTRY.

11.3. How Do I Update My BMW’s Software for Digital Instrument Cluster Compatibility?

Use BMW ISTA or E-SYS to update your BMW’s software. Ensure you have the latest PSdZData files for accurate coding.

11.4. Can I Enable Hidden Features on My Digital Instrument Cluster?

Yes, you can enable hidden features through advanced coding techniques. Research online forums and consult coding guides to identify and enable these features.

11.5. What Are the Legal Considerations for Retrofitting a Digital Instrument Cluster?

Ensure the retrofit complies with vehicle safety and emissions regulations. Disclose the retrofit to potential buyers and ensure accurate mileage reporting.

11.6. How Often Should I Update the Software on My Digital Instrument Cluster?

Check for software updates regularly, at least every six months, to ensure optimal performance and compatibility.

11.7. What Do I Do If I Encounter a CAFD File Error During BMW Coding?

Update your PSdZData files to the latest version to resolve CAFD file errors.

11.8. How Can I Customize the Display Settings on My Digital Instrument Cluster?

Access display settings through the vehicle’s menu system or diagnostic software. Adjust brightness, customize the layout, and change color schemes to suit your preferences.

11.9. Is It Possible to Retrofit a Digital Instrument Cluster on Older Vehicle Models?

It may be possible, but compatibility can be a challenge. Thorough research and expert consultation are essential.

11.10. Where Can I Find Professional Assistance for Digital Instrument Cluster Retrofitting?

Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for professional assistance and expert advice. They offer specialized tools and support for Mercedes-Benz and BMW vehicles.

12. Conclusion: Embracing the Future of Automotive Technology

Retrofitting a digital instrument cluster is a rewarding upgrade that enhances your vehicle’s aesthetics and functionality. While coding is essential, understanding the requirements, addressing potential challenges, and seeking expert assistance can ensure a successful retrofit. Embrace the future of automotive technology with confidence and enjoy the benefits of a modern, customizable digital display.

Ready to enhance your Mercedes-Benz with a digital instrument cluster? Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for expert guidance, diagnostic tools, and coding services. Our team of specialists is here to help you navigate the retrofitting process and unlock the full potential of your vehicle. Reach out to us today for a consultation and take the first step towards a modernized driving experience.

Contact Information:

- Address: 789 Oak Avenue, Miami, FL 33101, United States

- WhatsApp: +1 (641) 206-8880

- Website: MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

Let MERCEDES-DIAGNOSTIC-TOOL.EDU.VN be your trusted partner in automotive diagnostics, coding, and retrofitting solutions.