Yes, a single fault condition can indeed trigger multiple Diagnostic Trouble Codes (DTCs) that are related. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we help you understand how this occurs and provide solutions for accurate diagnosis and repair. Understanding the relationship between fault conditions and DTCs, along with utilizing the right diagnostic tools, is crucial for efficient Mercedes-Benz maintenance, leading to enhanced vehicle performance, minimized downtime, and cost savings.

Contents

- 1. Understanding Diagnostic Trouble Codes (DTCs) in Mercedes-Benz Vehicles

- 1.1. What are DTCs?

- 1.2. How DTCs are Generated

- 1.3. Standardized vs. Manufacturer-Specific DTCs

- 1.4. The Structure of a DTC

- 2. The Phenomenon of Multiple DTCs from a Single Fault

- 2.1. Interconnected Systems

- 2.2. Cascade Effect

- 2.3. Shared Sensors and Components

- 2.4. Electrical Issues

- 3. Examples of Fault Conditions and Their Related DTCs

- 3.1. Faulty Mass Airflow (MAF) Sensor

- 3.2. Malfunctioning Oxygen Sensor

- 3.3. Faulty Crankshaft Position Sensor

- 3.4. Low Battery Voltage

- 4. Diagnostic Strategies for Multiple DTCs

- 4.1. Record All DTCs

- 4.2. Research DTCs

- 4.3. Identify Common Causes

- 4.4. Prioritize DTCs

- 4.5. Perform Visual Inspection

- 4.6. Test Components

- 4.7. Analyze Freeze Frame Data

- 4.8. Consult Technical Service Bulletins (TSBs)

- 4.9. Seek Expert Assistance

- 5. Tools and Equipment for Diagnosing Multiple DTCs

- 5.1. Diagnostic Scan Tool

- 5.2. Multimeter

- 5.3. Oscilloscope

- 5.4. Wiring Diagrams

- 5.5. Repair Manuals

- 5.6. Smoke Machine

- 5.7. Fuel Pressure Tester

- 6. Advanced Diagnostic Techniques

- 6.1. Data Logging

- 6.2. Component Simulation

- 6.3. Network Communication Analysis

- 6.4. Guided Diagnostics

- 7. Preventive Maintenance to Reduce DTCs

- 7.1. Regular Oil Changes

- 7.2. Air Filter Replacement

- 7.3. Spark Plug Replacement

- 7.4. Fuel Filter Replacement

- 7.5. Battery Maintenance

- 7.6. Regular Inspections

- 8. Common Mistakes to Avoid When Diagnosing DTCs

- 8.1. Replacing Parts Without Proper Diagnosis

- 8.2. Ignoring Related Symptoms

- 8.3. Clearing DTCs Without Addressing the Underlying Problem

- 8.4. Using Incorrect Diagnostic Procedures

- 8.5. Overlooking Technical Service Bulletins (TSBs)

- 9. The Role of MERCEDES-DIAGNOSTIC-TOOL.EDU.VN in DTC Diagnosis

- 9.1. Comprehensive Diagnostic Information

- 9.2. Expert Diagnostic Assistance

- 9.3. Access to Diagnostic Tools

- 9.4. Repair Resources and Guidance

- 9.5. Community Forum and Support

- 10. Real-World Case Studies

- 10.1. Case Study 1: Multiple Misfire Codes

- 10.2. Case Study 2: ABS and ESP Faults

- 11. The Future of DTC Diagnostics

- 11.1. Enhanced Diagnostic Scan Tools

- 11.2. Cloud-Based Diagnostics

- 11.3. Artificial Intelligence (AI)

- 11.4. Remote Diagnostics

- 11.5. Integration with Repair Information Systems

- 12. Conclusion: Mastering DTC Diagnosis for Mercedes-Benz Vehicles

- 13. Frequently Asked Questions (FAQ)

- 13.1. What is a DTC?

- 13.2. Can a single fault cause multiple DTCs?

- 13.3. How do I read DTCs on my Mercedes-Benz?

- 13.4. What should I do after reading DTCs?

- 13.5. Are all DTCs serious?

- 13.6. Can I fix DTCs myself?

- 13.7. How often should I scan my Mercedes-Benz for DTCs?

- 13.8. What is freeze frame data?

- 13.9. Where can I find more information about Mercedes-Benz DTCs?

- 13.10. What are the benefits of using MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for DTC diagnosis?

1. Understanding Diagnostic Trouble Codes (DTCs) in Mercedes-Benz Vehicles

Diagnostic Trouble Codes (DTCs) are standardized codes used in the automotive industry to identify specific faults or issues detected by a vehicle’s onboard diagnostic system. These codes are crucial for diagnosing and repairing problems in modern vehicles, including Mercedes-Benz models. They provide a starting point for technicians and DIY enthusiasts to identify the source of a problem and perform the necessary repairs.

1.1. What are DTCs?

DTCs are alphanumeric codes that correspond to specific faults within a vehicle’s various systems, such as the engine, transmission, ABS, and airbag systems. When a fault is detected, the vehicle’s computer stores a DTC in its memory, which can then be retrieved using a diagnostic scan tool.

1.2. How DTCs are Generated

The vehicle’s Engine Control Unit (ECU) or other control modules continuously monitor the performance of various sensors and components. When a sensor reading falls outside the acceptable range or a component fails to operate as expected, the ECU detects a fault condition. This triggers the generation and storage of a DTC in the ECU’s memory.

1.3. Standardized vs. Manufacturer-Specific DTCs

There are two main types of DTCs:

- Standardized DTCs: These are defined by the Society of Automotive Engineers (SAE) and are common across all vehicle manufacturers. They typically cover basic engine and emissions-related faults.

- Manufacturer-Specific DTCs: These codes are specific to a particular vehicle manufacturer, such as Mercedes-Benz. They cover a wider range of faults, including those related to the vehicle’s unique systems and features.

1.4. The Structure of a DTC

A typical DTC consists of five characters: one letter followed by four numbers. The letter indicates the system where the fault occurred:

- P: Powertrain (engine, transmission)

- B: Body (airbags, central locking)

- C: Chassis (ABS, ESP)

- U: Network (communication)

The first number indicates whether the code is standardized (0) or manufacturer-specific (1). The remaining three numbers identify the specific fault. For example, P0300 indicates a random or multiple cylinder misfire, while B1000 is a Mercedes-Benz specific code.

2. The Phenomenon of Multiple DTCs from a Single Fault

It’s common for a single underlying fault condition to trigger multiple related DTCs in a Mercedes-Benz vehicle. This can occur for several reasons, primarily due to the interconnected nature of modern automotive systems. When one component or system malfunctions, it can affect other related systems, leading to a cascade of error codes.

2.1. Interconnected Systems

Modern vehicles, especially luxury brands like Mercedes-Benz, are equipped with highly integrated electronic systems. The engine, transmission, ABS, ESP, and other systems communicate with each other through a network of sensors and control modules. A fault in one system can directly impact the performance of another, resulting in multiple DTCs.

For example, a faulty mass airflow (MAF) sensor can cause the engine to run lean, leading to misfires and triggering DTCs related to both the MAF sensor and the engine’s combustion process.

2.2. Cascade Effect

The cascade effect refers to the phenomenon where a primary fault triggers a series of secondary faults in related systems. This is common in complex automotive systems where components rely on each other for proper operation.

For instance, a malfunctioning oxygen sensor can cause the engine control unit (ECU) to miscalculate the air-fuel mixture. This can lead to a variety of issues, such as reduced fuel efficiency, poor engine performance, and damage to the catalytic converter. As a result, the ECU may store multiple DTCs related to the oxygen sensor, fuel trim, misfires, and catalytic converter efficiency.

2.3. Shared Sensors and Components

Many sensors and components in a vehicle are shared between multiple systems. If a shared sensor fails, it can trigger DTCs in all the systems that rely on its data.

For example, the vehicle speed sensor (VSS) is used by the engine control unit (ECU), transmission control unit (TCU), and anti-lock braking system (ABS). If the VSS malfunctions, it can trigger DTCs related to engine performance, transmission shifting, and ABS operation.

2.4. Electrical Issues

Electrical issues, such as shorts, open circuits, and faulty wiring, can cause a wide range of problems in a vehicle’s electronic systems. These issues can trigger multiple DTCs in seemingly unrelated systems.

For example, a short circuit in the vehicle’s wiring harness can cause voltage fluctuations that affect various sensors and control modules. This can lead to the storage of DTCs related to engine performance, transmission operation, ABS function, and even airbag system status.

3. Examples of Fault Conditions and Their Related DTCs

To better illustrate the phenomenon of multiple DTCs from a single fault, let’s consider some specific examples:

3.1. Faulty Mass Airflow (MAF) Sensor

A faulty MAF sensor can cause the engine to receive incorrect information about the amount of air entering the engine. This can lead to a variety of issues, including:

- Lean or rich fuel mixture: The ECU may miscalculate the amount of fuel needed, resulting in a lean or rich fuel mixture.

- Misfires: An improper air-fuel mixture can cause the engine to misfire.

- Poor engine performance: The engine may run rough, hesitate, or lack power.

- Increased emissions: The engine may produce excessive emissions.

As a result, a faulty MAF sensor can trigger the following DTCs:

- P0100: Mass Air Flow Circuit Malfunction

- P0171: System Too Lean (Bank 1)

- P0172: System Too Rich (Bank 1)

- P0300: Random/Multiple Cylinder Misfire Detected

3.2. Malfunctioning Oxygen Sensor

A malfunctioning oxygen sensor can cause the ECU to miscalculate the air-fuel mixture, leading to:

- Reduced fuel efficiency: The engine may consume more fuel than necessary.

- Poor engine performance: The engine may run rough or hesitate.

- Catalytic converter damage: An improper air-fuel mixture can damage the catalytic converter.

- Increased emissions: The engine may produce excessive emissions.

A malfunctioning oxygen sensor can trigger the following DTCs:

- P0130: O2 Sensor Circuit Malfunction (Bank 1, Sensor 1)

- P0133: O2 Sensor Circuit Slow Response (Bank 1, Sensor 1)

- P0420: Catalyst System Efficiency Below Threshold (Bank 1)

3.3. Faulty Crankshaft Position Sensor

A faulty crankshaft position sensor can cause the ECU to lose track of the engine’s position, leading to:

- Engine stalling: The engine may stall unexpectedly.

- No-start condition: The engine may not start at all.

- Misfires: The engine may misfire due to incorrect timing.

- Poor engine performance: The engine may run rough or lack power.

A faulty crankshaft position sensor can trigger the following DTCs:

- P0335: Crankshaft Position Sensor A Circuit Malfunction

- P0336: Crankshaft Position Sensor A Circuit Range/Performance

- P0300: Random/Multiple Cylinder Misfire Detected

3.4. Low Battery Voltage

Low battery voltage can cause a variety of electrical issues in a vehicle, including:

- Sensor malfunctions: Sensors may not operate correctly due to insufficient voltage.

- Control module errors: Control modules may not function properly, leading to incorrect data processing.

- Communication problems: Control modules may not be able to communicate with each other.

Low battery voltage can trigger a wide range of DTCs in various systems, depending on the specific vehicle and the severity of the voltage drop.

4. Diagnostic Strategies for Multiple DTCs

When faced with multiple DTCs, it’s important to follow a systematic diagnostic approach to identify the underlying fault condition. Here’s a recommended strategy:

4.1. Record All DTCs

The first step is to record all the DTCs present in the vehicle’s computer. Use a diagnostic scan tool to retrieve and document the codes. Note the order in which the codes appear, as this may provide clues about the sequence of events.

4.2. Research DTCs

Once you have recorded the DTCs, research each code to understand its possible causes and related symptoms. Consult repair manuals, online databases, and technical service bulletins (TSBs) for information about the codes and their potential solutions.

4.3. Identify Common Causes

Look for common causes or relationships between the DTCs. Are there any shared sensors, components, or systems involved? Do the codes suggest a cascade effect, where one fault leads to another?

4.4. Prioritize DTCs

Prioritize the DTCs based on their severity and potential impact on vehicle operation. Focus on the codes that are most likely to be the root cause of the problem.

4.5. Perform Visual Inspection

Perform a thorough visual inspection of the vehicle’s engine compartment, wiring harnesses, and related components. Look for any obvious signs of damage, such as broken wires, loose connections, or corroded terminals.

4.6. Test Components

Test the components that are most likely to be the cause of the problem. Use a multimeter, oscilloscope, or other diagnostic tools to check the components’ electrical signals, resistance, and continuity.

4.7. Analyze Freeze Frame Data

Freeze frame data provides a snapshot of the vehicle’s operating conditions at the moment a DTC was stored. This data can be invaluable in diagnosing intermittent or difficult-to-reproduce problems.

4.8. Consult Technical Service Bulletins (TSBs)

Technical service bulletins (TSBs) are issued by vehicle manufacturers to address common problems and provide repair procedures. Consult TSBs for any relevant information about the DTCs you are investigating.

4.9. Seek Expert Assistance

If you are unable to diagnose the problem on your own, seek assistance from a qualified technician or diagnostic specialist. They have the experience, knowledge, and tools to diagnose and repair complex automotive problems.

5. Tools and Equipment for Diagnosing Multiple DTCs

Diagnosing multiple DTCs requires the right tools and equipment. Here are some essential tools for automotive diagnostics:

5.1. Diagnostic Scan Tool

A diagnostic scan tool is the most important tool for retrieving and clearing DTCs. It connects to the vehicle’s diagnostic port (OBD-II port) and allows you to access the vehicle’s computer. There are various types of scan tools available, ranging from basic code readers to advanced professional-grade tools.

5.2. Multimeter

A multimeter is an essential tool for measuring voltage, current, and resistance in electrical circuits. It can be used to test sensors, actuators, and wiring harnesses.

5.3. Oscilloscope

An oscilloscope is a more advanced tool that allows you to visualize electrical signals over time. It can be used to diagnose intermittent problems and analyze complex waveforms.

5.4. Wiring Diagrams

Wiring diagrams are essential for understanding the electrical circuits in a vehicle. They show the location of components, the wiring connections, and the flow of electricity.

5.5. Repair Manuals

Repair manuals provide detailed information about vehicle systems, components, and repair procedures. They are an invaluable resource for diagnosing and repairing automotive problems.

5.6. Smoke Machine

A smoke machine is used to detect vacuum leaks in the engine. It injects smoke into the intake system, and any leaks will be visible as smoke escaping from the engine.

5.7. Fuel Pressure Tester

A fuel pressure tester is used to measure the pressure in the fuel system. It can be used to diagnose fuel-related problems, such as a faulty fuel pump or fuel pressure regulator.

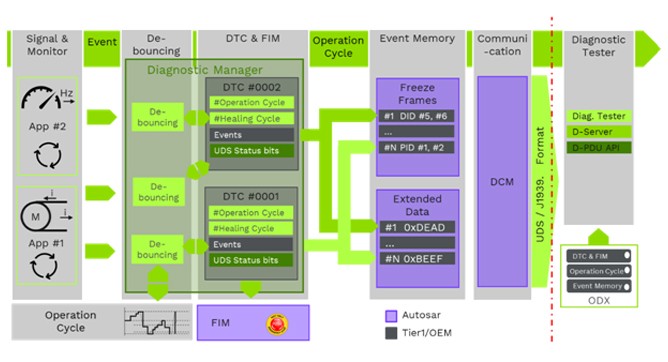

Process sequence of a DTC

Process sequence of a DTC

6. Advanced Diagnostic Techniques

In some cases, diagnosing multiple DTCs may require the use of advanced diagnostic techniques. Here are some examples:

6.1. Data Logging

Data logging involves recording the vehicle’s operating parameters over a period of time. This data can be analyzed to identify patterns and trends that may not be apparent during a static diagnostic test.

6.2. Component Simulation

Component simulation involves using a diagnostic tool to simulate the operation of a component. This can be used to test the ECU’s response to different inputs and identify problems with the ECU itself.

6.3. Network Communication Analysis

Network communication analysis involves monitoring the data that is transmitted between the vehicle’s control modules. This can be used to identify communication problems and diagnose issues with the vehicle’s network.

6.4. Guided Diagnostics

Some advanced diagnostic scan tools offer guided diagnostics features. These features provide step-by-step instructions for diagnosing specific DTCs, based on the vehicle’s symptoms and operating conditions.

7. Preventive Maintenance to Reduce DTCs

Preventive maintenance is essential for reducing the occurrence of DTCs and keeping your Mercedes-Benz running smoothly. Here are some important preventive maintenance tasks:

7.1. Regular Oil Changes

Regular oil changes are essential for maintaining engine health. Old or dirty oil can cause excessive wear and tear on engine components, leading to DTCs.

7.2. Air Filter Replacement

A clean air filter ensures that the engine receives a sufficient supply of clean air. A dirty air filter can restrict airflow, leading to poor engine performance and DTCs.

7.3. Spark Plug Replacement

Spark plugs ignite the air-fuel mixture in the engine. Worn or fouled spark plugs can cause misfires and other engine problems, leading to DTCs.

7.4. Fuel Filter Replacement

A clean fuel filter ensures that the engine receives a clean supply of fuel. A dirty fuel filter can restrict fuel flow, leading to poor engine performance and DTCs.

7.5. Battery Maintenance

A healthy battery is essential for proper vehicle operation. A weak or failing battery can cause a variety of electrical problems, leading to DTCs.

7.6. Regular Inspections

Regular inspections can help identify potential problems before they lead to DTCs. Check the vehicle’s fluids, belts, hoses, and other components for signs of wear or damage.

8. Common Mistakes to Avoid When Diagnosing DTCs

When diagnosing DTCs, it’s important to avoid common mistakes that can lead to incorrect diagnoses and unnecessary repairs. Here are some mistakes to avoid:

8.1. Replacing Parts Without Proper Diagnosis

Replacing parts without proper diagnosis is a common mistake. Always perform a thorough diagnostic investigation before replacing any parts.

8.2. Ignoring Related Symptoms

Ignoring related symptoms can lead to an incomplete diagnosis. Pay attention to all the symptoms the vehicle is exhibiting, as they may provide clues about the underlying problem.

8.3. Clearing DTCs Without Addressing the Underlying Problem

Clearing DTCs without addressing the underlying problem will only result in the codes returning. Always identify and repair the root cause of the problem before clearing the DTCs.

8.4. Using Incorrect Diagnostic Procedures

Using incorrect diagnostic procedures can lead to inaccurate results. Always follow the manufacturer’s recommended diagnostic procedures.

8.5. Overlooking Technical Service Bulletins (TSBs)

Overlooking technical service bulletins (TSBs) can cause you to miss important information about common problems and repair procedures. Always consult TSBs for any relevant information.

9. The Role of MERCEDES-DIAGNOSTIC-TOOL.EDU.VN in DTC Diagnosis

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN plays a crucial role in assisting Mercedes-Benz owners and technicians with DTC diagnosis and repair. We offer a range of services and resources to help you accurately identify and resolve vehicle problems:

9.1. Comprehensive Diagnostic Information

Our website provides comprehensive information about Mercedes-Benz DTCs, including their possible causes, related symptoms, and recommended repair procedures. We compile data from various sources, including repair manuals, technical service bulletins (TSBs), and online databases, to provide you with the most accurate and up-to-date information.

9.2. Expert Diagnostic Assistance

Our team of experienced Mercedes-Benz technicians can provide expert diagnostic assistance to help you troubleshoot complex problems. We can assist you with interpreting DTCs, performing diagnostic tests, and identifying the root cause of vehicle issues.

9.3. Access to Diagnostic Tools

We offer access to a wide range of diagnostic tools, including scan tools, multimeters, oscilloscopes, and other equipment. We can help you select the right tools for your needs and provide training on how to use them effectively.

9.4. Repair Resources and Guidance

Our website provides a wealth of repair resources and guidance, including step-by-step repair procedures, wiring diagrams, and component testing information. We can help you perform repairs safely and effectively.

9.5. Community Forum and Support

Our community forum provides a platform for Mercedes-Benz owners and technicians to share information, ask questions, and receive support from other members. Our forum is a valuable resource for troubleshooting problems and learning about Mercedes-Benz vehicles.

10. Real-World Case Studies

Let’s examine a couple of real-world case studies to illustrate the importance of proper DTC diagnosis:

10.1. Case Study 1: Multiple Misfire Codes

A Mercedes-Benz C-Class owner reported multiple misfire codes (P0300, P0301, P0302) and a rough-running engine. The owner initially replaced the spark plugs and ignition coils, but the problem persisted.

Upon further investigation, a technician discovered a vacuum leak in the intake manifold. The vacuum leak was causing the engine to run lean, leading to the misfires. After repairing the vacuum leak, the engine ran smoothly, and the misfire codes disappeared.

This case study highlights the importance of not just replacing parts based on DTCs, but identifying the root cause of the problem.

10.2. Case Study 2: ABS and ESP Faults

A Mercedes-Benz E-Class owner reported ABS and ESP warning lights and a loss of traction control. The diagnostic scan revealed multiple DTCs related to the ABS and ESP systems.

A technician performed a thorough diagnostic investigation and discovered a faulty wheel speed sensor. The faulty wheel speed sensor was providing incorrect data to the ABS and ESP systems, causing them to malfunction. After replacing the wheel speed sensor, the ABS and ESP systems functioned normally, and the warning lights disappeared.

This case study illustrates how a single faulty component can trigger multiple DTCs in related systems.

11. The Future of DTC Diagnostics

The field of DTC diagnostics is constantly evolving, with new technologies and techniques emerging to improve the accuracy and efficiency of problem solving. Here are some trends shaping the future of DTC diagnostics:

11.1. Enhanced Diagnostic Scan Tools

Diagnostic scan tools are becoming more sophisticated, with advanced features such as guided diagnostics, component simulation, and network communication analysis.

11.2. Cloud-Based Diagnostics

Cloud-based diagnostics allow technicians to access diagnostic information and resources from anywhere with an internet connection. This can improve collaboration and knowledge sharing.

11.3. Artificial Intelligence (AI)

Artificial intelligence (AI) is being used to develop diagnostic algorithms that can analyze DTCs and other data to identify the most likely cause of a problem.

11.4. Remote Diagnostics

Remote diagnostics allow technicians to diagnose and repair vehicles remotely, using telematics and remote access technologies.

11.5. Integration with Repair Information Systems

Diagnostic tools are being integrated with repair information systems, providing technicians with access to repair procedures, wiring diagrams, and other resources directly from the scan tool.

12. Conclusion: Mastering DTC Diagnosis for Mercedes-Benz Vehicles

Understanding how a single fault condition can set multiple related DTCs is vital for accurately diagnosing and repairing Mercedes-Benz vehicles. By following a systematic diagnostic approach, using the right tools and equipment, and staying up-to-date with the latest diagnostic techniques, you can effectively troubleshoot complex problems and keep your Mercedes-Benz running smoothly.

Remember, MERCEDES-DIAGNOSTIC-TOOL.EDU.VN is here to support you with comprehensive diagnostic information, expert assistance, and access to the tools and resources you need. By utilizing our services and resources, you can master DTC diagnosis and keep your Mercedes-Benz in top condition.

Address: 789 Oak Avenue, Miami, FL 33101, United States. Whatsapp: +1 (641) 206-8880. Website: MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

Are you facing challenges in diagnosing complex issues in your Mercedes-Benz? Do you want to unlock hidden features and optimize your vehicle’s performance? Contact us at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN today for expert consultation on diagnostic tools, unlocking hidden features, and guidance on Mercedes-Benz repair and maintenance. Let us help you enhance your Mercedes-Benz experience.

13. Frequently Asked Questions (FAQ)

13.1. What is a DTC?

A DTC, or Diagnostic Trouble Code, is a code stored in a vehicle’s computer system that indicates a malfunction or issue detected by the onboard diagnostic system.

13.2. Can a single fault cause multiple DTCs?

Yes, a single fault condition can often trigger multiple related DTCs due to the interconnected nature of modern automotive systems.

13.3. How do I read DTCs on my Mercedes-Benz?

You can read DTCs using a diagnostic scan tool that connects to your vehicle’s OBD-II port.

13.4. What should I do after reading DTCs?

After reading DTCs, research each code to understand its possible causes and related symptoms, then follow a systematic diagnostic approach to identify the underlying fault condition.

13.5. Are all DTCs serious?

Not all DTCs indicate a serious problem, but it’s important to investigate each code to determine the severity of the issue and take appropriate action.

13.6. Can I fix DTCs myself?

Depending on your mechanical skills and the complexity of the problem, you may be able to fix some DTCs yourself. However, it’s often best to seek assistance from a qualified technician.

13.7. How often should I scan my Mercedes-Benz for DTCs?

You should scan your Mercedes-Benz for DTCs whenever you notice any unusual symptoms or warning lights.

13.8. What is freeze frame data?

Freeze frame data is a snapshot of the vehicle’s operating conditions at the moment a DTC was stored. This data can be helpful in diagnosing intermittent or difficult-to-reproduce problems.

13.9. Where can I find more information about Mercedes-Benz DTCs?

You can find more information about Mercedes-Benz DTCs on our website, MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, or by consulting repair manuals and technical service bulletins (TSBs).

13.10. What are the benefits of using MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for DTC diagnosis?

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers comprehensive diagnostic information, expert assistance, access to diagnostic tools, repair resources, and a community forum to help you accurately diagnose and repair Mercedes-Benz vehicles.