Diagnostic Trouble Codes (DTCs) definitely can highlight problems within electric and hybrid vehicle battery cooling systems, offering valuable insights for technicians. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we provide comprehensive resources and diagnostic tools to accurately pinpoint these issues and ensure your vehicle operates at peak performance, promoting safety and efficiency with reliable diagnostic solutions, expert insights, and proactive maintenance. Keep your Mercedes running smoothly.

Contents

- 1. Understanding the Role of Battery Cooling Systems

- 1.1. Why Cooling Systems Are Critical

- 1.2. Types of Cooling Systems

- 2. How DTCs Relate to Cooling Systems

- 2.1. Common DTCs for Cooling System Issues

- 2.2. Interpreting DTCs

- 2.3. Using Diagnostic Tools

- 3. Specific Cooling System Components and Their DTCs

- 3.1. Cooling Fans

- Associated DTCs:

- 3.2. Coolant Pumps

- Associated DTCs:

- 3.3. Temperature Sensors

- Associated DTCs:

- 3.4. Control Modules

- Associated DTCs:

- 3.5. Radiators and Heat Exchangers

- Associated DTCs:

- 4. Diagnosing Cooling System Issues

- 4.1. Step-by-Step Diagnostic Process

- 4.2. Advanced Diagnostic Techniques

- 4.3. Using MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Resources

- 5. Repairing Cooling System Issues

- 5.1. Common Repairs

- 5.2. Safety Precautions

- 5.3. Using Genuine Mercedes-Benz Parts

- 6. Preventing Cooling System Issues

- 6.1. Regular Inspections

- **6.2. Coolant Maintenance

- 6.3. Battery Maintenance

- 6.4. Utilizing MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Services

- 7. The Future of Cooling Systems

- 7.1. Advancements in Cooling Technology

- 7.2. Implications for Diagnostics

- 8. Case Studies

- 8.1. Case Study 1: Overheating Battery Pack

- 8.2. Case Study 2: Coolant Leak

- 9. FAQ: Troubleshooting Electric/Hybrid Vehicle Battery Cooling Systems

- 9.1. What are the main signs of a cooling system problem in an electric or hybrid vehicle?

- 9.2. How often should I inspect the cooling system in my electric or hybrid vehicle?

- 9.3. Can I use regular coolant in my electric or hybrid vehicle?

- 9.4. What is the typical lifespan of a battery cooling fan?

- 9.5. How can I check the health of my battery cooling system?

- 9.6. What should I do if I suspect a coolant leak?

- 9.7. Are there any DIY maintenance tasks I can perform on my battery cooling system?

- 9.8. How important is it to use genuine Mercedes-Benz parts for cooling system repairs?

- 9.9. What are the long-term consequences of neglecting cooling system maintenance?

- 9.10. Where can I find reliable diagnostic tools and repair manuals for my Mercedes-Benz electric or hybrid vehicle?

- 10. Contact Us

1. Understanding the Role of Battery Cooling Systems

The battery cooling system in an electric or hybrid vehicle is essential for maintaining optimal battery performance and longevity. Batteries generate heat during charging and discharging, and excessive temperatures can significantly degrade their performance, reduce lifespan, and even pose safety risks. Efficient cooling systems mitigate these risks by dissipating heat and maintaining the battery within its ideal temperature range.

1.1. Why Cooling Systems Are Critical

Maintaining the right temperature is vital for battery health. High temperatures can lead to:

- Reduced Battery Life: Heat accelerates the degradation of battery cells.

- Decreased Performance: Overheating can limit the battery’s ability to deliver power.

- Safety Concerns: Extreme heat can cause thermal runaway, a dangerous condition that can lead to fire.

According to a study by the U.S. Department of Energy, maintaining battery temperature within a specific range can extend battery life by up to 30%.

1.2. Types of Cooling Systems

Several types of cooling systems are used in electric and hybrid vehicles:

- Air Cooling: Uses ambient air to cool the battery pack. This is a simpler, less expensive option but is less effective in extreme climates.

- Liquid Cooling: Circulates a coolant (usually a water-glycol mixture) through channels in the battery pack. This method is more efficient at removing heat and maintaining consistent temperatures.

- Refrigerant Cooling: Similar to air conditioning, this system uses a refrigerant to cool the battery pack. It’s the most effective but also the most complex and expensive.

2. How DTCs Relate to Cooling Systems

DTCs are codes generated by the vehicle’s onboard diagnostic system to indicate specific faults or issues. When a problem arises in the battery cooling system, it often triggers a DTC, providing valuable information for diagnosing and repairing the issue.

2.1. Common DTCs for Cooling System Issues

Several DTCs are specifically related to the battery cooling system. Here are some common examples:

- P0A81 – P0A85 (Battery Cooling Fan): As mentioned in the original article, these codes indicate problems with the cooling fan, such as low motor voltage or increased battery temperature.

- P0A93 (Inverter Cooling System): This code suggests issues with the inverter cooling system, including coolant level, hose integrity, water pump connector, and cooling fan motor functionality.

- P0AA6 (Hybrid Battery Voltage System Isolation Fault): While primarily related to voltage isolation, this code can sometimes be triggered by electrolyte leakage, which can affect the cooling system’s performance.

2.2. Interpreting DTCs

Understanding the meaning of DTCs is crucial for effective diagnosis. Each code corresponds to a specific problem, and technicians can use this information to narrow down the potential causes.

For example, if a P0A83 code (Battery Cooling Fan 3 Control Circuit Low) is detected, it indicates a problem with the control circuit for the third cooling fan. This could be due to a faulty fan motor, wiring issue, or problem with the control module.

2.3. Using Diagnostic Tools

Diagnostic tools, such as scan tools, are essential for retrieving and interpreting DTCs. These tools connect to the vehicle’s diagnostic port and allow technicians to access the vehicle’s computer systems, read DTCs, and view live data.

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers a range of diagnostic tools specifically designed for Mercedes-Benz vehicles, ensuring accurate and reliable diagnosis of cooling system issues.

3. Specific Cooling System Components and Their DTCs

To effectively diagnose cooling system issues, it’s important to understand the different components of the system and the DTCs associated with each.

3.1. Cooling Fans

Cooling fans are responsible for circulating air through the battery pack to dissipate heat. Common issues include fan failure, motor problems, and control circuit faults.

Associated DTCs:

- P0A81: Hybrid Battery Pack Cooling Fan 1 Control Circuit

- P0A82: Hybrid Battery Pack Cooling Fan 1 Control Circuit Range/Performance

- P0A83: Hybrid Battery Pack Cooling Fan 1 Control Circuit Low

- P0A84: Hybrid Battery Pack Cooling Fan 1 Control Circuit High

- P0A85: Hybrid Battery Pack Cooling Fan 1 Control Circuit Open

According to a technical service bulletin from Toyota, cooling fan failures are a common cause of overheating in hybrid batteries, leading to reduced performance and lifespan.

3.2. Coolant Pumps

In liquid cooling systems, coolant pumps circulate coolant through the battery pack and radiator to remove heat. Issues can include pump failure, leaks, and blockages.

Associated DTCs:

- P0A93: Hybrid Inverter Cooling System Performance

- P0C2A: Auxiliary Coolant Pump Control Circuit Open

- P0C2B: Auxiliary Coolant Pump Control Circuit Low

- P0C2C: Auxiliary Coolant Pump Control Circuit High

3.3. Temperature Sensors

Temperature sensors monitor the temperature of the battery pack and coolant, providing feedback to the control module. Faulty sensors can lead to inaccurate temperature readings and improper cooling system operation.

Associated DTCs:

- P0A0D: Hybrid Battery Temperature Sensor Circuit

- P0A0E: Hybrid Battery Temperature Sensor Circuit Range/Performance

- P0A0F: Hybrid Battery Temperature Sensor Circuit Low

- P0A10: Hybrid Battery Temperature Sensor Circuit High

3.4. Control Modules

The control module manages the operation of the cooling system, adjusting fan speed and coolant flow based on temperature readings. Problems with the control module can disrupt the entire cooling process.

Associated DTCs:

- P0C55: Battery Pack Cooling System Control Module

- U0100: Lost Communication With ECM/PCM

- U0111: Lost Communication With Battery Energy Control Module

3.5. Radiators and Heat Exchangers

Radiators and heat exchangers dissipate heat from the coolant to the ambient air. Blockages, leaks, and damage can reduce their effectiveness.

Associated DTCs:

- P0A95: Hybrid Cooling System Radiator Fan Performance

- P0A96: Hybrid Cooling System Radiator Fan Control Circuit Low

- P0A97: Hybrid Cooling System Radiator Fan Control Circuit High

4. Diagnosing Cooling System Issues

Diagnosing cooling system issues involves a systematic approach to identify the root cause of the problem.

4.1. Step-by-Step Diagnostic Process

- Retrieve DTCs: Use a diagnostic tool to read the DTCs stored in the vehicle’s computer.

- Research DTCs: Consult a repair manual or online database to understand the meaning of each code and potential causes.

- Inspect Cooling System Components: Visually inspect the cooling fans, coolant pump, hoses, and radiator for leaks, damage, or blockages.

- Test Cooling System Components: Use a multimeter or other testing equipment to check the functionality of the cooling fans, coolant pump, and temperature sensors.

- Analyze Live Data: Use the diagnostic tool to monitor live data, such as battery temperature, coolant temperature, and fan speed, to identify any anomalies.

- Perform Functional Tests: Use the diagnostic tool to perform functional tests, such as activating the cooling fans or coolant pump, to verify their operation.

- Isolate the Fault: Based on the diagnostic findings, isolate the faulty component or circuit.

- Repair or Replace: Repair or replace the faulty component and clear the DTCs.

- Verify Repair: Retest the cooling system to ensure that the problem has been resolved and that no new DTCs are present.

4.2. Advanced Diagnostic Techniques

In some cases, advanced diagnostic techniques may be necessary to pinpoint the cause of a cooling system issue.

- Thermal Imaging: Use a thermal imaging camera to identify hotspots or cold spots in the battery pack or cooling system, indicating areas of high resistance or poor heat transfer.

- Coolant Analysis: Analyze the coolant for contaminants or degradation, which can indicate internal corrosion or leaks.

- Pressure Testing: Perform a pressure test on the cooling system to check for leaks.

4.3. Using MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Resources

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides a wealth of resources to assist in diagnosing and repairing cooling system issues, including:

- Diagnostic Tools: A range of diagnostic tools specifically designed for Mercedes-Benz vehicles.

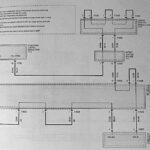

- Repair Manuals: Detailed repair manuals with step-by-step instructions and wiring diagrams.

- Technical Service Bulletins: Access to the latest technical service bulletins from Mercedes-Benz.

- Online Forum: A community forum where technicians can share their experiences and ask for advice.

5. Repairing Cooling System Issues

Once the cooling system issue has been diagnosed, the next step is to repair or replace the faulty component.

5.1. Common Repairs

- Cooling Fan Replacement: Replacing a faulty cooling fan is a common repair. Ensure that the replacement fan is compatible with the vehicle and that all connections are properly secured.

- Coolant Pump Replacement: Replacing a faulty coolant pump involves draining the cooling system, disconnecting the pump, and installing the new pump. Be sure to bleed the cooling system to remove any air pockets.

- Temperature Sensor Replacement: Replacing a faulty temperature sensor involves disconnecting the sensor and installing the new one. Ensure that the sensor is properly calibrated.

- Hose and Connector Repair: Repairing or replacing damaged hoses and connectors can prevent leaks and maintain proper coolant flow.

5.2. Safety Precautions

When working on the cooling system, it’s important to take the following safety precautions:

- Disconnect the High-Voltage System: Before working on any part of the cooling system, disconnect the high-voltage system to prevent electric shock.

- Wear Protective Gear: Wear gloves, safety glasses, and other protective gear to prevent injury.

- Handle Coolant Safely: Coolant is toxic and can cause skin irritation. Handle it with care and dispose of it properly.

5.3. Using Genuine Mercedes-Benz Parts

When replacing cooling system components, it’s important to use genuine Mercedes-Benz parts to ensure proper fit, performance, and reliability.

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers a wide selection of genuine Mercedes-Benz parts for cooling systems, including cooling fans, coolant pumps, temperature sensors, and hoses.

6. Preventing Cooling System Issues

Preventive maintenance is key to avoiding cooling system issues and ensuring the longevity of the battery pack.

6.1. Regular Inspections

Perform regular inspections of the cooling system, checking for leaks, damage, or blockages.

- Check Coolant Level: Ensure that the coolant level is within the specified range.

- Inspect Hoses and Connectors: Look for cracks, leaks, or damage to the hoses and connectors.

- Check Cooling Fans: Verify that the cooling fans are operating properly.

- Inspect Radiator: Check the radiator for blockages or damage.

**6.2. Coolant Maintenance

Follow the manufacturer’s recommendations for coolant replacement. Over time, coolant can become contaminated or degrade, reducing its ability to transfer heat.

According to Mercedes-Benz maintenance guidelines, coolant should be replaced every 50,000 miles or 5 years, whichever comes first.

6.3. Battery Maintenance

Proper battery maintenance can also help prevent cooling system issues.

- Avoid Extreme Temperatures: Park the vehicle in a shaded area to avoid exposing the battery pack to extreme temperatures.

- Follow Charging Guidelines: Follow the manufacturer’s recommendations for charging the battery pack.

- Regular Battery Health Checks: Perform regular battery health checks using a diagnostic tool to identify any potential issues early on.

6.4. Utilizing MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Services

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers a range of services to help prevent cooling system issues, including:

- Preventive Maintenance Inspections: Comprehensive inspections of the cooling system and battery pack.

- Coolant Replacement Service: Professional coolant replacement service using genuine Mercedes-Benz coolant.

- Battery Health Checks: Detailed battery health checks using advanced diagnostic tools.

7. The Future of Cooling Systems

As electric and hybrid vehicle technology continues to evolve, so too will cooling systems.

7.1. Advancements in Cooling Technology

- Direct Cooling: Direct cooling systems immerse the battery cells in a dielectric fluid, providing more efficient heat transfer.

- Phase Change Materials: Phase change materials absorb and release heat as they change state, providing passive cooling.

- Smart Cooling Systems: Smart cooling systems use advanced sensors and algorithms to optimize cooling performance based on driving conditions and battery temperature.

7.2. Implications for Diagnostics

These advancements will require technicians to stay up-to-date on the latest diagnostic techniques and tools.

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN is committed to providing technicians with the training and resources they need to diagnose and repair the latest cooling system technologies.

8. Case Studies

Let’s look at a couple of case studies that highlight the importance of diagnosing cooling system issues.

8.1. Case Study 1: Overheating Battery Pack

A Mercedes-Benz hybrid vehicle was brought into the shop with a complaint of reduced performance and frequent error messages. Diagnostic scan revealed a P0A80 code (Replace Hybrid Battery Pack) along with P0A83 (Hybrid Battery Pack Cooling Fan 1 Control Circuit Low). Inspection revealed that the cooling fan motor was faulty and not providing adequate airflow to the battery pack.

- Diagnosis: Faulty cooling fan motor

- Repair: Replaced the cooling fan motor with a genuine Mercedes-Benz part.

- Outcome: The vehicle’s performance was restored, and the error messages disappeared.

8.2. Case Study 2: Coolant Leak

A Mercedes-Benz electric vehicle was brought into the shop with a complaint of low coolant level and overheating. Diagnostic scan revealed no DTCs, but a visual inspection revealed a coolant leak at the coolant pump.

- Diagnosis: Coolant pump leak

- Repair: Replaced the coolant pump and topped off the coolant.

- Outcome: The coolant leak was resolved, and the vehicle’s temperature returned to normal.

9. FAQ: Troubleshooting Electric/Hybrid Vehicle Battery Cooling Systems

Navigating the complexities of electric and hybrid vehicle battery cooling systems can raise numerous questions. Here are some frequently asked questions to help you better understand these systems and their maintenance.

9.1. What are the main signs of a cooling system problem in an electric or hybrid vehicle?

The main signs include overheating, reduced battery performance, frequent error messages, coolant leaks, and unusual noises from the cooling fan.

9.2. How often should I inspect the cooling system in my electric or hybrid vehicle?

It is recommended to inspect the cooling system at least every 6 months or as part of your regular maintenance schedule.

9.3. Can I use regular coolant in my electric or hybrid vehicle?

No, you should only use coolant specifically designed for electric and hybrid vehicles, as it has different properties and requirements.

9.4. What is the typical lifespan of a battery cooling fan?

The typical lifespan of a battery cooling fan is 5-7 years, depending on usage and environmental conditions.

9.5. How can I check the health of my battery cooling system?

You can check the health of your battery cooling system by performing a visual inspection, checking the coolant level, and using a diagnostic tool to monitor temperature readings and fan speed.

9.6. What should I do if I suspect a coolant leak?

If you suspect a coolant leak, you should immediately take your vehicle to a qualified technician for inspection and repair.

9.7. Are there any DIY maintenance tasks I can perform on my battery cooling system?

Some DIY maintenance tasks you can perform include checking the coolant level, inspecting the hoses and connectors, and cleaning the cooling fan. However, more complex repairs should be left to a qualified technician.

9.8. How important is it to use genuine Mercedes-Benz parts for cooling system repairs?

Using genuine Mercedes-Benz parts is crucial for ensuring proper fit, performance, and reliability.

9.9. What are the long-term consequences of neglecting cooling system maintenance?

Neglecting cooling system maintenance can lead to reduced battery life, decreased performance, safety concerns, and costly repairs.

9.10. Where can I find reliable diagnostic tools and repair manuals for my Mercedes-Benz electric or hybrid vehicle?

You can find reliable diagnostic tools and repair manuals at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN.

10. Contact Us

Addressing cooling system issues promptly can significantly extend the life and efficiency of your electric or hybrid vehicle. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we understand the critical role these systems play and offer a suite of services to ensure your vehicle remains in optimal condition.

Don’t let cooling system concerns compromise your driving experience. Contact us today for expert assistance.

Address: 789 Oak Avenue, Miami, FL 33101, United States

WhatsApp: +1 (641) 206-8880

Website: MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

Our team is ready to provide you with:

- Expert diagnostics to accurately identify any cooling system issues.

- High-quality repair services using genuine Mercedes-Benz parts.

- Preventive maintenance plans to keep your system running smoothly.

- Professional advice and support tailored to your specific vehicle needs.

Take the first step towards ensuring your Mercedes-Benz operates at its best. Reach out to us at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, where expertise meets exceptional service. Let us help you keep your journey smooth and worry-free. Connect with us via WhatsApp at +1 (641) 206-8880 for immediate assistance and personalized support.