Wheel alignment issues can indeed trigger diagnostic trouble codes (DTCs) in stability control or Advanced Driver Assistance Systems (ADAS). At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we provide expert insights and tools to diagnose and address these complex interactions, ensuring your Mercedes-Benz operates at its peak performance. By understanding these systems and using the appropriate diagnostic tools, you can ensure the safety and reliability of your vehicle.

Contents

- 1. Understanding the Interconnectedness of Modern Vehicle Systems

- 1.1 How Stability Control Systems Rely on Accurate Wheel Alignment

- 1.2 The Role of Wheel Alignment in ADAS Functionality

- 1.3 Research and Studies Supporting the Importance of Wheel Alignment

- 2. Common Wheel Alignment Issues and Their Impact

- 2.1 Camber Issues and Their Effects

- 2.2 Caster Problems and Their Consequences

- 2.3 Toe Angle Misalignment and Its Implications

- 2.4 The Role of Ride Height

- 3. Diagnostic Trouble Codes (DTCs) Linked to Wheel Alignment

- 3.1 DTCs Related to Steering Angle Sensor

- 3.2 DTCs Associated with Wheel Speed Sensors

- 3.3 DTCs Involving Yaw Rate Sensor

- 3.4 Examples of ADAS-Related DTCs

- 4. The Diagnostic Process: Identifying Wheel Alignment Issues

- 4.1 Visual Inspection: What to Look For

- 4.2 Mechanical Measurements: Using Alignment Equipment

- 4.3 Utilizing Diagnostic Tools: Reading and Interpreting DTCs

- 4.4 Addressing Steering Issues

- 5. Repairing Wheel Alignment Issues and Clearing DTCs

- 5.1 Adjusting Camber, Caster, and Toe Angles

- 5.2 Calibrating Sensors

- 5.3 Clearing DTCs and Verifying Repairs

- 5.4 The Importance of Post-Alignment Checks

- 5.5 Understanding Collision Avoidance and Adaptive Cruise Control

- 6. The Benefits of Professional Wheel Alignment Services

- 6.1 Expertise and Experience

- 6.2 Access to Advanced Equipment

- 6.3 Comprehensive Services

- 6.4 The Cost-Effectiveness of Professional Alignment

- 7. Maintaining Proper Wheel Alignment: Tips and Best Practices

- 7.1 Regular Alignment Checks

- 7.2 Tire Maintenance

- 7.3 Avoid Road Hazards

- 7.4 Inspect Suspension Components

- 7.5 Addressing Steering Problems

- 8. The Role of MERCEDES-DIAGNOSTIC-TOOL.EDU.VN in Vehicle Maintenance

- 8.1 Providing Diagnostic Tools and Information

- 8.2 Offering Expert Advice and Support

- 8.3 Ensuring Vehicle Safety and Performance

- 9. Frequently Asked Questions (FAQs)

- 9.1 Can wheel alignment really affect my car’s stability control system?

- 9.2 How often should I get my wheels aligned?

- 9.3 What are the signs of a bad wheel alignment?

- 9.4 Can I align my wheels myself?

- 9.5 How much does a wheel alignment cost?

- 9.6 What is camber, caster, and toe?

- 9.7 Can misaligned wheels affect my gas mileage?

- 9.8 Can wheel alignment issues cause ADAS malfunction?

- 9.9 What kind of diagnostic tools do I need to check wheel alignment-related DTCs?

- 9.10 Where can I find reliable information about wheel alignment specifications for my Mercedes-Benz?

- 10. Conclusion: Ensuring Optimal Vehicle Performance Through Proper Wheel Alignment

1. Understanding the Interconnectedness of Modern Vehicle Systems

Modern vehicles, especially those from Mercedes-Benz, are marvels of engineering, integrating numerous complex systems to provide safety, comfort, and performance. These systems, including stability control and ADAS, rely on accurate data from various sensors to function correctly. Wheel alignment, often an overlooked aspect of vehicle maintenance, plays a crucial role in the accuracy of this data.

1.1 How Stability Control Systems Rely on Accurate Wheel Alignment

Stability control systems, such as Electronic Stability Program (ESP) in Mercedes-Benz vehicles, use sensors to monitor the vehicle’s direction and compare it to the driver’s intended path. These systems rely on data from wheel speed sensors, steering angle sensors, and yaw rate sensors to detect skidding or loss of control. Misaligned wheels can lead to inaccurate readings from these sensors, causing the stability control system to activate unnecessarily or fail to activate when needed.

1.2 The Role of Wheel Alignment in ADAS Functionality

Advanced Driver Assistance Systems (ADAS) encompass a range of technologies designed to enhance safety and convenience, including adaptive cruise control, lane departure warning, and automatic emergency braking. These systems often use cameras, radar, and ultrasonic sensors to monitor the vehicle’s surroundings. Proper wheel alignment is essential for these sensors to function accurately. For example, if the wheels are misaligned, the vehicle may not track straight, causing the lane departure warning system to issue false alerts or the adaptive cruise control to misjudge distances.

1.3 Research and Studies Supporting the Importance of Wheel Alignment

According to a study by the National Highway Traffic Safety Administration (NHTSA), misaligned wheels can increase tire wear by as much as 20%, leading to reduced braking performance and compromised handling. Furthermore, a study by the University of Michigan Transportation Research Institute found that vehicles with properly aligned wheels exhibit greater stability and control in emergency maneuvers. This highlights the critical role of wheel alignment in maintaining the safety and effectiveness of modern vehicle systems.

2. Common Wheel Alignment Issues and Their Impact

Several types of wheel alignment issues can affect vehicle performance and trigger DTCs in stability control and ADAS systems. Understanding these issues is crucial for effective diagnosis and repair.

2.1 Camber Issues and Their Effects

Camber refers to the angle of the wheel relative to the vertical axis when viewed from the front of the vehicle. Positive camber means the top of the wheel is tilted outward, while negative camber means the top of the wheel is tilted inward. Excessive camber, whether positive or negative, can cause uneven tire wear and affect handling. According to research from the Tire Industry Association (TIA), a camber angle that is off by just one degree can reduce tire life by as much as 15%. In addition, camber issues can affect the accuracy of sensors used by stability control and ADAS systems, leading to DTCs.

2.2 Caster Problems and Their Consequences

Caster is the angle of the steering pivot axis when viewed from the side of the vehicle. Positive caster means the steering pivot axis is tilted toward the rear of the vehicle, while negative caster means it is tilted toward the front. Caster affects steering stability and straight-line tracking. Incorrect caster angles can cause the vehicle to pull to one side, making it difficult to maintain a straight course. This can lead to increased driver fatigue and reduced safety. Furthermore, caster issues can affect the operation of ADAS systems, such as lane keeping assist, which rely on accurate steering input data.

2.3 Toe Angle Misalignment and Its Implications

Toe refers to the angle of the wheels relative to each other when viewed from above. Toe-in means the front of the wheels are closer together than the rear, while toe-out means the front of the wheels are farther apart than the rear. Toe misalignment is a common issue that can cause rapid tire wear and affect steering response. According to a study by the Society of Automotive Engineers (SAE), even a small amount of toe misalignment can significantly increase tire wear. In addition, toe issues can affect the accuracy of sensors used by stability control and ADAS systems, leading to DTCs and compromised performance.

2.4 The Role of Ride Height

Ride height also has an impact on wheel alignment. A vehicle sitting lower than designed will often have changes in camber and toe. These changes can affect the way the vehicle handles and the accuracy of the sensors used by ADAS systems.

Front Suspension Adjustments

Front Suspension Adjustments

Alt text: Front suspension adjustment diagram showcasing control arm and strut mount for proper camber setting.

3. Diagnostic Trouble Codes (DTCs) Linked to Wheel Alignment

When wheel alignment issues affect the performance of stability control and ADAS systems, the vehicle’s onboard diagnostics may generate specific DTCs. These codes can provide valuable clues for diagnosing the underlying problem.

3.1 DTCs Related to Steering Angle Sensor

The steering angle sensor is a critical component of both stability control and ADAS systems. It measures the angle of the steering wheel and provides this information to the vehicle’s control modules. Misalignment can cause the steering angle sensor to produce inaccurate readings, leading to DTCs such as:

- C0051: Steering Angle Sensor Circuit

- C0051-00: Steering Angle Sensor – General Failure Information

- C0051-07: Steering Angle Sensor – Mechanical Failure

These codes indicate a problem with the steering angle sensor itself or with the data it is providing. Addressing wheel alignment issues can often resolve these DTCs by ensuring the steering angle sensor is operating within its specified range.

3.2 DTCs Associated with Wheel Speed Sensors

Wheel speed sensors measure the rotational speed of each wheel and provide this information to the stability control system. Misalignment can affect the accuracy of these sensors, leading to DTCs such as:

- C0031: Left Front Wheel Speed Sensor Circuit

- C0034: Right Front Wheel Speed Sensor Circuit

- C0037: Left Rear Wheel Speed Sensor Circuit

- C003A: Right Rear Wheel Speed Sensor Circuit

These codes indicate a problem with one or more of the wheel speed sensors. While the sensors themselves may be faulty, it is important to consider wheel alignment as a potential contributing factor.

3.3 DTCs Involving Yaw Rate Sensor

The yaw rate sensor measures the vehicle’s rotation around its vertical axis and provides this information to the stability control system. Misalignment can affect the accuracy of the yaw rate sensor, leading to DTCs such as:

- C0196: Yaw Rate Sensor Circuit

- C0196-00: Yaw Rate Sensor – General Failure Information

- C0196-01: Yaw Rate Sensor – Internal Failure

These codes indicate a problem with the yaw rate sensor. Again, wheel alignment should be considered as a potential factor, especially if the DTC is accompanied by other alignment-related symptoms.

3.4 Examples of ADAS-Related DTCs

ADAS systems rely on a variety of sensors to function correctly. Misalignment can affect the accuracy of these sensors, leading to DTCs such as:

- U11A0: Lost Communication With Front Distance Range Sensor

- U11A1: Lost Communication With Camera

- B24BA: Radar Sensor Alignment

These codes indicate a problem with one or more of the sensors used by ADAS systems. Addressing wheel alignment issues can often resolve these DTCs by ensuring the sensors are properly aligned and calibrated.

4. The Diagnostic Process: Identifying Wheel Alignment Issues

Diagnosing wheel alignment issues requires a systematic approach, combining visual inspection, mechanical measurements, and diagnostic tools. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we offer a range of resources to help you through this process.

4.1 Visual Inspection: What to Look For

Begin by performing a thorough visual inspection of the vehicle, looking for signs of misalignment such as:

- Uneven tire wear: This is a common indicator of alignment issues.

- Vehicle pulling to one side: This can indicate caster or camber problems.

- Steering wheel off-center: This can indicate toe misalignment.

- Visible damage to suspension components: This can affect alignment angles.

4.2 Mechanical Measurements: Using Alignment Equipment

The next step is to use alignment equipment to measure the camber, caster, and toe angles of each wheel. This will provide precise data on the vehicle’s alignment status. Common types of alignment equipment include:

- Laser alignment systems: These systems use lasers to measure alignment angles with high accuracy.

- 3D alignment systems: These systems use cameras to create a three-dimensional model of the vehicle’s suspension, allowing for precise alignment adjustments.

- Traditional bubble alignment gauges: While less accurate than laser or 3D systems, these gauges can still provide useful information.

4.3 Utilizing Diagnostic Tools: Reading and Interpreting DTCs

Use a diagnostic scan tool to read any DTCs stored in the vehicle’s control modules. This will provide valuable clues about potential alignment-related issues. Be sure to record all DTCs and their descriptions.

4.4 Addressing Steering Issues

The Flex uses electric power steering, for more than just assisting the driver. It can make parking easier and even correct for uneven road surfaces. The Power Steering Control Module (PSCM) and Electric Power Assist Steering (EPAS) motor are mounted together. The steering angle is computed with position sensors on the motor, angle sensor on the column, and data from the ABS module. The system uses an electric motor coupled to the steering rack by a toothed belt. The PSCM uses a temperature sensor to monitor the internal temperature of the EPAS gear. The electronic power steering system adaptive learning helps correct road irregularities and improves overall handling and steering feel. It communicates with the brake system to help operate advanced stability control and accident avoidance systems. Additionally, whenever the battery is disconnected or a new battery is installed, you must drive your vehicle a short distance before the system relearns the strategy and reactivates all systems.

Rear Suspension Adjustments

Rear Suspension Adjustments

Alt text: Rear suspension adjustment setup demonstrating camber and toe adjustments for optimal tire contact.

5. Repairing Wheel Alignment Issues and Clearing DTCs

Once you have identified the underlying alignment issues, the next step is to perform the necessary repairs and clear any related DTCs.

5.1 Adjusting Camber, Caster, and Toe Angles

Adjust the camber, caster, and toe angles according to the vehicle manufacturer’s specifications. This may involve:

- Adjusting suspension components: Many vehicles have adjustable suspension components that allow for precise alignment adjustments.

- Replacing worn or damaged parts: Worn or damaged suspension components can affect alignment angles and should be replaced.

- Using shims or cam bolts: In some cases, shims or cam bolts may be needed to achieve the correct alignment angles.

5.2 Calibrating Sensors

After adjusting the alignment angles, it may be necessary to calibrate the sensors used by stability control and ADAS systems. This ensures that the sensors are providing accurate data to the vehicle’s control modules. Calibration procedures vary depending on the vehicle and the specific system.

5.3 Clearing DTCs and Verifying Repairs

Once the repairs are complete, use a diagnostic scan tool to clear any related DTCs. Then, perform a test drive to verify that the vehicle is handling correctly and that the stability control and ADAS systems are functioning properly. If any DTCs reappear, further diagnosis may be necessary.

5.4 The Importance of Post-Alignment Checks

After performing a wheel alignment, it’s essential to conduct post-alignment checks to ensure the vehicle meets the manufacturer’s specifications. These checks include:

- Verifying steering wheel centering: The steering wheel should be centered when the vehicle is traveling straight.

- Checking tire pressure: Correct tire pressure is essential for optimal handling and tire wear.

- Inspecting suspension components: Ensure that all suspension components are in good condition and properly tightened.

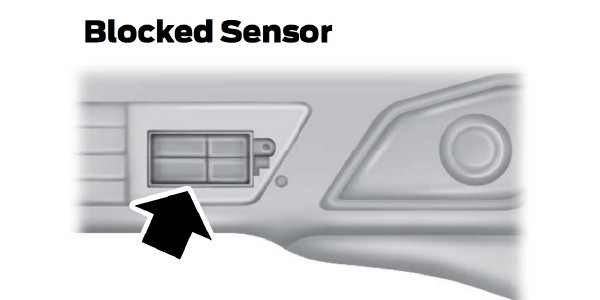

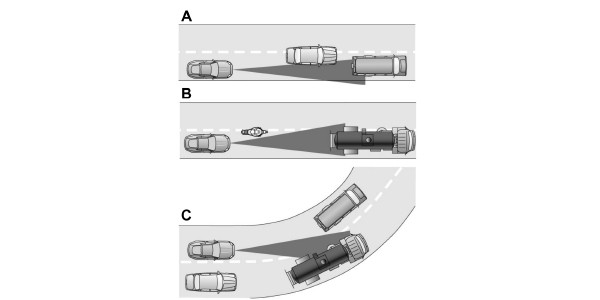

5.5 Understanding Collision Avoidance and Adaptive Cruise Control

The later models come with radar that is used for the adaptive cruise control and collision avoidance system. It is mounted in the lower-left area of the front bumper. Calibration of the radar requires the correct software scan tool and fixtures to align the radar module. The radar can cause issues and false alerts if it is covered in ice and snow or misaligned after a collision. This system is designed to alert the driver of certain collision risks. A radar detects if your vehicle is rapidly approaching another vehicle traveling in the same direction as yours. If it is, a red warning light illuminates and an audible warning chime sounds. The adaptive cruise can keep a set distance from another vehicle. The brake support system assists the driver in reducing the collision speed by charging the brakes. If the risk of collision further increases after the warning light illuminates, the brake support prepares the brake system for rapid braking. If there is no issue with the sensors, the warning system sensitivity can be adjusted. Three possible settings can be selected by using the information display control if collision warnings are perceived as being too frequent or disturbing. Setting lower sensitivity would lead to fewer and later system warnings.

Adaptive Cruise Control Radar

Adaptive Cruise Control Radar

Alt text: Illustration of adaptive cruise control radar unit placement, crucial for collision avoidance system alignment.

6. The Benefits of Professional Wheel Alignment Services

While it is possible to perform wheel alignment yourself, there are many benefits to using professional services.

6.1 Expertise and Experience

Professional alignment technicians have the expertise and experience to accurately diagnose and repair alignment issues. They are trained to use specialized equipment and follow precise procedures.

6.2 Access to Advanced Equipment

Professional alignment shops have access to advanced alignment equipment, such as laser and 3D alignment systems. This equipment allows them to perform more accurate alignments than can be achieved with DIY methods.

6.3 Comprehensive Services

Professional alignment services often include a comprehensive inspection of the vehicle’s suspension system, identifying any worn or damaged components that may be affecting alignment. They can also perform sensor calibrations and other related services.

6.4 The Cost-Effectiveness of Professional Alignment

While professional alignment services may seem expensive, they can actually save you money in the long run. By ensuring that your vehicle’s wheels are properly aligned, you can extend tire life, improve fuel efficiency, and reduce the risk of costly repairs.

7. Maintaining Proper Wheel Alignment: Tips and Best Practices

Proper wheel alignment is an ongoing process, not a one-time fix. By following these tips and best practices, you can help maintain proper alignment and prevent future issues.

7.1 Regular Alignment Checks

Schedule regular alignment checks, typically every 6,000 to 12,000 miles, or as recommended by the vehicle manufacturer. This will help identify any alignment issues early on, before they cause significant problems.

7.2 Tire Maintenance

Maintain proper tire pressure and rotate your tires regularly. This will help ensure even tire wear and prevent alignment issues.

7.3 Avoid Road Hazards

Avoid hitting potholes, curbs, and other road hazards. These can damage suspension components and knock your vehicle out of alignment.

7.4 Inspect Suspension Components

Regularly inspect your vehicle’s suspension components for signs of wear or damage. Replace any worn or damaged parts promptly.

7.5 Addressing Steering Problems

The wiring is a weak point. The connectors, modules and wires reside low in the engine bay and are subject to water, debris and heat from the engine. Ford has issued a general service bulletin and offers an updated harnesses to correct the problem.

8. The Role of MERCEDES-DIAGNOSTIC-TOOL.EDU.VN in Vehicle Maintenance

At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we are committed to providing you with the resources and tools you need to maintain your Mercedes-Benz in top condition.

8.1 Providing Diagnostic Tools and Information

We offer a wide range of diagnostic tools and information to help you identify and address wheel alignment issues. Our tools are designed to be user-friendly and accurate, providing you with the data you need to make informed decisions.

8.2 Offering Expert Advice and Support

Our team of expert technicians is available to provide advice and support, answering your questions and helping you troubleshoot any issues you may encounter.

8.3 Ensuring Vehicle Safety and Performance

By using our tools and resources, you can ensure that your Mercedes-Benz is operating safely and efficiently, providing you with years of reliable service.

9. Frequently Asked Questions (FAQs)

9.1 Can wheel alignment really affect my car’s stability control system?

Yes, misaligned wheels can cause inaccurate readings from sensors used by the stability control system, leading to unnecessary activation or failure to activate when needed.

9.2 How often should I get my wheels aligned?

It is generally recommended to get your wheels aligned every 6,000 to 12,000 miles, or as recommended by the vehicle manufacturer.

9.3 What are the signs of a bad wheel alignment?

Signs of a bad wheel alignment include uneven tire wear, the vehicle pulling to one side, and the steering wheel being off-center.

9.4 Can I align my wheels myself?

While it is possible to align your wheels yourself, it is generally recommended to use professional services, as they have access to advanced equipment and expertise.

9.5 How much does a wheel alignment cost?

The cost of a wheel alignment varies depending on the vehicle and the location, but it typically ranges from $75 to $200.

9.6 What is camber, caster, and toe?

Camber is the angle of the wheel relative to the vertical axis, caster is the angle of the steering pivot axis, and toe is the angle of the wheels relative to each other.

9.7 Can misaligned wheels affect my gas mileage?

Yes, misaligned wheels can increase rolling resistance, leading to reduced fuel efficiency.

9.8 Can wheel alignment issues cause ADAS malfunction?

Yes, misaligned wheels can affect the accuracy of sensors used by ADAS systems, leading to malfunction or false alerts.

9.9 What kind of diagnostic tools do I need to check wheel alignment-related DTCs?

You need a diagnostic scan tool that can read and interpret DTCs from the vehicle’s control modules.

9.10 Where can I find reliable information about wheel alignment specifications for my Mercedes-Benz?

You can find reliable information about wheel alignment specifications in your vehicle’s owner’s manual or from a trusted mechanic.

10. Conclusion: Ensuring Optimal Vehicle Performance Through Proper Wheel Alignment

Proper wheel alignment is essential for maintaining the safety, performance, and efficiency of your Mercedes-Benz. By understanding the interconnectedness of vehicle systems, recognizing the signs of misalignment, and utilizing professional diagnostic and repair services, you can ensure that your vehicle is operating at its best. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we are here to support you with the tools, information, and expertise you need to keep your Mercedes-Benz on the road for years to come.

Don’t let wheel alignment issues compromise your safety and driving experience. Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN today for expert advice and solutions. Visit us at 789 Oak Avenue, Miami, FL 33101, United States, or reach out via Whatsapp at +1 (641) 206-8880. For more information, visit our website at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN and discover how we can help you maintain your Mercedes-Benz in top condition.