When no Diagnostic Trouble Codes (DTCs) are stored, but a problem exists in your Mercedes-Benz, approaching the diagnosis requires a systematic and thoughtful methodology. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we empower you with the knowledge and tools necessary to effectively troubleshoot these elusive issues, maximizing your vehicle’s performance. Focusing on symptoms, gathering data, and utilizing advanced diagnostic techniques can reveal underlying problems and improve vehicle reliability.

Contents

- 1. Understanding the Challenge: When the Computer Doesn’t Talk

- 2. Identifying the Symptoms: The Foundation of Diagnosis

- 2.1. Common Symptoms and Potential Causes

- 3. Gathering Information: The Detective Work

- 4. Visual Inspection: The First Line of Defense

- 5. Advanced Diagnostic Techniques: Digging Deeper

- 5.1. Scan Tool Data Analysis

- 5.2. Component Testing

- 5.3. Smoke Testing

- 5.4. Oscilloscope Testing

- 5.5. Using Mercedes-Benz Specific Diagnostic Tools

- 5.6. Utilizing Wiring Diagrams and Service Manuals

- 6. Case Studies: Real-World Examples

- 6.1. Case Study 1: Intermittent Engine Stalling

- 6.2. Case Study 2: Poor Transmission Shifting

- 6.3. Case Study 3: Battery Drain

- 7. The Importance of a Systematic Approach

- 8. The Role of Experience and Intuition

- 9. Preventive Maintenance: Avoiding Future Headaches

- 10. Seeking Professional Help: When to Call in the Experts

- 11. Navigating Mercedes-Benz Diagnostic Tools at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

- 12. Unlocking Hidden Features: Beyond Diagnostics

- 13. Call to Action: Your Mercedes-Benz Expertise Starts Here

- 14. FAQ: Addressing Your Diagnostic Questions

- 15. Understanding E-E-A-T and YMYL for Automotive Diagnostics

Here’s a comprehensive guide to help you navigate this diagnostic challenge:

1. Understanding the Challenge: When the Computer Doesn’t Talk

Modern vehicles, especially Mercedes-Benz, rely heavily on onboard computers and sensors to monitor various systems. When a component malfunctions or operates outside of pre-defined parameters, the computer usually stores a DTC, providing technicians with a starting point for troubleshooting. However, some problems may not trigger a DTC for several reasons:

- Intermittent Faults: The issue might occur sporadically and not be present long enough to be detected.

- Sensor Malfunctions: A faulty sensor might provide incorrect data without triggering an error code related to the sensor itself.

- Mechanical Issues: Some mechanical problems, like a sticking valve or worn-out bushing, may not be directly monitored by the computer.

- Software Glitches: Rarely, software errors in the Engine Control Unit (ECU) can prevent accurate DTC storage.

When facing a symptom without a DTC, it’s crucial to avoid relying solely on code readers and instead employ a holistic diagnostic approach.

2. Identifying the Symptoms: The Foundation of Diagnosis

The first and most crucial step is to accurately identify and document the symptoms your Mercedes-Benz is exhibiting. This involves careful observation and communication with the vehicle owner (if it’s not your own). Here are some questions to consider:

- What is the vehicle doing (or not doing) that it should be?

- When does the problem occur (e.g., cold start, under acceleration, at highway speed)?

- How often does the problem occur (e.g., always, intermittently, only after long drives)?

- Are there any unusual noises, smells, or vibrations?

- Has the vehicle had any recent maintenance or repairs?

2.1. Common Symptoms and Potential Causes

Here are some common symptoms and their possible causes, even in the absence of DTCs:

| Symptom | Potential Causes |

|---|---|

| Poor Engine Performance (Hesitation, Stalling, Rough Idle) | Vacuum leaks, faulty mass airflow (MAF) sensor, clogged fuel filter, weak fuel pump, malfunctioning ignition coil, sticking EGR valve, worn spark plugs, low compression. |

| Transmission Problems (Slipping, Hard Shifting) | Low transmission fluid, worn clutch packs, faulty valve body, damaged torque converter. |

| Braking Issues (Pulsation, Squealing) | Worn brake pads, warped rotors, sticking calipers, air in brake lines. |

| Suspension Problems (Noises, Poor Handling) | Worn shocks or struts, damaged ball joints, worn control arm bushings, damaged sway bar links. |

| Electrical Issues (Lights Flickering, Battery Drain) | Loose connections, corroded terminals, faulty alternator, parasitic draw. |

3. Gathering Information: The Detective Work

Once you have a clear understanding of the symptoms, it’s time to gather more information. This may involve:

- Reviewing the Vehicle’s Maintenance History: Check for any patterns or recurring issues that might be related to the current problem.

- Consulting Technical Service Bulletins (TSBs): TSBs are issued by manufacturers to address known problems and provide repair procedures. Websites like NHTSA (National Highway Traffic Safety Administration) offer free access to TSBs.

- Searching Online Forums and Databases: Online forums dedicated to Mercedes-Benz vehicles can provide valuable insights from other owners and technicians who have experienced similar issues.

4. Visual Inspection: The First Line of Defense

A thorough visual inspection is crucial, even if no DTCs are present. Pay close attention to:

- Fluid Levels: Check engine oil, coolant, transmission fluid, brake fluid, and power steering fluid levels.

- Hoses and Belts: Look for cracks, leaks, or signs of wear.

- Wiring and Connectors: Inspect for loose connections, corrosion, or damaged wires.

- Vacuum Lines: Check for cracks or disconnections. Vacuum leaks are a common cause of engine performance problems.

- Exhaust System: Look for leaks or damage.

5. Advanced Diagnostic Techniques: Digging Deeper

If the visual inspection doesn’t reveal the problem, you’ll need to employ more advanced diagnostic techniques.

5.1. Scan Tool Data Analysis

Even without DTCs, a scan tool can provide valuable data.

- Live Data Monitoring: Monitor sensor readings in real-time to identify any anomalies. Pay attention to:

- Mass Airflow (MAF) Sensor: Readings should be within specifications at idle and increase smoothly with engine speed.

- Oxygen (O2) Sensors: Readings should fluctuate rapidly, indicating proper fuel mixture control.

- Throttle Position Sensor (TPS): Readings should increase smoothly as the throttle is opened.

- Engine Coolant Temperature (ECT) Sensor: Readings should correspond to the actual engine temperature.

- Freeze Frame Data: If a problem occurs intermittently, the scan tool may have captured freeze frame data, which records sensor readings at the time the problem occurred.

5.2. Component Testing

Testing individual components can help pinpoint the source of the problem.

- Multimeter Testing: Use a multimeter to check voltage, resistance, and continuity of electrical components.

- Fuel Pressure Testing: Check fuel pressure at the fuel rail to ensure the fuel pump is delivering adequate fuel.

- Compression Testing: Perform a compression test to check the condition of the engine’s cylinders.

- Vacuum Testing: Use a vacuum gauge to check for vacuum leaks.

- Ignition System Testing: Use an ignition tester to check for proper spark.

5.3. Smoke Testing

A smoke test is a valuable tool for finding vacuum leaks.

- Procedure: Connect a smoke machine to the intake system and introduce smoke. Observe where the smoke escapes to identify leaks.

5.4. Oscilloscope Testing

An oscilloscope can be used to analyze the waveforms of electrical signals, providing valuable information about the performance of sensors and actuators.

- Applications:

- Crankshaft Position Sensor (CKP) and Camshaft Position Sensor (CMP): Check for proper signal patterns and timing.

- Fuel Injectors: Verify proper pulse width and timing.

- Ignition Coils: Analyze the coil’s firing pattern.

5.5. Using Mercedes-Benz Specific Diagnostic Tools

Mercedes-Benz vehicles often require specialized diagnostic tools for in-depth analysis.

- Mercedes-Benz Star Diagnosis: This is the factory diagnostic system used by Mercedes-Benz dealerships. It provides access to advanced diagnostic functions, including:

- ECU Programming and Coding: Update software and configure control units.

- Component Activation and Testing: Activate and test individual components.

- Fault Code Reading and Clearing: Read and clear DTCs (although this is less relevant when no DTCs are stored).

- Guided Diagnostics: The system provides step-by-step instructions for troubleshooting specific problems.

- Launch X431: A popular aftermarket scan tool that offers extensive coverage for Mercedes-Benz vehicles, including many of the functions of the Star Diagnosis system.

- iCarsoft MB V3.0: A more affordable option for DIYers, offering basic diagnostic functions and some advanced features.

5.6. Utilizing Wiring Diagrams and Service Manuals

Wiring diagrams and service manuals are essential for accurate diagnosis and repair.

- Wiring Diagrams: Help you trace circuits, identify connectors, and locate components.

- Service Manuals: Provide detailed repair procedures, specifications, and troubleshooting guides.

6. Case Studies: Real-World Examples

Here are a few case studies illustrating how to diagnose problems when no DTCs are stored:

6.1. Case Study 1: Intermittent Engine Stalling

- Symptom: The vehicle would occasionally stall at idle, but no DTCs were stored.

- Diagnosis:

- Visual inspection revealed no obvious problems.

- Live data monitoring showed that the MAF sensor readings were erratic just before the stalling occurred.

- The MAF sensor was replaced, and the problem was resolved.

- Key Takeaway: Even without a DTC, live data monitoring can reveal subtle sensor malfunctions.

6.2. Case Study 2: Poor Transmission Shifting

- Symptom: The transmission was slipping and shifting hard, but no DTCs were stored.

- Diagnosis:

- Fluid level check revealed that the transmission fluid was low.

- Inspection of the transmission pan revealed metal shavings, indicating internal wear.

- The transmission was rebuilt, and the problem was resolved.

- Key Takeaway: Mechanical problems can cause symptoms without triggering DTCs.

6.3. Case Study 3: Battery Drain

- Symptom: The battery would drain overnight, but no DTCs were stored.

- Diagnosis:

- A parasitic draw test was performed to identify the circuit causing the drain.

- The source of the draw was traced to a faulty interior light switch.

- The switch was replaced, and the problem was resolved.

- Key Takeaway: Electrical problems can be difficult to diagnose without specialized testing.

7. The Importance of a Systematic Approach

When diagnosing problems without DTCs, it’s crucial to follow a systematic approach.

- Verify the Complaint:

- Ensure the reported symptom is consistently reproducible.

- Gather Preliminary Information:

- Review the vehicle’s history and any recent repairs.

- Perform a Thorough Visual Inspection:

- Check fluid levels, hoses, belts, wiring, and vacuum lines.

- Utilize Scan Tool Data:

- Monitor live data and review freeze frame data.

- Perform Component Testing:

- Test individual components using a multimeter, fuel pressure gauge, compression tester, or vacuum gauge.

- Consider Specialized Tests:

- Perform a smoke test or oscilloscope test as needed.

- Consult Wiring Diagrams and Service Manuals:

- Use these resources to guide your diagnosis and repair.

- Document Your Findings:

- Keep a detailed record of your diagnostic steps and findings.

8. The Role of Experience and Intuition

While diagnostic tools and procedures are essential, experience and intuition also play a vital role in diagnosing problems without DTCs.

- Experience: Technicians who have worked on Mercedes-Benz vehicles for many years often develop a strong understanding of common problems and their potential causes.

- Intuition: Sometimes, a technician’s gut feeling can lead them to the source of the problem more quickly than following a strictly logical approach.

9. Preventive Maintenance: Avoiding Future Headaches

Preventive maintenance is crucial for minimizing the risk of problems that don’t trigger DTCs.

- Regular Fluid Changes: Change engine oil, coolant, transmission fluid, brake fluid, and power steering fluid at the recommended intervals.

- Inspection of Hoses and Belts: Inspect hoses and belts regularly and replace them as needed.

- Spark Plug Replacement: Replace spark plugs at the recommended intervals.

- Air Filter Replacement: Replace air filters regularly to ensure proper engine performance.

- Regular Tune-ups: Perform regular tune-ups to keep the engine running smoothly.

10. Seeking Professional Help: When to Call in the Experts

If you’ve exhausted your diagnostic efforts and are still unable to find the source of the problem, it’s time to seek professional help.

- Mercedes-Benz Dealerships: Dealerships have access to factory-trained technicians and specialized diagnostic equipment.

- Independent Mercedes-Benz Specialists: Independent shops specializing in Mercedes-Benz vehicles often offer a more affordable alternative to dealerships.

11. Navigating Mercedes-Benz Diagnostic Tools at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we provide comprehensive information about various diagnostic tools suitable for Mercedes-Benz vehicles. Our resources include:

- Detailed comparisons of different scan tools: Helping you choose the right tool for your needs and budget.

- Step-by-step guides on using specific diagnostic tools: Providing clear instructions for performing various diagnostic tests.

- Troubleshooting tips and tricks: Sharing expert advice on diagnosing common Mercedes-Benz problems.

- Access to wiring diagrams and service manuals: Providing the resources you need to accurately diagnose and repair your vehicle.

12. Unlocking Hidden Features: Beyond Diagnostics

Beyond diagnostics, MERCEDES-DIAGNOSTIC-TOOL.EDU.VN also offers information on unlocking hidden features in your Mercedes-Benz. These features may include:

- Activating Ambient Lighting: Customizing the interior lighting to your preferences.

- Enabling Sport Displays: Displaying performance data on the instrument cluster.

- Adjusting Suspension Settings: Optimizing the suspension for different driving conditions.

- Activating Cornering Lights: Improving visibility when turning.

Note: Unlocking hidden features may void your vehicle’s warranty. Consult with a qualified technician before making any modifications.

13. Call to Action: Your Mercedes-Benz Expertise Starts Here

Don’t let elusive automotive issues keep you off the road. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we empower you with the knowledge and tools to tackle even the trickiest diagnostic challenges on your Mercedes-Benz. Our comprehensive resources, expert guidance, and commitment to your success make us your ideal partner in automotive care.

Ready to take control of your Mercedes-Benz’s health and unlock its full potential?

- Contact us today via WhatsApp at +1 (641) 206-8880 for personalized advice on selecting the right diagnostic tools and accessing our exclusive troubleshooting resources.

- Visit our website at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN to explore our extensive collection of articles, guides, and videos.

- Stop by our location at 789 Oak Avenue, Miami, FL 33101, United States, and let our experienced technicians provide expert assistance.

Let MERCEDES-DIAGNOSTIC-TOOL.EDU.VN be your trusted resource for all things Mercedes-Benz diagnostics and beyond. Together, we’ll ensure your vehicle performs at its peak and provides you with years of driving pleasure.

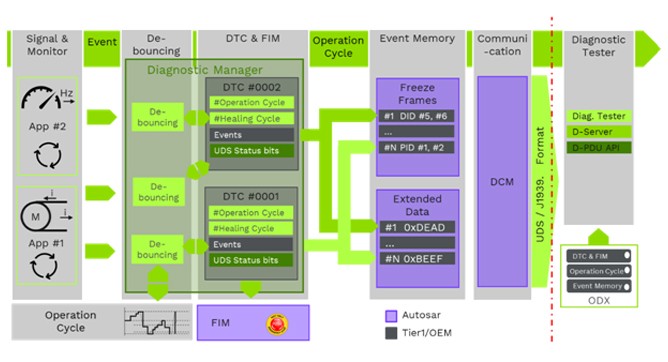

Process sequence of a DTC

Process sequence of a DTC

14. FAQ: Addressing Your Diagnostic Questions

Here are some frequently asked questions about diagnosing problems when no DTCs are stored:

- What is the best Mercedes-Benz diagnostic tool? The best tool depends on your needs and budget. Options range from professional-grade systems like the Mercedes-Benz Star Diagnosis to more affordable aftermarket tools like the Launch X431 and iCarsoft MB V3.0.

- How do I find vacuum leaks on my Mercedes-Benz? A smoke test is the most effective method for finding vacuum leaks.

- Can a faulty sensor cause problems without triggering a DTC? Yes, a faulty sensor might provide incorrect data without triggering an error code related to the sensor itself.

- How often should I perform preventive maintenance on my Mercedes-Benz? Follow the maintenance schedule outlined in your vehicle’s owner’s manual.

- What are some common problems that don’t trigger DTCs? Vacuum leaks, mechanical problems, and intermittent electrical issues are common culprits.

- Where can I find wiring diagrams and service manuals for my Mercedes-Benz? Online resources and some diagnostic tool subscriptions provide access to wiring diagrams and service manuals.

- Is it safe to unlock hidden features on my Mercedes-Benz? Unlocking hidden features may void your vehicle’s warranty. Consult with a qualified technician before making any modifications.

- How can I improve my diagnostic skills? Practice, experience, and continuous learning are key to improving your diagnostic skills.

- What is live data monitoring, and how can it help me diagnose problems? Live data monitoring allows you to observe sensor readings in real-time, helping you identify anomalies that might not trigger DTCs.

- What should I do if I’m unable to diagnose a problem on my Mercedes-Benz? Seek professional help from a Mercedes-Benz dealership or an independent Mercedes-Benz specialist.

15. Understanding E-E-A-T and YMYL for Automotive Diagnostics

In the realm of online content, Google prioritizes expertise, experience, authoritativeness, and trustworthiness (E-E-A-T), especially for “Your Money or Your Life” (YMYL) topics like automotive diagnostics. This means that content must be:

- Expert: Created by individuals with demonstrable knowledge and skills in automotive repair.

- Experienced: Reflective of real-world experience in diagnosing and repairing vehicles.

- Authoritative: Recognized as a reliable source of information within the automotive community.

- Trustworthy: Backed by credible sources and presented in a transparent and unbiased manner.

Since automotive diagnostics directly impacts vehicle safety and reliability, it falls under the YMYL category. Therefore, it’s crucial to ensure that all content related to this topic adheres to the highest standards of E-E-A-T. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we are committed to providing accurate, reliable, and trustworthy information to help you keep your Mercedes-Benz running smoothly and safely.

By following these guidelines and utilizing the resources available at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, you can confidently approach the challenge of diagnosing problems on your Mercedes-Benz, even when no DTCs are stored. Remember, a systematic approach, careful observation, and a willingness to learn are essential for success.