Interpreting Diagnostic Trouble Codes (DTCs) with symptom bytes or sub-codes requires manufacturer-specific information to pinpoint the precise issue within your Mercedes-Benz, and MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers expert guidance and resources to navigate these complex codes. Understanding these codes empowers owners and technicians to diagnose problems accurately, leading to efficient repairs and maintenance, so explore advanced diagnostics, fault code analysis, and repair solutions to keep your Mercedes performing at its best.

Contents

- 1. Understanding Diagnostic Trouble Codes (DTCs) in Mercedes-Benz Vehicles

- 1.1 The Role of OBD Systems in Modern Vehicles

- 1.2 Generic vs. Manufacturer-Specific DTCs

- 1.3 The Structure and Components of a DTC

- 2. Understanding Symptom Bytes and Sub-Codes

- 2.1 What are Symptom Bytes?

- 2.2 What are Sub-Codes?

- 2.3 The Purpose of Symptom Bytes and Sub-Codes in Diagnostics

- 3. The Importance of Manufacturer-Specific Information

- 3.1 Accessing Mercedes-Benz Diagnostic Documentation

- 3.2 Using Mercedes-Benz Diagnostic Tools

- 3.3 The Role of Technical Service Bulletins (TSBs)

- 4. Step-by-Step Guide to Interpreting DTCs with Symptom Bytes or Sub-Codes

- 4.1 Step 1: Retrieve the DTC

- 4.2 Step 2: Identify the Vehicle and System

- 4.3 Step 3: Consult Manufacturer-Specific Documentation

- 4.4 Step 4: Analyze Symptom Bytes and Sub-Codes

- 4.5 Step 5: Perform Diagnostic Tests

- 4.6 Step 6: Repair the Fault

- 5. Case Studies: Interpreting Real-World DTCs in Mercedes-Benz Vehicles

- 5.1 Case Study 1: P0171 with Symptom Byte Indicating Low Fuel Pressure

- 5.2 Case Study 2: B1000 with Sub-Code Indicating Driver’s Seat Occupancy Sensor Fault

- 5.3 Case Study 3: C1500 with Symptom Byte Indicating Steering Angle Sensor Calibration Error

- 6. Common Mistakes to Avoid When Interpreting DTCs

- 6.1 Ignoring Symptom Bytes and Sub-Codes

- 6.2 Relying Solely on Generic DTC Definitions

- 6.3 Failing to Perform Diagnostic Tests

- 6.4 Neglecting Wiring and Connections

- 6.5 Overlooking Related Systems

- 7. Advanced Diagnostic Techniques for Complex DTCs

- 7.1 Data Logging

- 7.2 Oscilloscope Analysis

- 7.3 Advanced Scan Tool Functions

- 8. The Future of Vehicle Diagnostics

- 8.1 Artificial Intelligence (AI) in Diagnostics

- 8.2 Remote Diagnostics

- 8.3 Augmented Reality (AR) in Diagnostics

- 9. FAQ: Interpreting DTCs with Symptom Bytes or Sub-Codes

- 10. Get Expert Help from MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

1. Understanding Diagnostic Trouble Codes (DTCs) in Mercedes-Benz Vehicles

Diagnostic Trouble Codes (DTCs) are alphanumeric codes generated by a vehicle’s On-Board Diagnostics (OBD) system to indicate a malfunction or issue detected within various systems. The Society of Automotive Engineers (SAE) standardized DTCs, ensuring a common framework for identifying problems across different vehicle makes and models, and a typical DTC consists of five characters: a letter indicating the system (e.g., P for Powertrain, B for Body, C for Chassis, U for Network), a number indicating whether the code is generic (0) or manufacturer-specific (1), and three additional characters specifying the fault, according to the EPA.

1.1 The Role of OBD Systems in Modern Vehicles

On-Board Diagnostics (OBD) systems play a crucial role in modern vehicles by continuously monitoring the performance of various components and systems, with the EPA mandating OBD-II systems in all cars and light trucks sold in the United States after January 1, 1996. These systems detect deviations from normal operating parameters and store corresponding DTCs in the vehicle’s computer, alerting the driver through the check engine light or malfunction indicator lamp (MIL).

1.2 Generic vs. Manufacturer-Specific DTCs

DTCs are broadly categorized into generic and manufacturer-specific codes, and generic codes are standardized across all OBD-II compliant vehicles, while manufacturer-specific codes are unique to a particular make or model. Understanding the distinction between these code types is essential for accurate diagnostics, according to Bosch Automotive Handbook:

- Generic DTCs: These codes cover common issues that are standardized across the automotive industry, allowing technicians to use the same diagnostic procedures for similar problems in different vehicles.

- Manufacturer-Specific DTCs: These codes address unique systems or components specific to a particular manufacturer, requiring specialized knowledge and diagnostic tools to interpret correctly.

1.3 The Structure and Components of a DTC

A standard DTC follows a specific structure that provides valuable information about the nature and location of the fault. Each character in the code has a defined meaning, helping technicians narrow down the potential causes of the issue, and a typical DTC structure includes:

- First Character: Indicates the system affected (P, B, C, or U).

- Second Character: Specifies whether the code is generic (0) or manufacturer-specific (1).

- Third Character: Identifies the subsystem at fault.

- Fourth and Fifth Characters: Provide a specific fault index, pinpointing the exact issue.

2. Understanding Symptom Bytes and Sub-Codes

Symptom bytes and sub-codes are additional pieces of information appended to a DTC to provide a more detailed description of the fault, and these supplemental codes are often manufacturer-specific and require access to proprietary information for accurate interpretation. Symptom bytes and sub-codes offer greater diagnostic precision by specifying the conditions under which the fault occurred or the specific component affected.

2.1 What are Symptom Bytes?

Symptom bytes are additional bytes of data that accompany a DTC, providing more context about the conditions under which the fault was detected, according to the Society of Automotive Engineers (SAE). These bytes can indicate factors such as temperature, pressure, voltage, or other relevant parameters at the time of the fault, and symptom bytes help technicians understand the specific circumstances leading to the DTC, enabling more targeted troubleshooting.

2.2 What are Sub-Codes?

Sub-codes are numeric or alphanumeric codes appended to a DTC to further specify the nature or location of the fault, per the Mercedes-Benz Workshop Information System (WIS). These sub-codes are often manufacturer-specific and provide detailed information about the component or circuit affected, and sub-codes allow technicians to pinpoint the exact cause of the problem, reducing diagnostic time and minimizing the risk of misdiagnosis.

2.3 The Purpose of Symptom Bytes and Sub-Codes in Diagnostics

The primary purpose of symptom bytes and sub-codes is to enhance the accuracy and efficiency of vehicle diagnostics, and by providing additional information about the fault, these codes help technicians:

- Pinpoint the Exact Cause: Symptom bytes and sub-codes narrow down the potential causes of a DTC, enabling technicians to focus on the most likely issues.

- Reduce Diagnostic Time: By providing more specific information, these codes reduce the time required to diagnose and repair a vehicle.

- Minimize Misdiagnosis: Detailed fault information minimizes the risk of misdiagnosis, ensuring that the correct repairs are performed.

3. The Importance of Manufacturer-Specific Information

Interpreting DTCs with symptom bytes or sub-codes requires access to manufacturer-specific information, such as repair manuals, technical service bulletins (TSBs), and diagnostic software, since these codes are often proprietary and not publicly available. Without the correct information, technicians may struggle to understand the meaning of the codes and accurately diagnose the fault.

3.1 Accessing Mercedes-Benz Diagnostic Documentation

To effectively interpret DTCs with symptom bytes or sub-codes in Mercedes-Benz vehicles, technicians need access to the official Mercedes-Benz diagnostic documentation, according to the Mercedes-Benz Workshop Information System (WIS). This documentation provides detailed information about the meaning of specific codes, as well as troubleshooting procedures and repair instructions.

3.2 Using Mercedes-Benz Diagnostic Tools

Mercedes-Benz offers a range of diagnostic tools specifically designed for their vehicles, such as the XENTRY Diagnosis system, and these tools provide access to manufacturer-specific DTC information, as well as advanced diagnostic functions and guided troubleshooting procedures. Using these tools ensures that technicians have the most accurate and up-to-date information available for diagnosing and repairing Mercedes-Benz vehicles.

3.3 The Role of Technical Service Bulletins (TSBs)

Technical Service Bulletins (TSBs) are documents issued by vehicle manufacturers to inform technicians about common issues or problems that may arise in specific models, per the National Highway Traffic Safety Administration (NHTSA). TSBs often contain information about DTCs with symptom bytes or sub-codes, as well as recommended repair procedures, and reviewing TSBs can help technicians quickly identify known issues and implement the appropriate solutions.

Mercedes-Benz diagnostic tools

Mercedes-Benz diagnostic tools

4. Step-by-Step Guide to Interpreting DTCs with Symptom Bytes or Sub-Codes

Interpreting DTCs with symptom bytes or sub-codes can be a complex process, but following a systematic approach can help ensure accuracy and efficiency, according to the Bosch Automotive Handbook. This step-by-step guide outlines the key steps involved in interpreting these codes:

4.1 Step 1: Retrieve the DTC

The first step is to retrieve the DTC from the vehicle’s computer using a diagnostic scan tool, and connect the scan tool to the OBD-II port and follow the manufacturer’s instructions to read the stored DTCs. Make sure to record the entire code, including any symptom bytes or sub-codes, as this information will be crucial for accurate interpretation.

4.2 Step 2: Identify the Vehicle and System

Next, identify the specific vehicle make, model, and year, as well as the system associated with the DTC, and this information will help you access the correct manufacturer-specific documentation and diagnostic procedures. Use the first character of the DTC (P, B, C, or U) to identify the system affected.

4.3 Step 3: Consult Manufacturer-Specific Documentation

Consult the manufacturer-specific documentation for the vehicle, such as the repair manual or diagnostic software, per the Mercedes-Benz Workshop Information System (WIS). Look for the DTC in the documentation and note any information about symptom bytes or sub-codes associated with the code, and the documentation should provide a detailed explanation of the meaning of each symptom byte or sub-code, as well as troubleshooting steps and repair instructions.

4.4 Step 4: Analyze Symptom Bytes and Sub-Codes

Analyze the symptom bytes and sub-codes to gain a deeper understanding of the fault, per the Society of Automotive Engineers (SAE). Determine the specific conditions under which the fault occurred, such as temperature, pressure, or voltage, and use this information to narrow down the potential causes of the issue.

4.5 Step 5: Perform Diagnostic Tests

Based on the information gathered from the DTC, symptom bytes, and sub-codes, perform diagnostic tests to verify the fault and identify the root cause, according to the Bosch Automotive Handbook. These tests may include visual inspections, electrical tests, or component tests, and follow the manufacturer’s recommended procedures for each test, and use the diagnostic tool to monitor relevant parameters and compare them to the expected values.

4.6 Step 6: Repair the Fault

Once the root cause of the fault has been identified, perform the necessary repairs to correct the issue, according to the Mercedes-Benz Workshop Information System (WIS). Follow the manufacturer’s recommended repair procedures and use the appropriate tools and equipment. After completing the repairs, clear the DTC from the vehicle’s computer and perform a test drive to ensure that the issue has been resolved.

5. Case Studies: Interpreting Real-World DTCs in Mercedes-Benz Vehicles

Examining real-world case studies can provide valuable insights into the process of interpreting DTCs with symptom bytes or sub-codes, and these examples illustrate how to apply the step-by-step guide to diagnose and repair actual faults in Mercedes-Benz vehicles. By studying these cases, technicians can develop a better understanding of the complexities involved in interpreting these codes and improve their diagnostic skills.

5.1 Case Study 1: P0171 with Symptom Byte Indicating Low Fuel Pressure

A Mercedes-Benz C-Class presents with a P0171 DTC (System Too Lean, Bank 1) and a symptom byte indicating low fuel pressure, and consulting the Mercedes-Benz diagnostic documentation reveals that this symptom byte suggests a potential issue with the fuel pump, fuel filter, or fuel pressure regulator. Performing a fuel pressure test confirms that the fuel pressure is below the specified range, and further investigation reveals that the fuel filter is clogged. Replacing the fuel filter resolves the issue, and the P0171 DTC is cleared.

5.2 Case Study 2: B1000 with Sub-Code Indicating Driver’s Seat Occupancy Sensor Fault

A Mercedes-Benz E-Class displays a B1000 DTC (Control Unit Fault) with a sub-code indicating a fault in the driver’s seat occupancy sensor, and the Mercedes-Benz diagnostic documentation confirms that this sub-code points to a potential problem with the sensor itself or the wiring harness connecting the sensor to the control unit. Performing a diagnostic test on the sensor reveals that it is not functioning correctly, and replacing the sensor resolves the issue, and the B1000 DTC is cleared.

5.3 Case Study 3: C1500 with Symptom Byte Indicating Steering Angle Sensor Calibration Error

A Mercedes-Benz S-Class exhibits a C1500 DTC (Electronic Stability Program (ESP) Control Unit Fault) with a symptom byte indicating a steering angle sensor calibration error, and the Mercedes-Benz diagnostic documentation suggests that this symptom byte may be caused by a misaligned steering wheel or a faulty steering angle sensor. Performing a steering angle sensor calibration procedure resolves the issue, and the C1500 DTC is cleared.

6. Common Mistakes to Avoid When Interpreting DTCs

Interpreting DTCs can be challenging, and it’s essential to avoid common mistakes that can lead to misdiagnosis and unnecessary repairs, according to the Bosch Automotive Handbook. Here are some common mistakes to avoid:

6.1 Ignoring Symptom Bytes and Sub-Codes

Failing to consider symptom bytes and sub-codes can result in an incomplete understanding of the fault, and these additional codes provide valuable information about the conditions under which the fault occurred or the specific component affected. Always analyze symptom bytes and sub-codes to gain a more complete picture of the issue.

6.2 Relying Solely on Generic DTC Definitions

Generic DTC definitions provide a general overview of the fault, but they may not capture the nuances of manufacturer-specific issues, and always consult manufacturer-specific documentation for accurate interpretations of DTCs, especially when symptom bytes or sub-codes are present.

6.3 Failing to Perform Diagnostic Tests

DTCs provide a starting point for diagnosis, but they do not always pinpoint the root cause of the issue, and always perform diagnostic tests to verify the fault and identify the underlying problem before proceeding with repairs.

6.4 Neglecting Wiring and Connections

Wiring and connection issues can often trigger DTCs, especially those related to sensors or circuits, and always inspect wiring harnesses and connections for damage, corrosion, or loose connections before replacing components.

6.5 Overlooking Related Systems

Faults in one system can sometimes trigger DTCs in related systems, and consider the interdependencies between different systems when diagnosing DTCs, and look for potential issues in related systems that may be contributing to the problem.

7. Advanced Diagnostic Techniques for Complex DTCs

In some cases, interpreting DTCs with symptom bytes or sub-codes may require advanced diagnostic techniques, such as data logging, oscilloscope analysis, or advanced scan tool functions, according to the Bosch Automotive Handbook. These techniques can help technicians gather more detailed information about the fault and identify elusive problems.

7.1 Data Logging

Data logging involves recording data from various sensors and systems over a period of time, allowing technicians to analyze the behavior of the vehicle under different conditions, per the Society of Automotive Engineers (SAE). This technique can be helpful for identifying intermittent faults or issues that only occur under specific circumstances, and use a diagnostic scan tool to record data from relevant sensors and systems, such as engine speed, fuel pressure, and oxygen sensor readings.

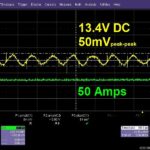

7.2 Oscilloscope Analysis

Oscilloscope analysis involves using an oscilloscope to visualize electrical signals, allowing technicians to identify issues with wiring, sensors, or actuators, according to Fluke Corporation. This technique can be helpful for diagnosing complex electrical problems, such as short circuits, open circuits, or signal distortion, and connect the oscilloscope to the relevant circuit and analyze the waveform to identify any abnormalities.

7.3 Advanced Scan Tool Functions

Advanced scan tools offer a range of functions that can aid in diagnosing complex DTCs, such as component activation, system tests, and guided diagnostics, per the Mercedes-Benz Workshop Information System (WIS). These functions can help technicians isolate faults and verify the functionality of individual components, and use the scan tool to activate specific components, such as fuel injectors or solenoids, and observe their response.

8. The Future of Vehicle Diagnostics

Vehicle diagnostics is constantly evolving, with new technologies and techniques emerging to improve the accuracy and efficiency of fault diagnosis, according to the Bosch Automotive Handbook. As vehicles become more complex, the need for advanced diagnostic tools and techniques will continue to grow, and here are some of the key trends shaping the future of vehicle diagnostics:

8.1 Artificial Intelligence (AI) in Diagnostics

Artificial intelligence (AI) is being increasingly used in vehicle diagnostics to analyze data from various sources and identify potential faults, per McKinsey & Company. AI algorithms can learn from vast amounts of data and identify patterns that humans may miss, helping technicians diagnose complex issues more quickly and accurately, and these algorithms can also provide predictive diagnostics, alerting technicians to potential problems before they occur.

8.2 Remote Diagnostics

Remote diagnostics allows technicians to diagnose vehicles remotely, using telematics data and remote access tools, per Continental AG. This technology can be helpful for diagnosing vehicles in remote locations or for providing support to technicians in the field, and remote diagnostics can also enable over-the-air (OTA) software updates, allowing manufacturers to fix software bugs and improve vehicle performance without requiring a visit to the dealership.

8.3 Augmented Reality (AR) in Diagnostics

Augmented reality (AR) is being used to overlay diagnostic information onto the technician’s view of the vehicle, providing step-by-step instructions and real-time data, according to PTC. This technology can help technicians perform complex diagnostic procedures more efficiently and accurately, and AR can also be used to train technicians on new diagnostic techniques.

9. FAQ: Interpreting DTCs with Symptom Bytes or Sub-Codes

1. What is a DTC symptom byte?

A DTC symptom byte is an additional piece of data appended to a Diagnostic Trouble Code (DTC) that provides more context about the conditions under which the fault was detected, such as temperature, pressure, or voltage.

2. What is a DTC sub-code?

A DTC sub-code is a numeric or alphanumeric code appended to a DTC to further specify the nature or location of the fault, often providing detailed information about the component or circuit affected.

3. Why is manufacturer-specific information important for interpreting DTCs with symptom bytes or sub-codes?

Manufacturer-specific information is crucial because symptom bytes and sub-codes are often proprietary and not publicly available, requiring access to repair manuals, technical service bulletins (TSBs), and diagnostic software for accurate interpretation.

4. How can I access Mercedes-Benz diagnostic documentation?

You can access Mercedes-Benz diagnostic documentation through the Mercedes-Benz Workshop Information System (WIS) or by using Mercedes-Benz diagnostic tools such as the XENTRY Diagnosis system.

5. What are some common mistakes to avoid when interpreting DTCs?

Common mistakes include ignoring symptom bytes and sub-codes, relying solely on generic DTC definitions, failing to perform diagnostic tests, neglecting wiring and connections, and overlooking related systems.

6. What advanced diagnostic techniques can be used for complex DTCs?

Advanced diagnostic techniques include data logging, oscilloscope analysis, and using advanced scan tool functions such as component activation, system tests, and guided diagnostics.

7. How is artificial intelligence (AI) being used in vehicle diagnostics?

Artificial intelligence (AI) is being used to analyze data from various sources, identify potential faults, provide predictive diagnostics, and help technicians diagnose complex issues more quickly and accurately.

8. What is remote diagnostics?

Remote diagnostics allows technicians to diagnose vehicles remotely, using telematics data and remote access tools, which can be helpful for diagnosing vehicles in remote locations or for providing support to technicians in the field.

9. How is augmented reality (AR) being used in vehicle diagnostics?

Augmented reality (AR) is being used to overlay diagnostic information onto the technician’s view of the vehicle, providing step-by-step instructions and real-time data to help technicians perform complex diagnostic procedures more efficiently and accurately.

10. Where can I get expert help with Mercedes-Benz diagnostics?

You can get expert help with Mercedes-Benz diagnostics from MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, which offers resources, guidance, and support for diagnosing and repairing Mercedes-Benz vehicles.

10. Get Expert Help from MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

Interpreting DTCs with symptom bytes or sub-codes can be challenging, but MERCEDES-DIAGNOSTIC-TOOL.EDU.VN is here to help. Our team of experienced Mercedes-Benz technicians can provide expert guidance and support to help you diagnose and repair your vehicle quickly and efficiently, so whether you’re a professional technician or a DIY enthusiast, we have the resources and expertise you need to keep your Mercedes-Benz performing at its best.

Ready to take the next step in diagnosing and repairing your Mercedes-Benz? Contact us today for expert assistance with diagnostic tools, unlocking hidden features, and step-by-step repair guides, so you can reach us at 789 Oak Avenue, Miami, FL 33101, United States, or call us on Whatsapp at +1 (641) 206-8880, or visit our website at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN. Let MERCEDES-DIAGNOSTIC-TOOL.EDU.VN be your trusted partner in keeping your Mercedes-Benz running smoothly and efficiently.