Pressure transducers are indispensable tools for diagnosing HVAC and boost pressure Diagnostic Trouble Codes (DTCs). MERCEDES-DIAGNOSTIC-TOOL.EDU.VN equips you with the knowledge to effectively utilize pressure transducers, ensuring precise diagnostics and efficient repairs. Mastering their use allows for accurate assessment of system pressures, pinpointing leaks, blockages, or malfunctioning components with confidence.

Contents

- 1. Understanding the Role of Pressure Transducers in Automotive Diagnostics

- 1.1. What is a Pressure Transducer?

- 1.2. Why Use Pressure Transducers for HVAC and Boost Pressure Diagnostics?

- 1.3. Key Features of a Good Automotive Pressure Transducer

- 1.4. Safety Precautions When Working with Pressure Transducers

- 2. Diagnosing HVAC Systems with Pressure Transducers

- 2.1. Common HVAC Issues Detectable with Pressure Transducers

- 2.2. Step-by-Step Guide to Diagnosing Refrigerant Leaks

- 2.3. Identifying Compressor Problems Using Pressure Readings

- 2.4. Diagnosing Expansion Valve Issues with Pressure Transducers

- 3. Using Pressure Transducers for Boost Pressure Diagnostics

- 3.1. Common Boost Pressure Issues Detectable with Pressure Transducers

- 3.2. Step-by-Step Guide to Diagnosing Boost Leaks

- 3.3. Identifying Turbocharger Problems Using Pressure Readings

- 3.4. Diagnosing Wastegate Issues with Pressure Transducers

- 4. Advanced Techniques for Using Pressure Transducers

- 4.1. Differential Pressure Measurements

- 4.2. Pressure Drop Testing

- 4.3. Dynamic Pressure Analysis

- 5. Choosing the Right Pressure Transducer for the Job

- 5.1. Types of Pressure Transducers

- 5.2. Calibration and Maintenance of Pressure Transducers

- 6. Integrating Pressure Transducers with Diagnostic Tools

- 6.1. Connecting Transducers to Diagnostic Equipment

- 6.2. Software and Apps for Analyzing Pressure Transducer Data

- 6.3. Interpreting Data from Pressure Transducers

- 7. Case Studies: Real-World Examples of Pressure Transducer Use

- 7.1. Diagnosing a Faulty AC Compressor in a Mercedes-Benz C-Class

- 7.2. Identifying a Boost Leak in a Mercedes-Benz AMG Model

- 7.3. Diagnosing a Clogged Catalytic Converter in a Mercedes-Benz E-Class

- 8. Tips and Tricks for Effective Pressure Transducer Use

- 9. Future Trends in Pressure Transducer Technology

- 9.1. Wireless Pressure Transducers

- 9.2. Miniaturized Pressure Transducers

- 9.3. High-Temperature Pressure Transducers

- 10. Conclusion: Mastering Pressure Transducer Use for Automotive Diagnostics

- 11. FAQ: Frequently Asked Questions About Pressure Transducers

- 11.1. What is the Best Pressure Transducer for Automotive Use?

- 11.2. How Often Should I Calibrate My Pressure Transducer?

- 11.3. Can I Use a Pressure Transducer to Measure Vacuum?

- 11.4. What is the Difference Between Absolute, Gauge, and Differential Pressure Transducers?

- 11.5. How Do I Protect My Pressure Transducer from Damage?

- 11.6. Can I Use a Pressure Transducer to Diagnose Fuel Pressure Issues?

- 11.7. What is the Typical Response Time of a Pressure Transducer?

- 11.8. How Do I Interpret the Output Signal from a Pressure Transducer?

- 11.9. Can I Use a Pressure Transducer to Measure Tire Pressure?

- 11.10. Where Can I Buy High-Quality Pressure Transducers for Automotive Use?

1. Understanding the Role of Pressure Transducers in Automotive Diagnostics

Pressure transducers are essential diagnostic tools that convert pressure into an electrical signal. This signal can then be interpreted by a diagnostic tool or multimeter, providing a precise pressure reading. These readings are critical for diagnosing issues within HVAC (Heating, Ventilation, and Air Conditioning) systems and boost pressure systems in turbocharged engines. Pressure transducers offer a far more accurate and reliable method compared to traditional mechanical gauges. They enable technicians to monitor pressure changes in real-time, capture transient pressure variations, and identify subtle pressure irregularities that might be missed by other diagnostic methods. This capability is especially valuable when diagnosing intermittent faults or complex pressure-related problems. The use of pressure transducers aligns with modern automotive diagnostic practices, ensuring efficiency, accuracy, and a deeper understanding of system performance.

1.1. What is a Pressure Transducer?

A pressure transducer is a device that converts pressure into an electrical signal. The transducer contains a pressure-sensitive diaphragm or membrane. When pressure is applied, the diaphragm deflects, causing a change in an electrical property, such as resistance or capacitance. This change is then converted into a voltage or current signal proportional to the applied pressure. This electrical signal can be read by a diagnostic tool, oscilloscope, or multimeter, providing a precise measurement of the pressure.

1.2. Why Use Pressure Transducers for HVAC and Boost Pressure Diagnostics?

Using pressure transducers for HVAC and boost pressure diagnostics offers several advantages over traditional methods:

- Accuracy: Pressure transducers provide highly accurate pressure readings, often more precise than mechanical gauges.

- Real-time Data: They allow for real-time monitoring of pressure changes, enabling technicians to capture transient pressure variations.

- Digital Readings: The electrical signal output allows for easy integration with diagnostic tools and data logging systems.

- Versatility: Transducers can measure a wide range of pressures, making them suitable for various automotive applications.

- Efficiency: They help pinpoint leaks, blockages, or malfunctioning components quickly and accurately, reducing diagnostic time.

According to a study by the Society of Automotive Engineers (SAE), the use of pressure transducers in automotive diagnostics can reduce diagnostic time by up to 40% compared to traditional methods.

1.3. Key Features of a Good Automotive Pressure Transducer

When selecting a pressure transducer for automotive diagnostics, consider the following key features:

- Pressure Range: Ensure the transducer’s pressure range matches the pressures you’ll be measuring in HVAC and boost pressure systems.

- Accuracy: Look for transducers with high accuracy, typically specified as a percentage of full-scale output.

- Resolution: Higher resolution transducers provide more precise measurements, allowing for detection of small pressure changes.

- Durability: Choose a transducer designed to withstand the harsh automotive environment, including temperature variations and exposure to fluids.

- Connectivity: Ensure the transducer is compatible with your diagnostic tools and has the appropriate connectors.

- Response Time: A fast response time is crucial for capturing transient pressure changes accurately.

1.4. Safety Precautions When Working with Pressure Transducers

When working with pressure transducers in automotive diagnostics, it’s essential to follow safety precautions to prevent injury and equipment damage:

- Depressurize the System: Before connecting or disconnecting a pressure transducer, always depressurize the system being tested to avoid sudden pressure releases.

- Wear Safety Glasses: Protect your eyes from potential splashes of refrigerant or other fluids.

- Use Proper Connectors: Ensure that the connectors used are compatible with the system being tested to prevent leaks or damage.

- Avoid Overpressure: Never exceed the maximum pressure rating of the transducer to prevent damage to the sensor.

- Handle with Care: Avoid dropping or mishandling the transducer, as this can affect its accuracy and performance.

- Follow Manufacturer’s Instructions: Always follow the manufacturer’s instructions for the specific transducer being used.

2. Diagnosing HVAC Systems with Pressure Transducers

Pressure transducers are invaluable for diagnosing issues within automotive HVAC systems. By measuring pressures at various points in the system, technicians can identify problems such as refrigerant leaks, compressor inefficiencies, blockages in the refrigerant lines, and faulty expansion valves. Understanding the normal operating pressures of an HVAC system is crucial for accurate diagnosis. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides detailed specifications for various Mercedes-Benz models, ensuring technicians have the necessary data at their fingertips. The real-time data provided by pressure transducers allows for dynamic testing, such as monitoring pressure changes during compressor cycling or engine speed variations.

2.1. Common HVAC Issues Detectable with Pressure Transducers

Pressure transducers can help diagnose a wide range of HVAC issues, including:

- Refrigerant Leaks: Low pressure readings on both the high and low sides of the system.

- Compressor Inefficiency: Abnormally low high-side pressure or failure to reach specified pressure levels.

- Blockages in Refrigerant Lines: High pressure on the high side and low pressure on the low side.

- Faulty Expansion Valve: Incorrect pressure drop across the expansion valve, leading to poor cooling performance.

- Overcharged System: Excessively high pressures on both the high and low sides.

- Contaminated Refrigerant: Unusual pressure readings and system performance.

2.2. Step-by-Step Guide to Diagnosing Refrigerant Leaks

Diagnosing refrigerant leaks using pressure transducers involves a systematic approach:

- Connect Transducers: Connect pressure transducers to the high and low-side service ports of the HVAC system.

- Record Initial Pressures: Note the initial pressure readings with the engine and AC system off.

- Start the Engine and AC: Start the engine and turn on the AC system to maximum cooling.

- Monitor Pressure Changes: Observe the pressure readings on both the high and low sides as the system operates.

- Compare to Specifications: Compare the observed pressures to the manufacturer’s specifications for the vehicle and refrigerant type. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides these specifications for Mercedes-Benz models.

- Identify Leaks: If pressures are low on both sides, suspect a refrigerant leak. Use a refrigerant leak detector to pinpoint the location of the leak.

2.3. Identifying Compressor Problems Using Pressure Readings

Pressure transducers are essential for diagnosing compressor issues:

- Low High-Side Pressure: If the high-side pressure is significantly lower than specified, the compressor may be weak or inefficient.

- Failure to Reach Specified Pressure: If the compressor fails to reach the specified high-side pressure, it may have internal damage or worn components.

- Unusual Pressure Fluctuations: Erratic pressure fluctuations can indicate problems with the compressor’s internal valves or pistons.

To confirm compressor issues, compare the pressure readings with the compressor’s performance specifications and consider performing a compressor efficiency test using a specialized diagnostic tool.

2.4. Diagnosing Expansion Valve Issues with Pressure Transducers

The expansion valve regulates refrigerant flow and pressure drop in the HVAC system. Issues with the expansion valve can be diagnosed using pressure transducers:

- Incorrect Pressure Drop: If the pressure drop across the expansion valve is not within the specified range, the valve may be faulty or blocked.

- High Low-Side Pressure: A blocked or restricted expansion valve can cause excessively high low-side pressure.

- Low High-Side Pressure: A malfunctioning expansion valve can lead to inadequate refrigerant flow, resulting in low high-side pressure.

To diagnose expansion valve issues, compare the pressure readings upstream and downstream of the valve with the manufacturer’s specifications.

3. Using Pressure Transducers for Boost Pressure Diagnostics

In turbocharged engines, pressure transducers are vital for diagnosing boost pressure-related issues. These sensors enable technicians to measure and monitor the pressure generated by the turbocharger, helping identify problems such as leaks in the intake system, malfunctioning turbocharger components, and issues with the boost control system. Understanding the normal boost pressure range for a specific engine is crucial for accurate diagnosis. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers detailed boost pressure specifications for Mercedes-Benz turbocharged engines, ensuring technicians have the necessary data. Real-time monitoring of boost pressure allows for dynamic testing, such as observing pressure changes during acceleration or under load.

3.1. Common Boost Pressure Issues Detectable with Pressure Transducers

Pressure transducers can help diagnose a variety of boost pressure-related issues, including:

- Boost Leaks: Low boost pressure readings during acceleration or under load.

- Turbocharger Problems: Inability to reach specified boost pressure levels, indicating a faulty turbocharger.

- Wastegate Issues: Incorrect wastegate operation, leading to overboost or underboost conditions.

- Boost Control Solenoid Problems: Malfunctioning boost control solenoid, resulting in unstable or incorrect boost pressure.

- Intercooler Problems: Blockages or leaks in the intercooler, causing reduced boost pressure and performance.

3.2. Step-by-Step Guide to Diagnosing Boost Leaks

Diagnosing boost leaks using pressure transducers involves a systematic approach:

- Connect Transducer: Connect a pressure transducer to a suitable point in the intake system, such as the intake manifold or intercooler outlet.

- Seal the System: Seal the intake system downstream of the transducer to prevent air from escaping.

- Pressurize the System: Use a regulated air source to pressurize the intake system to the specified test pressure (typically around 15-20 psi).

- Monitor Pressure: Observe the pressure reading on the transducer and listen for air leaks.

- Locate Leaks: Use a soapy water solution to spray suspected leak areas, such as hoses, connections, and intercooler seams. Bubbles will form at the leak locations.

3.3. Identifying Turbocharger Problems Using Pressure Readings

Pressure transducers are essential for diagnosing turbocharger issues:

- Low Boost Pressure: If the boost pressure is significantly lower than specified, the turbocharger may be damaged or worn.

- Failure to Reach Specified Pressure: If the turbocharger fails to reach the specified boost pressure, it may have internal damage or a malfunctioning wastegate.

- Overboost Condition: If the boost pressure exceeds the specified maximum, the wastegate may be stuck closed or the boost control system may be faulty.

To confirm turbocharger issues, compare the pressure readings with the turbocharger’s performance specifications and consider performing a turbocharger efficiency test using a specialized diagnostic tool.

3.4. Diagnosing Wastegate Issues with Pressure Transducers

The wastegate controls the amount of exhaust gas diverted away from the turbine wheel, regulating boost pressure. Issues with the wastegate can be diagnosed using pressure transducers:

- Underboost Condition: If the wastegate is stuck open or leaking, it can cause an underboost condition, resulting in reduced engine power.

- Overboost Condition: If the wastegate is stuck closed, it can cause an overboost condition, which can damage the engine.

- Inconsistent Boost Pressure: Erratic or unstable boost pressure can indicate problems with the wastegate actuator or control system.

To diagnose wastegate issues, monitor the boost pressure and wastegate actuator position during various engine operating conditions.

4. Advanced Techniques for Using Pressure Transducers

Beyond basic pressure measurements, pressure transducers can be used in advanced diagnostic techniques to gain deeper insights into system performance. These techniques include differential pressure measurements, pressure drop testing, and dynamic pressure analysis.

4.1. Differential Pressure Measurements

Differential pressure measurements involve using two pressure transducers to measure the pressure difference between two points in a system. This technique is useful for diagnosing restrictions in filters, heat exchangers, and other components.

- Air Filters: Measuring the pressure drop across an air filter can indicate whether it is clogged or restricted.

- Catalytic Converters: Measuring the pressure drop across a catalytic converter can indicate whether it is blocked or damaged.

- HVAC Evaporators: Measuring the pressure drop across an HVAC evaporator can indicate whether it is restricted or iced up.

4.2. Pressure Drop Testing

Pressure drop testing involves pressurizing a system and monitoring the rate at which the pressure decreases over time. This technique is useful for identifying leaks in closed systems, such as refrigerant lines or intake systems.

- Refrigerant Lines: Pressurize the refrigerant lines with nitrogen and monitor the pressure drop to identify refrigerant leaks.

- Intake Systems: Pressurize the intake system and monitor the pressure drop to identify boost leaks.

- Cooling Systems: Pressurize the cooling system and monitor the pressure drop to identify coolant leaks.

4.3. Dynamic Pressure Analysis

Dynamic pressure analysis involves monitoring pressure changes over time to identify transient events or anomalies in system performance. This technique requires the use of a high-speed data acquisition system or oscilloscope.

- Compressor Cycling: Monitor pressure changes during compressor cycling to identify issues with the compressor, expansion valve, or refrigerant charge.

- Turbocharger Response: Monitor boost pressure changes during acceleration to assess turbocharger response and identify potential issues with the turbocharger or boost control system.

- Valve Timing: Monitor cylinder pressure changes to verify valve timing and identify potential issues with camshafts or valvetrain components.

5. Choosing the Right Pressure Transducer for the Job

Selecting the appropriate pressure transducer is crucial for accurate and reliable diagnostics. Consider the following factors when choosing a pressure transducer:

- Pressure Range: Ensure the transducer’s pressure range matches the pressures you’ll be measuring.

- Accuracy: Look for transducers with high accuracy, typically specified as a percentage of full-scale output.

- Media Compatibility: Ensure the transducer is compatible with the fluids or gases you’ll be measuring.

- Temperature Range: Choose a transducer that can operate within the temperature range of the environment you’ll be working in.

- Connectivity: Ensure the transducer is compatible with your diagnostic tools and has the appropriate connectors.

- Durability: Choose a transducer designed to withstand the harsh automotive environment.

5.1. Types of Pressure Transducers

There are several types of pressure transducers available, each with its own advantages and disadvantages:

- Strain Gauge Transducers: These transducers use strain gauges to measure the deflection of a diaphragm under pressure. They are known for their accuracy and stability.

- Capacitive Transducers: These transducers use a capacitor to measure the deflection of a diaphragm under pressure. They are known for their high sensitivity and low power consumption.

- Piezoelectric Transducers: These transducers use a piezoelectric crystal to generate a voltage when subjected to pressure. They are known for their fast response time and high-frequency response.

5.2. Calibration and Maintenance of Pressure Transducers

To ensure accurate and reliable measurements, pressure transducers should be calibrated regularly. Calibration involves comparing the transducer’s output to a known pressure standard and adjusting the transducer’s output to match the standard.

In addition to calibration, pressure transducers should be maintained properly to ensure their longevity and performance. This includes:

- Cleaning: Clean the transducer regularly to remove dirt, oil, and other contaminants.

- Storage: Store the transducer in a clean, dry place when not in use.

- Inspection: Inspect the transducer regularly for damage, such as cracks, leaks, or damaged connectors.

6. Integrating Pressure Transducers with Diagnostic Tools

Modern diagnostic tools often have the capability to interface directly with pressure transducers, allowing for real-time data logging and analysis. This integration can significantly enhance the diagnostic process, providing technicians with a comprehensive view of system performance.

6.1. Connecting Transducers to Diagnostic Equipment

To connect pressure transducers to diagnostic equipment, follow these steps:

- Identify the Appropriate Connector: Determine the type of connector required for your diagnostic tool and pressure transducer.

- Connect the Transducer: Connect the pressure transducer to the diagnostic tool using the appropriate connector.

- Configure the Diagnostic Tool: Configure the diagnostic tool to recognize the pressure transducer and display the pressure readings.

- Verify the Connection: Verify that the diagnostic tool is receiving data from the pressure transducer and that the pressure readings are accurate.

6.2. Software and Apps for Analyzing Pressure Transducer Data

There are several software programs and mobile apps available for analyzing pressure transducer data. These tools allow technicians to:

- Display Real-Time Data: View pressure readings in real-time.

- Log Data: Record pressure readings over time for later analysis.

- Graph Data: Create graphs of pressure readings to visualize trends and anomalies.

- Compare Data: Compare pressure readings to manufacturer’s specifications or baseline data.

- Generate Reports: Generate reports summarizing pressure readings and diagnostic findings.

6.3. Interpreting Data from Pressure Transducers

Interpreting data from pressure transducers requires a thorough understanding of the system being tested and the expected pressure ranges. Compare the measured pressure readings to manufacturer’s specifications and look for deviations that may indicate a problem.

Consider the following when interpreting pressure transducer data:

- Pressure Range: Ensure the measured pressure readings are within the expected range for the system being tested.

- Pressure Stability: Look for stable pressure readings, as erratic pressure fluctuations can indicate a problem.

- Pressure Drop: Monitor pressure drop across components to identify restrictions or leaks.

- Pressure Response: Assess the system’s response to changes in operating conditions, such as acceleration or load.

7. Case Studies: Real-World Examples of Pressure Transducer Use

Examining real-world case studies can provide valuable insights into how pressure transducers are used to diagnose automotive issues.

7.1. Diagnosing a Faulty AC Compressor in a Mercedes-Benz C-Class

A Mercedes-Benz C-Class was brought in with complaints of poor AC performance. Using pressure transducers, the technician measured the high and low-side pressures and found that the high-side pressure was significantly lower than specified. This indicated a potential issue with the AC compressor. Further testing confirmed that the compressor was weak and unable to generate sufficient pressure, leading to poor cooling performance. The compressor was replaced, and the AC system was recharged, restoring the vehicle’s cooling performance.

7.2. Identifying a Boost Leak in a Mercedes-Benz AMG Model

A Mercedes-Benz AMG model was experiencing a loss of power and poor acceleration. Using a pressure transducer, the technician pressurized the intake system and monitored the pressure drop. A significant pressure drop was observed, indicating a boost leak. The technician then used a soapy water solution to identify the source of the leak, which was a loose connection on the intercooler. The connection was tightened, and the system was retested, confirming that the boost leak had been resolved.

7.3. Diagnosing a Clogged Catalytic Converter in a Mercedes-Benz E-Class

A Mercedes-Benz E-Class was setting a code for catalytic converter inefficiency. Using pressure transducers, the technician measured the pressure drop across the catalytic converter. A high-pressure drop was observed, indicating that the catalytic converter was clogged. The catalytic converter was replaced, resolving the code and restoring the vehicle’s performance.

8. Tips and Tricks for Effective Pressure Transducer Use

To maximize the effectiveness of pressure transducers in automotive diagnostics, consider the following tips and tricks:

- Use High-Quality Transducers: Invest in high-quality pressure transducers for accurate and reliable measurements.

- Calibrate Regularly: Calibrate your pressure transducers regularly to ensure their accuracy.

- Protect Transducers from Damage: Handle pressure transducers with care to prevent damage.

- Use Appropriate Connectors: Use the appropriate connectors for your diagnostic tools and pressure transducers.

- Monitor Pressure Changes Over Time: Monitor pressure changes over time to identify trends and anomalies.

- Compare to Specifications: Compare measured pressure readings to manufacturer’s specifications.

- Use Differential Pressure Measurements: Use differential pressure measurements to diagnose restrictions in components.

- Keep Records: Keep records of pressure readings and diagnostic findings for future reference.

9. Future Trends in Pressure Transducer Technology

Pressure transducer technology is constantly evolving, with new advancements on the horizon.

9.1. Wireless Pressure Transducers

Wireless pressure transducers are becoming increasingly popular, as they eliminate the need for physical connections and cables. This can simplify the diagnostic process and improve safety.

9.2. Miniaturized Pressure Transducers

Miniaturized pressure transducers are being developed for use in tight spaces and for integration into smaller diagnostic tools.

9.3. High-Temperature Pressure Transducers

High-temperature pressure transducers are being developed for use in extreme environments, such as exhaust systems and combustion chambers.

10. Conclusion: Mastering Pressure Transducer Use for Automotive Diagnostics

Mastering the use of pressure transducers is essential for accurate and efficient automotive diagnostics. By understanding the principles of pressure measurement, selecting the appropriate transducers, and using advanced diagnostic techniques, technicians can quickly and accurately diagnose a wide range of HVAC and boost pressure-related issues. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides the resources and knowledge needed to excel in this critical area of automotive diagnostics.

Ready to take your diagnostic skills to the next level? Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN today for expert advice on selecting the right diagnostic tools, unlocking hidden features, and mastering advanced repair techniques for your Mercedes-Benz. Our team of experienced technicians is ready to help you get the most out of your vehicle.

Contact us:

- Address: 789 Oak Avenue, Miami, FL 33101, United States

- Whatsapp: +1 (641) 206-8880

- Website: MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

11. FAQ: Frequently Asked Questions About Pressure Transducers

11.1. What is the Best Pressure Transducer for Automotive Use?

The best pressure transducer for automotive use depends on the specific application. However, strain gauge transducers are generally considered to be the most accurate and reliable for a wide range of applications.

11.2. How Often Should I Calibrate My Pressure Transducer?

Pressure transducers should be calibrated at least once a year, or more frequently if they are used in demanding applications.

11.3. Can I Use a Pressure Transducer to Measure Vacuum?

Yes, pressure transducers can be used to measure vacuum. However, you will need a transducer that is designed for vacuum measurement.

11.4. What is the Difference Between Absolute, Gauge, and Differential Pressure Transducers?

- Absolute Pressure Transducers: Measure pressure relative to a perfect vacuum.

- Gauge Pressure Transducers: Measure pressure relative to atmospheric pressure.

- Differential Pressure Transducers: Measure the pressure difference between two points.

11.5. How Do I Protect My Pressure Transducer from Damage?

To protect your pressure transducer from damage, handle it with care, avoid overpressure, and use the appropriate connectors.

11.6. Can I Use a Pressure Transducer to Diagnose Fuel Pressure Issues?

Yes, pressure transducers can be used to diagnose fuel pressure issues. However, you will need a transducer that is compatible with fuel and has the appropriate pressure range.

11.7. What is the Typical Response Time of a Pressure Transducer?

The typical response time of a pressure transducer varies depending on the type and model. However, most transducers have a response time of less than 1 millisecond.

11.8. How Do I Interpret the Output Signal from a Pressure Transducer?

The output signal from a pressure transducer is typically a voltage or current signal that is proportional to the applied pressure. You will need to consult the transducer’s datasheet to determine the exact relationship between the output signal and the pressure.

11.9. Can I Use a Pressure Transducer to Measure Tire Pressure?

Yes, pressure transducers can be used to measure tire pressure. However, you will need a transducer that is designed for tire pressure measurement and has the appropriate pressure range.

11.10. Where Can I Buy High-Quality Pressure Transducers for Automotive Use?

High-quality pressure transducers for automotive use can be purchased from reputable suppliers of automotive diagnostic tools and equipment. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN can provide recommendations for trusted suppliers.

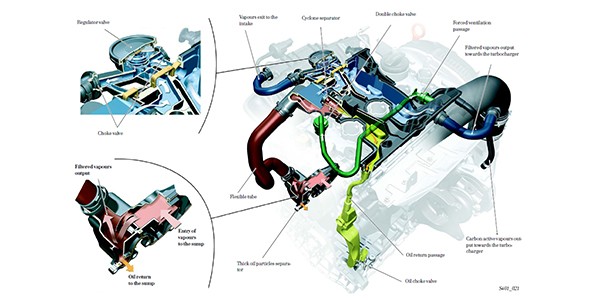

VW EA888 PCV System Overview

VW EA888 PCV System Overview

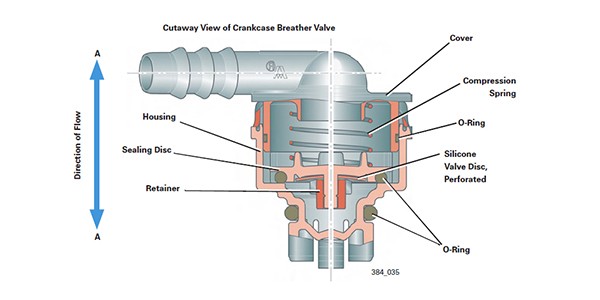

VW-Audi 2.0T Crankcase Breather Valve Cutaway

VW-Audi 2.0T Crankcase Breather Valve Cutaway