Understanding the nuances of Diagnostic Trouble Codes (DTCs) is essential for maintaining your Mercedes-Benz, especially when dealing with heavy-duty vehicles. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers comprehensive insights into how DTC formats differ for heavy-duty vehicles using the J1939 standard, ensuring accurate diagnostics and efficient repairs. This guide will clarify the differences and help you interpret these codes effectively.

Contents

- 1. What is a Diagnostic Trouble Code (DTC)?

- 2. What are OBD-II and J1939 Standards?

- 3. How Do I Determine if My Vehicle is OBD-II or J1939 Compliant?

- 4. What is the Structure of an OBD-II DTC?

- 5. How Do I Interpret an OBD-II DTC?

- 6. What are Some Common OBD-II DTCs?

- 7. How Does the DTC Format Differ for Heavy-Duty Vehicles (J1939)?

- 8. What are the Key Components of a J1939 DTC?

- 9. How Do SPN and FMI Contribute to J1939 DTC Interpretation?

- 10. Can you provide examples of SPN and FMI combinations and their meanings?

- 11. What Role Does the Occurrence Counter (OC) Play in Diagnosing J1939 DTCs?

- 12. How Does the SPN Conversion Method (CM) Affect DTC Interpretation?

- 13. What Tools Can Fleet Managers Use to Read J1939 DTCs?

- 14. How Can Telematics Solutions Simplify DTC Management?

- 15. What are the Benefits of Using a Telematics Solution for DTC Monitoring?

- 16. What is the Role of Diagnostic Software in Interpreting J1939 DTCs?

- 17. How Does Proper Interpretation of J1939 DTCs Prevent Costly Repairs?

- 18. What are Some Common J1939 DTCs in Heavy-Duty Vehicles?

- 19. How Can I Stay Updated on the Latest J1939 DTC Information?

- 20. What Resources Does MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Offer for Understanding DTCs?

- 21. How Can Proper Maintenance and Diagnostics Extend Vehicle Lifespan?

- 22. What Training and Certifications are Available for Heavy-Duty Vehicle Diagnostics?

- 23. How Do Environmental Factors Impact DTCs in Heavy-Duty Vehicles?

- 24. What are the Future Trends in Heavy-Duty Vehicle Diagnostics and DTCs?

- 25. How Can Regular Software Updates Improve DTC Diagnostics?

1. What is a Diagnostic Trouble Code (DTC)?

A Diagnostic Trouble Code (DTC) is a standardized code that pinpoints malfunctions within a vehicle’s systems. These codes are essential for diagnosing issues, enabling technicians and vehicle owners to identify and address problems efficiently. DTCs are generated by the vehicle’s On-Board Diagnostics (OBD) system when it detects a fault, alerting the driver through a check engine light or other warning indicators. By understanding DTCs, you can proactively maintain your vehicle and prevent costly repairs.

2. What are OBD-II and J1939 Standards?

There are primarily two main standards used to read DTCs in vehicles: OBD-II and J1939. OBD-II is commonly used for light- and medium-duty vehicles, while J1939 is designed for heavy-duty vehicles and equipment. The Society of Automotive Engineers (SAE) established a standard DTC list with the implementation of OBD-II, which includes codes common across various manufacturers. However, manufacturers may also create specific DTCs to supplement the universal list, which can be challenging to interpret without specialized knowledge.

- OBD-II (On-Board Diagnostics II): This standard is used in most cars and light trucks manufactured and sold in the United States after January 1, 1996. OBD-II provides a standardized interface for accessing diagnostic information, including DTCs, from the vehicle’s computer system.

- J1939: This standard is used primarily in heavy-duty vehicles and equipment, such as diesel engine vehicles, trucks, and buses. J1939 is a high-speed communication protocol that allows various electronic control units (ECUs) within the vehicle to communicate with each other.

OBD II Scanner

OBD II Scanner

3. How Do I Determine if My Vehicle is OBD-II or J1939 Compliant?

Determining whether your vehicle is OBD-II or J1939 compliant is essential for proper diagnostics. Generally, cars and light trucks built and sold in the United States after January 1, 1996, are OBD-II compliant. Most diesel engine manufactured vehicles and heavy-duty equipment follow the J1939 standard.

If you’re uncertain, consult your vehicle manual, conduct online research, or seek confirmation from your dealership to ensure compatibility. Knowing this distinction will help you choose the appropriate diagnostic tools and interpret the DTCs accurately.

4. What is the Structure of an OBD-II DTC?

Understanding the structure of an OBD-II DTC is crucial for accurate diagnosis. Each DTC is five characters long, providing specific information about the vehicle’s problem. Here’s a breakdown:

- First Character (Letter): Indicates the control system with an issue.

- P (Powertrain): Engine, transmission, fuel system, and related accessories.

- C (Chassis): Steering, suspension, braking, and other mechanical systems outside the passenger compartment.

- B (Body): Parts primarily found in the passenger compartment area.

- U (Network): Onboard computers and related systems.

- Second Character (Digit): Shows whether the code is standardized.

- 0: Generic, standardized SAE code.

- 1: Vehicle manufacturer-specific code.

- 2 or 3: Typically manufacturer-specific, but meanings depend on the preceding letter.

- Third Character (Digit 1-8): Reveals the subsystem at fault.

- 1: Fuel or air metering system.

- 2: Fuel or air metering injection system.

- 3: Ignition system.

- 4: Emissions system.

- 5: Vehicle speed controls and idle control system.

- 6: Computer output circuit.

- 7 and 8: Transmission-related issues.

- Fourth and Fifth Characters (Digits 0-99): Known as the specific fault index, identifying the exact issue.

Consult your vehicle manufacturer or manual for detailed explanations if unsure about the code’s meaning.

5. How Do I Interpret an OBD-II DTC?

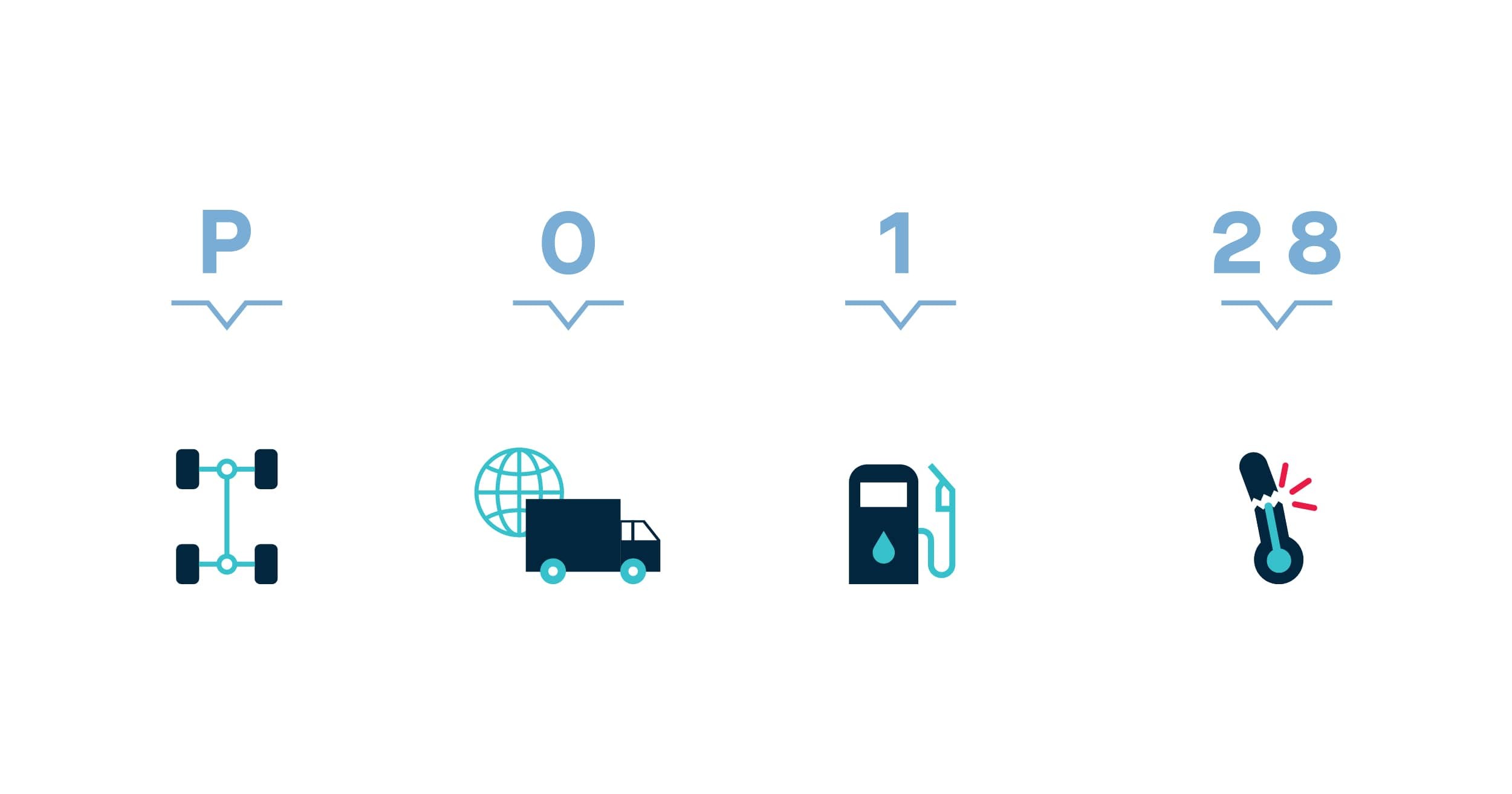

Interpreting an OBD-II DTC involves understanding each character’s meaning to pinpoint the specific malfunction. For example, the DTC P0128 can be interpreted as follows:

- P: Indicates the issue lies within the powertrain.

- 0: Signifies that the code is not manufacturer-specific and is a standardized SAE code.

- 1: Reveals that the issue is within the fuel and air metering subsystem.

- 28: The specific fault index.

Therefore, P0128 indicates an issue with the engine coolant temperature being below the thermostat regulating temperature. This structured approach enables a clear understanding of the problem and facilitates targeted repairs.

6. What are Some Common OBD-II DTCs?

Certain OBD-II DTCs appear more frequently than others. Here are some common DTCs and their corresponding malfunctions:

- P0442: Small leak in the vehicle’s evaporative emission control system.

- P0606: Malfunction in the powertrain control module (PCM) or engine control module (ECM).

- P0101: Fault in the mass air flow (MAF) sensor or circuit.

- P0110: Malfunction in the intake air temperature sensor circuit.

- P0500: Vehicle speed sensor malfunction.

- P0706: Fault in the transmission range sensor circuit range.

While DTCs help identify malfunctions, further diagnosis by a qualified mechanic is essential to determine and address the underlying cause.

7. How Does the DTC Format Differ for Heavy-Duty Vehicles (J1939)?

The DTC format for heavy-duty vehicles using the J1939 standard differs significantly from the OBD-II format. A J1939 DTC contains four key fields that relay information about the reported fault. These fields are:

- Suspect Parameter Number (SPN): Represents the specific parameter with an error. Each defined SPN can be used in a DTC.

- Failure Mode Identifier (FMI): Indicates the nature and type of error that occurred, such as value range violation (high or low), sensor short-circuits, incorrect update rate, or calibration error.

- Occurrence Counter (OC): A counter that tracks the number of times the error condition has occurred for each SPN. It stores this count even when the error is no longer active.

- SPN Conversion Method (CM): Defines the byte alignment within the DTC. A value of “0” represents the standard method shown in the DTC structure. A value of “1” indicates a distinction between three previously valid methods that must be known for the system.

Understanding these fields is crucial for accurately diagnosing issues in heavy-duty vehicles.

8. What are the Key Components of a J1939 DTC?

A J1939 DTC is structured with four essential components that provide a comprehensive overview of the fault. These components are the Suspect Parameter Number (SPN), Failure Mode Identifier (FMI), Occurrence Counter (OC), and SPN Conversion Method (CM). Each component plays a critical role in identifying and interpreting the error, allowing for precise diagnostics.

- Suspect Parameter Number (SPN): This identifies the specific parameter that has encountered an error. For instance, it could refer to engine temperature, oil pressure, or fuel level. Every defined SPN can be used within a DTC to pinpoint the source of the problem.

- Failure Mode Identifier (FMI): This describes the type and nature of the error. It might indicate a value range violation (either too high or too low), a sensor short-circuit, an incorrect update rate, or a calibration error. The FMI helps to understand how the parameter failed.

- Occurrence Counter (OC): The OC is a counter that keeps track of how many times the error condition has occurred for a specific SPN. This count is stored even when the error is no longer actively present, providing valuable historical data.

- SPN Conversion Method (CM): The CM defines the byte alignment within the DTC. A value of “0” indicates the standard method as shown in a typical DTC structure. A value of “1” signals that there are distinctions among three previously valid methods, which the system needs to recognize.

9. How Do SPN and FMI Contribute to J1939 DTC Interpretation?

SPN (Suspect Parameter Number) and FMI (Failure Mode Identifier) are crucial for interpreting J1939 DTCs. The SPN identifies the specific parameter that is experiencing an issue, while the FMI describes the nature of the fault.

For example, if an SPN indicates “Engine Oil Pressure” and the FMI indicates “Low,” the DTC is signaling that the engine oil pressure is too low. This combination provides a clear and specific diagnosis, enabling technicians to address the issue effectively.

10. Can you provide examples of SPN and FMI combinations and their meanings?

Certainly, here are some examples of SPN and FMI combinations and their meanings within the J1939 DTC context:

-

SPN: 100 (Engine Oil Pressure)

-

FMI: 3 (Voltage Above Normal or Shorted High)

- Meaning: The engine oil pressure sensor is reporting a voltage level that is higher than the normal operating range, which could indicate a short circuit in the sensor or its wiring.

-

-

SPN: 94 (Fuel Delivery Pressure)

-

FMI: 4 (Voltage Below Normal or Shorted Low)

- Meaning: The fuel delivery pressure sensor is reporting a voltage level that is lower than the normal operating range, which might suggest a short circuit to ground in the sensor or its wiring.

-

-

SPN: 102 (Intake Manifold #1 Pressure)

-

FMI: 1 (Data Valid But Below Normal Operating Range – Most Severe Level)

- Meaning: The intake manifold pressure is valid but lower than the normal operating range, indicating a significant issue such as a severe leak or restriction in the intake system.

-

-

SPN: 110 (Engine Coolant Temperature)

-

FMI: 0 (Data Valid But Above Normal Operating Range – Most Severe Level)

- Meaning: The engine coolant temperature is valid but higher than the normal operating range, suggesting overheating which could be due to a failing thermostat, radiator issues, or coolant leaks.

-

-

SPN: 513 (EGR Valve Position)

-

FMI: 13 (Out of Calibration)

- Meaning: The EGR (Exhaust Gas Recirculation) valve position is out of calibration, indicating that the valve is not operating within its specified parameters, which can affect emissions and engine performance.

-

-

SPN: 620 (Vehicle Speed)

-

FMI: 2 (Data Erratic, Intermittent, or Incorrect)

- Meaning: The vehicle speed data is erratic, intermittent, or incorrect, which could stem from a faulty speed sensor, wiring issues, or problems with the vehicle’s ECU (Engine Control Unit).

-

These examples show how SPN and FMI work together to give a precise understanding of the problem. The SPN identifies what parameter is affected, while the FMI details how it is affected. This detailed information is crucial for diagnosing and fixing problems in heavy-duty vehicles.

11. What Role Does the Occurrence Counter (OC) Play in Diagnosing J1939 DTCs?

The Occurrence Counter (OC) plays a significant role in diagnosing J1939 DTCs by tracking the frequency of error occurrences for each SPN. This historical data helps technicians understand whether the issue is intermittent or persistent, aiding in targeted diagnostics. A high OC value indicates a recurring problem that requires immediate attention, while a low value might suggest a transient issue.

12. How Does the SPN Conversion Method (CM) Affect DTC Interpretation?

The SPN Conversion Method (CM) affects DTC interpretation by defining the byte alignment within the DTC. A CM value of “0” represents the standard method, while a value of “1” indicates that the system must distinguish between three previously valid methods. Understanding the CM ensures that the DTC is correctly interpreted, as different methods can alter the meaning of the data.

13. What Tools Can Fleet Managers Use to Read J1939 DTCs?

Fleet managers have several options for reading J1939 DTCs, including:

- OBD-II Scanners: While primarily designed for OBD-II, some advanced scanners can also read J1939 codes with the appropriate adapters.

- Dedicated J1939 Scanners: These scanners are specifically designed for heavy-duty vehicles and provide comprehensive diagnostic capabilities for J1939 systems.

- Telematics Solutions: Fleet management solutions like Samsara offer vehicle gateways that plug directly into the vehicle’s J1939 port, relaying DTC information to a centralized dashboard.

These tools help fleet managers efficiently monitor vehicle health and schedule maintenance as needed.

14. How Can Telematics Solutions Simplify DTC Management?

Telematics solutions streamline DTC management by providing real-time data and automated alerts. These systems, like Samsara, use vehicle gateways that plug directly into the OBD-II or J1939 port, transmitting DTC information to a centralized dashboard. This allows fleet managers to:

- Receive instant notifications of DTC occurrences via alerts.

- Quickly identify issues and schedule maintenance.

- Filter DTCs to focus on the most critical alerts.

This proactive approach ensures timely maintenance, reduces downtime, and enhances overall fleet efficiency.

15. What are the Benefits of Using a Telematics Solution for DTC Monitoring?

Using a telematics solution for DTC monitoring offers several benefits:

- Real-Time Data: Access immediate DTC information for quick diagnostics.

- Automated Alerts: Receive notifications when DTCs occur, ensuring timely intervention.

- Remote Diagnostics: Monitor vehicle health remotely, reducing the need for manual checks.

- Efficient Maintenance Scheduling: Streamline maintenance scheduling based on DTC alerts, minimizing downtime.

- Improved Fleet Efficiency: Enhance overall fleet operations through proactive vehicle health management.

These advantages make telematics solutions invaluable for fleet managers aiming to optimize vehicle performance and reduce maintenance costs.

16. What is the Role of Diagnostic Software in Interpreting J1939 DTCs?

Diagnostic software plays a critical role in interpreting J1939 DTCs by providing detailed information about the error, potential causes, and recommended solutions. This software often includes:

- DTC Definitions: Comprehensive descriptions of SPNs and FMIs.

- Troubleshooting Guides: Step-by-step instructions for diagnosing and resolving issues.

- Wiring Diagrams: Visual aids for tracing electrical faults.

- Data Logging: Recording vehicle data for in-depth analysis.

By leveraging diagnostic software, technicians can accurately interpret DTCs, identify root causes, and perform effective repairs.

17. How Does Proper Interpretation of J1939 DTCs Prevent Costly Repairs?

Proper interpretation of J1939 DTCs prevents costly repairs by enabling accurate and timely diagnostics. By understanding the specific fault indicated by the DTC, technicians can:

- Identify the Root Cause: Pinpoint the underlying issue rather than just addressing the symptom.

- Perform Targeted Repairs: Avoid unnecessary part replacements and labor costs.

- Prevent Further Damage: Address issues before they escalate into more significant problems.

- Optimize Maintenance Schedules: Ensure timely maintenance to prevent breakdowns and extend vehicle lifespan.

This proactive approach reduces downtime, minimizes repair expenses, and enhances overall fleet efficiency.

18. What are Some Common J1939 DTCs in Heavy-Duty Vehicles?

Some common J1939 DTCs encountered in heavy-duty vehicles include:

- SPN 100 FMI 1: Low Engine Oil Pressure

- SPN 94 FMI 4: Low Fuel Delivery Pressure

- SPN 110 FMI 0: High Engine Coolant Temperature

- SPN 513 FMI 13: EGR Valve Out of Calibration

- SPN 620 FMI 2: Erratic Vehicle Speed Data

These codes indicate common issues related to engine performance, fuel delivery, cooling systems, and vehicle speed, requiring prompt attention to maintain vehicle health.

19. How Can I Stay Updated on the Latest J1939 DTC Information?

Staying updated on the latest J1939 DTC information is essential for accurate diagnostics and effective maintenance. Here are several ways to remain informed:

- Subscribe to Industry Publications: Follow reputable industry publications and newsletters that cover the latest advancements in heavy-duty vehicle diagnostics and J1939 standards.

- Attend Training Seminars: Participate in training seminars and workshops offered by industry experts and manufacturers. These sessions provide in-depth knowledge and hands-on experience with J1939 systems.

- Join Online Forums: Engage with online forums and communities where technicians and fleet managers share their experiences and insights on J1939 DTCs.

- Use Diagnostic Software: Utilize diagnostic software that regularly updates its DTC database to reflect the latest changes and additions to the J1939 standard.

- Consult Manufacturer Resources: Refer to manufacturer resources, such as service manuals and technical bulletins, for the most accurate and up-to-date information on J1939 DTCs specific to your vehicle make and model.

- Follow Regulatory Updates: Keep track of regulatory updates and compliance requirements related to J1939 standards, as these can impact diagnostic procedures and DTC interpretations.

By employing these strategies, you can ensure that you have the most current and reliable information for diagnosing and resolving J1939 DTCs, leading to improved vehicle performance and reduced downtime.

20. What Resources Does MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Offer for Understanding DTCs?

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides a range of resources to help you understand DTCs and effectively diagnose and maintain your Mercedes-Benz:

- Detailed Articles: Comprehensive articles covering OBD-II and J1939 DTCs, their structure, and interpretation.

- Diagnostic Guides: Step-by-step guides for diagnosing common issues and performing targeted repairs.

- Software Recommendations: Reviews and recommendations for diagnostic software that supports J1939 DTC interpretation.

- Expert Support: Access to expert advice and assistance for complex diagnostic challenges.

- Training Materials: Educational materials and training programs to enhance your diagnostic skills.

By leveraging these resources, you can confidently tackle DTC-related issues and ensure the optimal performance of your Mercedes-Benz.

21. How Can Proper Maintenance and Diagnostics Extend Vehicle Lifespan?

Proper maintenance and diagnostics are crucial for extending vehicle lifespan. Regular maintenance, guided by accurate diagnostics, helps prevent major issues and ensures that all systems are functioning optimally. By addressing problems early, you can:

- Reduce Wear and Tear: Prevent excessive strain on vehicle components.

- Optimize Performance: Maintain fuel efficiency and overall performance.

- Prevent Breakdowns: Minimize the risk of unexpected breakdowns and downtime.

- Extend Component Lifespan: Ensure that parts last longer through timely maintenance and repairs.

This proactive approach not only keeps your vehicle running smoothly but also protects your investment by prolonging its lifespan.

22. What Training and Certifications are Available for Heavy-Duty Vehicle Diagnostics?

Several training and certification programs are available for heavy-duty vehicle diagnostics, enhancing your expertise in diagnosing and repairing complex systems. Some notable options include:

- ASE Certifications: The National Institute for Automotive Service Excellence (ASE) offers certifications in various areas of heavy-duty vehicle repair, including diesel engines, brakes, and electrical systems.

- Manufacturer-Specific Training: Many heavy-duty vehicle manufacturers, such as Daimler Trucks North America and Volvo Trucks, provide specialized training programs for their vehicles. These programs cover diagnostics, repair procedures, and the use of proprietary diagnostic tools.

- SAE Professional Development Programs: The Society of Automotive Engineers (SAE) offers professional development programs focused on vehicle diagnostics, J1939 standards, and related topics.

- Community College and Vocational Schools: Local community colleges and vocational schools often provide courses and certifications in diesel technology and heavy-duty vehicle repair.

- Online Training Courses: Numerous online platforms offer training courses on heavy-duty vehicle diagnostics, allowing you to learn at your own pace.

- OEM Diagnostic Tool Training: Original Equipment Manufacturers (OEMs) provide training on the use of their diagnostic tools, ensuring technicians can accurately diagnose and repair vehicles using the latest technology.

By pursuing these training and certification opportunities, technicians and fleet managers can gain the knowledge and skills necessary to effectively diagnose and maintain heavy-duty vehicles, leading to improved vehicle performance and reduced downtime.

23. How Do Environmental Factors Impact DTCs in Heavy-Duty Vehicles?

Environmental factors significantly impact DTCs in heavy-duty vehicles. Extreme temperatures, humidity, and road conditions can trigger various DTCs, affecting vehicle performance and longevity.

- Temperature Extremes: High temperatures can cause overheating and trigger DTCs related to the cooling system. Cold temperatures can affect battery performance and fuel efficiency, leading to DTCs related to the fuel and ignition systems.

- Humidity: High humidity can cause corrosion in electrical connectors and sensors, resulting in inaccurate readings and DTCs related to the electrical system.

- Road Conditions: Rough roads and off-road driving can damage suspension components and trigger DTCs related to the chassis and braking systems.

- Air Quality: Poor air quality and high levels of pollutants can affect the performance of the engine and emissions systems, leading to DTCs related to the powertrain and emissions control.

Understanding these environmental factors and their impact on DTCs is essential for effective diagnostics and maintenance.

24. What are the Future Trends in Heavy-Duty Vehicle Diagnostics and DTCs?

The future of heavy-duty vehicle diagnostics and DTCs is evolving rapidly, driven by advancements in technology and increasing regulatory requirements. Some key trends include:

- Predictive Maintenance: Using data analytics and machine learning to predict potential failures and schedule maintenance proactively.

- Remote Diagnostics: Enabling remote access to vehicle diagnostic data for faster and more efficient troubleshooting.

- Over-the-Air (OTA) Updates: Providing software updates and enhancements to vehicle systems remotely, reducing the need for physical visits to service centers.

- Enhanced Cybersecurity: Implementing robust cybersecurity measures to protect vehicle systems from unauthorized access and cyberattacks.

- Standardization of DTCs: Continuing efforts to standardize DTCs across different manufacturers to simplify diagnostics and reduce complexity.

- Integration with IoT: Connecting vehicles to the Internet of Things (IoT) to enable seamless data sharing and integration with other systems.

These trends will transform heavy-duty vehicle diagnostics and maintenance, leading to improved vehicle performance, reduced downtime, and lower operating costs.

25. How Can Regular Software Updates Improve DTC Diagnostics?

Regular software updates are essential for improving DTC diagnostics in modern vehicles. These updates:

- Enhance Diagnostic Accuracy: Incorporate the latest DTC definitions and troubleshooting procedures.

- Improve System Performance: Optimize vehicle systems to reduce the likelihood of DTCs.

- Address Known Issues: Resolve software glitches and known issues that can trigger false DTCs.

- Support New Features: Enable compatibility with new vehicle features and technologies.

- Enhance Security: Protect vehicle systems from cyber threats and unauthorized access.

By ensuring that your vehicle’s software is up to date, you can optimize DTC diagnostics and maintain peak performance.

Understanding the nuances of DTC formats for heavy-duty vehicles using the J1939 standard is crucial for maintaining your Mercedes-Benz. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides comprehensive insights and resources to help you interpret these codes effectively, ensuring accurate diagnostics and efficient repairs.

Need expert guidance on diagnosing your Mercedes-Benz? Contact us today for personalized support and solutions.

Address: 789 Oak Avenue, Miami, FL 33101, United States

WhatsApp: +1 (641) 206-8880

Website: MERCEDES-DIAGNOSTIC-TOOL.EDU.VN