Yes, there is a way to read the Diagnostic Trouble Code (DTC) that caused the Malfunction Indicator Lamp (MIL) to illuminate, and MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers comprehensive solutions for Mercedes-Benz vehicles. By understanding and addressing these codes efficiently, you can maintain optimal vehicle performance and avoid costly repairs with proper Mercedes diagnostic information, Mercedes error code readers, and Mercedes check engine light solutions.

Contents

- 1. Understanding Diagnostic Trouble Codes (DTCs)

- 1.1. What is a DTC?

- 1.2. Origin and Standardization of DTCs

- 1.3. The Importance of Standardization

- 1.4. Manufacturer-Specific DTCs

- 1.5. OBD-II vs. J1939 Compliance

- 2. Decoding OBD-II DTCs: A Comprehensive Guide

- 2.1. Understanding the Structure of an OBD-II DTC

- 2.2. The First Character: Identifying the Control System

- 2.3. The Second Character: Standardized vs. Manufacturer-Specific Codes

- 2.4. The Third Character: Pinpointing the Subsystem

- 2.5. The Fourth and Fifth Characters: The Specific Fault Index

- 2.6. Example: Interpreting DTC P0128

- 2.7. Resources for DTC Interpretation

- 3. Common DTCs and Their Meanings

- 3.1. Overview of Frequent Diagnostic Trouble Codes

- 3.2. Listing Common DTCs

- 3.3. Detailed Explanation of Selected DTCs

- 3.4. Importance of Further Diagnosis

- 4. Reading J1939 DTCs: A Guide for Heavy-Duty Vehicles

- 4.1. Introduction to J1939 DTCs

- 4.2. Key Fields in a J1939 DTC

- 4.3. Detailed Explanation of J1939 DTC Fields

- 4.4. Interpreting a J1939 DTC Example

- 4.5. Resources for J1939 DTC Interpretation

- 5. DTC Scan Tools for Efficient Fleet Management

- 5.1. The Challenge of Managing Fleet Vehicle Diagnostics

- 5.2. The Benefits of Telematics Solutions

- 5.3. Features of Effective DTC Scan Tools

- 5.4. How Telematics Simplifies DTC Management

- 5.5. Example: Using Telematics for DTC Management

- 5.6. Solutions Offered by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

- 6. Leveraging Telematics for Easy DTC Interpretation

- 6.1. The Role of Telematics in Understanding DTCs

- 6.2. Key Features of Telematics Systems for DTC Management

- 6.3. How Telematics Simplifies DTC Interpretation

- 6.4. Benefits of Using Telematics for DTC Management

- 6.5. Telematics Solutions Offered by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

- 6.6. Real-World Application of Telematics for DTC Management

- 6.7. Contacting MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Telematics Solutions

- 7. Advanced Diagnostic Tools for Mercedes-Benz Vehicles

- 7.1. Overview of Advanced Diagnostic Tools

- 7.2. Key Features of Advanced Diagnostic Tools

- 7.3. Specific Diagnostic Tools for Mercedes-Benz

- 7.4. Benefits of Using Advanced Diagnostic Tools

- 7.5. Advanced Diagnostic Services at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

- 7.6. Real-World Application of Advanced Diagnostic Tools

- 7.7. Contacting MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Diagnostic Services

- 8. Step-by-Step Guide to Reading DTCs on a Mercedes-Benz

- 8.1. Preparing to Read DTCs

- 8.2. Required Tools and Equipment

- 8.3. Step-by-Step Instructions

- 8.4. Additional Tips and Considerations

- 8.5. Benefits of Using MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Resources

- 8.6. Contacting MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Assistance

- 9. Opening Hidden Features on Mercedes-Benz Vehicles

- 9.1. What are Hidden Features?

- 9.2. Examples of Hidden Features

- 9.3. Tools and Software Required

- 9.4. Step-by-Step Guide to Unlocking Hidden Features

- 9.5. Precautions and Risks

- 9.6. Services Offered by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

- 9.7. Contacting MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Assistance

- 10. Regular Maintenance Tips for Mercedes-Benz Vehicles

- 10.1. The Importance of Regular Maintenance

- 10.2. Key Maintenance Tasks

- 10.3. Recommended Maintenance Schedule

- 10.4. Benefits of Following a Maintenance Schedule

- 10.5. Maintenance Services Offered by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

- 10.6. Real-World Application of Regular Maintenance

1. Understanding Diagnostic Trouble Codes (DTCs)

1.1. What is a DTC?

A Diagnostic Trouble Code (DTC) is a standardized code used to identify specific malfunctions within a vehicle’s systems. When the Malfunction Indicator Lamp (MIL), commonly known as the check engine light, illuminates, it signals that the vehicle’s onboard diagnostic system has detected an issue. The DTC provides crucial information about the nature and location of the problem. According to a study by the National Institute for Automotive Service Excellence (ASE), accurately interpreting DTCs is essential for effective vehicle repair. DTCs are also referred to as engine vehicle fault codes, which can be read using specialized scanners that connect directly to the vehicle’s diagnostic port.

1.2. Origin and Standardization of DTCs

DTCs are generated by the vehicle’s On-Board Diagnostics (OBD) system whenever a fault is detected. The OBD system diagnoses the fault and displays the DTC through visible warnings, such as the check engine light. It also allows external devices, like OBD scanners, to interact with the vehicle’s computer system.

Over the years, OBD interfaces evolved, with early versions (OBD-I) varying significantly between manufacturers. Today, two main standards are used for reading DTCs:

- OBD-II: Suitable for light- and medium-duty vehicles.

- J1939: Designed for heavy-duty vehicles and equipment.

The Society of Automotive Engineers (SAE) created a standardized DTC list with the implementation of OBD-II, which includes codes common to all manufacturers.

1.3. The Importance of Standardization

Standardization is a critical aspect of DTCs because it allows technicians and vehicle owners to understand and address issues using a common language, regardless of the vehicle manufacturer. According to research published by SAE International, standardized DTCs have significantly improved the efficiency of vehicle diagnostics and repairs. This standardization ensures that a P0300 code, indicating a random or multiple cylinder misfire, means the same thing across different vehicle brands, making it easier for mechanics to diagnose and fix the problem.

1.4. Manufacturer-Specific DTCs

While OBD-II promotes standardization, manufacturers can create their own DTCs to supplement the universal list if the vehicle requires it. These manufacturer-specific codes are often more difficult to interpret without specialized knowledge or tools. For Mercedes-Benz vehicles, having access to manufacturer-specific DTC definitions can be invaluable for accurate diagnostics. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides resources and tools that help interpret both standardized and manufacturer-specific DTCs, ensuring a comprehensive understanding of any issues your Mercedes-Benz may be experiencing.

1.5. OBD-II vs. J1939 Compliance

- OBD-II Compliance: Cars and light trucks built and sold in the United States after January 1, 1996, are required to be OBD-II equipped.

- J1939 Compliance: Most diesel engine manufactured vehicles or equipment are J1939 compliant and is the industry standard for most heavy-duty trucks and buses.

If unsure about your vehicle’s compliance, check the vehicle manual, research online, or consult with a dealership.

2. Decoding OBD-II DTCs: A Comprehensive Guide

2.1. Understanding the Structure of an OBD-II DTC

OBD-II DTCs are five characters long, with each character providing specific information about the vehicle’s problem. This structured format allows technicians to quickly identify the area and nature of the fault. According to the Environmental Protection Agency (EPA), this standardized structure has significantly improved the accuracy and speed of vehicle diagnostics.

2.2. The First Character: Identifying the Control System

The first character of a DTC is always a letter that indicates which control system has an issue:

- P (Powertrain): Refers to the engine, transmission, fuel system, and associated accessories.

- C (Chassis): Refers to mechanical systems generally outside the passenger compartment, such as steering, suspension, and braking.

- B (Body): Refers to parts mainly found in the passenger compartment area.

- U (Network): Refers to the vehicle’s onboard computers and related systems.

2.3. The Second Character: Standardized vs. Manufacturer-Specific Codes

The second character is a digit, typically 0 or 1, indicating whether the code is standardized or manufacturer-specific:

- 0: Indicates a generic, standardized SAE code adopted by all cars following the OBD-II standard.

- 1: Indicates a vehicle manufacturer-specific code unique to a specific car make or model.

- 2 or 3: More rare, with meanings dependent on the preceding letter. Generally, they indicate manufacturer-specific codes, with few exceptions.

2.4. The Third Character: Pinpointing the Subsystem

The third character is a digit ranging from 1 to 8, revealing the subsystem at fault:

- 1: Fuel or air metering system.

- 2: Fuel or air metering injection system.

- 3: Ignition system.

- 4: Emissions system.

- 5: Vehicle speed controls and idle control system.

- 6: Computer output circuit.

- 7 and 8: Transmission-related issues.

2.5. The Fourth and Fifth Characters: The Specific Fault Index

The fourth and fifth characters are read together as a two-digit number between 0 and 99, known as the specific fault index. These characters identify the exact issue within the subsystem. For example, a code of P0171 indicates a lean fuel mixture on bank 1. Consulting the vehicle manufacturer’s service manual or a comprehensive DTC database is crucial for accurate interpretation.

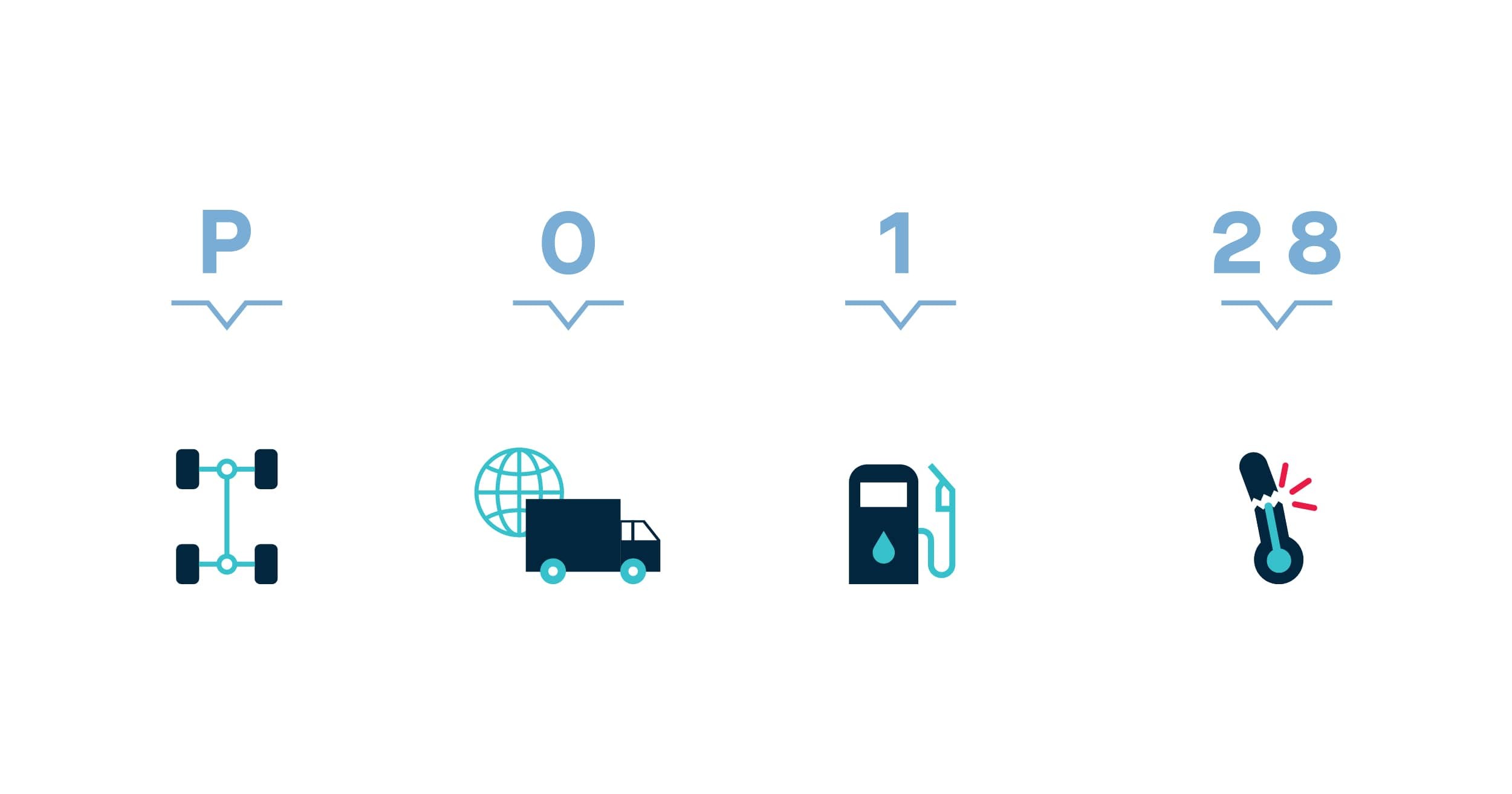

2.6. Example: Interpreting DTC P0128

Let’s break down the common DTC P0128:

- P: The issue lies in the powertrain.

- 0: The code is not manufacturer-specific; it is a standardized SAE code.

- 1: The issue is within the fuel and air metering subsystem.

- 28: The specific fault index.

Based on this, P0128 refers to an issue with the engine coolant temperature being below the thermostat regulating temperature. This detailed breakdown illustrates how each character contributes to a comprehensive understanding of the problem.

2.7. Resources for DTC Interpretation

For unsure code meanings, check with your vehicle manufacturer or vehicle manual for detailed explanations. Platforms like MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offer comprehensive databases and resources for interpreting DTCs, including manufacturer-specific codes. Access to detailed repair guides and technical service bulletins can further aid in diagnosing and resolving the underlying issues.

3. Common DTCs and Their Meanings

3.1. Overview of Frequent Diagnostic Trouble Codes

Certain DTCs appear more frequently than others, indicating common issues across various vehicle models. Understanding these common codes can help vehicle owners and technicians quickly identify and address prevalent problems. A survey by AAA revealed that misfires and emission system faults are among the most common issues reported by vehicle owners.

3.2. Listing Common DTCs

Here are some common DTCs and their corresponding malfunctions:

- P0442: Small system leak in the vehicle’s evaporative emission control system.

- P0606: Malfunction in the powertrain control module (PCM), also known as the engine control module (ECM).

- P0101: Fault in the mass air flow (MAF) sensor or circuit.

- P0110: Malfunction in the intake air temperature sensor circuit.

- P0500: Vehicle speed sensor malfunction.

- P0706: Fault in the transmission range sensor circuit range.

3.3. Detailed Explanation of Selected DTCs

Let’s delve deeper into a few of these common codes:

- P0442 (Evaporative Emission Control System Leak): This code indicates a small leak in the evaporative emission control system, which prevents fuel vapors from escaping into the atmosphere. Common causes include a loose or faulty gas cap, damaged vapor lines, or a malfunctioning purge valve. Regular inspection and maintenance of the fuel cap and vapor lines can help prevent this issue.

- P0101 (Mass Air Flow Sensor Circuit Range/Performance Problem): The mass air flow (MAF) sensor measures the amount of air entering the engine, which the engine control unit (ECU) uses to calculate the correct fuel mixture. A P0101 code can result from a dirty or failing MAF sensor, intake leaks, or wiring issues. Cleaning the MAF sensor or replacing it can often resolve this problem.

- P0110 (Intake Air Temperature Sensor Circuit Malfunction): The intake air temperature (IAT) sensor measures the temperature of the air entering the engine. This information is used by the ECU to adjust the fuel mixture for optimal performance. A P0110 code can be caused by a faulty IAT sensor, wiring problems, or a poor connection. Replacing the IAT sensor or repairing the wiring can address this issue.

3.4. Importance of Further Diagnosis

While DTCs are useful for identifying malfunctions, they do not explain why the malfunction occurred. A vehicle needs further diagnosis by a mechanic to identify and address the cause of the issue. According to a study by the Automotive Research Association of India (ARAI), relying solely on DTCs without further investigation can lead to misdiagnosis and ineffective repairs. Professional diagnostic tools and expertise are often necessary to pinpoint the root cause of the problem and implement the appropriate solution.

4. Reading J1939 DTCs: A Guide for Heavy-Duty Vehicles

4.1. Introduction to J1939 DTCs

J1939 is a communication protocol used in heavy-duty vehicles and equipment for transmitting diagnostic and control information. Unlike OBD-II, which is primarily used in light- and medium-duty vehicles, J1939 is designed to handle the more complex systems found in trucks, buses, and construction equipment. Understanding J1939 DTCs is essential for maintaining and repairing these vehicles effectively.

4.2. Key Fields in a J1939 DTC

A J1939 DTC contains four fields that relay information about the fault being reported:

- Suspect Parameter Number (SPN): Represents the SPN with the error. Every defined SPN can be used in a DTC.

- Failure Mode Identifier (FMI): Represents the nature and type of error that occurred (e.g., value range violation, sensor short-circuits, incorrect update rate, calibration error).

- Occurrence Counter (OC): A counter that tracks the number of times the error condition has occurred for each SPN, even when the error is no longer active.

- SPN Conversion Method (CM): Defines the byte alignment within the DTC. A value of “0” represents the standard method, while a value of “1” indicates one of three previously valid methods.

4.3. Detailed Explanation of J1939 DTC Fields

-

Suspect Parameter Number (SPN): The SPN identifies the specific component or system that is experiencing the fault. For example, an SPN might indicate a problem with the engine coolant temperature sensor or the fuel injection system. Each SPN is associated with a specific parameter defined by the SAE J1939 standard.

-

Failure Mode Identifier (FMI): The FMI provides information about the type of failure that has occurred. Common FMIs include:

- FMI 0: Data valid but above normal operational range (most severe level).

- FMI 1: Data valid but below normal operational range (most severe level).

- FMI 3: Voltage above normal or shorted to high source.

- FMI 4: Voltage below normal or shorted to low source.

- FMI 5: Current below normal or open circuit.

- FMI 6: Current above normal or grounded circuit.

-

Occurrence Counter (OC): The OC is a valuable tool for diagnosing intermittent issues. By tracking the number of times a fault has occurred, technicians can identify patterns and potential underlying causes. This is particularly useful for diagnosing issues that may not be present during a diagnostic test.

-

SPN Conversion Method (CM): The CM defines how the data is aligned within the DTC message. Understanding the conversion method is essential for correctly interpreting the DTC information.

4.4. Interpreting a J1939 DTC Example

Consider a J1939 DTC with the following values:

- SPN: 108 (Atmospheric Pressure)

- FMI: 4 (Voltage below normal or shorted to low source)

- OC: 2

- CM: 0

This DTC indicates that the atmospheric pressure sensor has a voltage below the normal range or is shorted to a low source. The occurrence counter shows that this fault has occurred twice. This information helps technicians focus on the atmospheric pressure sensor and its associated wiring to diagnose and resolve the issue.

4.5. Resources for J1939 DTC Interpretation

Interpreting J1939 DTCs requires access to comprehensive diagnostic tools and resources. The SAE J1939 standard provides detailed information about SPNs, FMIs, and other diagnostic parameters. Additionally, many diagnostic software tools and databases offer J1939 DTC lookup capabilities, allowing technicians to quickly identify the meaning of specific codes. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides advanced diagnostic tools compatible with J1939 protocols, enabling precise diagnostics for heavy-duty Mercedes-Benz vehicles.

5. DTC Scan Tools for Efficient Fleet Management

5.1. The Challenge of Managing Fleet Vehicle Diagnostics

Fleet managers responsible for numerous vehicles face the challenge of efficiently monitoring and maintaining their fleet. Manually checking each vehicle every time the check engine light illuminates can be time-consuming and inefficient. A proactive approach to vehicle diagnostics is essential for minimizing downtime and reducing maintenance costs.

5.2. The Benefits of Telematics Solutions

Telematics solutions offer a streamlined approach to fleet management by providing real-time vehicle data, including DTCs. These systems use vehicle gateways that plug directly into the OBD-II or J1939 port and transmit data to a central dashboard. This allows fleet managers to remotely monitor vehicle health and receive alerts when DTCs occur. According to a report by Berg Insight, the adoption of telematics solutions in fleet management has led to significant improvements in vehicle uptime and operational efficiency.

5.3. Features of Effective DTC Scan Tools

When selecting a telematics solution for fleet management, consider the following features:

- Real-time DTC Monitoring: The ability to monitor DTCs in real-time allows for immediate detection of vehicle issues.

- Customizable Alerts: Setting up alerts for specific DTCs enables fleet managers to prioritize critical issues and take prompt action.

- DTC Filtering: Filtering DTCs by severity or vehicle type helps focus on the most important problems.

- Comprehensive Reporting: Detailed reports provide insights into vehicle health trends and maintenance needs.

- Integration with Maintenance Systems: Integration with maintenance scheduling and tracking systems streamlines the repair process.

5.4. How Telematics Simplifies DTC Management

Telematics solutions simplify DTC management by automating the process of data collection and analysis. Instead of manually scanning each vehicle, fleet managers can rely on real-time data transmitted by the vehicle gateways. This data is displayed in an easy-to-understand dashboard, allowing for quick identification of issues and proactive maintenance scheduling.

5.5. Example: Using Telematics for DTC Management

Imagine a fleet manager receives an alert indicating that one of their vehicles has triggered a P0420 code (Catalyst System Efficiency Below Threshold). Using the telematics dashboard, the manager can quickly identify the vehicle, review the DTC details, and schedule a maintenance appointment. This proactive approach prevents the issue from escalating and potentially causing more significant damage.

5.6. Solutions Offered by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers a range of advanced diagnostic tools and telematics solutions designed for Mercedes-Benz vehicles. These tools provide real-time DTC monitoring, customizable alerts, and comprehensive reporting capabilities. By leveraging these solutions, fleet managers can efficiently maintain their Mercedes-Benz fleet and minimize downtime. Contact us at +1 (641) 206-8880 or visit our website at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN to learn more about our offerings.

OBD-II Port

OBD-II Port

6. Leveraging Telematics for Easy DTC Interpretation

6.1. The Role of Telematics in Understanding DTCs

Telematics solutions play a crucial role in simplifying the interpretation and management of DTCs. By providing real-time data and automated alerts, these systems enable vehicle owners and fleet managers to quickly identify and address vehicle issues. The integration of telematics with diagnostic tools enhances the efficiency of vehicle maintenance and reduces the risk of costly repairs.

6.2. Key Features of Telematics Systems for DTC Management

Effective telematics systems offer several key features for managing DTCs:

- Real-Time DTC Monitoring: Continuously monitors vehicle systems for faults and provides immediate alerts when DTCs are triggered.

- Automated Alerts: Sends notifications via email or mobile app when specific DTCs are detected, allowing for prompt action.

- Comprehensive DTC Database: Integrates with a comprehensive database of DTC definitions and troubleshooting guides.

- Customizable Reporting: Generates reports on vehicle health, DTC trends, and maintenance needs.

- Remote Diagnostics: Enables remote access to vehicle diagnostic data, allowing technicians to diagnose issues without physically being present.

6.3. How Telematics Simplifies DTC Interpretation

Telematics systems simplify DTC interpretation by providing clear and concise information about the nature and severity of the fault. Instead of relying on generic code readers, telematics systems often include detailed descriptions of the DTC, potential causes, and recommended solutions. This information empowers vehicle owners and fleet managers to make informed decisions about maintenance and repairs.

6.4. Benefits of Using Telematics for DTC Management

The benefits of using telematics for DTC management include:

- Reduced Downtime: Real-time monitoring and automated alerts enable proactive maintenance, reducing the risk of breakdowns and downtime.

- Lower Maintenance Costs: Early detection of issues prevents minor problems from escalating into major repairs, saving money on maintenance costs.

- Improved Vehicle Performance: Regular monitoring and maintenance ensure that vehicles operate at peak performance, improving fuel efficiency and reducing emissions.

- Enhanced Safety: Proactive identification of safety-related issues, such as brake problems or faulty sensors, enhances vehicle safety.

- Streamlined Fleet Management: Centralized data and reporting simplify fleet management tasks, such as maintenance scheduling and compliance tracking.

6.5. Telematics Solutions Offered by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers comprehensive telematics solutions designed to simplify DTC interpretation and management for Mercedes-Benz vehicles. Our systems provide real-time monitoring, automated alerts, and access to a comprehensive DTC database. By leveraging our telematics solutions, vehicle owners and fleet managers can efficiently maintain their Mercedes-Benz vehicles and minimize downtime.

6.6. Real-World Application of Telematics for DTC Management

Consider a scenario where a fleet of Mercedes-Benz vans is used for delivery services. Using a telematics system provided by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, the fleet manager can monitor the health of each vehicle in real-time. If a van triggers a P0301 code (Cylinder 1 Misfire Detected), the fleet manager receives an immediate alert. The telematics system provides detailed information about the DTC, potential causes, and recommended solutions. The fleet manager can then schedule a maintenance appointment to address the issue promptly, preventing further damage and ensuring the van remains operational.

6.7. Contacting MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Telematics Solutions

For more information about our telematics solutions and how they can help you manage DTCs in your Mercedes-Benz vehicles, please contact us at +1 (641) 206-8880 or visit our website at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN. Our team of experts can help you choose the right telematics solution for your needs and provide ongoing support to ensure you get the most out of your system. Our address is 789 Oak Avenue, Miami, FL 33101, United States.

7. Advanced Diagnostic Tools for Mercedes-Benz Vehicles

7.1. Overview of Advanced Diagnostic Tools

Advanced diagnostic tools are essential for accurately diagnosing and repairing modern vehicles, especially those with complex electronic systems like Mercedes-Benz. These tools go beyond basic code reading and provide in-depth analysis of vehicle systems, allowing technicians to pinpoint the root cause of problems. According to a study by the Automotive Management Institute (AMI), technicians who use advanced diagnostic tools are more efficient and accurate in their repairs.

7.2. Key Features of Advanced Diagnostic Tools

Key features of advanced diagnostic tools include:

- Comprehensive Code Reading: Reads and interprets both generic and manufacturer-specific DTCs.

- Live Data Streaming: Provides real-time data from vehicle sensors and systems, allowing technicians to monitor performance and identify anomalies.

- Bi-Directional Control: Enables technicians to activate and control vehicle components to test their functionality.

- Actuation Tests: Performs automated tests on various vehicle systems to verify their operation.

- Programming and Coding: Allows technicians to program and code vehicle modules, such as ECUs and TCMs.

- Oscilloscope Functionality: Provides visual representation of electrical signals, aiding in the diagnosis of electrical problems.

- Guided Diagnostics: Offers step-by-step guidance for diagnosing complex issues, based on DTCs and symptoms.

7.3. Specific Diagnostic Tools for Mercedes-Benz

Several diagnostic tools are specifically designed for Mercedes-Benz vehicles, offering enhanced capabilities and coverage. These tools include:

- Mercedes-Benz Star Diagnosis: The official diagnostic tool used by Mercedes-Benz dealerships, providing comprehensive coverage and functionality.

- Autel MaxiSys Elite: A versatile diagnostic tool that offers extensive coverage for Mercedes-Benz vehicles, including advanced functions like programming and coding.

- iCarsoft MB II: A cost-effective diagnostic tool that provides basic code reading and some advanced functions for Mercedes-Benz vehicles.

- Launch X431: A popular diagnostic tool that offers broad coverage for various vehicle makes, including Mercedes-Benz.

7.4. Benefits of Using Advanced Diagnostic Tools

The benefits of using advanced diagnostic tools include:

- Accurate Diagnosis: Pinpointing the root cause of problems with greater accuracy, reducing the risk of misdiagnosis and unnecessary repairs.

- Reduced Repair Time: Streamlining the diagnostic process, allowing technicians to identify and resolve issues more quickly.

- Enhanced Efficiency: Improving technician efficiency by providing access to comprehensive data and automated tests.

- Increased Customer Satisfaction: Providing accurate and reliable repairs, leading to greater customer satisfaction.

- Access to Advanced Functions: Enabling technicians to perform advanced functions like programming and coding, expanding their service capabilities.

7.5. Advanced Diagnostic Services at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers advanced diagnostic services for Mercedes-Benz vehicles, using state-of-the-art diagnostic tools and equipment. Our team of experienced technicians is trained to diagnose and repair even the most complex issues, ensuring that your Mercedes-Benz is running at its best.

7.6. Real-World Application of Advanced Diagnostic Tools

Consider a scenario where a Mercedes-Benz C-Class is experiencing intermittent engine stalling. A basic code reader reveals a P0087 code (Fuel Rail/System Pressure – Too Low). Using an advanced diagnostic tool, a technician can stream live data from the fuel pressure sensor, fuel pump, and other related components. By monitoring the data in real-time, the technician identifies that the fuel pump is not providing adequate pressure. The technician can then perform a bi-directional control test to activate the fuel pump and verify its operation. Based on these findings, the technician determines that the fuel pump needs to be replaced.

7.7. Contacting MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Diagnostic Services

For more information about our advanced diagnostic services and how we can help you maintain your Mercedes-Benz vehicle, please contact us at +1 (641) 206-8880 or visit our website at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN. Our address is 789 Oak Avenue, Miami, FL 33101, United States.

8. Step-by-Step Guide to Reading DTCs on a Mercedes-Benz

8.1. Preparing to Read DTCs

Before reading Diagnostic Trouble Codes (DTCs) on your Mercedes-Benz, it’s important to gather the necessary tools and information. This preparation ensures a smooth and accurate diagnostic process. According to Bosch Automotive Service Solutions, proper preparation is key to effective vehicle diagnostics.

8.2. Required Tools and Equipment

- OBD-II Scanner: A diagnostic scanner compatible with Mercedes-Benz vehicles. Ensure it supports both generic and manufacturer-specific codes.

- Vehicle Manual: Your Mercedes-Benz owner’s manual can provide valuable information about DTCs and diagnostic procedures.

- Diagnostic Software (Optional): Some advanced scanners require software installation on a laptop or mobile device.

- Battery Charger (Optional): If your vehicle’s battery is weak, a charger can prevent interruptions during the diagnostic process.

8.3. Step-by-Step Instructions

-

Locate the OBD-II Port: The OBD-II port is typically located under the dashboard on the driver’s side. Refer to your vehicle manual for the exact location.

-

Turn on the Ignition: Insert the key into the ignition and turn it to the “ON” position. Do not start the engine.

-

Connect the OBD-II Scanner: Plug the scanner into the OBD-II port. Ensure it is securely connected.

-

Power on the Scanner: Turn on the scanner and wait for it to establish a connection with the vehicle’s computer.

-

Read DTCs: Navigate the scanner menu to the “Read Codes” or “Diagnostic Codes” option. The scanner will display any stored DTCs.

-

Record the Codes: Write down each DTC along with its description. Note any freeze frame data, which provides information about the conditions when the code was triggered.

-

Clear DTCs (Optional): If desired, you can clear the DTCs after recording them. Be aware that clearing codes may erase important diagnostic information.

-

Verify the Repair: After addressing the issue, clear the DTCs and drive the vehicle to see if the code returns. This confirms that the repair was successful.

8.4. Additional Tips and Considerations

- Use a Reputable Scanner: Invest in a high-quality OBD-II scanner from a reputable brand to ensure accurate and reliable results.

- Consult a Professional: If you are unsure about interpreting the DTCs or performing repairs, consult a qualified mechanic or Mercedes-Benz technician.

- Keep Records: Maintain a record of all DTCs, repairs, and maintenance performed on your vehicle. This can be helpful for future diagnostics.

- Check for Technical Service Bulletins (TSBs): Review TSBs issued by Mercedes-Benz for your vehicle model. These bulletins often provide information about common issues and recommended solutions.

8.5. Benefits of Using MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Resources

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides comprehensive resources to assist you in reading and interpreting DTCs on your Mercedes-Benz vehicle. Our website offers:

- DTC Database: A searchable database of DTCs with detailed descriptions and troubleshooting guides.

- Diagnostic Tutorials: Step-by-step tutorials on reading and interpreting DTCs.

- Expert Support: Access to our team of experienced Mercedes-Benz technicians for diagnostic assistance.

8.6. Contacting MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Assistance

If you need assistance with reading or interpreting DTCs on your Mercedes-Benz vehicle, please contact us at +1 (641) 206-8880 or visit our website at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN. Our address is 789 Oak Avenue, Miami, FL 33101, United States.

9. Opening Hidden Features on Mercedes-Benz Vehicles

9.1. What are Hidden Features?

Hidden features on Mercedes-Benz vehicles are functionalities that are pre-programmed into the car’s computer but are not activated by default. These features can range from cosmetic enhancements to performance upgrades and convenience functions. Activating these hidden features can enhance your driving experience and personalize your vehicle to your preferences. According to a survey by J.D. Power, vehicle personalization is a growing trend among car owners.

9.2. Examples of Hidden Features

- Cornering Lights: Activate fog lights to illuminate the side of the road when turning.

- Ambient Lighting Customization: Adjust the color and intensity of the interior ambient lighting.

- Sport Display: Display engine performance data, such as horsepower and torque, on the instrument cluster.

- ECO Start/Stop Individualization: Customize the behavior of the ECO Start/Stop system.

- AMG Menu: Unlock the AMG menu in the instrument cluster for additional performance data and settings.

- Video in Motion: Enable video playback on the infotainment screen while the vehicle is in motion.

9.3. Tools and Software Required

To unlock hidden features on your Mercedes-Benz, you will typically need the following tools and software:

- OBD-II Adapter: A compatible OBD-II adapter that connects to your vehicle’s diagnostic port.

- Diagnostic Software: Specialized software designed for Mercedes-Benz vehicles, such as Xentry/DAS, Vediamo, or DTS Monaco.

- Laptop: A laptop with the diagnostic software installed and configured.

- Internet Connection: An internet connection may be required for software activation or updates.

9.4. Step-by-Step Guide to Unlocking Hidden Features

Disclaimer: Unlocking hidden features may void your vehicle’s warranty. Proceed with caution and consult a professional if you are unsure.

- Connect the OBD-II Adapter: Plug the OBD-II adapter into your vehicle’s diagnostic port.

- Turn on the Ignition: Insert the key into the ignition and turn it to the “ON” position. Do not start the engine.

- Launch the Diagnostic Software: Open the diagnostic software on your laptop and connect to the vehicle’s computer.

- Navigate to the Control Unit: Locate the control unit that contains the hidden features you want to unlock. This may vary depending on the vehicle model and feature.

- Modify the Coding: Use the software to modify the coding or parameters of the control unit to activate the desired features. Follow the software’s instructions carefully.

- Save the Changes: Save the changes to the control unit and disconnect the OBD-II adapter.

- Test the Features: Test the activated features to ensure they are functioning correctly.

9.5. Precautions and Risks

- Warranty Issues: Unlocking hidden features may void your vehicle’s warranty.

- Software Compatibility: Ensure that the diagnostic software is compatible with your vehicle model and control units.

- Coding Errors: Incorrect coding can cause malfunctions or damage to your vehicle’s electronic systems.

- Professional Assistance: If you are unsure about the process, seek assistance from a qualified Mercedes-Benz technician.

9.6. Services Offered by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers professional services for unlocking hidden features on Mercedes-Benz vehicles. Our experienced technicians use advanced diagnostic tools and software to safely and effectively activate the features you desire.

9.7. Contacting MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Assistance

For more information about our services for unlocking hidden features on Mercedes-Benz vehicles, please contact us at +1 (641) 206-8880 or visit our website at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN. Our address is 789 Oak Avenue, Miami, FL 33101, United States.

10. Regular Maintenance Tips for Mercedes-Benz Vehicles

10.1. The Importance of Regular Maintenance

Regular maintenance is crucial for ensuring the longevity, reliability, and performance of your Mercedes-Benz vehicle. Following a consistent maintenance schedule can prevent costly repairs, extend the life of your vehicle, and maintain its resale value. According to a study by Consumer Reports, vehicles that receive regular maintenance are more reliable and require fewer repairs over their lifespan.

10.2. Key Maintenance Tasks

- Oil Changes: Regular oil changes are essential for lubricating engine components and preventing wear. Follow the recommended oil change interval in your vehicle’s manual.

- Filter Replacements: Replace air filters, fuel filters, and cabin filters at the recommended intervals to maintain optimal engine performance and air quality.

- Fluid Checks and Top-Ups: Regularly check and top up fluid levels, including coolant, brake fluid, power steering fluid, and transmission fluid.

- Brake Inspections: Inspect brake pads, rotors, and calipers regularly to ensure proper braking performance.

- Tire Rotations and Alignments: Rotate tires and perform wheel alignments to ensure even tire wear and optimal handling.

- Spark Plug Replacements: Replace spark plugs at the recommended intervals to maintain efficient engine combustion.

- Belt and Hose Inspections: Inspect belts and hoses for cracks, wear, and leaks. Replace them as needed to prevent engine damage.

- Battery Maintenance: Clean battery terminals and test battery voltage regularly to ensure reliable starting performance.

10.3. Recommended Maintenance Schedule

Refer to your Mercedes-Benz owner’s manual for the recommended maintenance schedule for your vehicle model. This schedule typically includes mileage-based or time-based intervals for various maintenance tasks.

10.4. Benefits of Following a Maintenance Schedule

- Extended Vehicle Life: Regular maintenance can extend the life of your Mercedes-Benz vehicle by preventing wear and tear.

- Improved Reliability: Following a maintenance schedule can improve the reliability of your vehicle and reduce the risk of breakdowns.

- Optimal Performance: Regular maintenance ensures that your vehicle operates at peak performance, improving fuel efficiency and handling.

- Increased Resale Value: Vehicles that have been well-maintained typically have a higher resale value.

- Reduced Repair Costs: Preventing minor issues from escalating into major repairs can save you money on repair costs.

10.5. Maintenance Services Offered by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers comprehensive maintenance services for Mercedes-Benz vehicles. Our experienced technicians use genuine Mercedes-Benz parts and fluids to ensure the highest quality of service.

10.6. Real-World Application of Regular Maintenance

Consider a Mercedes-Benz E-Class that follows a regular maintenance schedule. The owner changes the oil every 10,000 miles, replaces the air filter every 20,000 miles, and inspects the brakes every 30,000 miles. As a result, the vehicle maintains optimal performance, fuel efficiency, and reliability. The owner avoids costly repairs and enjoys a smooth and trouble