A smoke machine is used to diagnose diagnostic trouble codes (DTCs) related to EVAP leaks and vacuum leaks by introducing visible smoke into a vehicle’s system, revealing the location of any leaks. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we ensure you have the right tools and information for efficient vehicle diagnostics. By using a smoke machine, pinpointing these leaks becomes straightforward, saving time and money on unnecessary repairs, and improving vehicle performance.

1. What is a Smoke Machine and How Does It Work in Automotive Diagnostics?

A smoke machine, also known as a smoke tester or leak detector, is a diagnostic tool that introduces visible vapor into a vehicle’s sealed systems, such as the evaporative emission control (EVAP) system, vacuum lines, intake manifold, exhaust system, and cooling system. This vapor, typically a non-toxic mineral oil-based smoke, is pressurized to a low level and forced into the system. Any leaks present in the system will allow the smoke to escape, making them easily visible to the technician.

How it Works:

- Smoke Generation: The machine heats a special fluid (mineral oil or a similar substance) to create a dense, white smoke.

- System Introduction: The smoke is pumped into the system being tested via a hose and adapter.

- Leak Visualization: The technician visually inspects the system for escaping smoke, identifying the precise location of leaks.

2. Why Use a Smoke Machine for Diagnosing EVAP and Vacuum Leaks?

Smoke machines provide a fast, accurate, and reliable method for detecting leaks in various automotive systems, especially EVAP and vacuum systems. Traditional methods, such as visual inspection or using soapy water, are often time-consuming and less effective, particularly for small or hard-to-reach leaks.

Advantages of Using a Smoke Machine:

- Accuracy: Smoke machines can pinpoint even the smallest leaks that might be missed by other methods.

- Efficiency: They significantly reduce diagnostic time by quickly identifying the source of the problem.

- Versatility: Smoke machines can be used on a wide range of systems, including EVAP, vacuum, intake, exhaust, and cooling systems.

- Safety: Modern smoke machines use non-toxic, non-corrosive smoke, making them safe for the vehicle and the technician.

3. What are the Key Components of a Smoke Machine?

A typical smoke machine consists of several key components that work together to generate and deliver smoke into the vehicle’s system.

Key Components:

- Smoke Generator: This is the core of the machine, where the smoke fluid is heated and vaporized.

- Air Pump or Compressor: This component provides the necessary pressure to push the smoke into the system being tested.

- Flow Control Valve: This valve allows the technician to regulate the flow of smoke, preventing over-pressurization.

- Pressure Gauge: This gauge monitors the pressure within the system, ensuring it stays within safe limits.

- Hoses and Adapters: These components connect the smoke machine to the vehicle’s system, allowing for a tight seal and efficient smoke delivery.

- Smoke Fluid: A specially formulated fluid, typically mineral oil-based, that produces dense, visible smoke when heated.

4. How to Use a Smoke Machine to Diagnose EVAP Leaks?

The EVAP system prevents fuel vapors from escaping into the atmosphere. Leaks in this system can cause the vehicle to fail emissions tests, reduce fuel efficiency, and trigger diagnostic trouble codes (DTCs).

Steps to Diagnose EVAP Leaks with a Smoke Machine:

- Preparation:

- Ensure the vehicle is in a well-ventilated area.

- Locate the EVAP test port or access point. This is often near the fuel tank or in the engine compartment.

- Disconnect any components that might be damaged by the smoke, such as mass airflow sensors or oxygen sensors.

- Connection:

- Connect the smoke machine’s hose to the EVAP test port using the appropriate adapter. Ensure a tight seal to prevent smoke from escaping.

- Smoke Introduction:

- Turn on the smoke machine and introduce smoke into the EVAP system. Start with a low pressure setting to avoid damaging any components.

- Leak Detection:

- Visually inspect all EVAP system components, including fuel tank, vapor lines, charcoal canister, and vent valve, for escaping smoke.

- Pay close attention to joints, connections, and areas prone to corrosion.

- Confirmation:

- Once a leak is found, confirm its location by applying a small amount of soapy water to the area. Bubbles will form if there is a leak.

- Repair:

- Repair or replace the leaking component.

- Re-test:

- After the repair, re-test the EVAP system with the smoke machine to ensure the leak is completely sealed.

5. How to Use a Smoke Machine to Diagnose Vacuum Leaks?

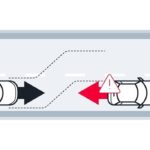

Vacuum leaks can cause a variety of performance issues, including rough idling, poor acceleration, and decreased fuel efficiency. These leaks can be difficult to find using traditional methods, but a smoke machine makes the process much easier.

Steps to Diagnose Vacuum Leaks with a Smoke Machine:

- Preparation:

- Ensure the vehicle is in a well-ventilated area.

- Locate a suitable vacuum line or port to connect the smoke machine. Common access points include brake booster lines, PCV valve hoses, or intake manifold vacuum ports.

- Disconnect any sensitive components that might be affected by the smoke.

- Connection:

- Connect the smoke machine’s hose to the selected vacuum line using an appropriate adapter. Ensure a tight seal.

- Smoke Introduction:

- Turn on the smoke machine and introduce smoke into the vacuum system. Use a low pressure setting to avoid damaging any components.

- Leak Detection:

- Visually inspect all vacuum lines, hoses, and connections for escaping smoke.

- Pay attention to areas around the intake manifold, throttle body, fuel injectors, and vacuum-operated accessories.

- Confirmation:

- Confirm the location of the leak by spraying soapy water on the suspected area. Bubbles will indicate a leak.

- Repair:

- Repair or replace the leaking vacuum line or component.

- Re-test:

- After the repair, re-test the vacuum system with the smoke machine to ensure the leak is completely sealed.

6. What Types of Smoke Machines Are Available on the Market?

There are several types of smoke machines available, each with its own features and benefits. Choosing the right machine depends on the specific needs of the technician and the types of vehicles being serviced.

Types of Smoke Machines:

- Basic Smoke Machines: These are entry-level machines that provide a simple and affordable solution for leak detection. They typically have a basic smoke generator and air pump.

- Advanced Smoke Machines: These machines offer more features, such as adjustable flow control, pressure gauges, and diagnostic capabilities. They are suitable for professional technicians and shops.

- Portable Smoke Machines: These compact and lightweight machines are designed for on-the-go diagnostics. They are ideal for mobile technicians and roadside repairs.

- Smoke Machines with Integrated Multimeters: Some advanced smoke machines include integrated multimeters, allowing technicians to perform electrical testing in addition to leak detection.

- Ultrasonic Leak Detectors: These use ultrasonic technology to detect leaks by sensing the high-frequency sound produced by escaping air or gas.

7. What Features Should You Look For When Buying a Smoke Machine?

When purchasing a smoke machine, consider the following features to ensure you get a reliable and effective tool:

Key Features to Consider:

- Smoke Output: The amount of smoke the machine can produce per minute. A higher output is better for larger systems and faster diagnostics.

- Pressure Control: The ability to adjust the pressure of the smoke output. This is important for preventing damage to sensitive components.

- Portability: Consider the size and weight of the machine, especially if you need to move it around the shop or use it for mobile repairs.

- Durability: Look for a machine with a robust construction and high-quality components.

- Accessories: Check what accessories are included, such as adapters, hoses, and nozzles.

- Warranty: A good warranty provides peace of mind and protects your investment.

- Safety Features: Ensure the machine has safety features such as over-pressure protection and automatic shut-off.

8. What are Some Common Diagnostic Trouble Codes (DTCs) Related to EVAP and Vacuum Leaks?

EVAP and vacuum leaks can trigger a variety of DTCs, which can help technicians narrow down the source of the problem.

Common DTCs Related to EVAP Leaks:

- P0440: Evaporative Emission Control System Malfunction

- P0441: Evaporative Emission Control System Incorrect Purge Flow

- P0442: Evaporative Emission Control System Leak Detected (Small Leak)

- P0446: Evaporative Emission Control System Vent Control Circuit Malfunction

- P0455: Evaporative Emission Control System Leak Detected (Gross Leak)

- P0456: Evaporative Emission Control System Leak Detected (Very Small Leak)

Common DTCs Related to Vacuum Leaks:

- P0171: System Too Lean (Bank 1)

- P0174: System Too Lean (Bank 2)

- P0300: Random Misfire Detected

- P0505: Idle Control System Malfunction

9. How Does a Smoke Machine Help in Diagnosing Other Vehicle Systems?

While smoke machines are commonly used for EVAP and vacuum leak detection, they can also be used to diagnose leaks in other vehicle systems.

Other Applications of Smoke Machines:

- Intake System Leaks: Detect leaks in the intake manifold, throttle body, and air ducts.

- Exhaust System Leaks: Locate leaks in the exhaust manifold, catalytic converter, and muffler.

- Cooling System Leaks: Find leaks in the radiator, hoses, and water pump.

- Turbocharger System Leaks: Identify leaks in the turbocharger, intercooler, and associated hoses.

- PCV System Leaks: Detect leaks in the positive crankcase ventilation (PCV) system.

10. What are the Safety Precautions to Take When Using a Smoke Machine?

Using a smoke machine involves working with pressurized systems and potentially flammable fluids. It is important to follow safety precautions to prevent accidents and injuries.

Safety Precautions:

- Ventilation: Always use the smoke machine in a well-ventilated area to avoid inhaling smoke.

- Eye Protection: Wear safety glasses or goggles to protect your eyes from smoke and debris.

- Gloves: Wear gloves to protect your skin from contact with smoke fluid.

- Fire Safety: Keep a fire extinguisher nearby in case of accidental ignition.

- Pressure Limits: Do not exceed the recommended pressure limits for the system being tested.

- Component Sensitivity: Be aware of sensitive components that may be damaged by smoke or pressure, such as mass airflow sensors and oxygen sensors.

- Machine Maintenance: Regularly inspect and maintain the smoke machine to ensure it is in good working condition.

11. What are the Benefits of Using a Smoke Machine for Mercedes-Benz Vehicles?

Mercedes-Benz vehicles are known for their complex systems and precise engineering. Diagnosing leaks in these vehicles can be challenging without the right tools and techniques. A smoke machine offers several benefits for diagnosing Mercedes-Benz vehicles.

Benefits for Mercedes-Benz Vehicles:

- Accurate Leak Detection: Smoke machines can pinpoint even the smallest leaks in the EVAP, vacuum, and other systems, ensuring accurate diagnosis and effective repairs.

- Reduced Diagnostic Time: By quickly identifying the source of leaks, smoke machines can significantly reduce diagnostic time, saving technicians time and money.

- Prevention of Further Damage: Early detection of leaks can prevent further damage to the vehicle’s systems, such as engine damage caused by vacuum leaks or emissions system failures caused by EVAP leaks.

- Improved Fuel Efficiency: Repairing leaks in the EVAP and vacuum systems can improve fuel efficiency, saving vehicle owners money on gas.

- Compliance with Emissions Standards: Addressing EVAP leaks helps ensure the vehicle complies with emissions standards, preventing fines and penalties.

- Enhanced Customer Satisfaction: By providing accurate and efficient diagnostics, technicians can enhance customer satisfaction and build trust.

12. What Maintenance is Required for a Smoke Machine?

Proper maintenance is essential for keeping a smoke machine in good working condition and ensuring accurate and reliable performance.

Maintenance Tips:

- Regular Cleaning: Clean the smoke generator and other components regularly to remove any buildup of residue or contaminants.

- Fluid Replacement: Replace the smoke fluid according to the manufacturer’s recommendations.

- Hose Inspection: Inspect the hoses and adapters for cracks, leaks, or damage. Replace them as needed.

- Filter Replacement: Replace the air filter regularly to ensure clean air is being used to generate the smoke.

- Storage: Store the smoke machine in a clean, dry place when not in use.

- Calibration: Calibrate the pressure gauge periodically to ensure accurate readings.

13. How to Interpret Smoke Machine Test Results?

Interpreting smoke machine test results involves carefully observing the location and intensity of escaping smoke to identify the source and severity of leaks.

Interpreting Test Results:

- Location of Smoke: The location of escaping smoke indicates the source of the leak. Pay close attention to joints, connections, and areas prone to wear or damage.

- Intensity of Smoke: The intensity of the smoke indicates the size of the leak. A larger leak will produce more smoke than a smaller leak.

- Multiple Leaks: Be aware that there may be multiple leaks in the system. Inspect all components carefully to identify all sources of escaping smoke.

- False Positives: In some cases, smoke may escape from areas that are not actually leaks. This can be caused by loose connections or faulty adapters. Double-check suspected leak locations to confirm the results.

14. What are Common Mistakes to Avoid When Using a Smoke Machine?

Using a smoke machine effectively requires proper technique and attention to detail. Avoiding common mistakes can help ensure accurate and reliable results.

Common Mistakes to Avoid:

- Over-Pressurizing the System: Using too much pressure can damage sensitive components. Always start with a low pressure setting and gradually increase it as needed.

- Ignoring Safety Precautions: Failing to follow safety precautions can lead to accidents and injuries. Always wear eye protection and gloves, and work in a well-ventilated area.

- Using the Wrong Fluid: Using the wrong type of smoke fluid can damage the machine or produce inaccurate results. Always use the fluid recommended by the manufacturer.

- Neglecting Maintenance: Neglecting regular maintenance can lead to machine malfunctions and inaccurate readings.

- Misinterpreting Results: Misinterpreting smoke patterns can lead to incorrect diagnoses. Double-check suspected leak locations to confirm the results.

15. Can a Smoke Machine Be Used on All Makes and Models of Vehicles?

While smoke machines are versatile tools that can be used on a wide range of vehicles, there are some limitations to consider.

Limitations:

- System Compatibility: Ensure the smoke machine is compatible with the system being tested. Some machines may not be suitable for certain types of systems or vehicles.

- Pressure Limits: Be aware of the pressure limits for the system being tested. Some systems may be more sensitive to pressure than others.

- Component Sensitivity: Be aware of sensitive components that may be damaged by smoke or pressure. Disconnect these components before testing.

- Access Points: Ensure there is a suitable access point for connecting the smoke machine to the system being tested.

16. What are the Advantages and Disadvantages of DIY Smoke Machine vs. Professional Smoke Machine?

DIY Smoke Machine:

- Advantages: Cost-effective for occasional use, simple to build.

- Disadvantages: Less accurate, lower smoke output, potentially unsafe, may not be suitable for all vehicles.

Professional Smoke Machine:

- Advantages: More accurate, higher smoke output, safer, more versatile, suitable for a wide range of vehicles.

- Disadvantages: More expensive.

17. How Do Smoke Machines Aid in Meeting Emission Standards?

Smoke machines are crucial in maintaining compliance with emission standards by identifying and rectifying leaks in the EVAP system. The EVAP system’s main function is to prevent fuel vapors from escaping into the atmosphere, thereby reducing air pollution.

Benefits of Smoke Machines in Meeting Emission Standards:

- Leak Detection: Accurately pinpoints leaks in the EVAP system.

- Emission Reduction: Prevents release of harmful fuel vapors.

- Compliance: Helps vehicles meet emission standards, avoiding penalties.

- Fuel Efficiency: Improves fuel economy by preventing vapor loss.

- Environmental Protection: Contributes to cleaner air by reducing pollution.

18. What Role Do Adapters Play in Smoke Machine Functionality?

Adapters are essential accessories for smoke machines, providing the necessary connections to different vehicle systems. They ensure a secure and airtight seal, which is crucial for accurate leak detection.

Key Roles of Adapters:

- Connectivity: Connect the smoke machine to various vehicle systems.

- Seal Integrity: Ensure an airtight seal to prevent smoke leakage.

- Versatility: Enable testing of different components and systems.

- Ease of Use: Simplify the connection process for efficient testing.

- Compatibility: Match the smoke machine to specific vehicle models and systems.

19. How Do Smoke Machines Compare to Electronic Leak Detectors?

Smoke machines and electronic leak detectors are both used to find leaks in vehicle systems, but they operate on different principles and have distinct advantages.

Smoke Machines:

- Method: Introduce visible smoke into the system.

- Advantages: Accurate, visual confirmation of leaks, versatile for various systems.

- Disadvantages: Requires visual inspection, may not be suitable for enclosed areas.

Electronic Leak Detectors:

- Method: Use sensors to detect the presence of gases escaping from leaks.

- Advantages: Can detect leaks in enclosed areas, no visual inspection required.

- Disadvantages: Less accurate for small leaks, may be affected by environmental factors.

20. Are There Eco-Friendly Smoke Fluids Available for Smoke Machines?

Yes, there are eco-friendly smoke fluids available for smoke machines. These fluids are typically made from natural, biodegradable materials and are designed to minimize environmental impact.

Benefits of Eco-Friendly Smoke Fluids:

- Biodegradable: Break down naturally in the environment.

- Non-Toxic: Safe for technicians and the environment.

- Low Odor: Minimal unpleasant smells during use.

- Reduced Environmental Impact: Minimize pollution and waste.

- Compliance: Meet environmental regulations and standards.

21. What Training is Recommended for Technicians Using Smoke Machines?

Proper training is essential for technicians using smoke machines to ensure accurate diagnostics and safe operation.

Recommended Training Topics:

- Machine Operation: Understanding the components and controls of the smoke machine.

- Safety Procedures: Following safety precautions to prevent accidents.

- Leak Detection Techniques: Identifying and interpreting smoke patterns.

- System Knowledge: Understanding the function and components of vehicle systems.

- Diagnostic Strategies: Using smoke machines to diagnose various types of leaks.

- Maintenance Procedures: Performing regular maintenance to keep the machine in good condition.

- Interpretation of Results: Accurately assess and interpret leak test outcomes, differentiating between significant leaks and minor seepages.

22. How Can a Smoke Machine Improve Diagnostic Efficiency in a Repair Shop?

A smoke machine can significantly improve diagnostic efficiency in a repair shop by quickly and accurately locating leaks, reducing diagnostic time, and preventing unnecessary repairs.

Benefits for Repair Shops:

- Faster Diagnostics: Quickly identifies the source of leaks.

- Accurate Results: Pinpoints even small leaks.

- Reduced Labor Costs: Minimizes diagnostic time, reducing labor costs.

- Improved Customer Satisfaction: Provides accurate and efficient service.

- Increased Revenue: Allows technicians to complete more repairs in less time.

- Versatile Tool: Can be used on various vehicle systems.

23. How Does a Smoke Machine Help in Diagnosing Intermittent Issues?

Smoke machines can be particularly useful in diagnosing intermittent issues, which are often difficult to trace using traditional methods.

Benefits for Intermittent Issues:

- Simulates Conditions: Can replicate conditions that trigger intermittent issues.

- Visual Confirmation: Provides visual confirmation of leaks that may only occur under certain conditions.

- Systematic Testing: Allows technicians to systematically test different components and systems.

- Reduced Guesswork: Minimizes guesswork by providing accurate and reliable results.

- Time Savings: Saves time by quickly identifying the source of intermittent issues.

24. What Are the Environmental Benefits of Using Smoke Machines?

Using smoke machines for leak detection offers several environmental benefits by helping to reduce emissions and improve fuel efficiency.

Environmental Benefits:

- Reduced Emissions: Prevents the release of harmful fuel vapors into the atmosphere.

- Improved Fuel Efficiency: Helps vehicles achieve better fuel economy.

- Pollution Prevention: Contributes to cleaner air and a healthier environment.

- Compliance: Supports compliance with environmental regulations and standards.

- Sustainable Practices: Promotes sustainable automotive repair practices.

25. What is the Future of Smoke Machine Technology in Automotive Diagnostics?

The future of smoke machine technology in automotive diagnostics is focused on advancements that improve accuracy, efficiency, and ease of use.

Future Trends:

- Smart Technology: Integration of sensors, data analysis, and wireless connectivity for real-time diagnostics.

- Enhanced Accuracy: Development of more sensitive and precise smoke generators.

- Improved Portability: Design of smaller, lighter, and more portable machines.

- Eco-Friendly Fluids: Use of more sustainable and environmentally friendly smoke fluids.

- Integration with Diagnostic Software: Seamless integration with vehicle diagnostic software for comprehensive analysis.

26. How Does MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Support Technicians in Diagnosing DTCs with Smoke Machines?

At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we provide comprehensive support for technicians using smoke machines to diagnose DTCs, ensuring they have the tools, knowledge, and resources needed for efficient and accurate diagnostics.

Support Services:

- High-Quality Smoke Machines: Offer a range of reliable and advanced smoke machines.

- Training Programs: Provide comprehensive training programs on smoke machine operation and diagnostic techniques.

- Technical Support: Offer expert technical support to assist technicians with diagnostic challenges.

- Access to Information: Provide access to a wealth of information, including diagnostic guides, technical bulletins, and troubleshooting tips.

- Equipment Maintenance: Offer equipment maintenance and repair services to keep smoke machines in top condition.

- Community Forums: Host community forums where technicians can share knowledge, ask questions, and collaborate on diagnostic challenges.

27. What are the Legal Implications of Ignoring EVAP and Vacuum Leaks?

Ignoring EVAP and vacuum leaks can have legal implications, particularly in areas with strict emission standards.

Legal Implications:

- Emission Test Failure: Vehicles with leaks may fail emission tests, resulting in fines and penalties.

- Registration Denial: In some areas, vehicle registration may be denied if the vehicle fails an emission test.

- Legal Liability: Vehicle owners may be held legally liable for environmental damage caused by excessive emissions.

- Warranty Voidance: Ignoring leaks may void the vehicle’s warranty.

28. How Can a Smoke Machine Be Used to Train New Automotive Technicians?

Smoke machines are excellent tools for training new automotive technicians, providing hands-on experience in leak detection and diagnostic techniques.

Training Benefits:

- Hands-On Learning: Allows technicians to gain practical experience in leak detection.

- Visual Demonstration: Provides a visual demonstration of leaks, making it easier to understand the diagnostic process.

- Skill Development: Helps technicians develop essential diagnostic skills.

- Confidence Building: Builds confidence in their ability to diagnose and repair leaks.

- Efficient Training: Accelerates the learning process by providing immediate feedback.

29. What is the ROI of Investing in a Smoke Machine for a Repair Shop?

Investing in a smoke machine offers a significant return on investment (ROI) for a repair shop by improving diagnostic efficiency, reducing labor costs, and increasing customer satisfaction.

ROI Benefits:

- Increased Revenue: Faster diagnostics allow technicians to complete more repairs, increasing revenue.

- Reduced Labor Costs: Minimizes diagnostic time, reducing labor costs.

- Improved Efficiency: Streamlines the diagnostic process, improving overall shop efficiency.

- Customer Loyalty: Provides accurate and efficient service, building customer loyalty.

- Competitive Advantage: Differentiates the shop from competitors by offering advanced diagnostic capabilities.

- Long-Term Savings: Prevents unnecessary repairs, saving customers money in the long run.

30. What Resources Does MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Provide for Understanding DTCs Related to Leaks?

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers a variety of resources to help technicians understand DTCs related to leaks, including:

Resources:

- Diagnostic Guides: Comprehensive guides that explain the causes and symptoms of various DTCs.

- Technical Bulletins: Up-to-date bulletins that provide the latest information on diagnostic procedures and repair techniques.

- Troubleshooting Tips: Practical tips for diagnosing and repairing leaks.

- DTC Lookup Tool: A tool that allows technicians to quickly look up the meaning and causes of DTCs.

- Online Forums: Forums where technicians can ask questions, share knowledge, and collaborate on diagnostic challenges.

- Training Programs: Comprehensive training programs on DTC diagnosis and repair.

31. How Does a Smoke Machine Help in Diagnosing Fuel Trim Issues?

Fuel trim issues, indicated by DTCs like P0171 (System Too Lean, Bank 1) and P0174 (System Too Lean, Bank 2), often stem from vacuum leaks that allow unmetered air into the engine. A smoke machine is invaluable for pinpointing these leaks.

Diagnostic Steps:

- Access the System: Introduce smoke into the intake manifold through a vacuum line or the throttle body.

- Observe Smoke Patterns: Watch for smoke escaping from vacuum lines, intake gaskets, or other connections.

- Identify the Leak Source: Mark the location of the escaping smoke to identify the source of the vacuum leak.

- Repair the Leak: Replace or repair the leaking component to resolve the fuel trim issue.

32. What Advanced Techniques Can Be Used with a Smoke Machine for Complex Diagnostics?

For complex diagnostic scenarios, advanced techniques can maximize the effectiveness of a smoke machine.

Advanced Techniques:

- Pulsed Smoke: Use a smoke machine with a pulsed smoke feature to create intermittent bursts of smoke, making it easier to detect small leaks.

- UV Dye: Add UV dye to the smoke fluid and use a UV light to enhance the visibility of leaks.

- Pressure Testing: Monitor the pressure within the system to identify pressure drops that indicate leaks.

- System Segmentation: Divide the system into segments and test each segment individually to narrow down the location of the leak.

- Data Logging: Use a scan tool to monitor engine parameters while performing the smoke test to correlate leaks with engine performance.

33. How to Choose the Right Smoke Fluid for Your Smoke Machine?

Selecting the correct smoke fluid is vital to ensure optimal performance and longevity of your smoke machine.

Key Considerations:

- Manufacturer Recommendations: Always follow the smoke machine manufacturer’s recommendations for fluid type.

- Fluid Composition: Choose a fluid specifically designed for automotive use, typically mineral oil-based.

- Smoke Density: Select a fluid that produces a dense, easily visible smoke.

- Safety: Ensure the fluid is non-toxic, non-corrosive, and safe for the environment.

- Eco-Friendliness: Opt for an eco-friendly fluid made from biodegradable materials.

34. What Role Do Vacuum Diagrams Play in Diagnosing Leaks with a Smoke Machine?

Vacuum diagrams are essential tools for diagnosing leaks with a smoke machine. They provide a visual representation of the vacuum system, helping technicians identify the location of vacuum lines and components.

Benefits of Vacuum Diagrams:

- System Understanding: Provide a clear understanding of the vacuum system layout.

- Component Identification: Help technicians identify the location of vacuum lines, hoses, and components.

- Leak Localization: Assist in localizing leaks by identifying potential leak points.

- Efficient Diagnostics: Streamline the diagnostic process by providing a visual reference.

- Accurate Repairs: Ensure accurate repairs by verifying the correct routing of vacuum lines.

35. How Do Barometric Pressure Sensors Influence Smoke Machine Diagnostics?

Barometric pressure sensors play a crucial role in engine management by measuring atmospheric pressure, which affects fuel delivery and engine performance. Understanding these sensors is critical during smoke machine diagnostics.

Sensor Influence:

- Leak Detection: Help technicians understand how leaks affect sensor readings.

- Data Analysis: Assist in analyzing sensor data to identify leak-related issues.

- System Understanding: Provide a clear understanding of the sensor’s role in engine management.

- Accurate Diagnostics: Contribute to more accurate diagnoses by considering sensor data.

- Efficient Repairs: Streamline the repair process by identifying sensor-related problems.

36. How Does Altitude Impact the Effectiveness of Smoke Machine Testing?

Altitude can affect the effectiveness of smoke machine testing because changes in atmospheric pressure can influence the behavior of leaks.

Impact of Altitude:

- Pressure Differences: Higher altitudes have lower atmospheric pressure, affecting leak detection.

- Smoke Behavior: Lower pressure can cause smoke to dissipate more quickly, making leaks harder to spot.

- Technique Adjustments: Technicians may need to adjust testing techniques to account for altitude changes.

- Equipment Calibration: Smoke machines may require calibration adjustments for optimal performance at different altitudes.

- Accurate Interpretation: Accurate interpretation of smoke patterns is crucial at higher altitudes.

37. What is the Importance of Performing a Pre-Test Inspection Before Using a Smoke Machine?

Performing a pre-test inspection before using a smoke machine is critical to ensure accurate results and prevent damage to the vehicle.

Inspection Steps:

- System Assessment: Assess the condition of the system being tested.

- Component Check: Check for any obvious leaks, damage, or loose connections.

- Sensor Disconnection: Disconnect any sensitive components that may be damaged by smoke.

- Access Point Selection: Choose a suitable access point for connecting the smoke machine.

- Safety Verification: Verify that all safety precautions are in place.

38. How Do Temperature Variations Affect Smoke Machine Diagnostics?

Temperature variations can significantly influence the effectiveness of smoke machine diagnostics. Temperature changes affect the density of the smoke, the expansion and contraction of materials, and the behavior of leaks.

Impact of Temperature:

- Smoke Density: Lower temperatures can cause the smoke to be denser and more visible.

- Material Expansion/Contraction: Temperature changes can cause materials to expand or contract, affecting the size and behavior of leaks.

- Leak Behavior: Leaks may be more pronounced at certain temperatures.

- Technique Adjustments: Technicians may need to adjust testing techniques based on temperature.

- Accurate Interpretation: Accurate interpretation of smoke patterns is crucial at different temperatures.

39. Can a Smoke Machine Help Diagnose Issues with the Catalytic Converter?

Yes, a smoke machine can help diagnose issues with the catalytic converter by detecting leaks in the exhaust system.

Diagnostic Steps:

- Access the System: Introduce smoke into the exhaust system through the tailpipe or an exhaust pipe connection.

- Observe Smoke Patterns: Watch for smoke escaping from the catalytic converter, exhaust pipes, or connections.

- Identify the Leak Source: Mark the location of the escaping smoke to identify the source of the exhaust leak.

- Assess Converter Condition: Check for physical damage or corrosion on the catalytic converter.

40. What is the Role of the PCV System in Smoke Machine Diagnostics?

The Positive Crankcase Ventilation (PCV) system is crucial for engine health by removing blow-by gases from the crankcase. Smoke machine diagnostics can reveal leaks in this system, ensuring it functions correctly.

Diagnostic Steps:

- Access the System: Connect the smoke machine to the PCV system via a suitable access point.

- Introduce Smoke: Introduce smoke into the PCV system.

- Observe Smoke Patterns: Look for smoke escaping from PCV valves, hoses, or connections.

- Identify Leaks: Mark the location of escaping smoke to identify leak sources.

- Repair Leaks: Replace or repair leaking PCV components to maintain engine health.

41. What Types of Adapters Are Most Useful for Smoke Machine Diagnostics?

Having a variety of adapters is essential for effectively using a smoke machine on different vehicles and systems.

Useful Adapters:

- Cone Adapters: Universal adapters that fit various openings.

- Hose Adapters: Connect to vacuum lines and hoses.

- Exhaust Adapters: Seal to the tailpipe for exhaust system testing.

- EVAP Adapters: Designed for EVAP system testing.

- Threaded Adapters: Screw into threaded ports for a secure connection.

42. How to Store a Smoke Machine Properly to Extend Its Lifespan?

Proper storage is crucial for extending the lifespan and maintaining the performance of your smoke machine.

Storage Tips:

- Clean the Machine: Clean the smoke machine after each use to remove residue.

- Drain the Fluid: Drain the smoke fluid from the machine before storing it.

- Store in a Dry Place: Store the machine in a dry, clean place to prevent corrosion.

- Cover the Machine: Cover the machine to protect it from dust and debris.

- Avoid Extreme Temperatures: Avoid storing the machine in extreme temperatures.

43. What is the Cost of Owning and Maintaining a Smoke Machine?

Owning and maintaining a smoke machine involves several costs, including the initial purchase price, the cost of smoke fluid, and maintenance expenses.

Cost Factors:

- Initial Purchase Price: Varies depending on the type and features of the machine.

- Smoke Fluid: Cost per bottle varies depending on the type and quantity.

- Maintenance: Includes the cost of replacement parts, filters, and repairs.

- Training: Cost of training technicians on how to use the machine.

- Storage: Cost of storing the machine.

44. How Can a Smoke Machine Be Used in Conjunction with a Scan Tool?

Using a smoke machine in conjunction with a scan tool can enhance diagnostic accuracy and efficiency.

Integration Benefits:

- Data Monitoring: Monitor engine parameters with the scan tool while performing the smoke test.

- Leak Correlation: Correlate leak detection with engine performance data.

- DTC Verification: Verify DTCs related to leaks.

- System Analysis: Analyze data from the scan tool to identify potential leak sources.

- Accurate Diagnosis: Achieve a more accurate diagnosis by combining smoke testing with scan tool data.

45. How Do Aftermarket Performance Parts Affect Smoke Machine Diagnostics?

Aftermarket performance parts can significantly affect smoke machine diagnostics by altering the vehicle’s systems and potentially creating new leak points.

Impact of Aftermarket Parts:

- New Leak Points: Aftermarket parts may introduce new leak points.

- System Alterations: Modifications can change the behavior of the system.

- Diagnostic Challenges: Aftermarket parts can complicate the diagnostic process.

- Compatibility Issues: Ensure the smoke machine is compatible with the modified system.

- Careful Inspection: Requires careful inspection of all connections and components.

46. What Advanced Sensors Can a Smoke Machine Help Diagnose?

Smoke machines can assist in diagnosing issues with advanced sensors by revealing leaks that affect their performance.

Sensors Diagnosed:

- Oxygen Sensors: Detect exhaust leaks affecting sensor readings.