The long-term outlook for the current Diagnostic Trouble Code (DTC) formatting and structure involves evolution rather than revolution, with standardization and enhanced data capabilities becoming increasingly important, especially as seen with tools like MERCEDES-DIAGNOSTIC-TOOL.EDU.VN providing insights. The focus shifts towards comprehensive diagnostic solutions, integrating advanced technology to offer detailed and efficient troubleshooting for modern vehicles. This includes a greater emphasis on cloud-based diagnostics and predictive maintenance.

Contents

- 1. Understanding Diagnostic Trouble Codes (DTCs)

- 1.1 Historical Context of DTCs

- 1.2 Evolution of DTC Formats

- 1.3 Key Standards: OBD and UDS

- 2. Current DTC Formatting and Structure

- 2.1 Components of a DTC

- 2.2 Diagnostic Trouble Code Structure Explained

- 2.3 Standardized Exchange Formats: DEXT and ODX

- 3. Factors Influencing the Future of DTC Formatting

- 3.1 Increasing Complexity of Vehicle Systems

- 3.2 Rise of Electric Vehicles (EVs) and Hybrid Vehicles

- 3.3 Advancements in Diagnostic Tools and Techniques

- 3.4 Need for Enhanced Data Capabilities

- 4. Long-Term Outlook for DTC Formatting and Structure

- 4.1 Standardization and Harmonization Efforts

- 4.2 Integration with Cloud-Based Diagnostic Systems

- 4.3 Predictive Maintenance and Proactive Diagnostics

- 4.4 Enhanced Cybersecurity Measures

- 5. Key Technologies Shaping the Future of DTCs

- 5.1 Artificial Intelligence (AI) and Machine Learning (ML)

- 5.2 Wireless Communication and IoT (Internet of Things)

- 5.3 Big Data Analytics

- 6. How MERCEDES-DIAGNOSTIC-TOOL.EDU.VN is Adapting

- 6.1 Utilizing Advanced Diagnostic Tools

- 6.2 Comprehensive Database of DTC Information

- 6.3 Training and Support for Technicians

- 6.4 Remote Diagnostic Services

- 7. Implications for Automotive Technicians and Workshops

- 7.1 Need for Continuous Training and Education

- 7.2 Investment in Advanced Diagnostic Equipment

- 7.3 Adapting to New Diagnostic Procedures

- 7.4 Collaboration and Knowledge Sharing

- 8. Challenges and Opportunities

- 8.1 Challenges

- 8.2 Opportunities

- 9. The Future of Vehicle Diagnostics

- 9.1 Focus on Predictive Maintenance

- 9.2 Integration of Augmented Reality (AR)

- 9.3 Greater Emphasis on Remote Diagnostics

- 10. FAQ: Understanding the Future of DTC Formatting

1. Understanding Diagnostic Trouble Codes (DTCs)

Diagnostic Trouble Codes (DTCs) are alphanumeric codes used in vehicle diagnostics to identify specific faults or malfunctions within a vehicle’s systems. These codes are essential for technicians and vehicle owners to quickly identify and address issues, ensuring the vehicle operates safely and efficiently.

1.1 Historical Context of DTCs

Initially, DTCs were simple flashing codes on control units, measured by counting the flashes. However, with the increasing complexity of vehicle electronics, these basic codes were no longer adequate for diagnosing intricate problems. This led to the development of more sophisticated, standardized DTCs.

1.2 Evolution of DTC Formats

The evolution of DTC formats has progressed from proprietary diagnostic procedures to standardized formats. Currently, DTCs are available in 2-byte (OBD legislated codes) and 3-byte formats (UDS standardized), providing more detailed information about the specific fault.

1.3 Key Standards: OBD and UDS

OBD (On-Board Diagnostics): A standardized system required in most modern vehicles, OBD ensures consistent diagnostic information is available across different makes and models. It uses 2-byte DTCs to report basic emission-related faults.

UDS (Unified Diagnostic Services): An international standard (ISO 14229) that provides a more comprehensive diagnostic protocol. UDS employs 3-byte DTCs, offering greater detail and specificity for fault identification, particularly in advanced vehicle systems.

2. Current DTC Formatting and Structure

The current structure of DTCs is designed to provide precise information about vehicle malfunctions. Understanding this structure is crucial for accurate diagnostics and repairs.

2.1 Components of a DTC

A typical DTC consists of several key components:

Code: A five-character alphanumeric code (e.g., P0300) that identifies the fault.

Definition: A brief description of the fault indicated by the code (e.g., “Random/Multiple Cylinder Misfire Detected”).

Possible Causes: A list of potential reasons for the fault, which helps technicians narrow down the source of the problem.

Symptoms: Observable issues or performance changes that accompany the fault, aiding in the diagnostic process.

2.2 Diagnostic Trouble Code Structure Explained

The structure of a DTC is standardized to ensure consistency across different vehicle manufacturers. Each character in the code has a specific meaning:

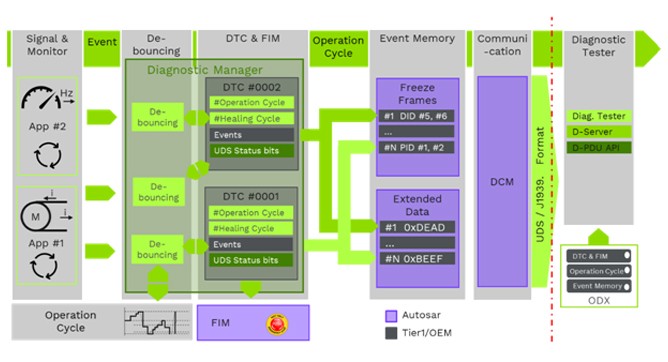

Process sequence of a DTC

Process sequence of a DTC

First Character: Indicates the system affected:

P (Powertrain): Relates to the engine, transmission, and related components.

B (Body): Concerns the vehicle’s body, including doors, seats, and airbags.

C (Chassis): Pertains to the chassis system, such as brakes, suspension, and steering.

U (Network): Indicates issues with the vehicle’s communication network.

Second Character: Specifies whether the code is generic or manufacturer-specific:

0: Generic OBD-II code, applicable to all vehicles.

1, 2, 3: Manufacturer-specific code, unique to a particular make and model.

Third Character: Identifies the specific subsystem affected:

0: Fuel and air metering and auxiliary emission controls.

1: Fuel and air metering.

2: Fuel and air metering – injector circuit.

3: Ignition system or misfires.

4: Auxiliary emission controls.

5: Vehicle speed control and idle control system.

6: Computer output circuit.

7: Transmission.

Fourth and Fifth Characters: Provide a specific fault number within the identified subsystem.

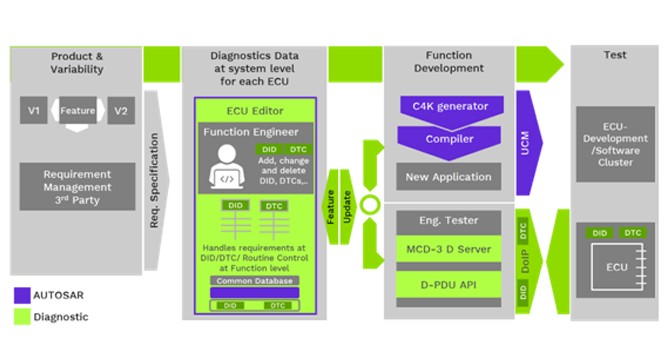

2.3 Standardized Exchange Formats: DEXT and ODX

Standardized exchange formats like DEXT (used in AUTOSAR) and ODX (used by ASAM) facilitate cooperation between vehicle manufacturers and suppliers by ensuring consistent data exchange during diagnostics.

DEXT (Diagnostic Exchange Format): Used primarily in embedded electronics development within the AUTOSAR framework, DEXT standardizes the way diagnostic data is structured and exchanged between different electronic control units (ECUs) in a vehicle. It defines the format for diagnostic events, DTC assignments, and related parameters, ensuring that diagnostic information is consistent and easily interpretable across different ECUs.

ODX (Open Diagnostic Data Exchange): ODX is used for off-board diagnostics. It provides a standardized format for exchanging diagnostic data between a vehicle and external diagnostic tools. ODX includes comprehensive information about DTCs, diagnostic services, data parameters, and vehicle variants, enabling diagnostic tools to accurately interpret and interact with vehicle ECUs.

3. Factors Influencing the Future of DTC Formatting

Several factors are shaping the future of DTC formatting and structure, requiring continuous adaptation to meet the demands of modern vehicle technology.

3.1 Increasing Complexity of Vehicle Systems

Modern vehicles are equipped with increasingly complex systems, including advanced driver-assistance systems (ADAS), electric powertrains, and sophisticated infotainment systems. This complexity necessitates more detailed and specific DTCs to accurately diagnose and address issues.

3.2 Rise of Electric Vehicles (EVs) and Hybrid Vehicles

The growing popularity of EVs and hybrid vehicles introduces new diagnostic challenges. Traditional DTCs designed for internal combustion engines may not be suitable for electric powertrains. As a result, new DTCs and diagnostic strategies are required to address the unique components and systems found in these vehicles, such as battery management systems, electric motors, and power inverters.

3.3 Advancements in Diagnostic Tools and Techniques

Advancements in diagnostic tools, such as wireless diagnostic interfaces, cloud-based diagnostics, and artificial intelligence (AI)-powered diagnostic platforms, are transforming the way DTCs are used. These tools enable technicians to access vehicle data remotely, perform complex diagnostic routines, and receive real-time assistance from expert systems.

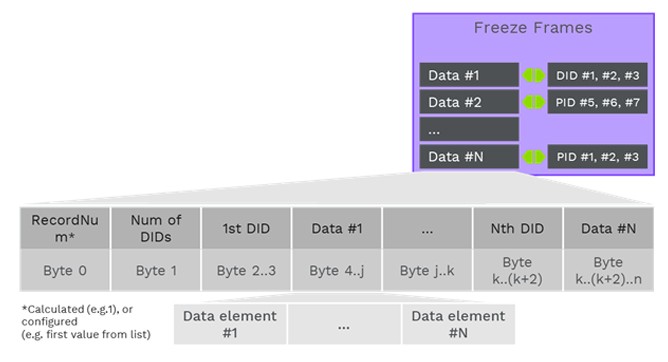

3.4 Need for Enhanced Data Capabilities

Enhanced data capabilities are essential for effective diagnostics. DTCs need to provide more than just a fault code; they should also include relevant data such as freeze frame data, sensor readings, and system status information. This additional data helps technicians understand the context of the fault, identify the root cause, and perform targeted repairs.

Details of DTC Snapshot Data

Details of DTC Snapshot Data

Freeze frame data captures the values of critical parameters at the moment a DTC is triggered, offering a snapshot of the conditions that led to the fault. Sensor readings provide real-time data from various sensors throughout the vehicle, allowing technicians to monitor system performance and identify anomalies. System status information indicates the operational state of different vehicle systems, helping technicians assess the overall health of the vehicle.

4. Long-Term Outlook for DTC Formatting and Structure

The long-term outlook for DTC formatting and structure involves several key trends and developments aimed at improving diagnostic accuracy, efficiency, and accessibility.

4.1 Standardization and Harmonization Efforts

Standardization and harmonization are crucial for ensuring that DTCs are consistent and easily understood across different vehicle makes and models. Efforts are underway to develop global standards for DTC formatting, terminology, and diagnostic procedures. These standards aim to reduce ambiguity, improve interoperability between diagnostic tools, and facilitate communication between technicians and vehicle manufacturers.

4.2 Integration with Cloud-Based Diagnostic Systems

The integration of DTCs with cloud-based diagnostic systems offers numerous benefits, including remote diagnostics, over-the-air updates, and predictive maintenance capabilities. Cloud-based systems allow technicians to access vehicle data remotely, perform diagnostic tests from anywhere with an internet connection, and receive real-time assistance from remote experts.

4.3 Predictive Maintenance and Proactive Diagnostics

Predictive maintenance uses data analytics and machine learning algorithms to identify potential faults before they occur. By analyzing historical DTC data, sensor readings, and other vehicle information, predictive maintenance systems can predict when a component is likely to fail and recommend proactive maintenance to prevent breakdowns.

4.4 Enhanced Cybersecurity Measures

As vehicles become more connected and reliant on software, cybersecurity is becoming increasingly important. DTC systems need to be protected from cyber threats to prevent unauthorized access, data breaches, and malicious attacks. Enhanced cybersecurity measures include secure boot processes, encryption of diagnostic data, and intrusion detection systems.

5. Key Technologies Shaping the Future of DTCs

Several key technologies are driving the evolution of DTCs, enhancing their capabilities and transforming the diagnostic process.

5.1 Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML are being used to analyze DTC data, identify patterns, and provide diagnostic insights. AI-powered diagnostic platforms can assist technicians in troubleshooting complex issues, recommend repair procedures, and even predict potential failures.

5.2 Wireless Communication and IoT (Internet of Things)

Wireless communication technologies such as Bluetooth, Wi-Fi, and cellular connectivity are enabling remote diagnostics and over-the-air updates. IoT devices, such as sensors and diagnostic dongles, can collect vehicle data and transmit it to cloud-based systems for analysis.

5.3 Big Data Analytics

Big data analytics involves collecting and analyzing large volumes of vehicle data to identify trends, patterns, and anomalies. By analyzing DTC data from thousands of vehicles, manufacturers can identify common failure points, improve vehicle designs, and develop more effective diagnostic strategies.

6. How MERCEDES-DIAGNOSTIC-TOOL.EDU.VN is Adapting

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN is at the forefront of adapting to the evolving landscape of DTC formatting and structure, ensuring that our users have access to the most advanced and comprehensive diagnostic solutions available.

6.1 Utilizing Advanced Diagnostic Tools

We leverage state-of-the-art diagnostic tools that support the latest DTC standards and protocols. Our tools are designed to accurately interpret DTCs, provide detailed fault information, and assist technicians in performing efficient and effective repairs.

6.2 Comprehensive Database of DTC Information

Our platform offers a comprehensive database of DTC information, including fault definitions, possible causes, symptoms, and repair procedures. This database is constantly updated to reflect the latest vehicle models and diagnostic standards, ensuring that our users have access to the most accurate and up-to-date information.

6.3 Training and Support for Technicians

We provide extensive training and support for technicians to help them stay ahead of the curve in vehicle diagnostics. Our training programs cover the latest DTC standards, diagnostic techniques, and repair procedures, empowering technicians to tackle even the most challenging diagnostic issues.

6.4 Remote Diagnostic Services

Our remote diagnostic services enable technicians to access expert support and assistance from anywhere with an internet connection. By connecting to a vehicle remotely, our diagnostic experts can analyze DTC data, perform diagnostic tests, and provide real-time guidance to technicians in the field.

7. Implications for Automotive Technicians and Workshops

The evolving landscape of DTC formatting and structure has significant implications for automotive technicians and workshops.

7.1 Need for Continuous Training and Education

Technicians need to continuously update their skills and knowledge to keep pace with the latest diagnostic standards and technologies. Training programs, certifications, and continuing education courses are essential for staying ahead of the curve.

7.2 Investment in Advanced Diagnostic Equipment

Workshops need to invest in advanced diagnostic equipment to accurately diagnose and repair modern vehicles. This equipment includes scan tools, diagnostic software, wireless interfaces, and cloud-based diagnostic platforms.

7.3 Adapting to New Diagnostic Procedures

Technicians need to adapt to new diagnostic procedures and techniques, such as remote diagnostics, predictive maintenance, and AI-powered diagnostics. These procedures require a different skill set and mindset compared to traditional diagnostic methods.

7.4 Collaboration and Knowledge Sharing

Collaboration and knowledge sharing are becoming increasingly important in the automotive industry. Technicians can benefit from sharing their experiences, insights, and best practices with their peers. Online forums, technical communities, and industry events provide valuable opportunities for collaboration and knowledge sharing.

Uniform data assignment process for DTCs and DIDs

Uniform data assignment process for DTCs and DIDs

8. Challenges and Opportunities

The evolution of DTC formatting and structure presents both challenges and opportunities for the automotive industry.

8.1 Challenges

Complexity: The increasing complexity of vehicle systems and DTC standards can be challenging for technicians to keep up with.

Cost: Investing in advanced diagnostic equipment and training can be costly for workshops.

Cybersecurity: Protecting DTC systems from cyber threats is an ongoing challenge.

Data Privacy: Ensuring the privacy and security of vehicle data is essential as DTC systems become more connected.

8.2 Opportunities

Improved Diagnostic Accuracy: Enhanced DTCs and diagnostic tools can improve the accuracy and efficiency of vehicle diagnostics.

Enhanced Customer Satisfaction: By addressing issues proactively and providing accurate diagnoses, workshops can enhance customer satisfaction.

New Revenue Streams: Remote diagnostics, predictive maintenance, and other advanced diagnostic services can create new revenue streams for workshops.

Industry Collaboration: Collaboration between vehicle manufacturers, diagnostic tool providers, and technicians can lead to more effective diagnostic solutions.

9. The Future of Vehicle Diagnostics

The future of vehicle diagnostics is bright, with numerous innovations and developments on the horizon. From AI-powered diagnostic platforms to cloud-based systems and predictive maintenance solutions, the automotive industry is poised to enter a new era of diagnostic capabilities.

9.1 Focus on Predictive Maintenance

Predictive maintenance will become increasingly prevalent as manufacturers and workshops seek to identify potential faults before they occur. By analyzing vehicle data and using machine learning algorithms, predictive maintenance systems can recommend proactive maintenance to prevent breakdowns and extend the lifespan of vehicles.

9.2 Integration of Augmented Reality (AR)

Augmented reality (AR) technology is being integrated into diagnostic tools to provide technicians with visual guidance and real-time information. AR-enabled diagnostic platforms can overlay diagnostic data onto the vehicle, highlighting components, displaying sensor readings, and providing step-by-step repair instructions.

9.3 Greater Emphasis on Remote Diagnostics

Remote diagnostics will become increasingly common as vehicles become more connected and diagnostic tools become more sophisticated. Remote diagnostic services enable technicians to access vehicle data remotely, perform diagnostic tests from anywhere with an internet connection, and receive real-time assistance from remote experts.

10. FAQ: Understanding the Future of DTC Formatting

Q1: What is the future of DTC formatting and structure?

A1: The future of DTC formatting and structure involves standardization, enhanced data capabilities, integration with cloud-based systems, and advancements in AI and machine learning.

Q2: How are DTCs evolving with the rise of electric vehicles?

A2: New DTCs and diagnostic strategies are being developed to address the unique components and systems in electric vehicles, such as battery management systems and electric motors.

Q3: What role does cloud-based diagnostics play in the future of DTCs?

A3: Cloud-based diagnostics enable remote diagnostics, over-the-air updates, and predictive maintenance capabilities, enhancing the efficiency and accuracy of vehicle diagnostics.

Q4: How is AI being used in vehicle diagnostics?

A4: AI is being used to analyze DTC data, identify patterns, provide diagnostic insights, and recommend repair procedures.

Q5: What are the key challenges in adapting to the evolving landscape of DTCs?

A5: Key challenges include the increasing complexity of vehicle systems, the cost of investing in advanced diagnostic equipment, cybersecurity threats, and data privacy concerns.

Q6: How can automotive technicians stay ahead of the curve in vehicle diagnostics?

A6: Technicians can stay ahead by continuously updating their skills, investing in advanced diagnostic equipment, adapting to new diagnostic procedures, and collaborating with peers.

Q7: What is predictive maintenance and how does it relate to DTCs?

A7: Predictive maintenance uses data analytics to identify potential faults before they occur, analyzing DTC data and sensor readings to recommend proactive maintenance.

Q8: How does MERCEDES-DIAGNOSTIC-TOOL.EDU.VN adapt to the evolving landscape of DTCs?

A8: MERCEDES-DIAGNOSTIC-TOOL.EDU.VN utilizes advanced diagnostic tools, maintains a comprehensive DTC database, provides training and support for technicians, and offers remote diagnostic services.

Q9: What are the benefits of standardized DTC formats?

A9: Standardized DTC formats ensure consistency across different vehicle makes and models, improve interoperability between diagnostic tools, and facilitate communication between technicians and manufacturers.

Q10: How are cybersecurity measures being enhanced in DTC systems?

A10: Enhanced cybersecurity measures include secure boot processes, encryption of diagnostic data, and intrusion detection systems to protect DTC systems from cyber threats.

Understanding the trajectory of DTC formatting and structure is essential for staying competitive in the automotive industry. By embracing new technologies and adapting to evolving standards, technicians and workshops can provide superior diagnostic services and enhance customer satisfaction. Stay informed and prepared with MERCEDES-DIAGNOSTIC-TOOL.EDU.VN.

Are you looking for expert guidance on the latest in Mercedes-Benz diagnostics? Contact us today for personalized advice on diagnostic tools, unlocking hidden features, and mastering Mercedes-Benz maintenance at 789 Oak Avenue, Miami, FL 33101, United States. Reach out via WhatsApp at +1 (641) 206-8880 or visit our website at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for more information. Let us help you keep your Mercedes-Benz running smoothly.