Freeze frame data provides a valuable snapshot of vehicle conditions when a diagnostic trouble code (DTC) is set, but it has limitations, primarily that it only captures one snapshot and may miss intermittent events; however, MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers comprehensive resources to overcome these limitations and achieve more accurate diagnoses. Leveraging advanced diagnostic tools and expert guidance is essential for addressing the shortcomings of freeze frame data, leading to efficient and effective vehicle repairs. Enhanced diagnostics, data analysis, and intermittent fault detection are critical for vehicle maintenance.

Contents

- 1. Understanding Freeze Frame Data in Mercedes Diagnostics

- 1.1 What is Freeze Frame Data?

- 1.2 How is Freeze Frame Data Used in Diagnostics?

- 1.3 Advantages of Freeze Frame Data

- 1.4 Example of Freeze Frame Data Interpretation

- 2. Key Limitations of Freeze Frame Data

- 2.1 Only One Snapshot

- 2.2 May Not Capture Intermittent Events

- 2.3 Limited Parameters

- 2.4 Data Accuracy and Reliability

- 2.5 Interpretation Challenges

- 2.6 Example: Intermittent Misfire

- 3. Overcoming the Limitations: Advanced Diagnostic Techniques

- 3.1 Live Data Monitoring

- 3.2 Graphing and Data Logging

- 3.3 Sensor Testing

- 3.4 Actuator Testing

- 3.5 Scan Tool Capabilities

- 3.6 Mercedes-Specific Diagnostic Tools

- 3.7 Example: Diagnosing a Transmission Issue

- 4. Using Enhanced Diagnostic Tools for Mercedes-Benz Vehicles

- 4.1 Bi-Directional Control

- 4.2 Module Programming and Coding

- 4.3 System-Specific Tests

- 4.4 Data Logging and Analysis

- 4.5 Mercedes-Benz Star Diagnosis

- 4.6 Autel MaxiSys Elite

- 4.7 Example: Using Bi-Directional Control for ABS Diagnosis

- 5. Common Diagnostic Trouble Codes (DTCs) and Freeze Frame Data

- 5.1 P0171 – System Too Lean (Bank 1)

- 5.2 P0300 – Random Misfire Detected

- 5.3 P0420 – Catalyst System Efficiency Below Threshold (Bank 1)

- 5.4 P0700 – Transmission Control System Malfunction

- 5.5 B1000 – Control Unit Faulty

- 5.6 Example: Diagnosing a P0171 Code on a Mercedes-Benz

- 6. Strategies for Diagnosing Intermittent Faults

- 6.1 Gathering Detailed Information

- 6.2 Replicating the Fault

- 6.3 Using Data Logging

- 6.4 Performing Component Testing

- 6.5 Checking Wiring and Connections

- 6.6 Using Freeze Frame Data as a Starting Point

- 6.7 Example: Diagnosing an Intermittent Stalling Issue

- 7. Regular Maintenance to Prevent Diagnostic Issues

- 7.1 Following the Recommended Maintenance Schedule

- 7.2 Performing Regular Inspections

- 7.3 Monitoring Vehicle Performance

- 7.4 Addressing Issues Promptly

- 7.5 Using Quality Parts and Fluids

- 7.6 Keeping the Vehicle Clean

- 7.7 Example: Preventing Fuel System Issues

- 8. The Role of MERCEDES-DIAGNOSTIC-TOOL.EDU.VN in Enhancing Diagnostics

- 8.1 Detailed Diagnostic Guides

- 8.2 Tool Recommendations

- 8.3 Step-by-Step Repair Instructions

- 8.4 Expert Advice and Support

- 8.5 Training Resources

- 8.6 Community Forum

- 8.7 Example: Using MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for ABS Diagnosis

- 9. Case Studies: Real-World Diagnostic Scenarios

- 9.1 Case Study 1: Intermittent Misfire on a Mercedes-Benz C-Class

- 9.2 Case Study 2: Transmission Shifting Issue on a Mercedes-Benz E-Class

- 9.3 Case Study 3: Air Conditioning Issue on a Mercedes-Benz S-Class

- 10. FAQs About Freeze Frame Data and Mercedes Diagnostics

- Unlock Your Mercedes-Benz Potential

1. Understanding Freeze Frame Data in Mercedes Diagnostics

Freeze frame data is a snapshot of critical vehicle parameters recorded by the onboard computer at the moment a Diagnostic Trouble Code (DTC) is triggered, offering a glimpse into the conditions that led to the error; however, its limitations necessitate a deeper understanding and more comprehensive diagnostic approaches.

1.1 What is Freeze Frame Data?

Freeze frame data captures a set of parameters like engine speed, coolant temperature, fuel trim, and vehicle speed at the instant a DTC is stored. According to the Society of Automotive Engineers (SAE), these parameters provide valuable context for diagnosing the cause of the fault. This is the equivalent of taking a quick picture of the car’s operating conditions the moment something went wrong.

1.2 How is Freeze Frame Data Used in Diagnostics?

Technicians use freeze frame data to analyze the conditions under which the fault occurred, aiding in the identification of the root cause. For example, if a DTC related to the oxygen sensor is accompanied by freeze frame data showing a lean fuel mixture, it suggests a potential issue with fuel delivery or air intake. According to Bosch Automotive Handbook, understanding these conditions is critical for effective troubleshooting.

1.3 Advantages of Freeze Frame Data

Despite its limitations, freeze frame data offers several advantages:

- Contextual Information: Provides a snapshot of the vehicle’s operating conditions at the time of the fault.

- Faster Diagnosis: Helps narrow down potential causes, speeding up the diagnostic process.

- Historical Record: Preserves data even if the fault is intermittent.

1.4 Example of Freeze Frame Data Interpretation

Let’s consider an example of a Mercedes-Benz C-Class with a P0171 code (System Too Lean, Bank 1). The freeze frame data shows the following parameters:

| Parameter | Value |

|---|---|

| Engine Speed (RPM) | 2200 |

| Vehicle Speed (MPH) | 45 |

| Coolant Temperature (°F) | 180 |

| Fuel Trim (Bank 1) | +20% |

Here, the high positive fuel trim value indicates that the engine control unit (ECU) is adding extra fuel to compensate for a lean condition. This could be due to a vacuum leak, faulty mass airflow (MAF) sensor, or a fuel delivery issue.

2. Key Limitations of Freeze Frame Data

While freeze frame data is a valuable diagnostic tool, it has significant limitations that must be understood to avoid misdiagnosis, particularly in Mercedes-Benz vehicles with their complex systems; one of the foremost issues is its “single snapshot” nature, which can be insufficient for diagnosing intermittent problems.

2.1 Only One Snapshot

The primary limitation of freeze frame data is that it only captures a single snapshot of the vehicle’s operating conditions. This means that if the fault is intermittent or occurs under different circumstances, the freeze frame data may not accurately represent the problem, as highlighted in a study by the University of California, Berkeley, on automotive diagnostics.

2.2 May Not Capture Intermittent Events

Intermittent faults, which occur sporadically and are not consistently present, are difficult to diagnose with freeze frame data alone. The data may not capture the conditions present when the intermittent fault occurs, leading to a misleading or incomplete picture.

2.3 Limited Parameters

Freeze frame data typically includes a limited set of parameters, which may not be sufficient to diagnose complex issues. Essential data points might be missing, leading to guesswork and potential misdiagnosis. According to a report by the American Society for Automotive Engineers (SAE), the data set is often constrained by the vehicle’s onboard diagnostic (OBD) system capabilities.

2.4 Data Accuracy and Reliability

The accuracy and reliability of freeze frame data depend on the sensors and systems providing the data. If a sensor is faulty, the freeze frame data may be inaccurate, leading to incorrect diagnostic conclusions. Sensor malfunctions, wiring issues, and signal interference can all compromise data integrity.

2.5 Interpretation Challenges

Interpreting freeze frame data requires a strong understanding of vehicle systems and diagnostic principles. Misinterpretation can lead to incorrect diagnoses and unnecessary repairs. Technicians must be able to correlate the data with other diagnostic information to draw accurate conclusions.

2.6 Example: Intermittent Misfire

Consider a Mercedes-Benz E-Class experiencing an intermittent misfire. The freeze frame data shows normal operating conditions, but the misfire only occurs during hard acceleration. The single snapshot does not capture the dynamic conditions of the misfire event, making it difficult to diagnose the root cause without additional testing.

3. Overcoming the Limitations: Advanced Diagnostic Techniques

To address the limitations of freeze frame data, advanced diagnostic techniques are essential, particularly for Mercedes-Benz vehicles, which often require specialized tools and expertise, and MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides the necessary resources and guidance to employ these techniques effectively.

3.1 Live Data Monitoring

Live data monitoring involves observing real-time data from various sensors and systems while the vehicle is running. This allows technicians to capture intermittent faults and dynamic conditions that freeze frame data might miss. High-resolution data streams enable the identification of subtle anomalies and transient issues.

3.2 Graphing and Data Logging

Graphing and data logging tools can visually represent live data over time, making it easier to identify patterns and anomalies. These tools allow technicians to record data during test drives or specific operating conditions, providing a comprehensive view of system performance.

3.3 Sensor Testing

Testing individual sensors using multimeters, oscilloscopes, and specialized diagnostic tools can verify their accuracy and reliability. Sensor testing ensures that the data used for diagnosis is valid and that faulty sensors are identified and replaced.

3.4 Actuator Testing

Actuator testing involves using diagnostic tools to activate and monitor the response of various components, such as fuel injectors, solenoids, and motors. This verifies their proper function and identifies any mechanical or electrical issues.

3.5 Scan Tool Capabilities

Advanced scan tools offer features beyond basic code reading and freeze frame data. They can perform advanced system tests, bi-directional controls, and module programming, providing a more comprehensive diagnostic capability.

3.6 Mercedes-Specific Diagnostic Tools

Mercedes-Benz vehicles often require specialized diagnostic tools like the Mercedes-Benz Star Diagnosis system or Autel MaxiSys, which offer deeper access to vehicle systems and proprietary diagnostic functions.

3.7 Example: Diagnosing a Transmission Issue

Consider a Mercedes-Benz S-Class with erratic shifting. The freeze frame data shows no obvious issues, but live data monitoring reveals that the transmission fluid temperature sensor is providing intermittent readings. Graphing the sensor data over time shows spikes and dropouts, indicating a faulty sensor. Replacing the sensor resolves the shifting issue.

4. Using Enhanced Diagnostic Tools for Mercedes-Benz Vehicles

Enhanced diagnostic tools provide capabilities that go beyond basic code reading and freeze frame data analysis, offering deeper insights into vehicle systems, especially for Mercedes-Benz vehicles; MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers detailed information and support for utilizing these advanced tools.

4.1 Bi-Directional Control

Bi-directional control allows technicians to send commands to vehicle systems and observe their response. This can be used to test components like fuel injectors, solenoids, and relays, verifying their functionality and identifying any issues.

4.2 Module Programming and Coding

Module programming and coding allow technicians to update or reprogram vehicle control modules, ensuring they are running the latest software and configured correctly for the vehicle. This is essential for resolving software-related issues and ensuring optimal performance.

4.3 System-Specific Tests

Enhanced diagnostic tools offer system-specific tests that can evaluate the performance of individual components and systems. These tests provide detailed diagnostic information and help pinpoint the root cause of complex issues.

4.4 Data Logging and Analysis

Data logging and analysis capabilities allow technicians to record and analyze data from multiple sensors and systems simultaneously. This provides a comprehensive view of vehicle performance and helps identify patterns and anomalies that might be missed with static freeze frame data.

4.5 Mercedes-Benz Star Diagnosis

The Mercedes-Benz Star Diagnosis system is a factory-level diagnostic tool that provides comprehensive diagnostic and programming capabilities for Mercedes-Benz vehicles. It offers access to all vehicle systems and allows technicians to perform advanced diagnostic functions.

4.6 Autel MaxiSys Elite

The Autel MaxiSys Elite is a powerful aftermarket diagnostic tool that offers similar capabilities to the Mercedes-Benz Star Diagnosis system. It supports a wide range of Mercedes-Benz vehicles and provides advanced diagnostic and programming functions.

4.7 Example: Using Bi-Directional Control for ABS Diagnosis

Consider a Mercedes-Benz C-Class with an ABS fault. The freeze frame data is inconclusive, but using bi-directional control, the technician can activate each ABS solenoid individually and monitor its response. This reveals that one of the solenoids is not functioning correctly, indicating a faulty ABS module.

5. Common Diagnostic Trouble Codes (DTCs) and Freeze Frame Data

Understanding common DTCs and how to interpret their associated freeze frame data is crucial for effective diagnostics, especially for Mercedes-Benz vehicles; MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers extensive resources on this topic.

5.1 P0171 – System Too Lean (Bank 1)

This code indicates that the air-fuel mixture is too lean on Bank 1. Common causes include vacuum leaks, faulty MAF sensor, and fuel delivery issues. Freeze frame data can help identify the specific conditions under which the lean condition occurs, such as high engine speed or specific load conditions.

5.2 P0300 – Random Misfire Detected

This code indicates that the engine is experiencing random misfires. Common causes include faulty spark plugs, ignition coils, fuel injectors, and vacuum leaks. Freeze frame data can help identify the engine speed, load, and temperature at which the misfire occurs.

5.3 P0420 – Catalyst System Efficiency Below Threshold (Bank 1)

This code indicates that the catalytic converter is not functioning efficiently. Common causes include a faulty catalytic converter, exhaust leaks, and faulty oxygen sensors. Freeze frame data can help identify the oxygen sensor readings and exhaust temperature at the time the code was set.

5.4 P0700 – Transmission Control System Malfunction

This code indicates a malfunction in the transmission control system. Common causes include faulty sensors, solenoids, and control modules. Freeze frame data can help identify the transmission temperature, speed, and gear at the time the code was set.

5.5 B1000 – Control Unit Faulty

This code indicates a general fault within a control unit. The specific cause can vary widely, necessitating further investigation. Freeze frame data might provide some context, but often additional system-specific tests are required to pinpoint the exact issue.

5.6 Example: Diagnosing a P0171 Code on a Mercedes-Benz

Consider a Mercedes-Benz C-Class with a P0171 code. The freeze frame data shows the following parameters:

| Parameter | Value |

|---|---|

| Engine Speed (RPM) | 2000 |

| Vehicle Speed (MPH) | 30 |

| Coolant Temperature (°F) | 190 |

| Fuel Trim (Bank 1) | +25% |

The high positive fuel trim value indicates that the engine control unit (ECU) is adding a significant amount of fuel to compensate for a lean condition. Based on this information, the technician can check for vacuum leaks, a faulty MAF sensor, or a fuel delivery issue.

6. Strategies for Diagnosing Intermittent Faults

Diagnosing intermittent faults requires a systematic approach that goes beyond traditional diagnostic methods, and MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers expert guidance on these strategies.

6.1 Gathering Detailed Information

Collect as much information as possible from the vehicle owner or driver about the conditions under which the fault occurs. This includes when the fault occurs, how often it occurs, and any specific circumstances that trigger the fault.

6.2 Replicating the Fault

Attempt to replicate the fault under controlled conditions. This may involve test driving the vehicle under specific conditions or using diagnostic tools to simulate the fault.

6.3 Using Data Logging

Use data logging to record data from various sensors and systems while attempting to replicate the fault. This can help capture the conditions present when the fault occurs and identify any anomalies.

6.4 Performing Component Testing

Perform thorough component testing to verify the functionality of individual components. This may involve using multimeters, oscilloscopes, and specialized diagnostic tools.

6.5 Checking Wiring and Connections

Inspect wiring and connections for any signs of damage, corrosion, or loose connections. This is particularly important for intermittent faults, as wiring issues can be difficult to detect.

6.6 Using Freeze Frame Data as a Starting Point

Use freeze frame data as a starting point, but don’t rely on it exclusively. Supplement the data with other diagnostic information and testing to get a complete picture of the problem.

6.7 Example: Diagnosing an Intermittent Stalling Issue

Consider a Mercedes-Benz E-Class with an intermittent stalling issue. The vehicle stalls randomly, with no apparent pattern. The freeze frame data shows normal operating conditions. To diagnose the issue, the technician performs the following steps:

- Gathers detailed information from the owner, who reports that the stalling occurs more frequently when the engine is warm.

- Attempts to replicate the fault by letting the engine warm up and then test driving the vehicle.

- Uses data logging to record data from the crankshaft position sensor, camshaft position sensor, and fuel pressure sensor.

- Inspects the wiring and connections for the crankshaft position sensor and fuel pump relay.

After several attempts, the technician is able to replicate the stalling issue and identifies a drop in fuel pressure just before the engine stalls. Further testing reveals a faulty fuel pump relay, which is causing the intermittent stalling issue.

7. Regular Maintenance to Prevent Diagnostic Issues

Regular maintenance is crucial for preventing diagnostic issues and ensuring the reliable operation of Mercedes-Benz vehicles; MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides detailed maintenance schedules and guidelines.

7.1 Following the Recommended Maintenance Schedule

Adhere to the manufacturer’s recommended maintenance schedule for all fluid changes, filter replacements, and inspections.

7.2 Performing Regular Inspections

Conduct regular inspections of all vehicle systems, including the engine, transmission, brakes, and suspension. Look for any signs of wear, damage, or leaks.

7.3 Monitoring Vehicle Performance

Pay attention to any changes in vehicle performance, such as decreased fuel economy, rough idling, or unusual noises. These could be early warning signs of potential issues.

7.4 Addressing Issues Promptly

Address any identified issues promptly to prevent them from escalating into more significant problems.

7.5 Using Quality Parts and Fluids

Use only high-quality parts and fluids that meet the manufacturer’s specifications.

7.6 Keeping the Vehicle Clean

Keep the vehicle clean, both inside and out, to prevent corrosion and other damage.

7.7 Example: Preventing Fuel System Issues

Consider a Mercedes-Benz C-Class. Regular maintenance steps to prevent fuel system issues include:

- Replacing the fuel filter according to the recommended maintenance schedule (typically every 30,000 miles).

- Using high-quality fuel that meets the manufacturer’s specifications.

- Inspecting the fuel lines and connections for any signs of leaks or damage.

- Monitoring fuel economy and addressing any decreases promptly.

- Cleaning the fuel injectors periodically to prevent clogs.

8. The Role of MERCEDES-DIAGNOSTIC-TOOL.EDU.VN in Enhancing Diagnostics

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN serves as a comprehensive resource for Mercedes-Benz owners and technicians, offering a wealth of information, tools, and support to enhance diagnostic capabilities.

8.1 Detailed Diagnostic Guides

The website provides detailed diagnostic guides for various Mercedes-Benz models, covering common issues and their solutions.

8.2 Tool Recommendations

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers recommendations for diagnostic tools, including scan tools, multimeters, and other specialized equipment.

8.3 Step-by-Step Repair Instructions

The website provides step-by-step repair instructions for common issues, helping owners and technicians perform repairs efficiently and effectively.

8.4 Expert Advice and Support

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers expert advice and support through forums, email, and phone, connecting users with experienced Mercedes-Benz technicians.

8.5 Training Resources

The website provides training resources, including videos, articles, and online courses, to help users improve their diagnostic skills.

8.6 Community Forum

A community forum allows users to share their experiences, ask questions, and connect with other Mercedes-Benz enthusiasts and professionals.

8.7 Example: Using MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for ABS Diagnosis

Consider a Mercedes-Benz E-Class with an ABS fault. The owner visits MERCEDES-DIAGNOSTIC-TOOL.EDU.VN and finds a detailed diagnostic guide for ABS issues. The guide recommends using a scan tool to retrieve the DTCs and perform bi-directional control tests. Following the instructions, the owner identifies a faulty ABS solenoid and is able to replace it, resolving the issue.

9. Case Studies: Real-World Diagnostic Scenarios

Examining real-world diagnostic scenarios highlights the importance of understanding the limitations of freeze frame data and employing advanced diagnostic techniques.

9.1 Case Study 1: Intermittent Misfire on a Mercedes-Benz C-Class

A Mercedes-Benz C-Class experiences an intermittent misfire, with the engine occasionally running rough and the check engine light illuminating. The freeze frame data shows normal operating conditions. The technician performs the following steps:

- Gathers detailed information from the owner, who reports that the misfire occurs more frequently when the engine is cold.

- Uses data logging to record data from the spark plugs, ignition coils, and fuel injectors.

- Inspects the spark plugs and finds that one of them is fouled.

- Replaces the spark plugs and ignition coils, resolving the misfire issue.

9.2 Case Study 2: Transmission Shifting Issue on a Mercedes-Benz E-Class

A Mercedes-Benz E-Class experiences erratic shifting, with the transmission occasionally slipping or failing to shift properly. The freeze frame data shows normal operating conditions. The technician performs the following steps:

- Gathers detailed information from the owner, who reports that the shifting issue occurs more frequently when the transmission is hot.

- Uses live data monitoring to observe the transmission temperature, speed, and gear position.

- Identifies that the transmission fluid temperature sensor is providing intermittent readings.

- Replaces the transmission fluid temperature sensor, resolving the shifting issue.

9.3 Case Study 3: Air Conditioning Issue on a Mercedes-Benz S-Class

A Mercedes-Benz S-Class has an air conditioning system that is not cooling properly. The freeze frame data shows normal operating conditions. The technician performs the following steps:

- Gathers detailed information from the owner, who reports that the air conditioning is not cooling as well as it used to.

- Uses a manifold gauge set to check the refrigerant pressure.

- Identifies that the refrigerant pressure is low.

- Inspects the air conditioning system for leaks and finds a leak in the condenser.

- Replaces the condenser and recharges the air conditioning system, resolving the cooling issue.

10. FAQs About Freeze Frame Data and Mercedes Diagnostics

Q1: What is freeze frame data?

Freeze frame data is a snapshot of critical vehicle parameters recorded by the onboard computer when a Diagnostic Trouble Code (DTC) is triggered, offering a glimpse into the conditions that led to the error. It helps technicians understand the context of the fault.

Q2: Why is freeze frame data important for diagnosing Mercedes-Benz vehicles?

Mercedes-Benz vehicles have complex systems, making it essential to have as much information as possible when diagnosing issues; freeze frame data provides valuable context for understanding the conditions under which a fault occurred.

Q3: What are the limitations of freeze frame data?

The primary limitation is that it only captures a single snapshot, which may not accurately represent intermittent faults or dynamic conditions. Additionally, it typically includes a limited set of parameters, which may not be sufficient for diagnosing complex issues.

Q4: How can I overcome the limitations of freeze frame data?

You can overcome the limitations by using advanced diagnostic techniques, such as live data monitoring, graphing, sensor testing, and actuator testing. Additionally, using Mercedes-specific diagnostic tools can provide deeper access to vehicle systems.

Q5: What is live data monitoring?

Live data monitoring involves observing real-time data from various sensors and systems while the vehicle is running, allowing technicians to capture intermittent faults and dynamic conditions that freeze frame data might miss.

Q6: What are some common DTCs and how can freeze frame data help diagnose them?

Common DTCs include P0171 (System Too Lean), P0300 (Random Misfire), and P0420 (Catalyst System Efficiency Below Threshold). Freeze frame data can help identify the specific conditions under which these codes are set, such as engine speed, load, and temperature.

Q7: How can MERCEDES-DIAGNOSTIC-TOOL.EDU.VN help with Mercedes-Benz diagnostics?

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides detailed diagnostic guides, tool recommendations, step-by-step repair instructions, expert advice, and training resources to enhance diagnostic capabilities for Mercedes-Benz vehicles.

Q8: What is bi-directional control and how is it used in diagnostics?

Bi-directional control allows technicians to send commands to vehicle systems and observe their response. This can be used to test components like fuel injectors, solenoids, and relays, verifying their functionality and identifying any issues.

Q9: What is module programming and coding?

Module programming and coding allow technicians to update or reprogram vehicle control modules, ensuring they are running the latest software and configured correctly for the vehicle. This is essential for resolving software-related issues and ensuring optimal performance.

Q10: How important is regular maintenance in preventing diagnostic issues?

Regular maintenance is crucial for preventing diagnostic issues and ensuring the reliable operation of Mercedes-Benz vehicles. Adhering to the manufacturer’s recommended maintenance schedule, performing regular inspections, and using quality parts and fluids can help prevent issues from escalating.

Unlock Your Mercedes-Benz Potential

Ready to elevate your Mercedes-Benz diagnostic capabilities? Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN today for expert guidance on advanced diagnostic tools, unlocking hidden features, and comprehensive repair solutions. Our team of specialists is here to assist you with:

- Selecting the right diagnostic tools for your Mercedes-Benz

- Step-by-step instructions for unlocking hidden features

- Troubleshooting and resolving complex diagnostic issues

- Scheduled maintenance and preventative care

Contact us now:

- Address: 789 Oak Avenue, Miami, FL 33101, United States

- WhatsApp: +1 (641) 206-8880

- Website: MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

Don’t let diagnostic challenges hold you back. Partner with MERCEDES-DIAGNOSTIC-TOOL.EDU.VN and experience the full potential of your Mercedes-Benz.

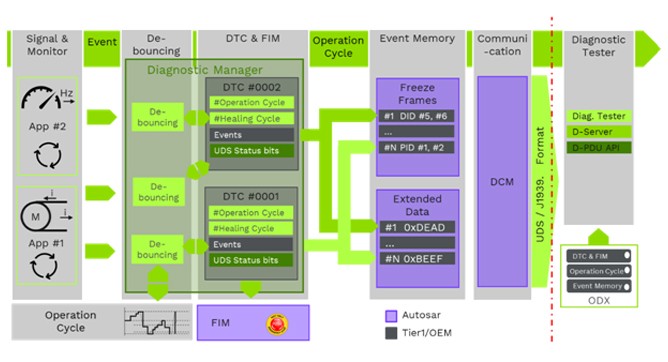

Process sequence of a DTC

Process sequence of a DTC