The system in the vehicle that generates DTCs is the onboard diagnostics (OBD) system, which includes modules like the ECU, ECM, and PCM. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we provide comprehensive information and resources to help you understand and utilize these diagnostic trouble codes effectively. By understanding these systems, you can enhance your vehicle’s performance and longevity through proactive maintenance. We offer solutions for decoding and addressing issues, leveraging advanced diagnostic tools for efficient vehicle management, and providing access to the latest technology for smarter fleet operations.

Contents

- 1. Understanding Diagnostic Trouble Codes (DTCs)

- 1.1. The Role of OBD Systems

- 1.2. Structure of a DTC

- 1.3. Types of DTCs

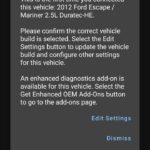

- 1.4. Interpreting DTCs Effectively

- 2. Key Components Generating DTCs: ECU, ECM, and PCM

- 2.1. Engine Control Unit (ECU)

- 2.2. Engine Control Module (ECM)

- 2.3. Powertrain Control Module (PCM)

- 2.4. How These Components Generate DTCs

- 3. Advanced DTC Monitoring and Telematics Systems

- 3.1. Real-Time Diagnostics

- 3.2. Benefits of Real-Time DTC Monitoring

- 3.3. Telematics Systems and DTC Management

- 3.4. Automating DTC Management

- 3.5. Motive’s Vehicle Diagnostics Feature

- 4. Interpreting DTCs: A Step-by-Step Guide

- 4.1. Understanding the DTC Structure

- 4.2. Accessing DTC Definitions

- 4.3. Performing Diagnostic Tests

- 4.4. Example: Interpreting DTC P0301

- 5. Common DTC Examples and Their Meanings

- 5.1. Powertrain (P) Codes

- 5.2. Chassis (C) Codes

- 5.3. Body (B) Codes

- 5.4. Network & Vehicle Integration (U) Codes

- 5.5. Using Fleet Management Systems for Troubleshooting

- 6. How to Read DTC Fault Codes Using a Scan Tool

- 6.1. Locating the OBD-II Diagnostic Connector

- 6.2. Connecting the Scan Tool

- 6.3. Turning on the Ignition

- 6.4. Selecting the “Read Codes” Option

- 6.5. Viewing the DTCs

- 6.6. Clearing DTCs (With Caution)

- 6.7. Using Telematics Systems for DTC Monitoring

- 7. Best Practices for Fleet Managers

- 7.1. Train Drivers

- 7.2. Leverage Technology

- 7.3. Use Predictive Maintenance

- 7.4. Partner with Experts

- 7.5. Implement a Preventive Maintenance Program

- 7.6. Utilize Fleet Management Software

- 7.7. Regularly Update Diagnostic Tools

- 8. Vehicle Diagnostics and Maintenance Solutions

- 8.1. Real-Time Fault Monitoring

- 8.2. Proactive Issue Diagnosis

- 8.3. Timely Intervention

- 8.4. Key Features of Effective Solutions

- 8.5. Benefits of Effective Solutions

- 9. The Future of DTCs and Vehicle Diagnostics

- 9.1. Increased Complexity of DTCs

- 9.2. Integration with Artificial Intelligence (AI)

- 9.3. Over-the-Air (OTA) Updates

- 9.4. Enhanced Cybersecurity

- 9.5. Shift Towards Remote Diagnostics

- 10. FAQ About DTCs and Vehicle Diagnostics

1. Understanding Diagnostic Trouble Codes (DTCs)

Diagnostic Trouble Codes (DTCs) are alphanumeric codes generated by a vehicle’s onboard diagnostics (OBD) system to identify specific issues or malfunctions. These codes are crucial for diagnosing and repairing vehicle problems, ensuring optimal performance and safety. Understanding the structure, types, and interpretation of DTCs is essential for effective vehicle maintenance and repair, and is a key aspect of the services offered at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN.

1.1. The Role of OBD Systems

Onboard diagnostics (OBD) systems continuously monitor the performance of various vehicle components and systems. When a malfunction is detected, the OBD system generates a DTC, which is stored in the vehicle’s computer memory. This code can be accessed using a diagnostic scan tool, providing valuable information about the nature and location of the problem. According to the Environmental Protection Agency (EPA), OBD systems have been standardized since 1996 to ensure consistent diagnostics across different vehicle makes and models.

1.2. Structure of a DTC

Each DTC consists of five characters:

- First Character: Indicates the system (e.g., P for Powertrain, C for Chassis, B for Body, U for Network).

- Second Character: Specifies whether the code is generic (0) or manufacturer-specific (1).

- Third Character: Indicates the subsystem (e.g., fuel, air metering, ignition).

- Fourth and Fifth Characters: Provide a specific fault description.

For example, the code “P0301” indicates a misfire in cylinder one (Powertrain system). Understanding this structure helps in quickly identifying the area of the vehicle affected by the issue.

1.3. Types of DTCs

DTCs can be broadly categorized based on the severity and impact of the issue:

- Critical Codes: These indicate severe issues requiring immediate attention to prevent significant damage, such as high engine temperatures or low oil pressure.

- Non-Critical Codes: These indicate emissions-related issues or minor faults that don’t require immediate action but still need attention to maintain compliance and avoid long-term damage.

1.4. Interpreting DTCs Effectively

Interpreting DTCs accurately requires understanding the code’s structure and consulting relevant resources, such as manufacturer-specific diagnostic manuals or online databases. Basic code readers or scanners typically only provide the five-character code, necessitating additional research to determine the code’s meaning. Advanced fleet management solutions and diagnostic tools, like those supported by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, offer complete code definitions automatically with fault alerts, streamlining the diagnostic process.

2. Key Components Generating DTCs: ECU, ECM, and PCM

The Engine Control Unit (ECU), Engine Control Module (ECM), and Powertrain Control Module (PCM) are critical components of a vehicle’s onboard diagnostics system. These modules monitor and control various engine and powertrain functions, generating DTCs when they detect a malfunction. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we provide in-depth information and diagnostic tools to help you understand and address issues related to these key components.

2.1. Engine Control Unit (ECU)

The Engine Control Unit (ECU) is a central computer that manages and controls the engine’s operation. It monitors various sensors throughout the engine and adjusts parameters such as fuel injection, ignition timing, and idle speed to optimize performance and efficiency. When the ECU detects a problem with any of these systems, it generates a DTC to alert the driver or technician.

- Functions of the ECU:

- Fuel Injection Control: Adjusts the amount of fuel injected into the engine cylinders based on sensor inputs.

- Ignition Timing Control: Controls the timing of the spark plugs to ensure optimal combustion.

- Idle Speed Control: Maintains a stable idle speed by adjusting the throttle position and air intake.

- Emissions Control: Manages emissions control systems to reduce harmful pollutants.

2.2. Engine Control Module (ECM)

The Engine Control Module (ECM) is a specific type of ECU that focuses primarily on engine-related functions. It is responsible for monitoring and controlling various engine parameters, such as air-fuel ratio, coolant temperature, and throttle position. The ECM uses data from sensors to make real-time adjustments to engine operation, ensuring optimal performance and efficiency.

- Key Responsibilities of the ECM:

- Monitoring Air-Fuel Ratio: Ensures the correct mixture of air and fuel for efficient combustion.

- Managing Coolant Temperature: Monitors engine temperature to prevent overheating.

- Controlling Throttle Position: Adjusts the throttle to regulate engine power output.

- Detecting Engine Misfires: Identifies and records misfires, which can indicate engine problems.

2.3. Powertrain Control Module (PCM)

The Powertrain Control Module (PCM) is an integrated control unit that combines the functions of both the ECU and Transmission Control Module (TCM). It manages both the engine and transmission, optimizing their interaction for smooth and efficient operation. The PCM monitors various sensors and actuators in both the engine and transmission, making real-time adjustments to ensure optimal performance.

- Integrated Functions of the PCM:

- Engine Management: Controls fuel injection, ignition timing, and idle speed.

- Transmission Management: Controls gear shifting, torque converter lockup, and transmission pressure.

- Coordination: Optimizes the interaction between the engine and transmission for smooth and efficient operation.

2.4. How These Components Generate DTCs

The ECU, ECM, and PCM continuously monitor the performance of various vehicle systems and components. They use data from sensors to detect deviations from expected values, indicating a potential problem. When a malfunction is detected, these modules generate a DTC and store it in the vehicle’s computer memory.

For example, if the oxygen sensor in the exhaust system detects an incorrect air-fuel ratio, the ECU will generate a DTC related to the oxygen sensor circuit. Similarly, if the PCM detects a problem with the transmission, it will generate a DTC related to the transmission control system. These DTCs provide valuable information for diagnosing and repairing vehicle problems.

Alt text: Engine Control Unit ECU diagram showing internal components and connections

3. Advanced DTC Monitoring and Telematics Systems

Modern advancements in telematics and fleet management software have revolutionized DTC monitoring, enabling real-time diagnostics and proactive maintenance. Telematics systems provide automatic transmission of fault codes to fleet management dashboards, supporting immediate action. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we offer comprehensive solutions that leverage these technologies to enhance vehicle uptime, streamline maintenance, and improve driver safety.

3.1. Real-Time Diagnostics

Real-time diagnostics involve the continuous monitoring of vehicle systems and the immediate reporting of any detected faults. This capability allows fleet managers and technicians to identify and address issues before they escalate into major problems, reducing downtime and repair costs.

3.2. Benefits of Real-Time DTC Monitoring

- Improved Uptime: Identifying issues early helps avoid costly breakdowns and extends vehicle lifespan.

- Streamlined Maintenance: Fault codes can be prioritized and addressed promptly, avoiding delays.

- Enhanced Driver Safety: Immediate alerts help prevent critical issues from escalating.

- Data-Driven Decisions: Historical fault code data can reveal patterns, aiding predictive maintenance.

3.3. Telematics Systems and DTC Management

Telematics systems use GPS tracking and onboard sensors to collect data about vehicle location, performance, and condition. This data is transmitted wirelessly to a central server, where it can be analyzed to identify potential problems. When a DTC is detected, the telematics system can send an alert to the fleet manager or technician, providing detailed information about the fault.

3.4. Automating DTC Management

Modern telematics systems simplify DTC management by:

- Automatically transmitting fault codes to fleet managers.

- Offering detailed descriptions and action recommendations.

- Integrating with maintenance workflows to prioritize repairs.

- Supporting predictive maintenance by analyzing historical fault trends.

3.5. Motive’s Vehicle Diagnostics Feature

Motive’s Vehicle Diagnostics feature provides a direct connection to onboard diagnostics, allowing fleets to:

- Monitor fault codes in real-time.

- Diagnose issues proactively.

- Reduce repair costs through timely intervention.

4. Interpreting DTCs: A Step-by-Step Guide

Interpreting Diagnostic Trouble Codes (DTCs) accurately is crucial for effective vehicle maintenance and repair. This process involves understanding the structure of the code, accessing relevant resources, and performing diagnostic tests to identify the root cause of the problem. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we provide comprehensive guidance and resources to help you interpret DTCs effectively.

4.1. Understanding the DTC Structure

As previously mentioned, each DTC consists of five characters that provide information about the system, code type, subsystem, and specific fault. Understanding this structure is the first step in interpreting the code.

- First Character: Indicates the system (e.g., P for Powertrain, C for Chassis, B for Body, U for Network).

- Second Character: Specifies whether the code is generic (0) or manufacturer-specific (1).

- Third Character: Indicates the subsystem (e.g., fuel, air metering, ignition).

- Fourth and Fifth Characters: Provide a specific fault description.

4.2. Accessing DTC Definitions

The next step in interpreting a DTC is to access its definition, which provides a description of the fault and potential causes. This can be done using a variety of resources, including:

- Standard DTC Lists: These lists provide definitions for generic DTCs, which are standardized across different vehicle makes and models.

- Manufacturer-Specific Diagnostic Manuals: These manuals provide detailed information about DTCs specific to a particular vehicle make and model.

- Online Databases: There are many online databases that offer DTC definitions and troubleshooting information.

- Fleet Management Solutions: Advanced fleet management solutions, like those supported by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, provide complete code definitions automatically with fault alerts.

4.3. Performing Diagnostic Tests

Once you have accessed the DTC definition, the next step is to perform diagnostic tests to identify the root cause of the problem. This may involve using a scan tool to gather additional data, inspecting the affected components, and performing electrical tests.

- Using a Scan Tool: A scan tool can be used to read live data from the vehicle’s sensors, which can provide valuable information about the performance of the affected system.

- Inspecting Components: Visually inspect the affected components for signs of damage, such as cracks, leaks, or corrosion.

- Performing Electrical Tests: Use a multimeter to test the electrical circuits associated with the affected components, checking for voltage, continuity, and resistance.

4.4. Example: Interpreting DTC P0301

Let’s consider the example of DTC P0301, which indicates a misfire in cylinder one.

-

Code Structure:

- P: Powertrain system

- 0: Generic code

- 3: Ignition systems or misfires

- 01: Cylinder one

-

DTC Definition: Misfire detected in cylinder one.

-

Potential Causes:

- Faulty spark plug

- Faulty ignition coil

- Faulty fuel injector

- Vacuum leak

- Low compression

-

Diagnostic Tests:

- Inspect the spark plug, ignition coil, and fuel injector in cylinder one.

- Perform a compression test on cylinder one.

- Check for vacuum leaks.

By following these steps, you can effectively interpret DTCs and identify the root cause of vehicle problems, enabling you to perform the necessary repairs and maintenance.

5. Common DTC Examples and Their Meanings

Understanding common Diagnostic Trouble Codes (DTCs) can help you quickly identify and address potential issues with your vehicle. While a comprehensive list of DTCs is extensive, knowing the meanings of frequently encountered codes can significantly streamline the diagnostic process. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we provide resources and tools to help you interpret these codes and maintain your vehicle effectively.

5.1. Powertrain (P) Codes

Powertrain codes relate to the engine, transmission, and associated components. Here are some common examples:

- P0101: Mass Air Flow (MAF) Sensor Fault

- Meaning: Indicates a problem with the MAF sensor, which measures the amount of air entering the engine.

- Symptoms: Poor engine performance, reduced fuel economy, and a check engine light.

- Possible Causes: Dirty or faulty MAF sensor, vacuum leaks, or wiring issues.

- P0300: Random/Multiple Cylinder Misfire Detected

- Meaning: Indicates that the engine is misfiring in one or more cylinders.

- Symptoms: Rough idling, poor acceleration, and a check engine light.

- Possible Causes: Faulty spark plugs, ignition coils, fuel injectors, or vacuum leaks.

- P0420: Catalyst System Efficiency Below Threshold (Bank 1)

- Meaning: Indicates that the catalytic converter is not functioning efficiently.

- Symptoms: Reduced fuel economy, poor engine performance, and a check engine light.

- Possible Causes: Faulty catalytic converter, oxygen sensors, or exhaust leaks.

- P0700: Transmission Control System Malfunction

- Meaning: Indicates a problem with the transmission control system.

- Symptoms: Erratic shifting, transmission slipping, and a check engine light.

- Possible Causes: Faulty transmission sensors, solenoids, or wiring issues.

5.2. Chassis (C) Codes

Chassis codes relate to the vehicle’s mechanical systems, such as steering, suspension, and braking.

- C0031: Left Front Wheel Speed Sensor Circuit

- Meaning: Indicates a problem with the left front wheel speed sensor.

- Symptoms: ABS light on, traction control issues, and potential braking problems.

- Possible Causes: Faulty wheel speed sensor, wiring issues, or ABS module problems.

5.3. Body (B) Codes

Body codes relate to parts primarily found in the passenger compartment area, such as windows, locks, and seats.

- B1001: ECU Hardware Failure

- Meaning: Indicates a hardware failure within the Engine Control Unit.

- Symptoms: The car might not start, erratic engine behavior, and multiple system failures.

- Possible Causes: The ECU needs replacement.

- B2209: Seat Drive Motor Circuit Failure

- Meaning: Indicates a problem with the seat drive motor circuit.

- Symptoms: The seat will not move, and there may be unusual noises when attempting to adjust the seat.

- Possible Causes: Damaged seat motor, a faulty switch, or wiring problems.

5.4. Network & Vehicle Integration (U) Codes

Network codes relate to functions managed by the onboard computer system.

- U0100: Lost Communication with ECM/PCM

- Meaning: Indicates a loss of communication with the Engine Control Module (ECM) or Powertrain Control Module (PCM).

- Symptoms: Check engine light, ABS light, and other warning lights, as well as potential drivability issues.

- Possible Causes: Wiring issues, faulty ECM/PCM, or problems with the CAN bus network.

5.5. Using Fleet Management Systems for Troubleshooting

For comprehensive troubleshooting, fleet management systems like those supported by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provide detailed fault code descriptions and recommended actions. These systems help fleet managers and technicians quickly identify and address potential issues, reducing downtime and repair costs.

6. How to Read DTC Fault Codes Using a Scan Tool

Reading Diagnostic Trouble Codes (DTCs) using a scan tool is a straightforward process that can provide valuable insights into your vehicle’s health. A scan tool connects to your vehicle’s onboard diagnostics (OBD) system and retrieves any stored DTCs. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we offer guidance and resources on how to use scan tools effectively.

6.1. Locating the OBD-II Diagnostic Connector

The first step in reading DTCs is to locate the OBD-II diagnostic connector in your vehicle. This connector is typically located on the steering column’s left side and under the dashboard. However, since connectors aren’t universal, vehicle diagnostic connectors manufactured before 1996 will require specific adapters. Consult the manufacturer’s vehicle manual to find the OBD-II diagnostic connector if it’s not in any of these locations.

6.2. Connecting the Scan Tool

Once you have located the diagnostic connector, plug the scan tool into the connector. Ensure that the connection is secure and that the scan tool is powered on.

6.3. Turning on the Ignition

Turn on the ignition or keep the engine running (depending on your vehicle’s OBD requirement). This allows the scan tool to communicate with your vehicle’s ECU.

6.4. Selecting the “Read Codes” Option

From the scan tool’s menu, select the option for “read codes.” You might need to enter specific information such as the vehicle model and year if your scanner isn’t set to get this data automatically.

6.5. Viewing the DTCs

The scan tool will then show any present DTC faults, usually in numerical order. In some tools, these will include the code definitions. Most of the latest scanners allow you to transfer the codes to a smartphone or computer via Wi-Fi, USB code (if available), and Bluetooth.

6.6. Clearing DTCs (With Caution)

Most scan tools also offer the option to clear DTCs. However, it’s important to exercise caution when clearing codes. Clearing codes won’t make the vehicle issues disappear. This can even be dangerous and lead to vehicle failure and expensive liabilities that can cost you thousands of dollars down the line. Only clear DTCs after you have diagnosed and repaired the underlying problem.

6.7. Using Telematics Systems for DTC Monitoring

Besides an OBD-II or DTC scanner, reliable telematics systems and devices provide more efficient ways to read and monitor engine diagnostics. Telematics systems can track your vehicle’s engine and systems in real-time, alerting you to any problems as they arise promptly. These systems often provide more detailed information about DTCs, including code definitions, potential causes, and recommended actions.

Alt text: Mercedes-Benz diagnostic tool connected to car OBD port during diagnostic process.

7. Best Practices for Fleet Managers

Effective management of Diagnostic Trouble Codes (DTCs) is essential for maintaining a healthy and efficient fleet. By implementing best practices for DTC management, fleet managers can reduce downtime, minimize repair costs, and improve driver safety. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we provide resources and solutions to help fleet managers optimize their DTC management strategies.

7.1. Train Drivers

Educate drivers on the importance of reporting warning lights promptly. Drivers should be trained to recognize the different types of warning lights and understand the potential severity of each. Encourage drivers to report any unusual vehicle behavior, even if a warning light is not illuminated.

7.2. Leverage Technology

Invest in robust telematics systems for real-time fault monitoring. Telematics systems can automatically detect DTCs and transmit the information to fleet managers, enabling them to take quick action. These systems often provide detailed code definitions, potential causes, and recommended actions, streamlining the diagnostic process.

7.3. Use Predictive Maintenance

Analyze fault code trends to anticipate and prevent issues. By tracking the frequency and types of DTCs that occur in your fleet, you can identify patterns and predict potential problems before they lead to breakdowns. This allows you to schedule proactive maintenance, reducing downtime and repair costs.

7.4. Partner with Experts

Collaborate with OEMs or certified technicians to resolve complex issues. While basic DTCs can be addressed with simple repairs, more complex codes may require specialized knowledge and equipment. Partnering with experts ensures that these issues are resolved correctly, preventing further damage and downtime.

7.5. Implement a Preventive Maintenance Program

Establish a schedule for regular vehicle inspections and maintenance. Preventive maintenance programs help identify potential problems before they trigger DTCs, reducing the likelihood of breakdowns and costly repairs. These programs should include regular checks of fluids, filters, brakes, tires, and other critical components.

7.6. Utilize Fleet Management Software

Implement fleet management software to track and manage DTCs. Fleet management software can automate many aspects of DTC management, including code detection, reporting, and tracking. This software can also integrate with maintenance workflows, ensuring that DTCs are addressed promptly and effectively.

7.7. Regularly Update Diagnostic Tools

Ensure that your diagnostic tools are up-to-date with the latest software and firmware. Regular updates ensure that your tools can accurately read and interpret the latest DTCs, providing you with the most accurate information.

8. Vehicle Diagnostics and Maintenance Solutions

Effective vehicle diagnostics and maintenance are essential for ensuring the reliability, safety, and efficiency of your fleet. By implementing comprehensive diagnostics and maintenance solutions, you can reduce downtime, minimize repair costs, and improve driver safety. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we offer a range of solutions to help you optimize your vehicle diagnostics and maintenance programs.

8.1. Real-Time Fault Monitoring

Real-time fault monitoring involves the continuous monitoring of vehicle systems and the immediate reporting of any detected faults. This capability allows fleet managers and technicians to identify and address issues before they escalate into major problems, reducing downtime and repair costs.

8.2. Proactive Issue Diagnosis

Proactive issue diagnosis involves using diagnostic tools and data analysis to identify potential problems before they trigger DTCs. This approach allows you to schedule proactive maintenance, preventing breakdowns and costly repairs.

8.3. Timely Intervention

Timely intervention involves taking quick action to address DTCs and other vehicle problems. This may involve scheduling repairs, replacing faulty components, or performing other maintenance tasks. By intervening promptly, you can prevent further damage and downtime.

8.4. Key Features of Effective Solutions

- Real-Time Data: Access to real-time data about vehicle performance and condition.

- Automated Alerts: Automated alerts for DTCs and other potential problems.

- Detailed Code Definitions: Detailed code definitions, potential causes, and recommended actions.

- Integration with Maintenance Workflows: Integration with maintenance workflows to prioritize repairs.

- Data Analysis and Reporting: Data analysis and reporting tools to track trends and identify potential problems.

8.5. Benefits of Effective Solutions

- Reduced Downtime: Identifying and addressing issues early helps avoid costly breakdowns and extends vehicle lifespan.

- Streamlined Maintenance: Fault codes can be prioritized and addressed promptly, avoiding delays.

- Enhanced Driver Safety: Immediate alerts help prevent critical issues from escalating.

- Data-Driven Decisions: Historical fault code data can reveal patterns, aiding predictive maintenance.

- Reduced Operational Costs: By preventing breakdowns and optimizing maintenance schedules, you can reduce operational costs.

9. The Future of DTCs and Vehicle Diagnostics

The field of vehicle diagnostics is constantly evolving, with new technologies and techniques emerging all the time. As vehicles become more complex and interconnected, the role of Diagnostic Trouble Codes (DTCs) will continue to grow in importance. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we are committed to staying at the forefront of these advancements, providing our customers with the latest tools and information.

9.1. Increased Complexity of DTCs

As vehicles become more complex, the number and complexity of DTCs are also increasing. Modern vehicles have dozens of sensors and control modules, each of which can generate DTCs. This increased complexity requires more sophisticated diagnostic tools and techniques.

9.2. Integration with Artificial Intelligence (AI)

AI is playing an increasingly important role in vehicle diagnostics. AI-powered diagnostic tools can analyze vast amounts of data to identify patterns and predict potential problems. These tools can also provide more detailed and accurate DTC definitions, helping technicians to diagnose and repair vehicle problems more quickly.

9.3. Over-the-Air (OTA) Updates

Over-the-air (OTA) updates are becoming increasingly common in modern vehicles. These updates allow manufacturers to remotely update vehicle software, including diagnostic systems. OTA updates can improve the accuracy of DTCs, add new diagnostic capabilities, and fix software bugs.

9.4. Enhanced Cybersecurity

As vehicles become more interconnected, cybersecurity is becoming a growing concern. Hackers could potentially exploit vulnerabilities in vehicle diagnostic systems to gain access to sensitive data or control vehicle functions. As a result, manufacturers are investing in enhanced cybersecurity measures to protect vehicle diagnostic systems from attack.

9.5. Shift Towards Remote Diagnostics

Remote diagnostics are becoming increasingly popular, allowing technicians to diagnose and repair vehicle problems remotely. Remote diagnostics can reduce downtime, minimize travel costs, and improve customer service.

10. FAQ About DTCs and Vehicle Diagnostics

Here are some frequently asked questions about Diagnostic Trouble Codes (DTCs) and vehicle diagnostics:

- What is a DTC?

- A Diagnostic Trouble Code (DTC) is an alphanumeric code generated by a vehicle’s onboard diagnostics (OBD) system to identify a specific issue or malfunction.

- What is an OBD system?

- An Onboard Diagnostics (OBD) system is a computer system in a vehicle that monitors the performance of various components and systems.

- How do I read DTCs?

- DTCs can be read using a scan tool, which connects to the vehicle’s OBD-II diagnostic connector.

- What do the characters in a DTC mean?

- Each DTC consists of five characters that provide information about the system, code type, subsystem, and specific fault.

- Where can I find DTC definitions?

- DTC definitions can be found in standard DTC lists, manufacturer-specific diagnostic manuals, online databases, and advanced fleet management solutions.

- What should I do after reading a DTC?

- After reading a DTC, you should access its definition, perform diagnostic tests to identify the root cause of the problem, and take the necessary steps to repair the issue.

- Can I clear DTCs?

- Yes, DTCs can be cleared using a scan tool, but it’s important to exercise caution and only clear codes after you have diagnosed and repaired the underlying problem.

- What are the benefits of real-time DTC monitoring?

- The benefits of real-time DTC monitoring include improved uptime, streamlined maintenance, enhanced driver safety, and data-driven decisions.

- What is predictive maintenance?

- Predictive maintenance involves analyzing fault code trends to anticipate and prevent issues, reducing the likelihood of breakdowns and costly repairs.

- How can fleet management software help with DTC management?

- Fleet management software can automate many aspects of DTC management, including code detection, reporting, and tracking, ensuring that DTCs are addressed promptly and effectively.

Understanding the system that generates DTCs is crucial for effective vehicle maintenance and diagnostics. Whether you’re a vehicle owner or a fleet manager, having the right tools and knowledge can make a significant difference in your vehicle’s performance and longevity. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we are dedicated to providing you with the resources and support you need to stay ahead in the world of vehicle diagnostics.

Ready to take control of your Mercedes-Benz diagnostics? Contact us at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, 789 Oak Avenue, Miami, FL 33101, United States, or via Whatsapp at +1 (641) 206-8880 for expert guidance on diagnostic tools, unlocking hidden features, and mastering Mercedes-Benz maintenance. Let us help you keep your Mercedes running smoothly and efficiently!