What Triggers An ECU To Set A DTC? An ECU (Engine Control Unit) sets a Diagnostic Trouble Code (DTC) when it detects a fault or abnormality in a vehicle’s system, and MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides in-depth expertise on deciphering these codes. This article explores the various triggers for DTCs, aiming to empower Mercedes-Benz owners and technicians with the knowledge to efficiently diagnose and resolve issues. Understanding the nuances of DTC triggers is crucial for effective vehicle maintenance, ensuring optimal performance and longevity.

Contents

- 1. Understanding Diagnostic Trouble Codes (DTCs)

- 1.1. What is an ECU and Its Role?

- 1.2. The Purpose of DTCs in Vehicle Diagnostics

- 1.3. Types of DTCs: Generic vs. Manufacturer-Specific

- 2. Common Triggers for ECU to Set a DTC

- 2.1. Sensor Malfunctions

- 2.2. Circuit Faults

- 2.3. Mechanical Failures

- 2.4. System Performance Issues

- 2.5. Communication Issues

- 3. The Role of Monitors and Diagnostic Routines

- 3.1. What are Monitors?

- 3.2. How Monitors Detect Faults

- 3.3. Diagnostic Routines and Testing Procedures

- 3.4. The Impact of Driving Conditions on DTCs

- 3.5. Freeze Frame Data: Capturing the Context

- 4. Understanding DTC Status and Severity

- 4.1. Pending, Confirmed, and Permanent DTCs

- 4.2. Severity Levels: Minor, Moderate, and Severe

- 4.3. How Severity Affects Repair Urgency

- 4.4. The Malfunction Indicator Lamp (MIL) and Its Signals

- 4.5. Reading DTCs with a Diagnostic Scan Tool

- 5. Interpreting DTCs for Mercedes-Benz Vehicles

- 5.1. Accessing Mercedes-Benz Specific DTC Information

- 5.2. Understanding Common Mercedes-Benz DTCs

- 5.3. Utilizing Diagnostic Flowcharts and Procedures

- 5.4. The Importance of Accurate Diagnosis

- 5.5. Resetting DTCs: When and How

- 6. Preventative Measures to Minimize DTCs

- 6.1. Regular Maintenance Schedules

- 6.2. Proper Driving Habits

- 6.3. Addressing Minor Issues Promptly

- 6.4. Using Quality Parts and Fluids

- 6.5. Staying Updated with Vehicle Software

- 7. Advanced Diagnostic Tools and Techniques

- 7.1. Oscilloscopes for Signal Analysis

- 7.2. Multimeters for Circuit Testing

- 7.3. Scan Tools with Advanced Functions

- 7.4. Smoke Machines for Leak Detection

- 7.5. Using Wiring Diagrams and Technical Resources

- 8. The Future of Vehicle Diagnostics

- 8.1. Over-the-Air (OTA) Diagnostics

- 8.2. Artificial Intelligence (AI) in Diagnostics

- 8.3. Enhanced Vehicle Data and Analytics

- 8.4. The Role of Telematics in Diagnostics

- 8.5. Preparing for the Next Generation of Vehicles

- 9. Case Studies: Real-World DTC Scenarios

- 9.1. Case Study 1: P0171 on a Mercedes-Benz C-Class

- 9.2. Case Study 2: P0300 on a Mercedes-Benz E-Class

- 9.3. Case Study 3: P0420 on a Mercedes-Benz S-Class

- 9.4. Lessons Learned from These Scenarios

- 9.5. The Value of Expertise in DTC Resolution

- 10. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN: Your Partner in Mercedes-Benz Diagnostics

- 10.1. Comprehensive Diagnostic Tool Information

- 10.2. Step-by-Step Guides for Unlocking Hidden Features

- 10.3. Expert Repair and Maintenance Advice

- 10.4. Addressing Customer Challenges with Expertise

- 10.5. Connecting with Us for Immediate Assistance

- FAQ: Decoding Your Mercedes-Benz DTCs

1. Understanding Diagnostic Trouble Codes (DTCs)

Diagnostic Trouble Codes, or DTCs, are codes generated by a vehicle’s onboard computer system, specifically the Engine Control Unit (ECU), when it detects a malfunction or anomaly in one of its monitored systems. These codes serve as vital clues for technicians and vehicle owners to identify and address potential issues affecting the vehicle’s performance, safety, and emissions.

1.1. What is an ECU and Its Role?

The Engine Control Unit (ECU) is the central processing unit of a vehicle’s electronic systems. It monitors and controls various sensors and actuators throughout the vehicle, including the engine, transmission, anti-lock braking system (ABS), and more. The ECU’s primary functions include:

- Monitoring Sensors: Collecting data from various sensors, such as temperature, pressure, and speed sensors.

- Controlling Actuators: Adjusting components like fuel injectors, ignition timing, and throttle position based on sensor data.

- Fault Detection: Identifying abnormalities or deviations from expected values in the sensor data.

- Diagnostic Reporting: Generating and storing DTCs when a fault is detected, providing information for troubleshooting.

1.2. The Purpose of DTCs in Vehicle Diagnostics

DTCs play a crucial role in modern vehicle diagnostics by providing a standardized method for identifying and addressing vehicle issues. Their primary purposes include:

- Fault Identification: DTCs pinpoint the specific system or component where a fault has occurred.

- Troubleshooting Guidance: DTCs offer technicians a starting point for diagnosing the root cause of the problem, saving time and effort.

- Repair Validation: DTCs can be cleared after a repair to verify that the issue has been resolved and the system is functioning correctly.

- Compliance and Regulation: DTCs are essential for complying with emissions regulations and ensuring vehicles meet safety standards.

1.3. Types of DTCs: Generic vs. Manufacturer-Specific

DTCs are categorized into two main types: generic and manufacturer-specific. Understanding the difference between these types is important for accurate diagnostics:

- Generic DTCs: These codes are standardized across all vehicle manufacturers and are defined by the Society of Automotive Engineers (SAE). They cover common issues related to engine, transmission, and emissions systems. Generic DTCs are identified with a “P0” prefix (e.g., P0300 for random misfire detected).

- Manufacturer-Specific DTCs: These codes are unique to each vehicle manufacturer and provide more detailed information about faults specific to their vehicles. They are identified with prefixes such as “P1,” “P2,” “P3,” “B,” “C,” or “U” (e.g., P1XXX for powertrain, BXXXX for body, CXXXX for chassis, and UXXXX for network communication issues).

2. Common Triggers for ECU to Set a DTC

ECUs are programmed to monitor a wide range of parameters and conditions within a vehicle. When a monitored value falls outside the specified range or deviates from the expected behavior, the ECU triggers a DTC. Common triggers for DTCs include sensor malfunctions, circuit faults, mechanical failures, and system performance issues.

2.1. Sensor Malfunctions

Sensors play a critical role in providing the ECU with accurate data about various vehicle systems. When a sensor fails or provides inaccurate readings, it can trigger a DTC. Common sensor-related issues include:

- Faulty Sensor Readings: A sensor may provide readings that are outside the acceptable range, such as a temperature sensor reporting an extremely high or low temperature.

- Sensor Circuit Issues: Problems in the sensor’s wiring or connections, such as open circuits, short circuits, or high resistance, can prevent the sensor from sending accurate data to the ECU.

- Sensor Contamination: Sensors can become contaminated by dirt, oil, or other debris, leading to inaccurate readings and DTCs.

- Sensor Damage: Physical damage to a sensor, such as cracks or breaks, can cause it to malfunction and trigger a DTC.

For example, if the oxygen sensor in a Mercedes-Benz fails to provide accurate readings, the ECU may set a DTC related to fuel trim or emissions. According to a study by Bosch, a leading automotive component manufacturer, faulty oxygen sensors are a common cause of DTCs related to engine performance and fuel efficiency.

2.2. Circuit Faults

Electrical circuits throughout the vehicle are essential for transmitting signals and power to various components. Faults in these circuits can disrupt communication between the ECU and other systems, leading to DTCs. Common circuit faults include:

- Open Circuits: A break in the circuit, preventing the flow of electricity.

- Short Circuits: An unintended connection between two points in the circuit, causing a surge of electricity.

- High Resistance: Excessive resistance in the circuit, reducing the flow of electricity.

- Grounding Issues: Problems with the circuit’s grounding, leading to erratic signals or a lack of power.

- Wiring Damage: Damaged or corroded wires can cause intermittent or complete circuit failures.

A study by the National Institute for Automotive Service Excellence (ASE) found that circuit faults are a significant cause of electrical system problems in vehicles. Properly diagnosing and repairing circuit faults requires specialized tools and knowledge.

2.3. Mechanical Failures

Mechanical components are subject to wear and tear over time, and failures in these components can trigger DTCs. Common mechanical failures include:

- Engine Misfires: A misfire occurs when one or more cylinders in the engine fail to fire properly. This can be caused by faulty spark plugs, ignition coils, fuel injectors, or other engine components.

- Transmission Problems: Issues with the transmission, such as slipping gears, rough shifting, or complete failure, can trigger DTCs related to transmission performance.

- Brake System Malfunctions: Problems with the brake system, such as worn brake pads, faulty ABS sensors, or hydraulic leaks, can trigger DTCs related to brake system performance.

- Exhaust System Issues: Leaks or blockages in the exhaust system can affect engine performance and trigger DTCs related to emissions.

According to a report by AAA, mechanical failures are a common cause of vehicle breakdowns and can lead to significant repair costs. Regular maintenance and timely repairs can help prevent mechanical failures and the associated DTCs.

2.4. System Performance Issues

The ECU monitors the overall performance of various vehicle systems, and deviations from expected performance can trigger DTCs. Common system performance issues include:

- Fuel System Problems: Issues with the fuel system, such as low fuel pressure, clogged fuel filters, or faulty fuel injectors, can affect engine performance and trigger DTCs related to fuel trim or air-fuel mixture.

- Emissions System Issues: Problems with the emissions system, such as faulty catalytic converters, oxygen sensors, or evaporative emissions control systems, can trigger DTCs related to emissions performance.

- Cooling System Problems: Issues with the cooling system, such as low coolant levels, faulty thermostats, or radiator leaks, can cause the engine to overheat and trigger DTCs related to engine temperature.

- Air Intake Problems: Restrictions or leaks in the air intake system can affect engine performance and trigger DTCs related to air-fuel mixture or mass airflow.

Maintaining proper system performance is essential for optimal vehicle operation and longevity. Regular inspections and maintenance can help identify and address potential system performance issues before they trigger DTCs.

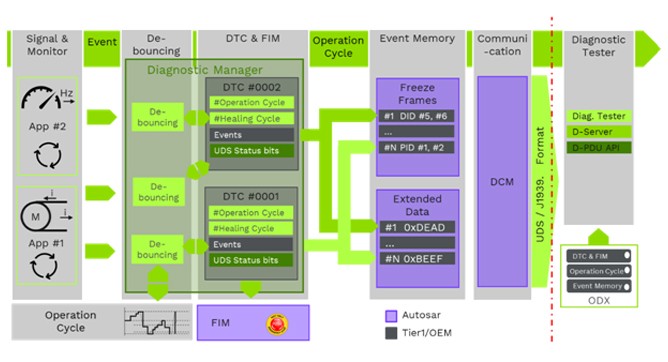

Process sequence of a DTC

Process sequence of a DTC

2.5. Communication Issues

Modern vehicles rely on complex communication networks to facilitate data exchange between different control units. Communication issues can arise when there are problems with the network or the control units themselves, resulting in DTCs related to network communication.

- CAN Bus Problems: The Controller Area Network (CAN) bus is the primary communication network in many vehicles. Issues such as wiring faults, faulty connectors, or malfunctioning control units can disrupt CAN bus communication and trigger DTCs related to network communication.

- Module Malfunctions: Individual control units, such as the transmission control module (TCM) or the body control module (BCM), can fail or malfunction, leading to communication errors and DTCs.

- Software Issues: Software glitches or corruption in the control units can also disrupt communication and trigger DTCs.

Diagnosing communication issues requires specialized tools, such as a CAN bus analyzer, and a thorough understanding of the vehicle’s network architecture.

3. The Role of Monitors and Diagnostic Routines

Monitors and diagnostic routines are integral components of the ECU’s fault detection system. They continuously assess the performance of various vehicle systems and components, triggering DTCs when deviations from expected behavior are detected.

3.1. What are Monitors?

Monitors are diagnostic functions within the ECU that continuously assess the performance and integrity of various vehicle systems and components. They compare sensor data and system parameters against predefined thresholds to identify potential faults or malfunctions. Monitors can be categorized as:

- Continuous Monitors: These monitors run continuously during vehicle operation, constantly assessing critical systems such as the engine misfire detection, fuel system, and comprehensive component monitoring.

- Non-Continuous Monitors: These monitors run under specific conditions, such as during a cold start or during certain driving modes. They assess systems that do not require constant monitoring, such as the evaporative emissions control system or the catalyst monitor.

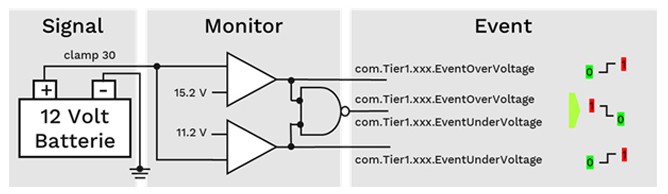

One monitor for battery monitoring with two events

One monitor for battery monitoring with two events

3.2. How Monitors Detect Faults

Monitors use various methods to detect faults, including:

- Range Checks: Comparing sensor data against predefined minimum and maximum values. If the sensor reading falls outside this range, a fault is detected.

- Rationality Checks: Comparing the readings of multiple sensors to ensure they are consistent with each other. If the readings are inconsistent, a fault is detected.

- Performance Checks: Assessing the performance of a system or component against predefined performance criteria. If the performance falls below the criteria, a fault is detected.

- Circuit Checks: Monitoring the electrical circuits for open circuits, short circuits, or other electrical faults.

When a monitor detects a fault, it sets a pending DTC and may illuminate the malfunction indicator lamp (MIL), also known as the check engine light.

3.3. Diagnostic Routines and Testing Procedures

In addition to monitors, ECUs also employ diagnostic routines and testing procedures to further evaluate potential faults. These routines may involve running specific tests on a system or component, such as activating a solenoid or measuring the voltage at a particular point in the circuit.

Diagnostic routines are often used to confirm a fault that has been detected by a monitor or to diagnose intermittent problems that are difficult to isolate.

3.4. The Impact of Driving Conditions on DTCs

Driving conditions can significantly impact the triggering of DTCs. For example, certain DTCs may only be triggered under specific driving conditions, such as high engine load, extreme temperatures, or prolonged idling.

Harsh driving conditions, such as frequent acceleration and braking, can also accelerate wear and tear on vehicle components, increasing the likelihood of mechanical failures and DTCs.

3.5. Freeze Frame Data: Capturing the Context

When a DTC is set, the ECU typically stores freeze frame data, which captures the values of various sensors and system parameters at the time the fault occurred. This data can provide valuable insight into the conditions that led to the DTC and help technicians diagnose the problem more effectively.

Freeze frame data may include parameters such as engine speed, engine load, fuel trim, coolant temperature, and vehicle speed.

4. Understanding DTC Status and Severity

DTCs are not all created equal. They vary in terms of their status (e.g., pending, confirmed, permanent) and severity (e.g., minor, moderate, severe). Understanding the status and severity of a DTC is essential for prioritizing repairs and addressing the most critical issues first.

4.1. Pending, Confirmed, and Permanent DTCs

DTCs can exist in different states or statuses, each indicating a different stage in the fault detection and confirmation process:

- Pending DTCs: A pending DTC is set when a monitor detects a potential fault, but the fault has not yet been confirmed. The ECU may require the fault to occur multiple times before setting a confirmed DTC. Pending DTCs may not illuminate the MIL.

- Confirmed DTCs: A confirmed DTC is set when a monitor has detected a fault and has confirmed that the fault is still present after multiple occurrences. Confirmed DTCs typically illuminate the MIL.

- Permanent DTCs: A permanent DTC is set when a confirmed DTC has been cleared, but the ECU still retains a record of the fault. Permanent DTCs cannot be cleared using a scan tool and will only be cleared after the ECU has determined that the fault is no longer present.

4.2. Severity Levels: Minor, Moderate, and Severe

DTCs can also be categorized based on their severity, which indicates the potential impact of the fault on vehicle performance, safety, and emissions:

- Minor DTCs: These DTCs indicate minor issues that may not significantly affect vehicle performance or safety. They may be related to non-critical systems or components.

- Moderate DTCs: These DTCs indicate more serious issues that could affect vehicle performance, safety, or emissions. They may be related to critical systems or components.

- Severe DTCs: These DTCs indicate critical issues that could cause significant damage to the vehicle or pose a safety hazard. They may be related to engine, transmission, or brake system malfunctions.

4.3. How Severity Affects Repair Urgency

The severity of a DTC should influence the urgency with which the repair is addressed. Severe DTCs should be addressed immediately to prevent further damage or safety hazards. Moderate DTCs should be addressed as soon as possible to prevent potential performance issues or emissions problems. Minor DTCs can be addressed at the next scheduled maintenance or repair appointment.

4.4. The Malfunction Indicator Lamp (MIL) and Its Signals

The Malfunction Indicator Lamp (MIL), commonly known as the check engine light, is a warning light on the vehicle’s instrument panel that illuminates when the ECU detects a fault. The MIL can provide important information about the severity of the fault:

- Solid MIL: A solid MIL typically indicates a moderate to severe fault that requires attention.

- Flashing MIL: A flashing MIL typically indicates a severe fault that could cause immediate damage to the vehicle, such as an engine misfire.

When the MIL illuminates, it is important to have the vehicle diagnosed by a qualified technician as soon as possible.

4.5. Reading DTCs with a Diagnostic Scan Tool

To retrieve DTCs from the ECU, a diagnostic scan tool is required. Scan tools connect to the vehicle’s diagnostic port (typically located under the dashboard) and communicate with the ECU to retrieve stored DTCs and freeze frame data.

Scan tools range from basic code readers to advanced diagnostic systems with enhanced capabilities, such as live data streaming, bidirectional controls, and programming functions.

5. Interpreting DTCs for Mercedes-Benz Vehicles

Interpreting DTCs for Mercedes-Benz vehicles requires specific knowledge and expertise, as these vehicles often have unique diagnostic systems and manufacturer-specific codes.

5.1. Accessing Mercedes-Benz Specific DTC Information

To access Mercedes-Benz specific DTC information, technicians and vehicle owners can utilize several resources:

- Mercedes-Benz Diagnostic Software: Mercedes-Benz offers proprietary diagnostic software, such as XENTRY and DAS, which provides access to detailed DTC information, diagnostic routines, and repair procedures.

- Online Databases: Online databases, such as those offered by ALLDATA and Mitchell 1, provide access to manufacturer-specific DTC information, wiring diagrams, and technical service bulletins.

- Mercedes-Benz Technical Service Bulletins (TSBs): TSBs are documents issued by Mercedes-Benz to address common issues or problems with their vehicles. TSBs often provide information about specific DTCs and recommended repair procedures.

5.2. Understanding Common Mercedes-Benz DTCs

Some common Mercedes-Benz DTCs include:

- P0171 and P0174: These codes indicate a lean fuel condition, which could be caused by vacuum leaks, faulty mass airflow sensors, or fuel system problems.

- P0300 through P0308: These codes indicate engine misfires, which could be caused by faulty spark plugs, ignition coils, fuel injectors, or other engine components.

- P0420: This code indicates a catalyst system efficiency below threshold, which could be caused by a faulty catalytic converter or oxygen sensor.

- U0100: This code indicates a loss of communication with the engine control module, which could be caused by wiring faults, faulty connectors, or a malfunctioning ECU.

5.3. Utilizing Diagnostic Flowcharts and Procedures

When diagnosing Mercedes-Benz DTCs, it is important to utilize diagnostic flowcharts and procedures provided by the manufacturer or reputable diagnostic resources. These flowcharts provide a step-by-step approach to diagnosing the root cause of the problem and recommending appropriate repairs.

5.4. The Importance of Accurate Diagnosis

Accurate diagnosis is critical when addressing Mercedes-Benz DTCs. Incorrect diagnoses can lead to unnecessary repairs, wasted time, and unresolved issues. To ensure accurate diagnoses, technicians should:

- Verify the DTC: Confirm that the DTC is actually present and not a false alarm.

- Gather Information: Collect as much information as possible about the vehicle’s symptoms, driving conditions, and recent maintenance history.

- Inspect the Vehicle: Perform a thorough visual inspection of the vehicle, looking for obvious signs of damage or wear.

- Test Components: Use diagnostic tools to test the performance of individual components, such as sensors, actuators, and circuits.

- Consult Resources: Consult manufacturer-specific diagnostic information, technical service bulletins, and online databases.

5.5. Resetting DTCs: When and How

After completing a repair, it is important to reset the DTCs to clear the MIL and verify that the issue has been resolved. DTCs can be reset using a diagnostic scan tool. However, it is important to note that resetting DTCs without addressing the underlying cause of the problem will only result in the DTCs returning.

In some cases, the ECU may require a drive cycle to be completed before the DTCs can be reset. A drive cycle is a series of specific driving maneuvers that allow the ECU to re-evaluate the performance of the affected systems.

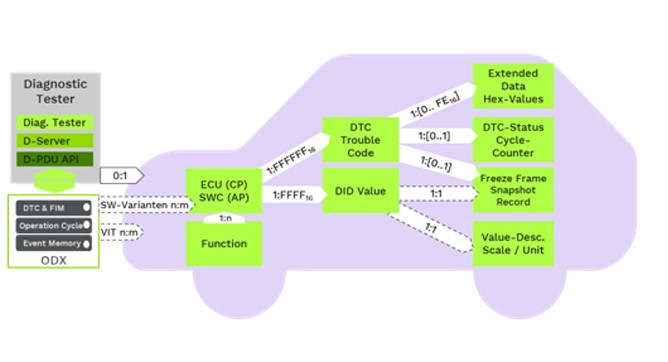

DTCs and associated data objects

DTCs and associated data objects

6. Preventative Measures to Minimize DTCs

Preventative maintenance and proper vehicle care can significantly reduce the likelihood of DTCs and costly repairs.

6.1. Regular Maintenance Schedules

Following the manufacturer’s recommended maintenance schedule is essential for keeping your Mercedes-Benz in top condition. Regular maintenance tasks include:

- Oil Changes: Regular oil changes help keep the engine lubricated and prevent wear and tear.

- Filter Replacements: Replacing air filters, fuel filters, and cabin filters helps maintain optimal engine performance and air quality.

- Fluid Checks: Checking and topping off fluid levels, such as coolant, brake fluid, and transmission fluid, helps prevent system malfunctions.

- Spark Plug Replacement: Replacing spark plugs at the recommended interval helps maintain proper engine performance and fuel efficiency.

- Tire Rotations: Rotating tires helps ensure even wear and prolong tire life.

6.2. Proper Driving Habits

Driving habits can also affect the likelihood of DTCs. Avoid harsh acceleration and braking, which can put stress on the engine and transmission. Also, avoid driving with low fuel levels, which can damage the fuel pump.

6.3. Addressing Minor Issues Promptly

Addressing minor issues promptly can prevent them from escalating into more serious problems that trigger DTCs. If you notice any unusual symptoms, such as strange noises, vibrations, or warning lights, have the vehicle inspected by a qualified technician as soon as possible.

6.4. Using Quality Parts and Fluids

Using quality parts and fluids is essential for maintaining the performance and reliability of your Mercedes-Benz. Avoid using cheap aftermarket parts, which may not meet the manufacturer’s specifications and could cause problems.

6.5. Staying Updated with Vehicle Software

Keeping your vehicle’s software up to date is important for ensuring optimal performance and compatibility with the latest diagnostic tools. Mercedes-Benz regularly releases software updates to address known issues and improve vehicle performance.

7. Advanced Diagnostic Tools and Techniques

For complex diagnostic challenges, advanced diagnostic tools and techniques may be required to accurately identify and address the root cause of the problem.

7.1. Oscilloscopes for Signal Analysis

Oscilloscopes are electronic instruments that display electrical signals as waveforms. They can be used to analyze the signals from sensors, actuators, and circuits to identify anomalies or deviations from expected behavior.

Oscilloscopes are particularly useful for diagnosing intermittent problems or circuit faults that are difficult to detect with other diagnostic tools.

7.2. Multimeters for Circuit Testing

Multimeters are versatile diagnostic tools that can measure voltage, current, and resistance in electrical circuits. They can be used to test the continuity of wires, check the voltage at various points in the circuit, and measure the resistance of components.

Multimeters are essential for diagnosing circuit faults, such as open circuits, short circuits, and high resistance.

7.3. Scan Tools with Advanced Functions

Advanced scan tools offer a wide range of functions beyond basic DTC reading and clearing. These functions may include:

- Live Data Streaming: Viewing real-time data from sensors and actuators.

- Bidirectional Controls: Activating or deactivating components to test their functionality.

- Programming Functions: Reprogramming or reflashing the ECU with updated software.

- Network Communication Testing: Testing the communication between different control units on the vehicle’s network.

7.4. Smoke Machines for Leak Detection

Smoke machines are used to detect leaks in the intake system, exhaust system, and evaporative emissions control system. They work by injecting smoke into the system and identifying areas where the smoke is escaping.

Smoke machines are particularly useful for diagnosing vacuum leaks, which can cause lean fuel conditions and DTCs related to fuel trim.

7.5. Using Wiring Diagrams and Technical Resources

When diagnosing complex electrical problems, it is essential to consult wiring diagrams and technical resources provided by the manufacturer or reputable diagnostic resources. These resources provide detailed information about the vehicle’s electrical system, including wiring schematics, component locations, and diagnostic procedures.

8. The Future of Vehicle Diagnostics

Vehicle diagnostics is constantly evolving, with new technologies and techniques emerging to improve the accuracy and efficiency of fault detection and repair.

8.1. Over-the-Air (OTA) Diagnostics

Over-the-air (OTA) diagnostics allows vehicle manufacturers to remotely monitor vehicle systems and diagnose potential problems. OTA diagnostics can be used to identify issues before they become major problems, schedule preventative maintenance, and even perform software updates remotely.

8.2. Artificial Intelligence (AI) in Diagnostics

Artificial intelligence (AI) is being used to develop advanced diagnostic systems that can analyze vast amounts of data from sensors and other sources to identify patterns and predict potential failures. AI-powered diagnostic systems can also provide technicians with step-by-step guidance for diagnosing and repairing complex problems.

8.3. Enhanced Vehicle Data and Analytics

The increasing amount of data generated by modern vehicles is providing valuable insights into vehicle performance and reliability. By analyzing this data, manufacturers and service providers can identify common issues, improve vehicle designs, and develop more effective diagnostic strategies.

8.4. The Role of Telematics in Diagnostics

Telematics systems, which combine telecommunications and informatics, are being used to collect and transmit vehicle data in real-time. This data can be used for a variety of purposes, including remote diagnostics, vehicle tracking, and driver behavior monitoring.

8.5. Preparing for the Next Generation of Vehicles

As vehicles become more complex and technologically advanced, it is important for technicians and vehicle owners to stay updated with the latest diagnostic tools and techniques. Investing in training and education is essential for preparing for the next generation of vehicles and ensuring that they can be properly diagnosed and repaired.

9. Case Studies: Real-World DTC Scenarios

Examining real-world DTC scenarios can provide valuable insights into the diagnostic process and highlight the importance of accurate diagnosis and repair.

9.1. Case Study 1: P0171 on a Mercedes-Benz C-Class

A Mercedes-Benz C-Class owner reported a check engine light and poor fuel economy. A scan tool revealed a P0171 code (System Too Lean, Bank 1). The technician performed a smoke test and discovered a vacuum leak at the intake manifold gasket. After replacing the gasket, the DTC was cleared, and the vehicle’s fuel economy returned to normal.

9.2. Case Study 2: P0300 on a Mercedes-Benz E-Class

A Mercedes-Benz E-Class owner complained of a rough idle and occasional misfires. A scan tool revealed a P0300 code (Random Misfire Detected). The technician used a multimeter to test the ignition coils and found that one of the coils was faulty. After replacing the faulty ignition coil, the DTC was cleared, and the engine ran smoothly.

9.3. Case Study 3: P0420 on a Mercedes-Benz S-Class

A Mercedes-Benz S-Class owner reported a check engine light and reduced engine performance. A scan tool revealed a P0420 code (Catalyst System Efficiency Below Threshold). The technician inspected the catalytic converter and found that it was damaged. After replacing the catalytic converter, the DTC was cleared, and the engine performance improved.

9.4. Lessons Learned from These Scenarios

These case studies highlight the importance of:

- Accurate Diagnosis: Correctly identifying the root cause of the problem is essential for effective repair.

- Thorough Inspection: Performing a thorough visual inspection of the vehicle can reveal obvious signs of damage or wear.

- Component Testing: Using diagnostic tools to test the performance of individual components can help isolate the source of the problem.

- Consulting Resources: Consulting manufacturer-specific diagnostic information, technical service bulletins, and online databases can provide valuable insights into the diagnostic process.

9.5. The Value of Expertise in DTC Resolution

Successfully resolving DTCs often requires a combination of technical knowledge, diagnostic skills, and experience. While some repairs can be performed by vehicle owners with basic mechanical skills, complex diagnostic challenges should be entrusted to qualified technicians with expertise in Mercedes-Benz vehicles.

10. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN: Your Partner in Mercedes-Benz Diagnostics

At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we understand the complexities of Mercedes-Benz diagnostics. We are dedicated to providing you with the information, tools, and expertise you need to keep your vehicle running smoothly.

10.1. Comprehensive Diagnostic Tool Information

We offer detailed information about a wide range of diagnostic tools for Mercedes-Benz vehicles, including:

- Basic Code Readers: Affordable and easy-to-use tools for reading and clearing DTCs.

- Advanced Scan Tools: Professional-grade tools with enhanced capabilities, such as live data streaming, bidirectional controls, and programming functions.

- Mercedes-Benz Specific Tools: Proprietary diagnostic software and hardware, such as XENTRY and DAS, for accessing detailed DTC information and performing advanced diagnostics.

10.2. Step-by-Step Guides for Unlocking Hidden Features

We provide step-by-step guides for unlocking hidden features on your Mercedes-Benz, such as:

- Enabling Sport Mode: Enhance your vehicle’s performance with a more aggressive throttle response and shift mapping.

- Activating Cornering Lights: Improve visibility when turning corners by activating the fog lights.

- Customizing Ambient Lighting: Personalize your vehicle’s interior with a wide range of ambient lighting colors.

10.3. Expert Repair and Maintenance Advice

Our team of experienced technicians offers expert repair and maintenance advice to help you keep your Mercedes-Benz in top condition. We provide guidance on:

- Troubleshooting Common DTCs: Diagnosing and repairing common DTCs related to engine, transmission, brake, and emissions systems.

- Performing Routine Maintenance: Following the manufacturer’s recommended maintenance schedule to prevent problems and extend the life of your vehicle.

- Upgrading Performance: Improving your vehicle’s performance with aftermarket parts and modifications.

10.4. Addressing Customer Challenges with Expertise

We understand the challenges that Mercedes-Benz owners face when it comes to diagnostics and repairs. We are committed to providing you with the expertise and support you need to overcome these challenges and keep your vehicle running smoothly.

10.5. Connecting with Us for Immediate Assistance

Do you have a specific question or concern about your Mercedes-Benz? Contact us today for immediate assistance!

- Address: 789 Oak Avenue, Miami, FL 33101, United States

- WhatsApp: +1 (641) 206-8880

- Website: MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

We are here to help you with all your Mercedes-Benz diagnostic needs.

Ready to take control of your Mercedes-Benz diagnostics? Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN today for expert advice, tools, and support!

FAQ: Decoding Your Mercedes-Benz DTCs

1. What does it mean when my check engine light comes on in my Mercedes-Benz?

When your check engine light illuminates, it signifies that the Engine Control Unit (ECU) has detected a problem within your vehicle’s systems, prompting the storage of a Diagnostic Trouble Code (DTC).

2. Can I diagnose my Mercedes-Benz without special tools?

While a basic visual inspection can help, accurately diagnosing most Mercedes-Benz issues requires a diagnostic scan tool to read the stored DTCs and understand the underlying problem.

3. What is the difference between a generic and a manufacturer-specific DTC?

Generic DTCs are standardized across all car brands, covering common issues. Manufacturer-specific DTCs, like those in Mercedes-Benz, provide more detailed information unique to the vehicle’s systems.

4. How do I find out what a specific DTC means for my Mercedes-Benz?

You can consult a Mercedes-Benz repair manual, use online databases that decode DTCs, or seek assistance from a qualified technician at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN.

5. Is it safe to drive my Mercedes-Benz with the check engine light on?

It depends on the nature of the problem. If the light is flashing or accompanied by severe drivability issues, it’s best to avoid driving and seek immediate professional help. If the light is solid and the car seems to run normally, you can drive it carefully to a service center.

6. Can I clear the DTC myself after fixing the issue?

Yes, using a diagnostic scan tool, you can clear the DTC. However, ensure the problem is genuinely resolved, as the code will reappear if the underlying issue persists.

7. How often should I have my Mercedes-Benz scanned for DTCs?

Regularly scanning for DTCs during scheduled maintenance can help detect potential problems early, preventing costly repairs down the line.

8. What are some common reasons for DTCs in Mercedes-Benz vehicles?

Common triggers include faulty sensors, vacuum leaks, engine misfires, issues with the catalytic converter, and problems within the complex electrical system.

9. How can I prevent DTCs from occurring in my Mercedes-Benz?

Adhering to the recommended maintenance schedule, using high-quality parts, practicing careful driving habits, and promptly addressing minor issues can help minimize the occurrence of DTCs.

10. Where can I get expert advice on diagnosing and repairing my Mercedes-Benz?

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers expert advice, comprehensive diagnostic tool information, and step-by-step guides for unlocking hidden features and performing repairs on your Mercedes-Benz. Contact us at +1 (641) 206-8880 or visit our website for more information.