DTS Monaco can be used to diagnose issues with Selective Catalytic Reduction (SCR) systems, offering comprehensive diagnostic capabilities, in-depth analysis, and ECU flashing, making it a powerful tool for technicians and enthusiasts working on Mercedes-Benz vehicles. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers expert guidance and resources, ensuring users can effectively utilize DTS Monaco for diagnosing and resolving SCR system problems, optimizing vehicle performance and minimizing emissions. To identify faults accurately, understand diagnostic trouble codes (DTCs), and perform advanced troubleshooting, enhancing overall diagnostic accuracy, and streamlining the repair process it is crucial to explore the features of the diagnostic software, ECU diagnostics, and OBD II scanner functions.

Contents

- 1. Understanding SCR Systems in Mercedes-Benz Vehicles

- 1.1. Components of an SCR System

- 1.2. Functionality of SCR Systems

- 1.3. Importance of SCR Systems

- 2. An Overview of DTS Monaco Diagnostic Software

- 2.1. Capabilities of DTS Monaco

- 2.2. Key Features of DTS Monaco

- 2.3. Advantages of Using DTS Monaco

- 3. Diagnosing SCR System Issues with DTS Monaco

- 3.1. Connecting DTS Monaco to the Vehicle

- 3.2. Reading Diagnostic Trouble Codes (DTCs)

- 3.3. Interpreting SCR-Related DTCs

- 3.4. Live Data Monitoring for SCR System Analysis

- 3.5. Performing Actuator Tests on SCR Components

- 3.6. Clearing DTCs and Verifying Repairs

- 4. Advanced Troubleshooting Techniques Using DTS Monaco

- 4.1. Oscilloscope Integration

- 4.2. Data Logging and Analysis

- 4.3. Fault Tree Analysis

- 4.4. ECU Flashing and Reprogramming

- 4.5. Variant Coding and Adaptation

- 5. Common SCR System Problems and How DTS Monaco Can Help

- 5.1. DEF Quality Issues

- 5.2. DEF Injector Malfunctions

- 5.3. NOx Sensor Failures

- 5.4. SCR Catalyst Issues

- 5.5. Temperature Sensor Problems

- 5.6. Wiring and Connection Problems

- 6. Step-by-Step Guide: Performing an SCR System Diagnosis with DTS Monaco

- Step 1: Preparation and Connection

- Step 2: Reading Diagnostic Trouble Codes (DTCs)

- Step 3: Live Data Monitoring

- Step 4: Actuator Tests

- Step 5: Advanced Troubleshooting (If Necessary)

- Step 6: Repair and Verification

- Step 7: Final Checks and Documentation

- 7. Tips for Optimizing SCR System Diagnostics with DTS Monaco

- 7.1. Keep Software Updated

- 7.2. Use High-Quality Diagnostic Hardware

- 7.3. Understand DTC Definitions

- 7.4. Utilize Live Data Effectively

- 7.5. Perform Actuator Tests Carefully

- 7.6. Use Oscilloscope for Detailed Signal Analysis

- 7.7. Log Data for Intermittent Issues

- 7.8. Follow a Systematic Approach

- 7.9. Consult Service Manuals and Technical Resources

- 7.10. Document Your Work

- 8. Advantages of Using MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for DTS Monaco Support

- 8.1. Comprehensive Diagnostic Information

- 8.2. Expert Technical Support

- 8.3. Step-by-Step Guides and Tutorials

- 8.4. Software Updates and Upgrades

- 8.5. Community Forums and Discussion Boards

- 8.6. Remote Diagnostic Assistance

- 8.7. Training Programs and Workshops

- 8.8. Cost-Effective Solutions

- 9. Real-World Examples of SCR System Diagnosis with DTS Monaco

- 9.1. Example 1: NOx Sensor Failure

- 9.2. Example 2: DEF Injector Clogging

1. Understanding SCR Systems in Mercedes-Benz Vehicles

Selective Catalytic Reduction (SCR) systems play a vital role in reducing harmful nitrogen oxide (NOx) emissions from diesel engines in Mercedes-Benz vehicles. To ensure effective emission control, understanding the components and functionality of SCR systems is essential.

1.1. Components of an SCR System

An SCR system consists of several key components working together to reduce NOx emissions:

- Diesel Exhaust Fluid (DEF) Tank: This tank stores the urea-based solution (DEF) required for the SCR process.

- DEF Injector: The DEF injector sprays DEF into the exhaust stream upstream of the SCR catalyst.

- SCR Catalyst: The SCR catalyst facilitates the chemical reaction between DEF and NOx, converting them into nitrogen and water.

- NOx Sensors: These sensors monitor NOx levels in the exhaust gas, providing feedback to the engine control unit (ECU) for precise DEF dosing.

- Temperature Sensors: Temperature sensors monitor the temperature of the exhaust gas and SCR catalyst, ensuring optimal operating conditions.

- Engine Control Unit (ECU): The ECU controls the entire SCR system, including DEF dosing, based on input from various sensors.

1.2. Functionality of SCR Systems

The SCR system operates through the following process:

- NOx Emission: As the engine operates, it produces NOx, a harmful pollutant.

- DEF Injection: The ECU calculates the required amount of DEF and commands the DEF injector to spray it into the exhaust stream.

- Mixing and Vaporization: The injected DEF mixes with the hot exhaust gases and vaporizes, forming ammonia (NH3).

- Catalytic Conversion: The exhaust gas, containing NOx and ammonia, flows through the SCR catalyst. The catalyst promotes a chemical reaction where NOx reacts with ammonia to form nitrogen (N2) and water (H2O), both of which are harmless.

- Monitoring: NOx sensors downstream of the catalyst monitor the NOx levels to ensure the system is functioning correctly. The ECU adjusts DEF dosing based on this feedback to maintain optimal NOx reduction.

1.3. Importance of SCR Systems

SCR systems are crucial for meeting stringent emission regulations and reducing the environmental impact of diesel vehicles. These systems help to:

- Reduce NOx Emissions: Significantly decrease the amount of NOx released into the atmosphere.

- Improve Air Quality: Contribute to cleaner air and reduce smog formation.

- Meet Regulatory Standards: Ensure vehicles comply with emission standards set by regulatory agencies.

- Enhance Fuel Efficiency: Optimize engine performance and fuel economy.

Understanding the components, functionality, and importance of SCR systems is the first step in effectively diagnosing and resolving issues related to these systems. Tools like DTS Monaco can then be employed to delve deeper into the system’s operation and pinpoint specific problems.

2. An Overview of DTS Monaco Diagnostic Software

DTS Monaco is a comprehensive diagnostic software used for Mercedes-Benz vehicles. It allows technicians and enthusiasts to perform in-depth diagnostics, ECU flashing, and advanced troubleshooting. This overview will explore the capabilities of DTS Monaco, its key features, and its advantages over other diagnostic tools.

2.1. Capabilities of DTS Monaco

DTS Monaco offers a wide range of diagnostic capabilities, including:

- Reading and Clearing Diagnostic Trouble Codes (DTCs): Identifies and clears error codes stored in the vehicle’s ECU.

- Live Data Monitoring: Provides real-time data from various sensors and components, allowing for thorough analysis of vehicle performance.

- Actuator Testing: Enables testing of individual components, such as injectors, valves, and motors, to verify their functionality.

- ECU Flashing: Allows updating or reprogramming the ECU with the latest software versions or custom calibrations.

- Variant Coding: Enables customization of vehicle settings and features to match specific requirements or preferences.

- Guided Diagnostics: Offers step-by-step instructions for diagnosing complex issues, reducing diagnostic time and improving accuracy.

2.2. Key Features of DTS Monaco

DTS Monaco is equipped with several key features that make it a powerful diagnostic tool:

- User-Friendly Interface: An intuitive interface that simplifies navigation and operation.

- Comprehensive Vehicle Coverage: Supports a wide range of Mercedes-Benz models, including passenger cars, trucks, and buses.

- Advanced Diagnostic Functions: Offers advanced diagnostic functions such as oscilloscope integration, data logging, and fault tree analysis.

- Offline Programming: Enables ECU flashing and programming without an internet connection, providing flexibility and convenience.

- Secure Data Handling: Ensures secure data transmission and storage to protect sensitive vehicle information.

2.3. Advantages of Using DTS Monaco

Compared to other diagnostic tools, DTS Monaco offers several advantages:

- OEM-Level Diagnostics: Provides diagnostic capabilities equivalent to those used by Mercedes-Benz dealerships, ensuring accurate and reliable results.

- Extensive Customization Options: Allows customization of vehicle settings and features beyond the capabilities of standard diagnostic tools.

- Efficient Troubleshooting: Offers advanced troubleshooting tools and guided diagnostics to quickly identify and resolve complex issues.

- Regular Updates: Receives regular software updates to support new vehicle models and diagnostic functions.

- Cost-Effectiveness: Reduces diagnostic costs by eliminating the need for expensive dealership visits.

DTS Monaco stands out as a versatile and powerful diagnostic tool for Mercedes-Benz vehicles, offering comprehensive capabilities, advanced features, and significant advantages over other diagnostic solutions. Understanding these aspects is crucial for leveraging DTS Monaco effectively in diagnosing SCR system issues.

3. Diagnosing SCR System Issues with DTS Monaco

Using DTS Monaco to diagnose issues within the Selective Catalytic Reduction (SCR) system of a Mercedes-Benz vehicle involves a systematic approach. This section provides a detailed guide on how to use DTS Monaco to identify and troubleshoot SCR system problems.

3.1. Connecting DTS Monaco to the Vehicle

The first step is to establish a reliable connection between DTS Monaco and the vehicle. Follow these steps:

- Connect the Diagnostic Interface: Plug the diagnostic interface (e.g., XENTRY Connect, eCOM) into the vehicle’s OBD II port, typically located under the dashboard.

- Connect to the Computer: Connect the diagnostic interface to your computer via USB or Wi-Fi.

- Launch DTS Monaco: Open the DTS Monaco software on your computer.

- Select the Vehicle Model: Choose the correct vehicle model and year from the DTS Monaco vehicle selection menu.

- Establish Connection: Follow the on-screen prompts to establish a connection between DTS Monaco and the vehicle’s ECU. Verify that the connection is stable before proceeding.

3.2. Reading Diagnostic Trouble Codes (DTCs)

Once connected, the next step is to read and interpret the Diagnostic Trouble Codes (DTCs) related to the SCR system:

- Navigate to Fault Memory: In DTS Monaco, navigate to the “Fault Memory” or “Trouble Codes” section.

- Read DTCs: Initiate the process to read DTCs from the vehicle’s ECU. DTS Monaco will display a list of stored fault codes along with their descriptions.

- Identify SCR-Related Codes: Look for codes specifically related to the SCR system, such as:

- P20EE: SCR NOx Catalyst Efficiency Below Threshold

- P20E8: Reductant Injection Valve Circuit Range/Performance

- P20F5: Reductant Consumption Too Low

- P204F: SCR System Malfunction

- Record DTCs: Note down all relevant DTCs and their descriptions for further analysis.

3.3. Interpreting SCR-Related DTCs

Understanding the meaning of each DTC is crucial for accurate diagnosis:

- P20EE (SCR NOx Catalyst Efficiency Below Threshold): This code indicates that the SCR catalyst is not effectively reducing NOx emissions. Possible causes include a faulty catalyst, incorrect DEF dosing, or issues with NOx sensors.

- P20E8 (Reductant Injection Valve Circuit Range/Performance): This code suggests a problem with the DEF injector circuit, such as a short, open, or high resistance. It could also indicate a malfunctioning DEF injector.

- P20F5 (Reductant Consumption Too Low): This code indicates that the DEF consumption is lower than expected, which could be due to a clogged DEF injector, a faulty DEF pump, or a leak in the DEF system.

- P204F (SCR System Malfunction): This generic code indicates a general issue within the SCR system. Further diagnostics are needed to pinpoint the exact cause.

3.4. Live Data Monitoring for SCR System Analysis

Live data monitoring allows real-time analysis of the SCR system’s performance. To use this feature:

- Access Live Data: In DTS Monaco, navigate to the “Live Data” or “Actual Values” section.

- Select Relevant Parameters: Choose parameters related to the SCR system, such as:

- NOx sensor readings (upstream and downstream of the catalyst)

- DEF injector duty cycle

- DEF tank level

- Exhaust gas temperature

- SCR catalyst temperature

- Monitor Data: Observe the live data while the engine is running. Pay attention to any abnormal readings or deviations from expected values.

- Analyze Data:

- NOx Sensor Readings: Compare the readings from the upstream and downstream NOx sensors. A significant difference indicates the SCR catalyst is functioning correctly. If the downstream reading is similar to the upstream reading, the catalyst may be faulty.

- DEF Injector Duty Cycle: Monitor the DEF injector duty cycle to ensure it is within the specified range. An excessively high or low duty cycle could indicate a problem with the injector or the DEF dosing system.

- DEF Tank Level: Verify the DEF tank level to rule out the possibility of an empty or low DEF supply.

- Exhaust Gas Temperature: Ensure the exhaust gas temperature is within the optimal range for SCR operation. Low temperatures can reduce the efficiency of the catalyst.

- SCR Catalyst Temperature: Monitor the SCR catalyst temperature to ensure it reaches the required temperature for NOx reduction.

3.5. Performing Actuator Tests on SCR Components

Actuator tests allow you to activate individual SCR components to verify their functionality:

- Access Actuator Tests: In DTS Monaco, navigate to the “Actuator Tests” or “Component Activation” section.

- Select SCR Components: Choose the components you want to test, such as:

- DEF injector

- DEF pump

- DEF metering valve

- Initiate Tests: Follow the on-screen prompts to activate the selected components.

- Observe Component Response:

- DEF Injector: Listen for the injector clicking or spraying when activated. If there is no response, the injector may be faulty or the circuit may be damaged.

- DEF Pump: Check if the DEF pump is running and delivering fluid. If the pump is not running, it may be faulty or the circuit may be damaged.

- DEF Metering Valve: Verify that the metering valve is opening and closing correctly. If the valve is stuck or unresponsive, it may need to be replaced.

3.6. Clearing DTCs and Verifying Repairs

After performing the necessary repairs, clear the DTCs and verify that the issue has been resolved:

- Clear DTCs: In DTS Monaco, navigate to the “Fault Memory” section and clear all SCR-related DTCs.

- Verify Repairs: Start the engine and monitor the SCR system using live data. Ensure that all parameters are within the specified ranges and that no new DTCs appear.

- Road Test: Perform a road test to simulate real-world driving conditions. Monitor the SCR system throughout the test to ensure that the issue does not reappear.

By following these steps, you can effectively use DTS Monaco to diagnose and resolve SCR system issues in Mercedes-Benz vehicles. Accurate diagnosis and timely repairs are essential for maintaining optimal emission control and vehicle performance.

4. Advanced Troubleshooting Techniques Using DTS Monaco

Beyond basic diagnostics, DTS Monaco offers advanced troubleshooting techniques that can help identify and resolve complex issues within the Selective Catalytic Reduction (SCR) systems of Mercedes-Benz vehicles. This section explores some of these advanced techniques.

4.1. Oscilloscope Integration

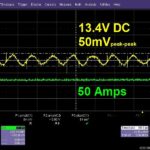

DTS Monaco can be integrated with an oscilloscope to visualize electrical signals within the SCR system. This can be particularly useful for diagnosing issues with sensors, actuators, and wiring.

- Connect Oscilloscope: Connect the oscilloscope to the relevant test points in the SCR system (e.g., DEF injector signal wire, NOx sensor output).

- Configure DTS Monaco: Configure DTS Monaco to display the oscilloscope data.

- Analyze Waveforms: Analyze the waveforms to identify any abnormalities, such as signal distortion, voltage drops, or timing issues.

For example, when diagnosing a DEF injector issue, an oscilloscope can help determine if the injector is receiving the correct pulse width modulation (PWM) signal from the ECU. A distorted or missing PWM signal indicates a problem with the ECU or the wiring.

4.2. Data Logging and Analysis

DTS Monaco allows you to log data from various sensors and components over time. This can be useful for identifying intermittent issues or analyzing system behavior under different operating conditions.

- Configure Data Logging: Select the parameters you want to log (e.g., NOx sensor readings, DEF injector duty cycle, exhaust gas temperature) and set the logging interval.

- Start Logging: Start the data logging process and drive the vehicle under various conditions.

- Analyze Logged Data: Download the logged data and analyze it using DTS Monaco’s data analysis tools or export it to a spreadsheet program for further analysis.

For example, data logging can help identify if the NOx levels are consistently high under certain driving conditions, indicating a potential issue with the SCR catalyst or DEF dosing strategy.

4.3. Fault Tree Analysis

DTS Monaco includes a fault tree analysis feature that helps you systematically diagnose complex issues by guiding you through a series of tests and checks.

- Access Fault Tree Analysis: In DTS Monaco, navigate to the “Fault Tree Analysis” section.

- Select Relevant Fault Code: Choose the fault code you are troubleshooting (e.g., P20EE – SCR NOx Catalyst Efficiency Below Threshold).

- Follow Diagnostic Steps: Follow the step-by-step diagnostic procedures outlined in the fault tree. This may involve checking wiring, testing components, and performing specific measurements.

- Identify Root Cause: Based on the results of each test, the fault tree will guide you towards the most likely root cause of the issue.

4.4. ECU Flashing and Reprogramming

In some cases, SCR system issues may be resolved by updating or reprogramming the ECU with the latest software version. DTS Monaco allows you to perform ECU flashing and reprogramming.

- Check for Software Updates: Check if there are any software updates available for the vehicle’s ECU.

- Backup ECU Data: Before flashing the ECU, create a backup of the existing ECU data in case something goes wrong.

- Flash ECU: Follow the on-screen prompts to flash the ECU with the new software.

- Verify Programming: After flashing the ECU, verify that the programming was successful and that the SCR system is functioning correctly.

Caution: ECU flashing can be a complex and risky process. Make sure you have the necessary knowledge and experience before attempting to flash the ECU.

4.5. Variant Coding and Adaptation

DTS Monaco allows you to perform variant coding and adaptation, which involves customizing vehicle settings and features to match specific requirements. This can be useful for troubleshooting SCR system issues related to incorrect configurations.

- Access Variant Coding: In DTS Monaco, navigate to the “Variant Coding” or “Adaptation” section.

- Check Configuration Settings: Verify that all the configuration settings related to the SCR system are correct.

- Modify Settings: Modify any incorrect settings to match the vehicle’s specifications.

- Save Changes: Save the changes and verify that the SCR system is functioning correctly.

By utilizing these advanced troubleshooting techniques, you can effectively diagnose and resolve complex issues within the SCR systems of Mercedes-Benz vehicles using DTS Monaco.

5. Common SCR System Problems and How DTS Monaco Can Help

Selective Catalytic Reduction (SCR) systems are complex and can encounter various issues that affect their performance. DTS Monaco can be instrumental in diagnosing and addressing these common problems. Here’s a look at some of the typical SCR system faults and how DTS Monaco aids in their resolution.

5.1. DEF Quality Issues

One of the most common problems is related to the quality of Diesel Exhaust Fluid (DEF).

- Issue: Contaminated or expired DEF can lead to poor NOx reduction and potential system damage.

- DTS Monaco Assistance:

- DTC Reading: DTS Monaco can read DTCs related to DEF quality, such as codes indicating incorrect DEF concentration or contamination.

- Live Data Monitoring: Monitor DEF tank level and DEF injector performance to detect irregularities.

- Actuator Tests: Perform tests on the DEF injector to ensure it is spraying correctly.

5.2. DEF Injector Malfunctions

The DEF injector can become clogged or fail, leading to improper DEF dosing.

- Issue: Clogged or malfunctioning DEF injector results in reduced NOx reduction efficiency.

- DTS Monaco Assistance:

- DTC Reading: Detect codes related to the DEF injector circuit, such as open or short circuits.

- Actuator Tests: Activate the DEF injector to check for proper operation. Listen for the characteristic clicking sound and verify that DEF is being sprayed.

- Oscilloscope Integration: Use an oscilloscope to analyze the electrical signal to the DEF injector, ensuring it is receiving the correct signal from the ECU.

5.3. NOx Sensor Failures

NOx sensors are critical for monitoring the performance of the SCR system.

- Issue: Faulty NOx sensors provide incorrect data to the ECU, leading to incorrect DEF dosing and reduced NOx reduction efficiency.

- DTS Monaco Assistance:

- Live Data Monitoring: Monitor the readings from the upstream and downstream NOx sensors. Compare the readings to ensure they are within the expected range.

- DTC Reading: Identify codes related to NOx sensor failures, such as signal range or performance issues.

- Component Testing: Use DTS Monaco to perform component tests on the NOx sensors to verify their functionality.

5.4. SCR Catalyst Issues

The SCR catalyst can degrade over time, reducing its ability to convert NOx.

- Issue: Degraded SCR catalyst leads to reduced NOx reduction efficiency.

- DTS Monaco Assistance:

- Live Data Monitoring: Monitor NOx levels upstream and downstream of the catalyst to assess its efficiency.

- DTC Reading: Detect codes related to SCR catalyst efficiency, such as “SCR NOx Catalyst Efficiency Below Threshold.”

- Data Logging: Log data over time to monitor the catalyst’s performance under various driving conditions.

5.5. Temperature Sensor Problems

Temperature sensors are used to monitor the temperature of the exhaust gas and SCR catalyst.

- Issue: Faulty temperature sensors provide incorrect temperature readings to the ECU, affecting DEF dosing and SCR system performance.

- DTS Monaco Assistance:

- Live Data Monitoring: Monitor the readings from the temperature sensors to ensure they are within the expected range.

- DTC Reading: Identify codes related to temperature sensor failures, such as signal range or performance issues.

- Component Testing: Use DTS Monaco to perform component tests on the temperature sensors to verify their functionality.

5.6. Wiring and Connection Problems

Wiring and connection issues can cause a variety of SCR system problems.

- Issue: Corroded or damaged wiring can lead to intermittent or complete failure of SCR system components.

- DTS Monaco Assistance:

- DTC Reading: Detect codes related to circuit faults, such as open or short circuits.

- Live Data Monitoring: Monitor the readings from sensors and actuators to identify any erratic or missing signals.

- Visual Inspection: Use DTS Monaco in conjunction with a visual inspection of the wiring and connections to identify any obvious problems.

By using DTS Monaco to diagnose and address these common SCR system problems, you can ensure that your Mercedes-Benz vehicle is running efficiently and meeting emission standards.

6. Step-by-Step Guide: Performing an SCR System Diagnosis with DTS Monaco

To effectively diagnose issues with the Selective Catalytic Reduction (SCR) system in Mercedes-Benz vehicles, it’s crucial to follow a structured approach using DTS Monaco. Here’s a detailed step-by-step guide:

Step 1: Preparation and Connection

- Gather Necessary Equipment:

- DTS Monaco software installed on a laptop.

- A compatible diagnostic interface (e.g., XENTRY Connect, eCOM).

- OBD II cable to connect the interface to the vehicle.

- Connect Diagnostic Interface:

- Turn off the vehicle’s ignition.

- Locate the OBD II port (typically under the dashboard).

- Connect the diagnostic interface to the OBD II port.

- Establish Connection with DTS Monaco:

- Turn on the laptop and launch the DTS Monaco software.

- Turn on the vehicle’s ignition (but do not start the engine).

- Select the correct vehicle model and ECU from the DTS Monaco menu.

- Establish a connection between the software and the vehicle’s ECU. Verify the connection is stable.

Step 2: Reading Diagnostic Trouble Codes (DTCs)

- Navigate to Fault Memory:

- In DTS Monaco, navigate to the section labeled “Fault Memory,” “Trouble Codes,” or similar.

- Read Stored DTCs:

- Initiate the process to read DTCs from the vehicle’s ECU. The software will display a list of stored fault codes along with their descriptions.

- Identify SCR-Related Codes:

- Look for specific DTCs related to the SCR system. Common SCR-related DTCs include:

- P20EE: SCR NOx Catalyst Efficiency Below Threshold

- P20E8: Reductant Injection Valve Circuit Range/Performance

- P20F5: Reductant Consumption Too Low

- P204F: SCR System Malfunction

- Look for specific DTCs related to the SCR system. Common SCR-related DTCs include:

- Record DTCs:

- Note down all relevant DTCs and their descriptions for further analysis.

Step 3: Live Data Monitoring

- Access Live Data:

- In DTS Monaco, navigate to the “Live Data” or “Actual Values” section.

- Select Relevant Parameters:

- Choose the following parameters related to the SCR system:

- Upstream and downstream NOx sensor readings

- DEF injector duty cycle

- DEF tank level

- Exhaust gas temperature

- SCR catalyst temperature

- Choose the following parameters related to the SCR system:

- Monitor and Analyze Data:

- Start the engine and allow it to reach operating temperature.

- Observe the live data readings. Look for any abnormal values or deviations from expected ranges.

- Compare the upstream and downstream NOx sensor readings. A significant difference indicates the SCR catalyst is functioning correctly. If the downstream reading is similar to the upstream reading, the catalyst may be faulty.

- Monitor the DEF injector duty cycle to ensure it is within the specified range. An excessively high or low duty cycle could indicate a problem with the injector or the DEF dosing system.

- Verify the DEF tank level to rule out the possibility of an empty or low DEF supply.

- Ensure the exhaust gas temperature is within the optimal range for SCR operation. Low temperatures can reduce the efficiency of the catalyst.

- Monitor the SCR catalyst temperature to ensure it reaches the required temperature for NOx reduction.

Step 4: Actuator Tests

- Access Actuator Tests:

- In DTS Monaco, navigate to the “Actuator Tests” or “Component Activation” section.

- Select SCR Components:

- Choose the components you want to test, such as:

- DEF injector

- DEF pump

- DEF metering valve

- Choose the components you want to test, such as:

- Initiate Tests:

- Follow the on-screen prompts to activate the selected components.

- Observe Component Response:

- DEF Injector: Listen for the injector clicking or spraying when activated. If there is no response, the injector may be faulty or the circuit may be damaged.

- DEF Pump: Check if the DEF pump is running and delivering fluid. If the pump is not running, it may be faulty or the circuit may be damaged.

- DEF Metering Valve: Verify that the metering valve is opening and closing correctly. If the valve is stuck or unresponsive, it may need to be replaced.

Step 5: Advanced Troubleshooting (If Necessary)

- Oscilloscope Integration:

- If available, use an oscilloscope to analyze electrical signals to sensors and actuators for more detailed diagnostics.

- Data Logging:

- Log data over time to identify intermittent issues or analyze system behavior under different driving conditions.

- Fault Tree Analysis:

- Utilize DTS Monaco’s fault tree analysis feature to systematically diagnose complex issues by following a series of guided tests and checks.

Step 6: Repair and Verification

- Perform Necessary Repairs:

- Based on the diagnostic findings, perform the necessary repairs, such as replacing faulty sensors, injectors, or the SCR catalyst.

- Clear DTCs:

- After completing the repairs, return to the “Fault Memory” section in DTS Monaco and clear all SCR-related DTCs.

- Verify Repairs:

- Start the engine and monitor the SCR system using live data to ensure that all parameters are within the specified ranges and that no new DTCs appear.

- Road Test:

- Perform a road test to simulate real-world driving conditions. Monitor the SCR system throughout the test to ensure that the issue does not reappear.

Step 7: Final Checks and Documentation

- Perform a Final Scan:

- Conduct a final scan of the vehicle to ensure no new DTCs have been triggered during the repair and testing process.

- Document the Process:

- Document all diagnostic steps, findings, and repairs performed. This documentation can be valuable for future reference and troubleshooting.

By following this step-by-step guide, you can effectively use DTS Monaco to diagnose and resolve SCR system issues in Mercedes-Benz vehicles, ensuring optimal emission control and vehicle performance.

7. Tips for Optimizing SCR System Diagnostics with DTS Monaco

To maximize the effectiveness of DTS Monaco in diagnosing Selective Catalytic Reduction (SCR) system issues, consider these optimization tips.

7.1. Keep Software Updated

- Regular Updates: Ensure that your DTS Monaco software is always updated to the latest version. Updates often include bug fixes, improved diagnostic capabilities, and support for new vehicle models.

- Benefits: Keeping the software updated ensures you have access to the most accurate and comprehensive diagnostic information.

7.2. Use High-Quality Diagnostic Hardware

- Reliable Interface: Invest in a high-quality diagnostic interface (e.g., XENTRY Connect, eCOM) to ensure a stable and reliable connection with the vehicle’s ECU.

- Avoid Compatibility Issues: Using a compatible and reliable interface minimizes the risk of data corruption and communication errors during diagnostics.

7.3. Understand DTC Definitions

- Detailed Information: Don’t just read the DTCs; take the time to understand their definitions and possible causes. DTS Monaco typically provides detailed information about each DTC, including potential symptoms and troubleshooting steps.

- Accurate Diagnosis: A thorough understanding of DTC definitions helps you narrow down the possible causes of the problem and perform more targeted diagnostics.

7.4. Utilize Live Data Effectively

- Select Relevant Parameters: When monitoring live data, focus on the parameters that are most relevant to the SCR system, such as NOx sensor readings, DEF injector duty cycle, exhaust gas temperature, and SCR catalyst temperature.

- Compare Values: Compare the live data values to the expected ranges specified in the vehicle’s service manual. Look for any deviations that could indicate a problem.

7.5. Perform Actuator Tests Carefully

- Safety Precautions: When performing actuator tests, follow all safety precautions and guidelines. Some tests may require the engine to be running, so be sure to take appropriate safety measures.

- Observe Component Response: Carefully observe the response of each component during the actuator test. Listen for unusual noises or vibrations, and visually inspect the component for any signs of damage or malfunction.

7.6. Use Oscilloscope for Detailed Signal Analysis

- Advanced Diagnostics: If you have access to an oscilloscope, use it to analyze the electrical signals to sensors and actuators for more detailed diagnostics. This can help you identify issues such as signal distortion, voltage drops, or timing problems.

- Accurate Readings: Ensure the oscilloscope is properly calibrated and connected to get accurate readings.

7.7. Log Data for Intermittent Issues

- Capture Intermittent Faults: If you are troubleshooting an intermittent issue, use DTS Monaco’s data logging feature to record data over time. This can help you capture the fault when it occurs and analyze the data to identify the cause.

- Analyze Driving Conditions: Log data under various driving conditions to see if the issue is related to specific operating parameters.

7.8. Follow a Systematic Approach

- Structured Diagnostics: Follow a systematic approach to SCR system diagnostics, starting with reading DTCs, then monitoring live data, performing actuator tests, and finally, using advanced troubleshooting techniques if necessary.

- Efficient Troubleshooting: A structured approach helps you avoid wasting time on unnecessary tests and ensures that you address all possible causes of the problem.

7.9. Consult Service Manuals and Technical Resources

- Reference Materials: Refer to the vehicle’s service manual and other technical resources for detailed information about the SCR system, including component locations, wiring diagrams, and troubleshooting procedures.

- Accurate Information: Having access to accurate information helps you perform diagnostics more efficiently and accurately.

7.10. Document Your Work

- Detailed Records: Keep detailed records of all diagnostic steps, findings, and repairs performed. This documentation can be valuable for future reference and troubleshooting.

- Future Reference: Accurate documentation also helps you track the history of the vehicle and identify any recurring issues.

By following these tips, you can optimize your use of DTS Monaco for SCR system diagnostics, ensuring accurate and efficient troubleshooting and repairs.

8. Advantages of Using MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for DTS Monaco Support

When diagnosing and troubleshooting SCR system issues in Mercedes-Benz vehicles using DTS Monaco, having reliable support and resources is essential. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers several advantages in this regard.

8.1. Comprehensive Diagnostic Information

- Extensive Database: Access a comprehensive database of diagnostic information, including DTC definitions, troubleshooting guides, and technical specifications for Mercedes-Benz vehicles.

- Accurate Solutions: Having access to detailed and accurate information helps you diagnose SCR system issues more efficiently and effectively.

8.2. Expert Technical Support

- Experienced Technicians: Receive expert technical support from experienced Mercedes-Benz technicians who are knowledgeable about DTS Monaco and SCR systems.

- Prompt Assistance: Get prompt answers to your diagnostic questions and assistance with troubleshooting complex issues.

8.3. Step-by-Step Guides and Tutorials

- Detailed Instructions: Benefit from step-by-step guides and tutorials that walk you through the process of diagnosing and repairing SCR system issues using DTS Monaco.

- Efficient Learning: These resources make it easier to learn how to use DTS Monaco effectively and perform accurate diagnostics.

8.4. Software Updates and Upgrades

- Latest Versions: Stay up-to-date with the latest DTS Monaco software versions and upgrades, ensuring you have access to the most current diagnostic capabilities.

- Improved Performance: Receive notifications about new updates and instructions on how to install them.

8.5. Community Forums and Discussion Boards

- Shared Knowledge: Participate in community forums and discussion boards where you can share your experiences, ask questions, and learn from other DTS Monaco users.

- Collaborative Solutions: This collaborative environment helps you find solutions to common SCR system issues and stay informed about the latest diagnostic techniques.

8.6. Remote Diagnostic Assistance

- Remote Support: Receive remote diagnostic assistance from expert technicians who can connect to your computer and vehicle to help you troubleshoot SCR system issues in real-time.

- Convenient Solutions: This service provides a convenient and efficient way to get the help you need without having to take your vehicle to a repair shop.

8.7. Training Programs and Workshops

- Hands-On Experience: Participate in training programs and workshops that provide hands-on experience using DTS Monaco to diagnose and repair SCR system issues.

- Enhanced Skills: These programs help you develop the skills and knowledge you need to become a proficient DTS Monaco user and perform accurate diagnostics.

8.8. Cost-Effective Solutions

- Affordable Services: Access cost-effective diagnostic solutions and support services that help you save time and money on SCR system repairs.

- Reduced Downtime: With reliable support and resources, you can minimize vehicle downtime and get back on the road quickly.

By leveraging the resources and support offered by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, you can maximize the effectiveness of DTS Monaco for diagnosing and repairing SCR system issues in Mercedes-Benz vehicles.

9. Real-World Examples of SCR System Diagnosis with DTS Monaco

To illustrate the practical application of DTS Monaco in diagnosing SCR system issues, here are real-world examples demonstrating how the software can be used to identify and resolve problems.

9.1. Example 1: NOx Sensor Failure

- Scenario: A Mercedes-Benz owner notices a check engine light and experiences reduced engine performance.

- Diagnostic Steps:

- Connect DTS Monaco to the vehicle and read DTCs.

- DTS Monaco displays DTC P2200: NOx Sensor Circuit Range/Performance (Bank 1).

- Access live data and monitor the readings from the upstream and downstream NOx sensors.

- The upstream NOx sensor reading is within the expected range, but the downstream NOx sensor reading is erratic and out of range.

- Perform an actuator test on the downstream NOx sensor. The sensor does not respond.

- Resolution:

- Based on the diagnostic findings, the downstream NOx sensor is identified as faulty.

- Replace the faulty NOx sensor with a new one.

- Clear the DTCs using DTS Monaco.

- Monitor the live data to ensure that the NOx sensor readings are now within the expected range.

- Perform a road test to verify that the check engine light does not reappear and that the engine performance is restored.

9.2. Example 2: DEF Injector Clogging

- Scenario: A Mercedes-Benz truck driver notices a reduction in DEF consumption and receives a warning message indicating a problem with the SCR system.

- Diagnostic Steps:

- Connect DTS Monaco to the vehicle and read DTCs.

- DTS Monaco displays DTC P20E8: Reductant Injection Valve Circuit Range/Performance.

- Access live data and monitor the DEF injector duty cycle. The duty cycle is significantly higher than expected.

- Perform an actuator test on the DEF injector. The injector does not produce a consistent spray pattern.

- Resolution:

- Based on the diagnostic findings, the DEF injector is identified as clogged.

- Remove the DEF injector and clean it thoroughly.

- Reinstall the DEF injector and perform another actuator test. The injector now produces a consistent spray pattern