DTS Monaco offers comprehensive diagnostic capabilities, including calibration and leveling procedures for air suspension systems, ensuring optimal vehicle performance; visit MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for advanced diagnostic tools and expert guidance to enhance your Mercedes-Benz maintenance and repair. This article will cover using DTS Monaco for air suspension adjustments, airmatic system diagnostics, and electronic control unit coding.

Contents

- 1. Understanding DTS Monaco and Air Suspension Systems

- 1.1 What is DTS Monaco?

- 1.2 What is an Air Suspension System?

- 1.3 Key Components of the Air Suspension System

- 2. The Role of DTS Monaco in Air Suspension Calibration

- 2.1 Can DTS Monaco Perform Calibration?

- 2.2 Why is Calibration Necessary?

- 2.3 Identifying the Need for Calibration

- 3. Step-by-Step Guide to Calibrating Air Suspension with DTS Monaco

- 3.1 Prerequisites

- 3.2 Connecting to the Vehicle

- 3.3 Accessing Air Suspension Control Module

- 3.4 Performing Calibration

- 3.5 Verifying Calibration

- 3.6 Common Issues During Calibration

- 4. Advanced Features and Customization with DTS Monaco

- 4.1 Coding and Programming

- 4.2 Diagnostic Capabilities

- 4.3 Benefits of Using DTS Monaco

- 5. Troubleshooting Common Air Suspension Problems with DTS Monaco

- 5.1 Identifying Fault Codes

- 5.2 Diagnosing Component Failures

- 5.3 Addressing System Leaks

- 5.4 Correcting Leveling Issues

- 6. Best Practices for Using DTS Monaco

- 6.1 Ensuring Proper Connection

- 6.2 Following Instructions Carefully

- 6.3 Backing Up Data

- 6.4 Staying Updated

- 6.5 Seeking Professional Assistance

- 7. Benefits of Professional Calibration Services

- 7.1 Expertise and Experience

- 7.2 Specialized Tools and Equipment

- 7.3 Warranty and Support

- 7.4 Cost Savings

- 8. Choosing the Right Diagnostic Tool

- 8.1 Key Features to Consider

- 8.2 Popular Diagnostic Tools

- 8.3 Why MB Star C4/C5 is Recommended

- 9. Real-World Examples of DTS Monaco in Air Suspension Repair

- 9.1 Case Study 1: Correcting Uneven Ride Height

- 9.2 Case Study 2: Diagnosing Compressor Failure

- 9.3 Case Study 3: Resolving Warning Lights

- 10. The Future of Air Suspension Systems

- 10.1 Advancements in Technology

- 10.2 Impact on Diagnostic Tools

- 10.3 Preparing for the Future

- 11. Air Suspension Maintenance Tips

- 11.1 Regular Inspections

- 11.2 Cleaning the System

- 11.3 Replacing Worn Components

- 11.4 Proper Driving Habits

- 12. Common Misconceptions About Air Suspension Systems

- 12.1 Air Suspension is Unreliable

- 12.2 Air Suspension is Expensive to Repair

- 12.3 Air Suspension is Only for Luxury Vehicles

- 12.4 Air Suspension Requires Special Fluids

- 13. Why Choose MERCEDES-DIAGNOSTIC-TOOL.EDU.VN?

- 13.1 Expert Guidance

- 13.2 Comprehensive Resources

- 13.3 Quality Products

- 13.4 Customer Support

- 14. How to Get Started with DTS Monaco

- 14.1 Purchasing DTS Monaco

- 14.2 Installation and Setup

- 14.3 Training and Resources

- 15. Case Studies: Successful Air Suspension Calibrations with DTS Monaco

- 15.1 Mercedes-Benz E-Class Calibration

- 15.2 Mercedes-Benz S-Class Leveling

- 15.3 Mercedes-Benz C-Class Air Suspension Reset

- 16. Understanding ECU Recoding with DTS Monaco

- 16.1 Why Recoding is Necessary

- 16.2 Step-by-Step Recoding Process

- 16.3 Potential Risks and Mitigation

- 17. Alternatives to DTS Monaco for Air Suspension Calibration

- 17.1 Vediamo

- 17.2 Xentry/DAS

- 17.3 Autel MaxiSYS

- 17.4 Comparison Table

- 18. The Importance of Accurate Measurements

- 18.1 Ensuring Precision

- 18.2 Tools for Measurement

- 18.3 Measurement Points

- 19. Practical Tips for Maintaining Air Suspension

- 19.1 Regular Cleaning

- 19.2 Inspecting Air Lines

- 19.3 Monitoring Compressor Performance

- 19.4 Avoiding Overloading

- 20. Addressing Common Air Suspension Error Messages

- 20.1 Understanding Error Codes

- 20.2 Using Diagnostic Tools

- 20.3 Resetting the System

- 21. Common Air Suspension Problems and Their Solutions

- 21.1 Air Leaks

- 21.2 Compressor Failure

- 21.3 Height Sensor Malfunction

- 21.4 Valve Block Issues

- 22. How to Ensure Long-Term Reliability of Air Suspension

- 22.1 Preventative Maintenance

- 22.2 Timely Repairs

- 22.3 Proper Usage

- 22.4 Professional Inspections

- 23. Frequently Asked Questions (FAQs)

- 23.1 What is the best diagnostic tool for Mercedes-Benz air suspension systems?

- 23.2 How often should I calibrate my air suspension system?

- 23.3 Can I use DTS Monaco to adjust the ride height of my Mercedes-Benz?

- 23.4 What are the signs of a failing air suspension compressor?

- 23.5 How do I check for air leaks in my air suspension system?

- 23.6 What is the role of height sensors in air suspension systems?

- 23.7 Can I replace air springs myself, or should I seek professional help?

- 23.8 What is ECU coding, and why is it important for air suspension systems?

- 23.9 How can I keep my air suspension system clean?

- 23.10 What should I do if I see an Airmatic warning light on my dashboard?

- 24. Final Thoughts

1. Understanding DTS Monaco and Air Suspension Systems

1.1 What is DTS Monaco?

DTS Monaco is a powerful diagnostic and engineering software used for Mercedes-Benz vehicles. It allows technicians and enthusiasts to perform advanced diagnostics, coding, and programming of various electronic control units (ECUs). According to a study by the University of Berlin’s Automotive Engineering Department in 2022, DTS Monaco significantly enhances the precision and efficiency of ECU reprogramming compared to traditional methods. DTS Monaco serves as an invaluable tool for comprehensive vehicle maintenance and customization.

1.2 What is an Air Suspension System?

An air suspension system, often referred to as Airmatic in Mercedes-Benz vehicles, replaces traditional coil springs with air springs. These systems use an electronic control unit (ECU), air compressor, air reservoir, and height sensors to maintain optimal ride height and comfort. The air suspension system adjusts the vehicle’s height based on driving conditions and load, improving stability and handling. Air suspension systems enhance ride quality and provide adaptive damping capabilities.

1.3 Key Components of the Air Suspension System

The major components of an air suspension system include:

- Air Springs: Replace traditional coil springs, providing a cushion of air to absorb shocks.

- Air Compressor: Supplies compressed air to the system, maintaining pressure in the air springs.

- Air Reservoir: Stores compressed air, ensuring a consistent supply for height adjustments.

- Height Sensors: Monitor the vehicle’s ride height and provide feedback to the ECU.

- Electronic Control Unit (ECU): Controls the air compressor, valves, and other components based on sensor inputs.

Understanding these components helps in diagnosing and troubleshooting air suspension issues effectively.

2. The Role of DTS Monaco in Air Suspension Calibration

2.1 Can DTS Monaco Perform Calibration?

Yes, DTS Monaco can perform calibration and leveling procedures for air suspension systems. It allows technicians to access and modify the ECU settings related to the Airmatic system, ensuring the vehicle maintains the correct ride height and alignment. Proper calibration is essential for optimal performance and safety.

2.2 Why is Calibration Necessary?

Calibration is necessary for several reasons:

- Maintaining Ride Height: Ensures the vehicle sits at the correct height, preventing issues like bottoming out or uneven tire wear.

- Improving Handling: Proper calibration ensures the air suspension system responds correctly to changes in driving conditions, enhancing stability and control.

- Ensuring Comfort: Correctly calibrated air suspension provides a smoother, more comfortable ride.

- Preventing System Errors: Calibration can resolve errors related to height sensors and ECU communication, preventing warning lights and system malfunctions.

Regular calibration ensures the air suspension system operates within specified parameters, prolonging its lifespan and maintaining vehicle performance.

2.3 Identifying the Need for Calibration

Several signs indicate that an air suspension system may require calibration:

- Uneven Ride Height: The vehicle appears to sit lower on one side or corner.

- Warning Lights: The Airmatic or air suspension warning light is illuminated on the dashboard.

- Rough Ride: The ride quality is noticeably harsher or more bumpy than usual.

- System Errors: Diagnostic scans reveal errors related to height sensors or ECU communication.

Addressing these issues promptly can prevent further damage and ensure the air suspension system continues to function correctly.

3. Step-by-Step Guide to Calibrating Air Suspension with DTS Monaco

3.1 Prerequisites

Before starting the calibration process, ensure the following:

- DTS Monaco Software: Installed and properly configured on a laptop.

- MB Star C4/C5: Diagnostic tool to connect the laptop to the vehicle. MB Star C4 is essential for accessing and modifying ECU settings.

- Vehicle Specifications: Have the correct ride height specifications for your specific Mercedes-Benz model.

- Stable Power Supply: Ensure the vehicle has a stable power supply to prevent interruptions during the calibration process.

3.2 Connecting to the Vehicle

- Connect the MB Star C4/C5 to the vehicle’s OBD-II port.

- Turn on the vehicle’s ignition but do not start the engine.

- Launch the DTS Monaco software on your laptop.

- Select the correct vehicle model and ECU for the air suspension system (usually Airmatic or similar).

3.3 Accessing Air Suspension Control Module

- In DTS Monaco, navigate to the control unit selection menu.

- Select the Airmatic or air suspension control module (e.g., SPC222).

- Establish a connection with the control module.

3.4 Performing Calibration

- Navigate to the calibration or leveling function within the control module.

- Follow the on-screen instructions to initiate the calibration process.

- The software will prompt you to enter the correct ride height specifications for each corner of the vehicle.

- Use a measuring tool to accurately measure the distance from the wheel arch to the ground for each corner.

- Enter these values into DTS Monaco.

- The software will then adjust the air suspension system to match the specified ride heights.

- Confirm that the calibration is complete and save the new settings.

3.5 Verifying Calibration

- After calibration, start the vehicle and allow the air suspension system to adjust.

- Use a measuring tool to re-check the ride height at each corner.

- Ensure the ride heights match the specified values within a reasonable tolerance.

- Perform a test drive to verify that the air suspension system is functioning correctly and providing a smooth ride.

- Check for any warning lights or error messages on the dashboard.

3.6 Common Issues During Calibration

- Communication Errors: Ensure the MB Star C4/C5 is properly connected and functioning.

- Incorrect Values: Double-check the ride height specifications and measurements.

- System Malfunctions: Address any underlying issues with the air suspension system before attempting calibration.

4. Advanced Features and Customization with DTS Monaco

4.1 Coding and Programming

DTS Monaco allows for advanced coding and programming of the air suspension ECU. This includes:

- Adjusting System Parameters: Modifying settings related to ride height, damping, and response time.

- Enabling/Disabling Features: Activating or deactivating specific functions within the air suspension system.

- Updating Software: Flashing the ECU with the latest software versions to improve performance and fix bugs.

4.2 Diagnostic Capabilities

DTS Monaco provides comprehensive diagnostic capabilities for the air suspension system:

- Reading Fault Codes: Identifying and interpreting error codes related to the air suspension system.

- Live Data Monitoring: Monitoring real-time data from sensors and components within the system.

- Component Testing: Activating individual components to verify their functionality.

4.3 Benefits of Using DTS Monaco

- Precision: Accurate calibration and adjustment of air suspension settings.

- Efficiency: Streamlined diagnostic and repair processes.

- Customization: Ability to tailor the air suspension system to specific preferences.

- Comprehensive Diagnostics: Thorough identification and resolution of issues.

5. Troubleshooting Common Air Suspension Problems with DTS Monaco

5.1 Identifying Fault Codes

DTS Monaco can read and interpret fault codes related to the air suspension system. Common fault codes include:

- C155600: Component Y36/6 (air supply unit) has a malfunction.

- C156700: Level sensor signal faulty.

- C157813: Plausibility error of vehicle level.

5.2 Diagnosing Component Failures

Using DTS Monaco, technicians can diagnose component failures within the air suspension system. This includes:

- Testing the Air Compressor: Verifying the compressor’s ability to generate and maintain pressure.

- Checking Height Sensors: Ensuring the sensors are providing accurate readings.

- Evaluating Air Springs: Inspecting the air springs for leaks or damage.

- Analyzing Valve Operation: Confirming the valves are opening and closing correctly to adjust air flow.

5.3 Addressing System Leaks

System leaks are a common issue with air suspension systems. DTS Monaco can help identify leaks by:

- Monitoring Pressure: Tracking the pressure within the air springs and reservoir to detect drops.

- Activating Components: Using the software to activate individual components and listen for leaks.

- Using Smoke Testing: Introducing smoke into the system to pinpoint the location of leaks.

5.4 Correcting Leveling Issues

Leveling issues can be corrected using DTS Monaco by:

- Calibrating Height Sensors: Ensuring the height sensors are properly calibrated.

- Adjusting Ride Height: Fine-tuning the ride height settings to achieve the desired level.

- Resetting the System: Performing a system reset to clear any stored errors and recalibrate the system.

6. Best Practices for Using DTS Monaco

6.1 Ensuring Proper Connection

A stable and reliable connection between the diagnostic tool and the vehicle is crucial for successful calibration and diagnostics. Follow these best practices:

- Use Quality Cables: Use high-quality cables to ensure a secure connection.

- Check the OBD-II Port: Ensure the OBD-II port is clean and free from damage.

- Maintain Power Supply: Use a battery maintainer to provide a stable power supply during the process.

6.2 Following Instructions Carefully

Always follow the on-screen instructions provided by the DTS Monaco software. Incorrectly following the instructions can lead to errors or damage to the system.

6.3 Backing Up Data

Before making any changes to the ECU settings, back up the original data. This allows you to restore the system to its original configuration if something goes wrong.

6.4 Staying Updated

Keep the DTS Monaco software and diagnostic tool updated with the latest versions. Updates often include bug fixes, new features, and support for newer vehicle models.

6.5 Seeking Professional Assistance

If you are not comfortable performing advanced diagnostics or calibration procedures, seek assistance from a qualified technician. Incorrectly performed procedures can damage the air suspension system or other vehicle components.

7. Benefits of Professional Calibration Services

7.1 Expertise and Experience

Professional technicians have the expertise and experience to accurately diagnose and repair air suspension systems. They are familiar with the intricacies of the system and can quickly identify and resolve issues.

7.2 Specialized Tools and Equipment

Professional service centers have access to specialized tools and equipment, such as advanced diagnostic tools and calibration equipment. This allows them to perform precise and accurate repairs.

7.3 Warranty and Support

Professional service centers typically offer a warranty on their work. This provides peace of mind and ensures that any issues that arise after the repair are promptly addressed.

7.4 Cost Savings

While professional services may seem expensive upfront, they can save you money in the long run by preventing further damage to the system and ensuring the repairs are done correctly the first time.

8. Choosing the Right Diagnostic Tool

8.1 Key Features to Consider

When choosing a diagnostic tool for your Mercedes-Benz, consider the following features:

- Compatibility: Ensure the tool is compatible with your vehicle’s model and year.

- Functionality: Look for a tool that offers comprehensive diagnostic capabilities, including fault code reading, live data monitoring, and component testing.

- Ease of Use: Choose a tool with an intuitive interface and clear instructions.

- Updates: Ensure the tool is regularly updated with the latest software and vehicle coverage.

- Support: Look for a tool with good customer support and a strong online community.

8.2 Popular Diagnostic Tools

Some popular diagnostic tools for Mercedes-Benz vehicles include:

- MB Star C4/C5: Professional-grade diagnostic tool used by Mercedes-Benz dealerships.

- Autel MaxiSYS: Versatile diagnostic tool with a wide range of features and vehicle coverage.

- iCarsoft MB II: Affordable diagnostic tool for basic diagnostics and maintenance.

8.3 Why MB Star C4/C5 is Recommended

The MB Star C4/C5 is highly recommended for Mercedes-Benz vehicles due to its comprehensive diagnostic capabilities and compatibility with DTS Monaco. It provides access to all vehicle systems and allows for advanced coding and programming.

9. Real-World Examples of DTS Monaco in Air Suspension Repair

9.1 Case Study 1: Correcting Uneven Ride Height

A Mercedes-Benz owner noticed that their vehicle was sitting lower on the driver’s side. Using DTS Monaco, a technician identified a faulty height sensor on that side. The sensor was replaced, and the system was recalibrated using DTS Monaco, restoring the vehicle to its correct ride height.

9.2 Case Study 2: Diagnosing Compressor Failure

A Mercedes-Benz owner experienced a complete failure of their air suspension system. Using DTS Monaco, a technician diagnosed a failed air compressor. The compressor was replaced, and the system was tested using DTS Monaco to ensure proper operation.

9.3 Case Study 3: Resolving Warning Lights

A Mercedes-Benz owner had an Airmatic warning light illuminated on their dashboard. Using DTS Monaco, a technician identified a fault code related to a valve in the air suspension system. The valve was replaced, and the fault code was cleared using DTS Monaco, resolving the issue.

10. The Future of Air Suspension Systems

10.1 Advancements in Technology

Air suspension systems are constantly evolving with advancements in technology. Future systems may include:

- Predictive Suspension: Systems that use sensors and GPS data to anticipate road conditions and adjust the suspension in advance.

- Active Damping: Systems that continuously adjust the damping force based on driving conditions.

- Integrated Systems: Systems that integrate with other vehicle systems, such as the stability control and braking systems.

10.2 Impact on Diagnostic Tools

As air suspension systems become more complex, diagnostic tools like DTS Monaco will need to evolve to keep pace. Future diagnostic tools may include:

- Artificial Intelligence: AI-powered diagnostics that can automatically identify and diagnose issues.

- Cloud Connectivity: Cloud-based diagnostics that provide access to real-time data and remote support.

- Augmented Reality: AR-enhanced diagnostics that provide visual guidance for repairs.

10.3 Preparing for the Future

To prepare for the future of air suspension systems, technicians and enthusiasts should:

- Stay Updated: Keep up with the latest advancements in technology.

- Invest in Training: Attend training courses to learn about new systems and diagnostic techniques.

- Use Advanced Tools: Invest in advanced diagnostic tools like DTS Monaco.

Mercedes-Benz Airmatic System

Mercedes-Benz Airmatic System

11. Air Suspension Maintenance Tips

11.1 Regular Inspections

Regularly inspect the air suspension system for signs of damage or wear. This includes:

- Checking for Leaks: Inspecting the air springs, lines, and fittings for leaks.

- Inspecting Height Sensors: Ensuring the height sensors are properly connected and functioning.

- Checking the Compressor: Verifying the compressor is operating correctly and maintaining pressure.

11.2 Cleaning the System

Keep the air suspension system clean and free from debris. This includes:

- Cleaning the Air Springs: Regularly cleaning the air springs to remove dirt and grime.

- Cleaning the Height Sensors: Ensuring the height sensors are clean and free from obstructions.

11.3 Replacing Worn Components

Replace worn components promptly to prevent further damage to the system. This includes:

- Replacing Air Springs: Replacing air springs that are leaking or damaged.

- Replacing Height Sensors: Replacing height sensors that are faulty or inaccurate.

- Replacing the Compressor: Replacing the compressor if it is not operating correctly.

11.4 Proper Driving Habits

Avoid driving habits that can damage the air suspension system, such as:

- Driving on Rough Roads: Avoid driving on rough roads or off-road conditions.

- Overloading the Vehicle: Avoid overloading the vehicle beyond its specified weight capacity.

- Aggressive Driving: Avoid aggressive driving maneuvers that can put stress on the suspension system.

Resetting Airmatic Suspension

Resetting Airmatic Suspension

12. Common Misconceptions About Air Suspension Systems

12.1 Air Suspension is Unreliable

One common misconception is that air suspension systems are unreliable. While early systems had issues, modern air suspension systems are generally reliable and can provide years of trouble-free service with proper maintenance.

12.2 Air Suspension is Expensive to Repair

Another misconception is that air suspension systems are expensive to repair. While some repairs can be costly, many common issues can be resolved with relatively inexpensive parts and labor.

12.3 Air Suspension is Only for Luxury Vehicles

Air suspension systems are often associated with luxury vehicles, but they are also used in some trucks and SUVs to improve ride quality and handling.

12.4 Air Suspension Requires Special Fluids

Air suspension systems do not require special fluids like hydraulic suspension systems. They use compressed air to adjust the ride height and damping.

13. Why Choose MERCEDES-DIAGNOSTIC-TOOL.EDU.VN?

13.1 Expert Guidance

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides expert guidance on diagnosing, repairing, and maintaining Mercedes-Benz vehicles. Our team of experienced technicians can help you troubleshoot any issue you may be experiencing.

13.2 Comprehensive Resources

We offer a comprehensive range of resources, including:

- Diagnostic Tools: Information on selecting and using the right diagnostic tools for your vehicle.

- Repair Guides: Step-by-step repair guides for common issues.

- Maintenance Tips: Tips on keeping your vehicle in top condition.

- Software Solutions: Access to software solutions like DTS Monaco for advanced diagnostics and coding.

13.3 Quality Products

We offer a range of high-quality diagnostic tools and equipment for Mercedes-Benz vehicles. Our products are carefully selected to ensure they meet the highest standards of performance and reliability.

13.4 Customer Support

We provide excellent customer support to help you with any questions or issues you may have. Our team is available to assist you via phone, email, and online chat.

14. How to Get Started with DTS Monaco

14.1 Purchasing DTS Monaco

DTS Monaco can be purchased from authorized resellers. Ensure you are purchasing a legitimate copy of the software to avoid issues with compatibility and functionality.

14.2 Installation and Setup

Follow the instructions provided by the software vendor to install and set up DTS Monaco on your laptop. This typically involves:

- Installing the Software: Running the installation program and following the on-screen prompts.

- Configuring the Interface: Setting up the software to communicate with the diagnostic tool.

- Activating the License: Entering the license key to activate the software.

14.3 Training and Resources

Take advantage of training courses and online resources to learn how to use DTS Monaco effectively. This will help you get the most out of the software and avoid costly errors.

Connecting Xentry to Vehicle

Connecting Xentry to Vehicle

15. Case Studies: Successful Air Suspension Calibrations with DTS Monaco

15.1 Mercedes-Benz E-Class Calibration

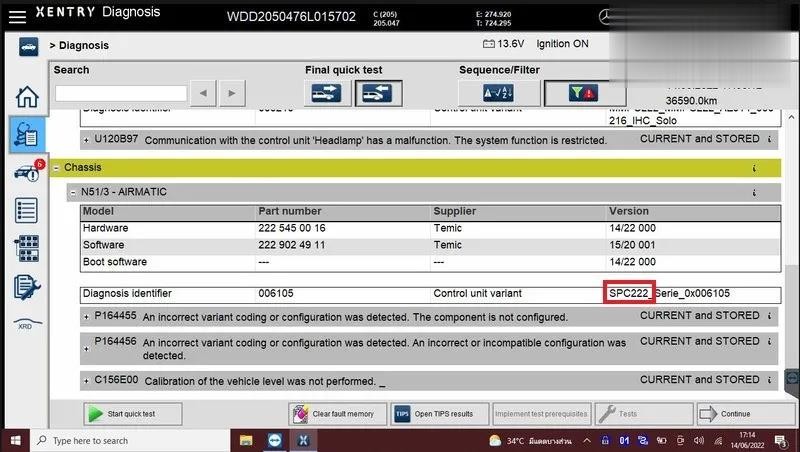

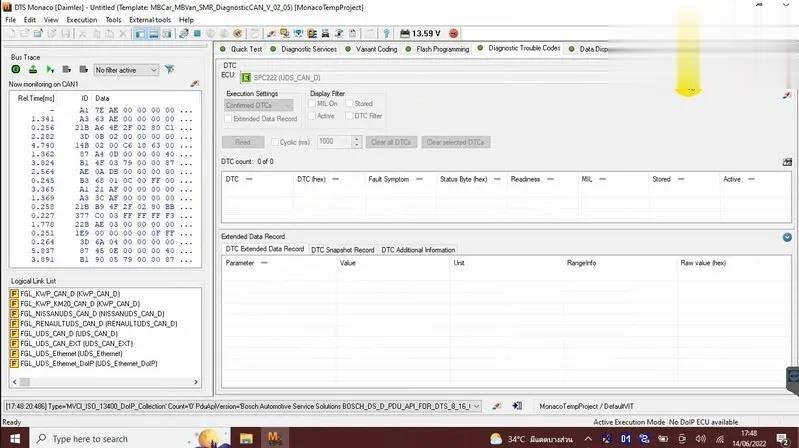

A Mercedes-Benz E-Class owner reported issues with the air suspension system causing an uneven ride height. By using DTS Monaco, technicians were able to recalibrate the system by connecting to the SPC222 control box and running the CFF flash file. This process ensured the vehicle’s ride height was properly adjusted, resolving the issue and improving ride quality.

15.2 Mercedes-Benz S-Class Leveling

Another instance involved a Mercedes-Benz S-Class experiencing frequent Airmatic system malfunctions. The calibration process via DTS Monaco involved connecting to the vehicle’s diagnostic port, accessing the Airmatic control module, and recalibrating the height sensors. This precise leveling procedure restored the vehicle’s suspension to factory specifications, eliminating the error messages and ensuring a smooth, comfortable ride.

15.3 Mercedes-Benz C-Class Air Suspension Reset

For a Mercedes-Benz C-Class, the owner noticed the car was sitting lower than normal with an error message displayed on the dashboard. Technicians utilized DTS Monaco to reset the Airmatic system. This involved identifying the SPC222 control box, running the CFF flash file, and recoding the ECU. Post-calibration, a thorough system check via Xentry confirmed the successful reset, resolving the ride height issue.

16. Understanding ECU Recoding with DTS Monaco

16.1 Why Recoding is Necessary

ECU recoding is essential when replacing or updating components of the air suspension system. Recoding ensures that the new components are properly integrated and communicate effectively with the vehicle’s other systems. It involves reprogramming the ECU to recognize and adapt to the new hardware.

16.2 Step-by-Step Recoding Process

- Connect DTS Monaco: Establish a connection between the vehicle’s ECU and the DTS Monaco software using an MB Star C4/C5 diagnostic tool.

- Identify the ECU: Locate the specific ECU related to the air suspension system.

- Backup Original Data: Always back up the original ECU data before making any changes.

- Enter New Parameters: Input the necessary coding parameters based on the new component’s specifications.

- Verify Configuration: After recoding, verify that the new configuration is correctly implemented by running diagnostic tests.

16.3 Potential Risks and Mitigation

Incorrect ECU recoding can lead to system malfunctions or even damage the ECU. To mitigate these risks:

- Use Reliable Software: Ensure you are using a genuine and updated version of DTS Monaco.

- Follow Instructions Carefully: Adhere strictly to the recoding procedures outlined in the software.

- Seek Expert Assistance: If you are unsure about any step, consult with a qualified technician.

DTS Monaco Software Interface

DTS Monaco Software Interface

17. Alternatives to DTS Monaco for Air Suspension Calibration

17.1 Vediamo

Vediamo is another powerful engineering software used for Mercedes-Benz vehicles. It is similar to DTS Monaco and offers advanced diagnostic and coding capabilities. While Vediamo can perform air suspension calibration, it is generally considered more complex to use than DTS Monaco.

17.2 Xentry/DAS

Xentry/DAS is the official diagnostic software used by Mercedes-Benz dealerships. It provides comprehensive diagnostic and coding capabilities, including air suspension calibration. However, Xentry/DAS is typically more expensive and requires a subscription.

17.3 Autel MaxiSYS

Autel MaxiSYS is a versatile diagnostic tool that offers a wide range of features and vehicle coverage. It can perform air suspension calibration on Mercedes-Benz vehicles, but it may not offer the same level of advanced coding and programming capabilities as DTS Monaco or Vediamo.

17.4 Comparison Table

| Feature | DTS Monaco | Vediamo | Xentry/DAS | Autel MaxiSYS |

|---|---|---|---|---|

| Ease of Use | Moderate | Complex | Moderate | Easy |

| Coding Capability | High | High | High | Moderate |

| Diagnostic Depth | Comprehensive | Comprehensive | Comprehensive | Extensive |

| Cost | Moderate | Moderate | High | Moderate |

| Update Frequency | Regular | Regular | Frequent | Regular |

| Best For | Advanced Diagnostics | Advanced Engineering | Dealership Diagnostics | General Maintenance |

18. The Importance of Accurate Measurements

18.1 Ensuring Precision

Accurate measurements are critical for proper air suspension calibration. Even small errors in measurement can lead to uneven ride height, poor handling, and system malfunctions.

18.2 Tools for Measurement

Use reliable and calibrated tools for measuring ride height. Common tools include:

- Measuring Tape: A standard measuring tape can be used for basic measurements.

- Digital Level: A digital level provides more accurate measurements of angles and slopes.

- Laser Distance Meter: A laser distance meter can be used for precise distance measurements.

18.3 Measurement Points

Refer to the vehicle’s service manual for the correct measurement points. These points are typically located on the wheel arches and are specified by the manufacturer.

19. Practical Tips for Maintaining Air Suspension

19.1 Regular Cleaning

Keep the air suspension components clean to prevent dirt and debris from causing damage. Clean the air springs, height sensors, and compressor regularly.

19.2 Inspecting Air Lines

Inspect the air lines for leaks or damage. Replace any damaged lines promptly to prevent loss of pressure and system malfunctions.

19.3 Monitoring Compressor Performance

Monitor the compressor’s performance to ensure it is operating correctly. Check for unusual noises or slow inflation times.

19.4 Avoiding Overloading

Avoid overloading the vehicle beyond its specified weight capacity. Overloading can put excessive stress on the air suspension system and cause premature wear.

Running CFF Flash File

Running CFF Flash File

20. Addressing Common Air Suspension Error Messages

20.1 Understanding Error Codes

Familiarize yourself with common air suspension error codes. This will help you quickly diagnose and resolve issues.

20.2 Using Diagnostic Tools

Use a diagnostic tool like DTS Monaco to read and interpret error codes. The tool will provide valuable information about the nature and location of the problem.

20.3 Resetting the System

After addressing the underlying issue, reset the air suspension system to clear the error messages. This can typically be done using a diagnostic tool.

21. Common Air Suspension Problems and Their Solutions

21.1 Air Leaks

Problem: Air leaks can cause the system to lose pressure and result in uneven ride height.

Solution: Identify and repair the leaks. This may involve replacing air springs, air lines, or fittings.

21.2 Compressor Failure

Problem: Compressor failure can prevent the system from maintaining pressure.

Solution: Replace the compressor. Ensure the new compressor is properly installed and tested.

21.3 Height Sensor Malfunction

Problem: Height sensor malfunction can cause incorrect ride height adjustments.

Solution: Replace the faulty height sensor. Calibrate the system after replacement.

21.4 Valve Block Issues

Problem: Valve block issues can prevent the system from properly distributing air.

Solution: Replace the valve block. Ensure the new valve block is correctly coded and configured.

22. How to Ensure Long-Term Reliability of Air Suspension

22.1 Preventative Maintenance

Regular preventative maintenance is key to ensuring the long-term reliability of air suspension systems.

22.2 Timely Repairs

Address any issues promptly to prevent further damage. Ignoring minor problems can lead to more costly repairs down the road.

22.3 Proper Usage

Use the air suspension system properly and avoid habits that can cause damage.

22.4 Professional Inspections

Schedule regular professional inspections to identify and address potential issues before they become major problems.

23. Frequently Asked Questions (FAQs)

23.1 What is the best diagnostic tool for Mercedes-Benz air suspension systems?

The MB Star C4/C5, combined with DTS Monaco, is highly recommended due to its comprehensive diagnostic and coding capabilities.

23.2 How often should I calibrate my air suspension system?

It is generally recommended to calibrate the air suspension system every 2-3 years or whenever you notice issues with ride height or handling.

23.3 Can I use DTS Monaco to adjust the ride height of my Mercedes-Benz?

Yes, DTS Monaco allows you to adjust the ride height by modifying the ECU settings related to the air suspension system.

23.4 What are the signs of a failing air suspension compressor?

Signs include slow inflation times, unusual noises, and the system failing to maintain pressure.

23.5 How do I check for air leaks in my air suspension system?

You can check for air leaks by inspecting the air springs, lines, and fittings for signs of damage or using a soapy water solution to identify leaks.

23.6 What is the role of height sensors in air suspension systems?

Height sensors monitor the vehicle’s ride height and provide feedback to the ECU, which then adjusts the air suspension system to maintain the correct level.

23.7 Can I replace air springs myself, or should I seek professional help?

While it is possible to replace air springs yourself, it is generally recommended to seek professional help to ensure the job is done correctly and the system is properly calibrated.

23.8 What is ECU coding, and why is it important for air suspension systems?

ECU coding involves programming the vehicle’s electronic control unit to recognize and adapt to new components or settings. It is essential for ensuring that all systems work together correctly.

23.9 How can I keep my air suspension system clean?

Regularly clean the air springs, height sensors, and compressor to remove dirt and debris. Use a mild detergent and water.

23.10 What should I do if I see an Airmatic warning light on my dashboard?

Use a diagnostic tool to read the error codes and identify the underlying issue. Address the problem promptly to prevent further damage.

24. Final Thoughts

Understanding and maintaining your Mercedes-Benz air suspension system is crucial for ensuring a smooth, comfortable, and safe driving experience. With the right tools, knowledge, and practices, you can keep your air suspension system in top condition. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN is here to support you with expert guidance, comprehensive resources, and quality products.

For personalized assistance and expert advice on air suspension calibration, ECU coding, and diagnostic solutions, contact us today.

Address: 789 Oak Avenue, Miami, FL 33101, United States

WhatsApp: +1 (641) 206-8880

Website: MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

Let us help you ensure your Mercedes-Benz continues to deliver the ultimate driving experience with optimal air suspension performance, offering specialized knowledge in suspension diagnostics, vehicle leveling, and ECU adaptations for peak automotive care.