How does DTS Monaco interact with the vehicle’s power management system? DTS Monaco is a powerful diagnostic tool used to interact with a vehicle’s ECUs, and its functionality extends to the power management system, allowing for in-depth diagnostics, testing, and modifications; explore capabilities, benefits and usage tips provided by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN. This enables technicians to optimize vehicle performance and address complex electrical issues using advanced diagnostic tools, car coding, and ECU flashing.

Contents

- 1. Understanding Vehicle Power Management Systems

- 1.1. Key Components of a Vehicle Power Management System

- 1.2. Functions of a Vehicle Power Management System

- 1.3. The Importance of Maintaining a Healthy Power Management System

- 2. How DTS Monaco Connects to the Power Management System

- 2.1. Hardware Requirements for Connecting to the Power Management System

- 2.2. Software Setup and Configuration for Power Management Diagnostics

- 2.3. Establishing a Secure Connection with Power Management ECUs

- 3. Reading Power Management System Data with DTS Monaco

- 3.1. Accessing Diagnostic Trouble Codes (DTCs) Related to Power Management

- 3.2. Monitoring Live Data Parameters in the Power Management System

- 3.3. Identifying Power Management Module Information

- 4. Modifying Power Management System Settings with DTS Monaco

- 4.1. Clearing Diagnostic Trouble Codes (DTCs) in Power Management

- 4.2. Adjusting Parameters within the Power Management System

- 4.3. Performing Variant Coding for Power Management Features

- 4.4. ECU Flashing and Software Updates for Power Management Modules

- 5. Real-World Applications of DTS Monaco in Power Management

- 5.1. Diagnosing and Repairing Battery Drain Issues

- 5.2. Resolving Alternator and Voltage Regulator Problems

- 5.3. Optimizing Start-Stop System Performance

- 5.4. Customizing Power Management Features for Specific Needs

- 6. Tips and Tricks for Effective Power Management Diagnostics with DTS Monaco

- 6.1. Start with a Full System Scan

- 6.2. Monitor Live Data Parameters During Testing

- 6.3. Use a Stable Power Supply During Diagnostics

- 6.4. Refer to Vehicle-Specific Service Manuals

- 6.5. Document Your Findings

- 6.6. Test Components Individually

- 6.7. Use a Load Tester to Evaluate Battery Performance

- 6.8. Check for Wiring Issues

- 7. Common Mistakes to Avoid When Working with Power Management Systems

- 7.1. Neglecting Battery Condition

- 7.2. Failing to Use a Stable Power Supply

- 7.3. Ignoring Warning Messages

- 7.4. Modifying Parameters Without Documentation

- 7.5. Overlooking Wiring Issues

- 7.6. Using Incorrect Project Files

- 7.7. Interrupting the Flashing Process

- 7.8. Neglecting Software Updates

- 8. Integrating DTS Monaco with Other Tools for Comprehensive Diagnostics

- 8.1. Combining DTS Monaco with a Multimeter for Electrical Testing

- 8.2. Using DTS Monaco with an Oscilloscope for Signal Analysis

- 8.3. Integrating DTS Monaco with Vehicle Information Systems

- 8.4. Pairing DTS Monaco with Battery Testers

- 9. Power Management System Calibration and Adjustments with DTS Monaco

- 9.1. Sensor Calibration Procedures

- 9.2. Adjusting Charging Parameters for Optimal Battery Health

- 9.3. Configuring Load Management Settings for Efficiency

- 10. Advanced Troubleshooting Techniques for Complex Power Management Issues

- 10.1. Using Oscilloscopes to Analyze Signal Patterns

- 10.2. Performing Component-Level Diagnostics

- 10.3. Consulting with Experienced Technicians

1. Understanding Vehicle Power Management Systems

What is a vehicle power management system, and why is it crucial? A vehicle’s power management system is a complex network that controls the generation, distribution, and storage of electrical energy within the vehicle. It ensures that all electrical components receive the correct voltage and current, optimizing performance and preventing damage. The power management system’s efficiency directly impacts fuel economy, reliability, and the lifespan of electrical components.

1.1. Key Components of a Vehicle Power Management System

What are the main parts of a power management system? A modern vehicle power management system comprises several key components working in harmony:

- Battery: Stores electrical energy for starting the engine and powering accessories.

- Alternator: Generates electrical energy while the engine is running, replenishing the battery and powering the vehicle’s electrical loads.

- Voltage Regulator: Maintains a stable voltage output from the alternator to protect sensitive electronic components.

- Starter Motor: Cranks the engine to initiate combustion.

- Power Distribution Modules (PDMs): Distribute electrical power to various circuits and components throughout the vehicle.

- Electronic Control Units (ECUs): Manage and monitor the power management system, adjusting parameters to optimize performance and efficiency.

- Wiring Harness: Connects all electrical components, providing a pathway for current flow.

Understanding these components and their interactions is essential for diagnosing and repairing electrical issues effectively.

1.2. Functions of a Vehicle Power Management System

What tasks does the power management system handle? A vehicle’s power management system performs various critical functions, including:

- Battery Management: Monitoring the battery’s state of charge, temperature, and health, and adjusting charging parameters to optimize battery life.

- Load Management: Prioritizing and distributing electrical power to different components based on their needs, preventing overload and ensuring critical systems receive adequate power.

- Energy Conservation: Implementing strategies to reduce energy consumption, such as shutting off unnecessary accessories and optimizing alternator output.

- Fault Detection: Monitoring the power management system for faults and triggering warning lights to alert the driver of potential issues.

- Start-Stop System: Managing the engine start-stop function to improve fuel economy by automatically shutting off the engine when the vehicle is stationary and restarting it when needed.

- Regenerative Braking: Capturing energy during braking and using it to recharge the battery, improving overall efficiency (in hybrid and electric vehicles).

These functions collectively ensure the reliable and efficient operation of the vehicle’s electrical system.

1.3. The Importance of Maintaining a Healthy Power Management System

Why is it important to maintain power management? Maintaining a healthy power management system is crucial for several reasons:

- Reliability: A well-maintained system ensures that all electrical components receive the correct voltage and current, reducing the risk of failures and breakdowns.

- Performance: Optimizing the power management system can improve vehicle performance, fuel economy, and overall efficiency.

- Longevity: Proper maintenance can extend the lifespan of electrical components, such as the battery and alternator, saving you money in the long run.

- Safety: A malfunctioning power management system can compromise safety-critical systems, such as brakes and airbags, putting the driver and passengers at risk.

- Diagnostics: Addressing issues promptly can prevent minor problems from escalating into major repairs, reducing downtime and repair costs.

Regular inspections and maintenance can help identify and address potential issues before they cause significant problems.

2. How DTS Monaco Connects to the Power Management System

How does DTS Monaco access the vehicle’s power system? DTS Monaco connects to the vehicle’s power management system through the OBD-II port, utilizing a J2534 pass-thru device. This connection allows technicians to communicate with the ECUs responsible for managing the power system, enabling advanced diagnostics, coding, and programming.

2.1. Hardware Requirements for Connecting to the Power Management System

What equipment is needed for power system diagnostics? To connect DTS Monaco to the power management system, you’ll need the following hardware:

- Laptop: A computer with DTS Monaco installed and activated.

- J2534 Pass-Thru Device: An interface that allows DTS Monaco to communicate with the vehicle’s ECUs. Recommended devices include Tactrix Openport 2.0, Drew Technologies MongoosePro, and Scanmatik SM2 Pro.

- OBD-II Cable: Connects the J2534 pass-thru device to the vehicle’s OBD-II port.

- Stable Power Supply: A power stabilizer to maintain a consistent voltage level during diagnostics and programming.

Ensuring that you have the correct hardware and software versions is crucial for a successful connection.

2.2. Software Setup and Configuration for Power Management Diagnostics

How do you setup DTS Monaco for power system diagnostics? Proper software setup and configuration are essential for performing power management diagnostics with DTS Monaco:

- Install DTS Monaco: Install the latest version of DTS Monaco on your laptop, ensuring it is properly activated.

- Install J2534 Drivers: Install the correct drivers for your J2534 pass-thru device.

- Select Project File: Choose the appropriate project file for your vehicle model, which contains specific data and configurations for the power management system.

- Configure Communication Settings: Configure the communication settings in DTS Monaco to match your J2534 device.

- Test Connection: Test the connection by attempting to communicate with one of the power management ECUs to verify that everything is working correctly.

Proper software setup ensures that DTS Monaco can communicate effectively with the vehicle’s power management system.

2.3. Establishing a Secure Connection with Power Management ECUs

How to establish a secure connection with power management ECUs? Establishing a secure connection with power management ECUs involves the following steps:

- Connect Hardware: Connect your J2534 pass-thru device to the vehicle’s OBD-II port and your computer.

- Turn on Ignition: Turn the vehicle’s ignition to the “ON” position without starting the engine.

- Launch DTS Monaco: Open the DTS Monaco software on your computer.

- Select Project: Choose the appropriate project file for your Daimler vehicle model.

- Select ECU: Identify and select the specific power management ECU from the list (e.g., Battery Management System, Voltage Regulator).

- Establish Connection: Initiate communication with the ECU by clicking the “Connect” button.

- Verify Connection: Confirm that DTS Monaco is successfully communicating with the ECU by checking for ECU information or reading diagnostic trouble codes.

A secure and stable connection is crucial for accurate diagnostics and modifications.

3. Reading Power Management System Data with DTS Monaco

What kind of data can DTS Monaco read from power management system? DTS Monaco can read a variety of data from the power management system, including diagnostic trouble codes (DTCs), live data parameters, module identification information, and variant coding settings. This data provides valuable insights into the system’s operation and helps technicians diagnose problems effectively.

3.1. Accessing Diagnostic Trouble Codes (DTCs) Related to Power Management

How do you access DTCs related to power management? Accessing diagnostic trouble codes (DTCs) related to power management involves the following steps:

- Connect to the ECU: Establish a connection with the relevant power management ECU (e.g., Battery Management System) using DTS Monaco.

- Navigate to Diagnostic Functions: In DTS Monaco, find the diagnostic functions menu for the selected ECU.

- Read DTCs: Select the “Read DTCs” or “Read Fault Codes” option.

- Interpret DTCs: DTS Monaco will display any stored fault codes, along with their descriptions. Note these codes for further troubleshooting.

Understanding the meaning of these DTCs is essential for pinpointing the root cause of power management issues.

3.2. Monitoring Live Data Parameters in the Power Management System

What real-time data can be monitored using DTS Monaco? Monitoring live data parameters in the power management system allows technicians to observe real-time values and identify anomalies. Key parameters to monitor include:

- Battery Voltage: Indicates the current voltage level of the battery.

- Charging Current: Shows the current flowing into the battery during charging.

- Alternator Output Voltage: Displays the voltage being generated by the alternator.

- Alternator Load Percentage: Indicates the percentage of the alternator’s maximum output being used.

- Battery Temperature: Monitors the temperature of the battery, which can affect its performance and lifespan.

- ECU Temperature: Tracks the temperature of the ECU to prevent overheating.

To monitor these parameters:

- Connect to the ECU: Establish a connection with the relevant power management ECU.

- Select Live Data: In the diagnostic functions menu, choose the “Read Live Data” or “View Parameters” option.

- Choose Parameters: Select the parameters you want to monitor from the list.

- Monitor Data: DTS Monaco will display the real-time values of the selected parameters.

Observing these values can help identify issues such as a failing alternator, a weak battery, or excessive electrical loads.

3.3. Identifying Power Management Module Information

What module information can you identify using DTS Monaco? Identifying power management module information involves reading data such as:

- Part Number: The unique identifier for the module.

- Software Version: The version of the software running on the module.

- Hardware Version: The version of the hardware of the module.

- Manufacturing Date: The date when the module was manufactured.

- Coding Information: The specific coding and configuration settings of the module.

To access this information:

- Connect to the ECU: Establish a connection with the relevant power management ECU.

- Navigate to Identification Functions: In DTS Monaco, find the identification functions menu for the selected ECU.

- Read Module Information: Select the “Read Identification” or “Read Module Info” option.

- Record Data: DTS Monaco will display the module information, which you can record for future reference or troubleshooting.

This information is crucial for ensuring that the correct module is installed and that it is running the appropriate software version.

4. Modifying Power Management System Settings with DTS Monaco

What power system settings can be modified with DTS Monaco? DTS Monaco allows technicians to modify various power management system settings, including clearing DTCs, adjusting parameters, performing variant coding, and flashing ECUs. However, caution should be exercised when modifying these settings, as incorrect changes can lead to unintended consequences or damage to the system.

4.1. Clearing Diagnostic Trouble Codes (DTCs) in Power Management

How do you clear DTCs in power management using DTS Monaco? Clearing diagnostic trouble codes (DTCs) in power management involves the following steps:

- Connect to the ECU: Establish a connection with the relevant power management ECU.

- Navigate to Diagnostic Functions: In DTS Monaco, find the diagnostic functions menu.

- Clear DTCs: Select the “Clear DTCs” or “Erase Fault Codes” option.

- Verify Clearing: After clearing the codes, read DTCs again to ensure that they have been successfully erased.

Clearing DTCs should only be done after addressing the underlying issues that caused the codes to be stored.

4.2. Adjusting Parameters within the Power Management System

What parameters can be adjusted in power management? DTS Monaco allows technicians to adjust various parameters within the power management system, such as:

- Battery Charging Parameters: Adjusting the voltage and current used to charge the battery.

- Alternator Output Voltage: Modifying the voltage output of the alternator.

- Load Management Settings: Configuring how electrical loads are prioritized and distributed.

- Start-Stop System Settings: Adjusting the parameters of the engine start-stop function.

To adjust these parameters:

- Connect to the ECU: Establish a connection with the relevant power management ECU.

- Access Variant Coding: Navigate to the variant coding or adaptation menu.

- Select Parameter: Choose the parameter you want to modify.

- Enter New Value: Enter the new value for the parameter. Refer to the vehicle’s service manual or technical documentation for acceptable values.

- Apply Changes: Click the “Write” or “Apply” button to save the changes to the ECU.

- Verify Changes: Confirm that the changes have been successfully applied by reading the parameter value again or testing the system.

Modifying these parameters requires caution and a thorough understanding of the system to avoid unintended consequences.

4.3. Performing Variant Coding for Power Management Features

How do you perform variant coding for power management features? Performing variant coding for power management features involves customizing the system’s behavior to match specific vehicle configurations or customer preferences. This can include:

- Enabling or Disabling Features: Activating or deactivating certain power management features, such as the start-stop system or regenerative braking.

- Configuring System Behavior: Adjusting how the system responds to different conditions or inputs.

- Matching Components: Ensuring that the power management system is properly configured to work with other vehicle systems.

To perform variant coding:

- Connect to the ECU: Establish a connection with the relevant power management ECU.

- Access Variant Coding: Navigate to the variant coding or adaptation menu.

- Select Feature: Choose the feature you want to modify.

- Enter New Value: Enter the new value for the feature (e.g., “Enabled” or “Disabled”).

- Apply Changes: Click the “Write” or “Apply” button to save the changes to the ECU.

- Verify Changes: Confirm that the changes have been successfully applied by testing the feature or reading the parameter value again.

Variant coding requires a thorough understanding of the system and the potential impact of each setting.

4.4. ECU Flashing and Software Updates for Power Management Modules

How do you update power management software? ECU flashing and software updates for power management modules involve replacing the existing software on the ECU with a new version. This can be done to:

- Fix Software Bugs: Resolve issues caused by faulty software code.

- Improve Performance: Enhance the system’s responsiveness and efficiency.

- Add New Features: Introduce new functionalities or improvements to the power management system.

To perform ECU flashing:

- Connect to the ECU: Establish a connection with the relevant power management ECU.

- Access Flashing Functions: Navigate to the flashing functions menu.

- Select Firmware File: Choose the correct firmware file for your vehicle model and ECU.

- Initiate Flashing: Start the flashing process and wait for it to complete.

- Verify Flashing: Confirm that the flashing process was successful by checking the software version or testing the system.

ECU flashing is a complex process that requires caution and expertise. Interrupting the process or using the wrong firmware file can damage the ECU.

5. Real-World Applications of DTS Monaco in Power Management

What are the practical uses of DTS Monaco in power management? DTS Monaco offers numerous practical applications in power management, ranging from diagnosing and repairing electrical issues to optimizing system performance and customizing features. These applications enhance vehicle reliability, efficiency, and driver satisfaction.

5.1. Diagnosing and Repairing Battery Drain Issues

How can DTS Monaco help diagnose battery drain? DTS Monaco can help diagnose battery drain issues by:

- Monitoring Battery Voltage: Tracking the battery voltage over time to see if it is dropping excessively when the vehicle is turned off.

- Identifying Parasitic Loads: Identifying components that are drawing excessive current when the vehicle is off.

- Testing Charging System: Verifying that the alternator is properly charging the battery and that the voltage regulator is functioning correctly.

- Reading DTCs: Identifying fault codes related to the battery or charging system.

By analyzing this data, technicians can pinpoint the source of the battery drain and take corrective action.

5.2. Resolving Alternator and Voltage Regulator Problems

How can DTS Monaco help resolve alternator and voltage regulator issues? DTS Monaco can assist in resolving alternator and voltage regulator problems by:

- Monitoring Alternator Output Voltage: Verifying that the alternator is producing the correct voltage.

- Checking Alternator Load Percentage: Ensuring that the alternator is not being overloaded.

- Testing Voltage Regulator Functionality: Monitoring the voltage regulator’s output to see if it is maintaining a stable voltage.

- Reading DTCs: Identifying fault codes related to the alternator or voltage regulator.

By monitoring these parameters, technicians can determine if the alternator or voltage regulator is faulty and needs to be replaced.

5.3. Optimizing Start-Stop System Performance

How do you optimize start-stop system performance using DTS Monaco? DTS Monaco can be used to optimize start-stop system performance by:

- Adjusting System Parameters: Modifying the parameters that control when the engine is stopped and restarted.

- Monitoring Battery Condition: Ensuring that the battery is in good condition and can handle the demands of the start-stop system.

- Verifying System Functionality: Testing the start-stop system to ensure that it is working correctly.

- Reading DTCs: Identifying fault codes related to the start-stop system.

By fine-tuning these settings, technicians can improve the system’s responsiveness and efficiency.

5.4. Customizing Power Management Features for Specific Needs

How can DTS Monaco customize power management? DTS Monaco enables technicians to customize power management features for specific needs, such as:

- Adjusting Load Management: Configuring how electrical loads are prioritized and distributed to optimize performance or conserve energy.

- Enabling or Disabling Features: Activating or deactivating certain power management features, such as the start-stop system or regenerative braking, to suit customer preferences.

- Matching Components: Ensuring that the power management system is properly configured to work with aftermarket components or accessories.

These customizations can enhance the vehicle’s functionality and meet the specific needs of the driver.

6. Tips and Tricks for Effective Power Management Diagnostics with DTS Monaco

What are the best practices for diagnosing power management with DTS Monaco? To effectively diagnose power management issues with DTS Monaco, consider these tips and tricks:

6.1. Start with a Full System Scan

Always begin by performing a full system scan to identify any DTCs related to the power management system. This provides a comprehensive overview of the system’s health and can help pinpoint potential issues.

6.2. Monitor Live Data Parameters During Testing

Monitor live data parameters while testing the power management system. This allows you to observe real-time values and identify anomalies that may not be apparent from DTCs alone.

6.3. Use a Stable Power Supply During Diagnostics

Always use a stable power supply during diagnostics to prevent voltage fluctuations that can interfere with the testing process.

6.4. Refer to Vehicle-Specific Service Manuals

Refer to vehicle-specific service manuals and technical documentation for detailed information about the power management system and its components. This provides valuable insights into the system’s operation and helps you interpret diagnostic data correctly.

6.5. Document Your Findings

Keep a detailed record of your findings, including DTCs, live data parameters, and any modifications you make to the system. This documentation can be invaluable for troubleshooting issues or reverting to previous configurations.

6.6. Test Components Individually

Test individual components of the power management system, such as the battery, alternator, and voltage regulator, to verify their functionality. This helps isolate problems and identify faulty components.

6.7. Use a Load Tester to Evaluate Battery Performance

Use a load tester to evaluate battery performance under load. This provides a more accurate assessment of the battery’s health than simply measuring its voltage.

6.8. Check for Wiring Issues

Check for wiring issues, such as shorts, opens, and corrosion, that can affect the power management system’s operation. These issues can be difficult to detect but can cause a variety of problems.

7. Common Mistakes to Avoid When Working with Power Management Systems

What mistakes should be avoided when working with power management systems? Avoiding common mistakes when working with power management systems is essential for ensuring successful diagnostics, repairs, and modifications. Understanding these pitfalls and how to prevent them can save you time, money, and potential damage to vehicle systems.

7.1. Neglecting Battery Condition

Neglecting the battery condition is a common mistake that can lead to inaccurate diagnostic results. Always ensure that the battery is fully charged and in good condition before performing any tests or modifications.

7.2. Failing to Use a Stable Power Supply

Failing to use a stable power supply can cause voltage fluctuations that interfere with the testing process. Always use a power stabilizer to maintain a consistent voltage level during diagnostics and programming.

7.3. Ignoring Warning Messages

Ignoring warning messages from DTS Monaco can lead to unintended consequences. Always read and understand each warning message before proceeding with any modifications.

7.4. Modifying Parameters Without Documentation

Modifying parameters without proper documentation or understanding can damage the power management system. Always refer to the vehicle’s service manual or technical documentation before making any changes.

7.5. Overlooking Wiring Issues

Overlooking wiring issues, such as shorts, opens, and corrosion, can lead to misdiagnosis and ineffective repairs. Always inspect the wiring harness for any signs of damage or deterioration.

7.6. Using Incorrect Project Files

Using the wrong project file in DTS Monaco can cause communication errors or incorrect coding. Always verify that you are using the correct project file for your vehicle’s make, model, and year.

7.7. Interrupting the Flashing Process

Interrupting the ECU flashing process can cause serious damage to the power management module. Ensure that your laptop has a stable power supply and that you do not disconnect the J2534 pass-thru device during flashing.

7.8. Neglecting Software Updates

Neglecting to install the latest software updates for DTS Monaco and your J2534 pass-thru device can result in compatibility issues or missing features. Regularly check for updates to ensure you are using the latest versions.

8. Integrating DTS Monaco with Other Tools for Comprehensive Diagnostics

How does DTS Monaco work with other tools for comprehensive diagnostics? DTS Monaco can be integrated with other diagnostic tools to enhance its capabilities and provide a more comprehensive diagnostic solution. Combining DTS Monaco with other equipment allows technicians to tackle a wider range of automotive issues efficiently.

8.1. Combining DTS Monaco with a Multimeter for Electrical Testing

Combining DTS Monaco with a multimeter allows technicians to:

- Verify Electrical Signals: Use the multimeter to check voltage, current, and resistance in circuits related to the power management system.

- Diagnose Wiring Issues: Identify shorts, opens, and other wiring problems that may be affecting the system’s operation.

- Confirm Component Functionality: Test individual components, such as the battery, alternator, and voltage regulator, to ensure they are functioning correctly.

This combination provides a comprehensive approach to diagnosing and repairing electrical issues.

8.2. Using DTS Monaco with an Oscilloscope for Signal Analysis

Integrating DTS Monaco with an oscilloscope allows technicians to:

- Analyze Signal Patterns: Examine the waveforms of signals related to the power management system to identify anomalies or distortions.

- Diagnose Intermittent Issues: Capture intermittent signal problems that may not be detectable with a multimeter.

- Verify Sensor Performance: Assess the performance of sensors by analyzing their output signals.

This combination provides advanced diagnostic capabilities for complex electrical issues.

8.3. Integrating DTS Monaco with Vehicle Information Systems

Integrating DTS Monaco with vehicle information systems, such as ALLDATA or Mitchell OnDemand, provides access to:

- Wiring Diagrams: Detailed wiring diagrams that show the connections between components in the power management system.

- Technical Service Bulletins (TSBs): Information about known issues and recommended solutions for specific vehicle models.

- Component Locations: Diagrams showing the location of components in the power management system.

- Diagnostic Procedures: Step-by-step procedures for diagnosing and repairing power management issues.

This integration provides technicians with the information they need to diagnose and repair vehicles efficiently.

8.4. Pairing DTS Monaco with Battery Testers

Pairing DTS Monaco with battery testers, such as those from Midtronics or Bosch, allows technicians to:

- Assess Battery Health: Perform comprehensive tests to evaluate the battery’s state of charge, capacity, and internal resistance.

- Diagnose Battery Issues: Identify problems such as sulfation, shorts, and open circuits.

- Monitor Battery Performance: Track the battery’s performance over time to detect changes in its health.

This combination provides a complete solution for diagnosing and maintaining vehicle batteries.

DTS Monaco Main Screen

9. Power Management System Calibration and Adjustments with DTS Monaco

How can the power management system be calibrated and adjusted with DTS Monaco? DTS Monaco provides advanced capabilities for calibrating and adjusting the power management system to optimize performance and efficiency. These adjustments can include calibrating sensors, adjusting charging parameters, and configuring load management settings.

9.1. Sensor Calibration Procedures

What sensor calibration procedures can be done with DTS Monaco? Sensor calibration is essential for ensuring that the power management system is receiving accurate data. DTS Monaco can be used to calibrate various sensors, such as:

- Battery Temperature Sensor: Calibrating the sensor to ensure that it is accurately measuring the battery’s temperature.

- Current Sensor: Calibrating the sensor to ensure that it is accurately measuring the current flowing into and out of the battery.

- Voltage Sensor: Calibrating the sensor to ensure that it is accurately measuring the battery’s voltage.

To perform sensor calibration:

- Connect to the ECU: Establish a connection with the relevant power management ECU.

- Access Calibration Functions: Navigate to the calibration functions menu.

- Select Sensor: Choose the sensor you want to calibrate.

- Follow Calibration Procedure: Follow the on-screen instructions to perform the calibration.

- Verify Calibration: Confirm that the calibration was successful by reading the sensor’s output and comparing it to a known standard.

Accurate sensor calibration is crucial for the proper operation of the power management system.

9.2. Adjusting Charging Parameters for Optimal Battery Health

How do you adjust charging parameters with DTS Monaco? Adjusting charging parameters can optimize battery health and extend its lifespan. DTS Monaco allows technicians to modify various charging parameters, such as:

- Charging Voltage: Adjusting the voltage used to charge the battery.

- Charging Current: Modifying the current used to charge the battery.

- Charging Time: Adjusting the amount of time the battery is charged.

- Charging Mode: Selecting the appropriate charging mode for the battery type.

To adjust these parameters:

- Connect to the ECU: Establish a connection with the relevant power management ECU.

- Access Charging Settings: Navigate to the charging settings menu.

- Select Parameter: Choose the parameter you want to modify.

- Enter New Value: Enter the new value for the parameter. Refer to the battery manufacturer’s specifications for acceptable values.

- Apply Changes: Click the “Write” or “Apply” button to save the changes to the ECU.

- Verify Changes: Confirm that the changes have been successfully applied by reading the parameter value again or monitoring the battery’s performance.

Proper charging parameters are essential for maintaining battery health and preventing damage.

9.3. Configuring Load Management Settings for Efficiency

How do you configure load management settings with DTS Monaco? Configuring load management settings can improve the efficiency of the power management system by optimizing how electrical loads are prioritized and distributed. DTS Monaco allows technicians to modify various load management settings, such as:

- Load Priority: Assigning priorities to different electrical loads, such as the engine control unit, the brakes, and the lights.

- Load Shedding: Configuring the system to automatically shed non-essential loads when the battery voltage is low.

- Load Balancing: Distributing the electrical load evenly across the system to prevent overload.

To configure these settings:

- Connect to the ECU: Establish a connection with the relevant power management ECU.

- Access Load Management Settings: Navigate to the load management settings menu.

- Select Setting: Choose the setting you want to modify.

- Enter New Value: Enter the new value for the setting.

- Apply Changes: Click the “Write” or “Apply” button to save the changes to the ECU.

- Verify Changes: Confirm that the changes have been successfully applied by monitoring the system’s performance.

Proper load management settings can improve the efficiency and reliability of the power management system.

10. Advanced Troubleshooting Techniques for Complex Power Management Issues

What are some advanced techniques for troubleshooting power management issues? Advanced troubleshooting techniques are essential for resolving complex power management issues that cannot be diagnosed using basic methods. These techniques include using oscilloscopes to analyze signal patterns, performing component-level diagnostics, and consulting with experienced technicians.

10.1. Using Oscilloscopes to Analyze Signal Patterns

How can oscilloscopes help with troubleshooting? Oscilloscopes can be used to analyze signal patterns in the power management system to identify anomalies or distortions that may be causing problems. This can be particularly useful for diagnosing intermittent issues or problems with sensors and actuators.

To use an oscilloscope:

- Connect to the Circuit: Connect the oscilloscope probes to the circuit you want to analyze.

- Set Time and Voltage Scales: Set the appropriate time and voltage scales on the oscilloscope.

- Analyze Signal Pattern: Observe the signal pattern on the oscilloscope and look for any anomalies or distortions.

- Compare to Known Standards: Compare the signal pattern to known standards or waveforms to identify any deviations.

Analyzing signal patterns with an oscilloscope can provide valuable insights into the operation of the power management system.

10.2. Performing Component-Level Diagnostics

How do you perform component-level diagnostics? Component-level diagnostics involves testing individual components of the power management system to verify their functionality. This can include testing:

- Battery Cells: Testing the individual cells of the battery to identify weak or damaged cells.

- Alternator Diodes: Testing the diodes in the alternator to ensure that they are functioning correctly.

- Voltage Regulator Transistors: Testing the transistors in the voltage regulator to ensure that they are switching properly.

- Sensor Circuits: Testing the circuits that connect the sensors to the ECU to identify shorts, opens, or corrosion.

Performing component-level diagnostics requires specialized equipment and expertise.

10.3. Consulting with Experienced Technicians

When should you consult with experienced technicians? Consulting with experienced technicians can be invaluable when troubleshooting complex power management issues. Experienced technicians can provide insights and guidance based on their knowledge and experience, helping you to:

- Identify Potential Causes: Identify potential causes of the problem that you may have overlooked.

- Develop Diagnostic Strategies: Develop effective diagnostic strategies for resolving the issue.

- Interpret Diagnostic Data: Interpret diagnostic data correctly and identify the root cause of the problem.

- Implement Effective Solutions: Implement effective solutions for resolving the issue.

Consulting with experienced technicians can save you time and money and help you resolve complex power management issues effectively.

DTS Monaco is a versatile tool that enables in-depth interaction with a vehicle’s power management system, supporting tasks from basic diagnostics to advanced customizations. By following the outlined procedures and heeding the advice provided by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, technicians can optimize vehicle performance, address complex electrical issues, and improve overall system reliability. Explore our resources and training programs at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN to enhance your diagnostic capabilities and stay ahead in the ever-evolving automotive industry. Contact us today and let us guide you through the world of advanced vehicle diagnostics! Address: 789 Oak Avenue, Miami, FL 33101, United States. Whatsapp: +1 (641) 206-8880. Website: MERCEDES-DIAGNOSTIC-TOOL.EDU.VN.

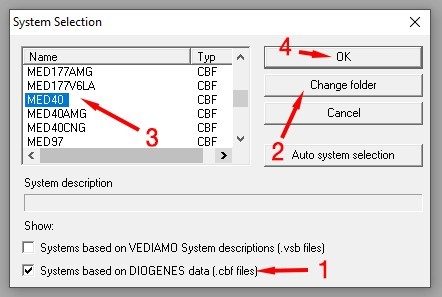

Selecting CBF Files in Vediamo

Selecting CBF Files in Vediamo

Variant Coding Dialog in Vediamo showcases the interface for customizing vehicle settings.

ECU Unlock Screen in Vediamo is a critical step for accessing protected functions within the vehicle’s systems.

MBSeedKey Application Screen demonstrates the process of generating keys for secure access to ECUs.

Selecting DLL File in MBSeedKey shows how to integrate necessary libraries for diagnostic operations.

Hard Reset Function in Vediamo provides a means to reset modules to their default settings.