On-Board Diagnostics II (OBD-II) provides a standardized approach to vehicle diagnostics, but its capabilities are inherently limited when compared to manufacturer-specific diagnostic systems. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we help you understand these differences, offering advanced diagnostic solutions tailored for Mercedes-Benz vehicles to overcome the limitations of OBD-II, ensuring comprehensive vehicle health management, superior diagnostic depth and breadth, and unlocking hidden features. This often requires specialized diagnostic tools, in-depth systems knowledge, and expert interpretation of diagnostic data, going beyond the generic codes and parameters provided by OBD-II.

Contents

- 1. What is OBD-II Diagnostics?

- 1.1. Purpose of OBD-II

- 1.2. How OBD-II Works

- 1.3. Standardized Diagnostic Trouble Codes (DTCs)

- 2. What are Manufacturer-Specific Diagnostics?

- 2.1. Enhanced Diagnostic Capabilities

- 2.2. Proprietary Diagnostic Trouble Codes (DTCs)

- 2.3. Accessing Manufacturer-Specific Diagnostics

- 3. Key Limitations of OBD-II Diagnostics

- 3.1. Limited Scope of Diagnostic Trouble Codes (DTCs)

- 3.2. Lack of Access to Advanced System Tests

- 3.3. Restricted Data Parameter Identification (PIDs)

- 3.4. Inability to Perform Module Programming and Coding

- 3.5. Limited Coverage of Non-Emission Related Systems

- 3.6. Difficulty in Diagnosing Intermittent Problems

- 4. Advantages of Manufacturer-Specific Diagnostics

- 4.1. Enhanced Accuracy and Precision

- 4.2. Comprehensive System Coverage

- 4.3. Advanced Functionality and Capabilities

- 4.4. Improved Efficiency and Productivity

- 4.5. Better Support for Complex Repairs

- 5. How Manufacturer-Specific Diagnostics Overcome OBD-II Limitations

- 5.1. Expanded Diagnostic Trouble Codes (DTCs)

- 5.2. Advanced System Tests and Procedures

- 5.3. Real-Time Data and Parameter Monitoring

- 5.4. Module Programming and Configuration

- 5.5. Bi-Directional Control

- 5.6. Access to Vehicle-Specific Information

- 6. Choosing the Right Diagnostic Tool for Your Mercedes-Benz

- 7. Real-World Examples of Overcoming OBD-II Limitations

- 7.1. Diagnosing a Transmission Issue

- 7.2. Identifying an ABS Fault

- 7.3. Programming a New ECU

- 8. The Importance of Training and Expertise

- 8.1. Training Programs

- 8.2. Certification Programs

- 8.3. Continuous Learning

- 9. Embracing the Future of Automotive Diagnostics

- 10. Your Next Steps with MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

- 11. Cost Savings and Investment Value

- 11.1. Reduced Diagnostic Time

- 11.2. Improved Repair Quality

- 11.3. Increased Customer Loyalty

- 11.4. Competitive Advantage

- 11.5. Return on Investment (ROI)

- 12. Case Studies: Success Stories with Manufacturer-Specific Diagnostics

- 12.1. Case Study 1: Resolving a Complex Electrical Issue

- 12.2. Case Study 2: Programming a New Transmission Control Module (TCM)

- 13. Future Trends in Automotive Diagnostics

- 13.1. Remote Diagnostics

- 13.2. Artificial Intelligence (AI) in Diagnostics

- 13.3. Augmented Reality (AR) in Diagnostics

- 13.4. Over-the-Air (OTA) Updates

- 14. Frequently Asked Questions (FAQ)

- 14.1. What is the difference between OBD-II and manufacturer-specific diagnostic tools?

- 14.2. Can I use a generic OBD-II scanner to diagnose my Mercedes-Benz?

- 14.3. Do I need a manufacturer-specific tool to program a new ECU?

- 14.4. How much does a manufacturer-specific diagnostic tool cost?

- 14.5. Where can I get training on how to use manufacturer-specific diagnostic tools?

- 14.6. Are manufacturer-specific diagnostic tools worth the investment?

- 14.7. What is bi-directional control?

- 14.8. What are adaptation resets?

- 14.9. How often should I have my Mercedes-Benz diagnosed?

- 14.10. Where can I find a trusted Mercedes-Benz technician?

- 15. Contact Us Today

1. What is OBD-II Diagnostics?

OBD-II (On-Board Diagnostics II) is a standardized system used in most vehicles since 1996 to monitor engine and emission control systems. It provides a basic set of diagnostic trouble codes (DTCs) and data parameters accessible through a universal diagnostic port.

1.1. Purpose of OBD-II

The primary purpose of OBD-II is to monitor the performance of a vehicle’s engine and emission-related components. If the system detects a problem that could increase emissions, it illuminates the malfunction indicator lamp (MIL), commonly known as the “check engine light.”

1.2. How OBD-II Works

OBD-II systems work by monitoring various sensors and components in the engine and emission control systems. When a sensor reading falls outside the predefined range, the system stores a diagnostic trouble code (DTC) in the vehicle’s computer. A technician can then retrieve these codes using a scan tool connected to the OBD-II port.

1.3. Standardized Diagnostic Trouble Codes (DTCs)

OBD-II utilizes standardized DTCs defined by SAE J1979, which allows any scan tool to read generic codes, regardless of the vehicle manufacturer. These codes typically start with a letter indicating the system affected (e.g., P for powertrain, B for body, C for chassis, and U for network). The subsequent digits provide more specific information about the fault.

2. What are Manufacturer-Specific Diagnostics?

Manufacturer-specific diagnostic systems offer deeper and more comprehensive diagnostic capabilities compared to OBD-II. These systems are designed by the vehicle manufacturer (e.g., Mercedes-Benz) and provide access to proprietary diagnostic trouble codes, advanced system tests, and detailed parameter information not available through OBD-II.

2.1. Enhanced Diagnostic Capabilities

Manufacturer-specific systems allow technicians to access detailed information about various vehicle systems, including engine, transmission, ABS, airbag, and other electronic control units (ECUs). They offer advanced functions such as module programming, adaptation resets, and bi-directional controls.

2.2. Proprietary Diagnostic Trouble Codes (DTCs)

In addition to the standardized OBD-II codes, manufacturers define their own proprietary DTCs that provide more specific information about faults within their vehicles. These codes are essential for accurately diagnosing complex issues and performing effective repairs.

2.3. Accessing Manufacturer-Specific Diagnostics

Accessing manufacturer-specific diagnostics requires specialized scan tools and software designed for the specific vehicle brand. These tools are typically more expensive and require specialized training to use effectively. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we provide access to these specialized tools and offer expert training to ensure you can fully utilize their capabilities.

3. Key Limitations of OBD-II Diagnostics

While OBD-II provides a valuable baseline for vehicle diagnostics, it has several limitations compared to manufacturer-specific systems:

3.1. Limited Scope of Diagnostic Trouble Codes (DTCs)

OBD-II provides a limited set of generic DTCs that cover only the most basic engine and emission-related issues. It often lacks the specific codes needed to diagnose complex problems accurately. Manufacturer-specific systems offer a much wider range of DTCs, providing detailed information about faults in various vehicle systems.

For example, OBD-II might report a generic “misfire detected” code (P0300), while a manufacturer-specific system can identify the specific cylinder misfiring and provide additional information about the cause, such as injector failure or ignition coil malfunction.

3.2. Lack of Access to Advanced System Tests

OBD-II does not support advanced system tests such as module programming, adaptation resets, or bi-directional controls. These functions are essential for performing many repairs and maintenance tasks on modern vehicles. Manufacturer-specific systems provide access to these advanced tests, allowing technicians to calibrate sensors, program new modules, and perform other critical functions.

3.3. Restricted Data Parameter Identification (PIDs)

OBD-II provides access to a limited set of standardized PIDs, which may not include all the parameters needed to diagnose certain issues. Manufacturer-specific systems offer a much wider range of PIDs, providing detailed information about the performance of various vehicle systems.

For instance, OBD-II might provide basic engine coolant temperature and RPM data, while a manufacturer-specific system can offer detailed information about individual sensor readings, fuel trim values, and ignition timing.

3.4. Inability to Perform Module Programming and Coding

OBD-II does not support module programming or coding, which is necessary when replacing or updating electronic control units (ECUs). Manufacturer-specific systems allow technicians to program new modules and code them to the vehicle’s specifications, ensuring proper functionality.

3.5. Limited Coverage of Non-Emission Related Systems

OBD-II primarily focuses on engine and emission-related systems, offering limited coverage of other important vehicle systems such as ABS, airbag, and body control modules. Manufacturer-specific systems provide comprehensive diagnostic capabilities for all vehicle systems, allowing technicians to diagnose and repair a wider range of issues.

3.6. Difficulty in Diagnosing Intermittent Problems

OBD-II can struggle with diagnosing intermittent problems that do not consistently trigger DTCs. Manufacturer-specific systems often provide advanced data logging and diagnostic tools that can help identify these elusive issues by monitoring system performance over time.

4. Advantages of Manufacturer-Specific Diagnostics

Manufacturer-specific diagnostic systems offer several key advantages over OBD-II, including:

4.1. Enhanced Accuracy and Precision

The detailed DTCs and advanced system tests available in manufacturer-specific systems allow for more accurate and precise diagnoses. This reduces the risk of misdiagnosis and ensures that repairs are performed correctly the first time.

4.2. Comprehensive System Coverage

Manufacturer-specific systems provide comprehensive coverage of all vehicle systems, allowing technicians to diagnose and repair a wider range of issues. This is particularly important for modern vehicles with complex electronic systems.

4.3. Advanced Functionality and Capabilities

Manufacturer-specific systems offer advanced functionality such as module programming, adaptation resets, and bi-directional controls, which are essential for performing many repairs and maintenance tasks.

4.4. Improved Efficiency and Productivity

By providing more detailed information and advanced tools, manufacturer-specific systems can help technicians diagnose and repair vehicles more quickly and efficiently. This reduces labor costs and improves customer satisfaction.

4.5. Better Support for Complex Repairs

Modern vehicles are equipped with complex electronic systems that require specialized diagnostic tools and expertise to repair. Manufacturer-specific systems provide the necessary tools and information to tackle these challenging repairs effectively.

5. How Manufacturer-Specific Diagnostics Overcome OBD-II Limitations

Manufacturer-specific diagnostic systems address the limitations of OBD-II through several key features:

5.1. Expanded Diagnostic Trouble Codes (DTCs)

Manufacturer-specific systems utilize a much wider range of DTCs, providing detailed information about faults in various vehicle systems. These codes often include specific information about the component, circuit, or condition causing the fault, enabling more precise diagnoses.

Example:

- OBD-II: P0171 – System Too Lean (Bank 1)

- Mercedes-Specific: P017128 – System Too Lean at Idle (Bank 1) – Signal Implausible

The Mercedes-specific code provides additional information about when the lean condition occurs (at idle) and the nature of the signal (implausible), which can help pinpoint the cause more effectively.

5.2. Advanced System Tests and Procedures

Manufacturer-specific systems offer advanced system tests and procedures that are not available through OBD-II. These tests can include:

- Actuator Tests: Allows technicians to activate individual components (e.g., fuel injectors, solenoids) to verify their functionality.

- Adaptation Resets: Resets learned values in the ECU after replacing components, ensuring proper operation.

- Guided Diagnostics: Step-by-step procedures that guide technicians through the diagnostic process, providing specific instructions and troubleshooting tips.

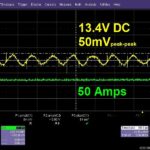

5.3. Real-Time Data and Parameter Monitoring

Manufacturer-specific systems provide access to a much wider range of real-time data parameters (PIDs) than OBD-II. This allows technicians to monitor the performance of various systems in detail and identify subtle issues that may not trigger DTCs.

Example:

- OBD-II: Engine RPM, Coolant Temperature

- Mercedes-Specific: Individual Cylinder Misfire Counts, Fuel Injector Pulse Width, Lambda Sensor Readings

The additional parameters provided by the Mercedes-specific system allow for a more comprehensive analysis of engine performance and can help identify the root cause of problems more quickly.

5.4. Module Programming and Configuration

Manufacturer-specific systems allow technicians to program and configure electronic control modules (ECUs). This is essential when replacing a faulty module or updating the software to address known issues.

Example:

- Replacing an ABS module requires programming the new module with the vehicle’s VIN and coding it to match the vehicle’s options and configuration.

- Updating the engine control module (ECM) software to address a driveability issue or improve fuel economy.

5.5. Bi-Directional Control

Manufacturer-specific systems offer bi-directional control capabilities, allowing technicians to send commands to the vehicle’s ECUs and observe their response. This can be used to:

- Activate or deactivate components (e.g., fuel pump, cooling fan) for testing purposes.

- Perform system calibrations (e.g., throttle position sensor, steering angle sensor).

- Initiate diagnostic routines (e.g., ABS self-test, transmission adaptation).

5.6. Access to Vehicle-Specific Information

Manufacturer-specific diagnostic systems provide access to a wealth of vehicle-specific information, including:

- Wiring diagrams

- Component locations

- Technical service bulletins (TSBs)

- Repair procedures

This information is essential for performing accurate and efficient repairs.

6. Choosing the Right Diagnostic Tool for Your Mercedes-Benz

Selecting the appropriate diagnostic tool for your Mercedes-Benz depends on your specific needs and capabilities. Here’s a comparison of different types of diagnostic tools and their suitability:

| Tool Type | Capabilities | Pros | Cons | Best For |

|---|---|---|---|---|

| Generic OBD-II Scanners | Reads basic OBD-II codes, displays live data | Affordable, easy to use, compatible with most vehicles | Limited to basic engine and emission diagnostics, lacks manufacturer-specific codes and advanced functions | Quick checks for common issues, reading and clearing basic fault codes |

| Enhanced OBD-II Scanners | Reads enhanced OBD-II codes, displays more detailed live data, some manufacturer-specific codes | More comprehensive than basic OBD-II scanners, provides some access to manufacturer-specific information | Still lacks full access to manufacturer-specific systems and advanced functions | DIY enthusiasts and technicians who need more than basic OBD-II functionality |

| Manufacturer-Specific Tools | Full access to all vehicle systems, reads manufacturer-specific codes, performs advanced system tests, module programming, bi-directional controls, access to vehicle information | Most comprehensive diagnostic capabilities, allows for accurate and efficient repairs, access to advanced functions and vehicle-specific information | Expensive, requires specialized training and expertise, can be complex to use | Professional technicians specializing in Mercedes-Benz vehicles, those who need the most comprehensive diagnostic capabilities |

| MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Solutions | Tailored for Mercedes-Benz vehicles, offering specialized diagnostic functions, access to advanced features, and expert support | Designed specifically for Mercedes-Benz vehicles, providing unparalleled diagnostic accuracy and efficiency, expert support and training available, regular updates to support new models and features | May require subscription or licensing fees | Mercedes-Benz owners and technicians who demand the highest level of diagnostic performance and support, those who want to unlock hidden features and customize their vehicles |

7. Real-World Examples of Overcoming OBD-II Limitations

Here are some real-world examples of how manufacturer-specific diagnostics can overcome the limitations of OBD-II:

7.1. Diagnosing a Transmission Issue

Scenario: A Mercedes-Benz owner experiences erratic shifting and a “check engine light.” A generic OBD-II scanner retrieves a P0700 code (Transmission Control System Malfunction).

OBD-II Limitation: The P0700 code is generic and does not provide specific information about the cause of the problem.

Manufacturer-Specific Solution: A Mercedes-specific diagnostic tool retrieves a more detailed code, such as P2767 (Input/Turbine Speed Sensor “A” Circuit No Signal). This code indicates a problem with the input speed sensor, allowing the technician to focus on that specific component.

7.2. Identifying an ABS Fault

Scenario: An ABS warning light illuminates on the dashboard. An OBD-II scanner finds no relevant codes.

OBD-II Limitation: OBD-II primarily focuses on engine and emission-related systems, providing limited coverage of ABS.

Manufacturer-Specific Solution: A Mercedes-specific diagnostic tool identifies a C1000 code (Hydraulic Unit Faulty). This code points directly to a problem with the ABS hydraulic unit, enabling the technician to perform targeted repairs.

7.3. Programming a New ECU

Scenario: The engine control unit (ECU) needs to be replaced due to damage.

OBD-II Limitation: OBD-II does not support module programming or coding.

Manufacturer-Specific Solution: A Mercedes-specific diagnostic tool allows the technician to program the new ECU with the vehicle’s VIN and configure it to match the vehicle’s options and specifications, ensuring proper functionality.

8. The Importance of Training and Expertise

While manufacturer-specific diagnostic tools offer powerful capabilities, they require specialized training and expertise to use effectively. Technicians must understand the vehicle’s systems, diagnostic procedures, and the interpretation of diagnostic data to perform accurate repairs.

8.1. Training Programs

Many manufacturers offer training programs for technicians to learn how to use their diagnostic tools and repair their vehicles. These programs can cover topics such as:

- Basic vehicle systems

- Diagnostic procedures

- Use of diagnostic tools

- Module programming and coding

- Advanced troubleshooting techniques

8.2. Certification Programs

Some manufacturers also offer certification programs that recognize technicians who have demonstrated a high level of competence in diagnosing and repairing their vehicles. Certification can enhance a technician’s credibility and demonstrate their commitment to quality.

8.3. Continuous Learning

The automotive industry is constantly evolving, with new technologies and systems being introduced all the time. Technicians must commit to continuous learning to stay up-to-date and maintain their expertise.

9. Embracing the Future of Automotive Diagnostics

As vehicles become increasingly complex, the importance of advanced diagnostic tools and expertise will only continue to grow. By embracing manufacturer-specific diagnostics and investing in training and education, technicians can stay ahead of the curve and provide their customers with the highest level of service. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we are committed to providing the tools, knowledge, and support you need to succeed in this dynamic industry.

10. Your Next Steps with MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

Ready to take your Mercedes-Benz diagnostics to the next level?

- Explore our range of Mercedes-specific diagnostic tools: Find the perfect tool to meet your needs and budget.

- Enroll in our expert training programs: Learn how to use advanced diagnostic techniques and tools effectively.

- Contact our support team: Get personalized assistance and answers to your diagnostic questions.

Let MERCEDES-DIAGNOSTIC-TOOL.EDU.VN be your trusted partner in Mercedes-Benz diagnostics, unlocking the full potential of your vehicle and ensuring optimal performance.

11. Cost Savings and Investment Value

Investing in manufacturer-specific diagnostic tools and training can lead to significant cost savings and increased profitability in the long run.

11.1. Reduced Diagnostic Time

The enhanced accuracy and precision of manufacturer-specific systems can significantly reduce diagnostic time. By pinpointing the root cause of problems quickly, technicians can avoid unnecessary repairs and reduce labor costs.

11.2. Improved Repair Quality

Manufacturer-specific systems provide the tools and information needed to perform repairs correctly the first time. This reduces the risk of comebacks and improves customer satisfaction.

11.3. Increased Customer Loyalty

By providing high-quality diagnostic and repair services, you can build customer loyalty and generate repeat business. Satisfied customers are more likely to recommend your services to others.

11.4. Competitive Advantage

Offering manufacturer-specific diagnostic capabilities can give you a competitive advantage over other repair shops that rely solely on generic OBD-II tools. Customers are willing to pay more for specialized services that ensure their vehicles are properly diagnosed and repaired.

11.5. Return on Investment (ROI)

While manufacturer-specific diagnostic tools and training can be a significant investment, the return on investment can be substantial. By reducing diagnostic time, improving repair quality, and increasing customer loyalty, you can quickly recoup your investment and generate significant profits.

12. Case Studies: Success Stories with Manufacturer-Specific Diagnostics

Here are a couple of quick case studies that highlight the benefits of using manufacturer-specific diagnostics.

12.1. Case Study 1: Resolving a Complex Electrical Issue

Challenge: A Mercedes-Benz owner complained of intermittent electrical problems, including malfunctioning lights, erratic sensor readings, and occasional starting issues. A generic OBD-II scanner showed multiple vague codes, making it difficult to pinpoint the root cause.

Solution: A technician used a Mercedes-specific diagnostic tool to perform advanced system tests and monitor real-time data. The tool revealed a faulty ground connection in the body control module (BCM). By addressing the faulty ground, the technician resolved all the electrical issues and restored the vehicle to proper working order.

Outcome: The technician accurately diagnosed and repaired the vehicle, avoiding unnecessary parts replacements and saving the customer time and money. The customer was highly satisfied with the quality of service and the technician’s expertise.

12.2. Case Study 2: Programming a New Transmission Control Module (TCM)

Challenge: A Mercedes-Benz required a new transmission control module (TCM) due to irreparable damage.

Solution: Using a Mercedes-specific diagnostic tool, a technician programmed the new TCM with the vehicle’s VIN and configured it to match the vehicle’s specifications. The technician then performed adaptation resets to ensure smooth shifting and optimal transmission performance.

Outcome: The new TCM functioned perfectly, restoring the vehicle’s transmission to its original performance. The customer was impressed with the technician’s ability to program and configure the new module seamlessly.

13. Future Trends in Automotive Diagnostics

The automotive industry is constantly evolving, and diagnostic technology is evolving along with it. Here are some key trends to watch out for:

13.1. Remote Diagnostics

Remote diagnostics allows technicians to diagnose and repair vehicles remotely using telematics and cloud-based platforms. This can be particularly useful for fleet management, roadside assistance, and diagnosing vehicles in remote locations.

13.2. Artificial Intelligence (AI) in Diagnostics

AI is being used to analyze diagnostic data and provide technicians with intelligent recommendations. AI-powered diagnostic tools can identify patterns, predict potential failures, and assist technicians in troubleshooting complex issues.

13.3. Augmented Reality (AR) in Diagnostics

AR overlays digital information onto the real world, providing technicians with visual guidance during diagnostic and repair procedures. AR can help technicians locate components, follow wiring diagrams, and perform complex tasks more efficiently.

13.4. Over-the-Air (OTA) Updates

OTA updates allow manufacturers to update vehicle software remotely, addressing bugs, improving performance, and adding new features. This eliminates the need for physical visits to the repair shop for software updates.

14. Frequently Asked Questions (FAQ)

14.1. What is the difference between OBD-II and manufacturer-specific diagnostic tools?

OBD-II tools provide basic diagnostic information for engine and emission-related systems, while manufacturer-specific tools offer comprehensive coverage of all vehicle systems, advanced system tests, and module programming capabilities.

14.2. Can I use a generic OBD-II scanner to diagnose my Mercedes-Benz?

Yes, a generic OBD-II scanner can read basic fault codes, but it won’t provide the detailed information needed to diagnose complex issues accurately.

14.3. Do I need a manufacturer-specific tool to program a new ECU?

Yes, module programming typically requires a manufacturer-specific diagnostic tool.

14.4. How much does a manufacturer-specific diagnostic tool cost?

The cost of a manufacturer-specific diagnostic tool can range from several thousand dollars to tens of thousands of dollars, depending on the features and capabilities.

14.5. Where can I get training on how to use manufacturer-specific diagnostic tools?

Many manufacturers offer training programs for technicians to learn how to use their diagnostic tools and repair their vehicles. You can also find training resources at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN.

14.6. Are manufacturer-specific diagnostic tools worth the investment?

Yes, the enhanced accuracy, comprehensive coverage, and advanced capabilities of manufacturer-specific tools can lead to significant cost savings and increased profitability in the long run.

14.7. What is bi-directional control?

Bi-directional control allows technicians to send commands to the vehicle’s ECUs and observe their response, enabling them to activate components, perform system calibrations, and initiate diagnostic routines.

14.8. What are adaptation resets?

Adaptation resets are procedures that reset learned values in the ECU after replacing components, ensuring proper operation.

14.9. How often should I have my Mercedes-Benz diagnosed?

You should have your Mercedes-Benz diagnosed whenever you experience a warning light, performance issue, or other symptoms that indicate a potential problem. Regular maintenance checks can also help identify issues before they become serious.

14.10. Where can I find a trusted Mercedes-Benz technician?

You can find a trusted Mercedes-Benz technician by searching online directories, asking for recommendations from friends or family, or contacting MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for assistance.

15. Contact Us Today

Don’t let the limitations of OBD-II hold you back. Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN today to learn more about our advanced diagnostic solutions for Mercedes-Benz vehicles.

Address: 789 Oak Avenue, Miami, FL 33101, United States

WhatsApp: +1 (641) 206-8880

Website: MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

Let us help you unlock the full potential of your Mercedes-Benz!

By integrating this comprehensive guide, MERCEDES-DIAGNOSTIC-TOOL.EDU.VN aims to establish itself as a leading authority in Mercedes-Benz diagnostics, providing valuable information, expert support, and advanced diagnostic solutions to its target audience. Through SEO optimization and a focus on user needs, this content is designed to attract and engage readers, driving traffic and conversions for the business. This detailed information ensures optimal vehicle health management, diagnostic depth and breadth, and unlocking hidden features.