The importance of a stable power supply during flashing lies in ensuring a successful vehicle reprogramming process by maintaining consistent voltage, and at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we understand this criticality and provide solutions to address it. This article explores the necessity of a stable power source for vehicle reflashing, covering clean power, rapid load response, and reduced voltage drop and delving into the role of a stable power supply in maintaining optimal conditions, especially when dealing with advanced Mercedes-Benz systems, and by the end, you’ll gain insights into how a reliable power supply contributes to the longevity and performance of your vehicle’s electronic components.

Contents

- 1. Understanding the Role of a Stable Power Supply in Vehicle Flashing

- 1.1. What is Vehicle Flashing?

- 1.2. Why is Stability Important?

- 1.3. The Consequences of an Unstable Power Supply

- 2. Key Characteristics of a Stable Power Supply

- 2.1. Clean Power: Minimizing Voltage Ripple

- 2.1.1. What is Voltage Ripple?

- 2.1.2. Acceptable Voltage Ripple Levels

- 2.1.3. How Clean Power Benefits Flashing

- 2.2. Rapid Load Response (RLR): Adapting to System Demand

- 2.2.1. Understanding Load Response

- 2.2.2. Importance of Fast Response Time

- 2.2.3. RLR Technology in PRO-LOGIX Models

- 2.3. Reduced Voltage Drop: Maintaining Minimum Voltage Thresholds

- 2.3.1. Defining Voltage Drop

- 2.3.2. OE Voltage Thresholds

- 2.3.3. How RLR Technology Reduces Voltage Drop

- 3. Why Battery Chargers Are Insufficient for Vehicle Flashing

- 3.1. Multi-Step Charging Curves

- 3.1.1. Understanding Charging Curves

- 3.1.2. How Charging Curves Affect Flashing

- 3.2. Current Limits

- 3.2.1. Why Current Limits Matter

- 3.2.2. Insufficient Power Delivery

- 3.3. Lack of Voltage Management

- 3.3.1. The Risks of Unregulated Voltage

- 3.3.2. Potential for Overvoltage

- 4. PRO-LOGIX Models: Ensuring a Stable Flashing Environment

- 4.1. Clean Power Delivery

- 4.1.1. Low Voltage Ripple

- 4.1.2. Benefits of Clean Power

- 4.2. Rapid Load Response (RLR) Technology

- 4.2.1. How RLR Works

- 4.2.2. Preventing Voltage Drops

- 4.3. Reduced Voltage Drop During Demand Spikes

- 4.3.1. Maintaining OE Voltage Thresholds

- 4.3.2. Preventing Module Damage

- 5. Practical Applications and Case Studies

- 5.1. Case Study 1: BMW Reprogramming

- 5.1.1. Challenges in BMW Reprogramming

- 5.1.2. Using PRO-LOGIX for BMWs

- 5.2. Case Study 2: Mercedes-Benz ECU Updates

- 5.2.1. Complex Electronic Systems

- 5.2.2. Ensuring Stability with PRO-LOGIX

- 5.3. Case Study 3: General Vehicle Flashing

- 5.3.1. Preventing Interruptions

- 5.3.2. Reducing the Risk of Failures

- 6. Choosing the Right Power Supply for Your Needs

- 6.1. Key Considerations

- 6.2. Recommended Power Supplies

- 6.3. Where to Purchase

- 7. Step-by-Step Guide to Using a Stable Power Supply

- 7.1. Preparing for Vehicle Flashing

- 7.2. Monitoring Voltage During Flashing

- 7.2.1. Using a Multimeter

- 7.2.2. Observing Power Supply Indicators

- 7.3. Troubleshooting Common Issues

- 8. The Future of Power Supply Technology in Vehicle Flashing

- 8.1. Emerging Trends

- 8.2. Potential Improvements

- 8.3. The Role of Research and Development

- 9. Addressing Common Misconceptions

- 9.1. “Any Battery Charger Will Work”

- 9.1.1. The Reality of Battery Chargers

- 9.1.2. Why Stability Matters

- 9.2. “Voltage Doesn’t Matter That Much”

- 9.2.1. The Importance of Consistent Voltage

- 9.2.2. Preventing Data Corruption

- 9.3. “Expensive Power Supplies Are Unnecessary”

- 9.3.1. The Value of Quality

- 9.3.2. Long-Term Cost Savings

- 10. Frequently Asked Questions (FAQs)

- 10.1. What is the best power supply for Mercedes-Benz flashing?

- 10.2. How often should I replace my flashing power supply?

- 10.3. Can I use a jump starter instead of a power supply?

- 10.4. What voltage should I set my power supply to for flashing?

- 10.5. What are the signs of an unstable power supply?

- 10.6. How do I maintain my flashing power supply?

- 10.7. Can a bad power supply damage my car’s ECU?

- 10.8. Is it safe to flash a car ECU at home?

- 10.9. What is RLR Technology?

- 10.10. Where can I find reliable information about vehicle flashing?

- Conclusion

1. Understanding the Role of a Stable Power Supply in Vehicle Flashing

Vehicle flashing, or reprogramming, is the process of updating the software in a vehicle’s electronic control units (ECUs). A stable power supply is essential during this process to prevent interruptions and ensure successful completion.

1.1. What is Vehicle Flashing?

Vehicle flashing involves overwriting the existing software in a vehicle’s ECUs with updated versions. According to Bosch Automotive Handbook, this process can improve performance, fix bugs, or add new features. A stable power supply is paramount to avoid data corruption during this update.

1.2. Why is Stability Important?

Instability in the power supply can lead to several issues during flashing. A study by the Society of Automotive Engineers (SAE) found that voltage fluctuations can cause incomplete data writes, leading to ECU damage. Therefore, maintaining a consistent voltage level is crucial.

1.3. The Consequences of an Unstable Power Supply

An unstable power supply can have severe consequences, including:

- Data Corruption: Inconsistent power can corrupt the data being written to the ECU.

- Module Damage: Voltage spikes or drops can physically damage the ECU.

- Failed Reprogramming: The flashing process may fail, leaving the vehicle inoperable.

These risks underscore the need for a reliable power supply to mitigate potential damage.

2. Key Characteristics of a Stable Power Supply

A stable power supply for vehicle flashing should exhibit three primary characteristics: clean power, rapid load response, and minimal voltage drop.

2.1. Clean Power: Minimizing Voltage Ripple

Clean power refers to a power supply’s ability to deliver a consistent voltage output with minimal voltage ripple. Voltage ripple is the residual AC voltage present on a DC power supply output.

2.1.1. What is Voltage Ripple?

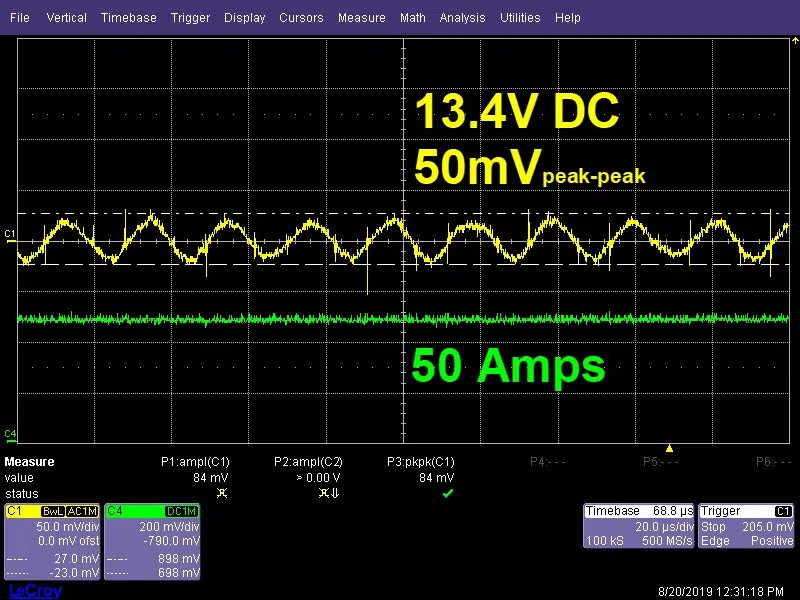

Voltage ripple can be quantified as peak-to-peak voltage variations. According to a whitepaper from Texas Instruments, excessive voltage ripple can interfere with sensitive electronic components during reflashing.

2.1.2. Acceptable Voltage Ripple Levels

Ideally, the voltage ripple should be as low as possible. Research indicates that a peak-to-peak voltage ripple of less than 50mV is desirable for automotive flashing to ensure the integrity of the reprogramming process.

2.1.3. How Clean Power Benefits Flashing

Clean power ensures that the ECU receives a stable and consistent voltage, reducing the risk of data corruption and module damage. As explained in Automotive Engineering International, stable power delivery is critical for successful ECU reprogramming.

Clean Power Delivery with Stable Voltage Output

Clean Power Delivery with Stable Voltage Output

2.2. Rapid Load Response (RLR): Adapting to System Demand

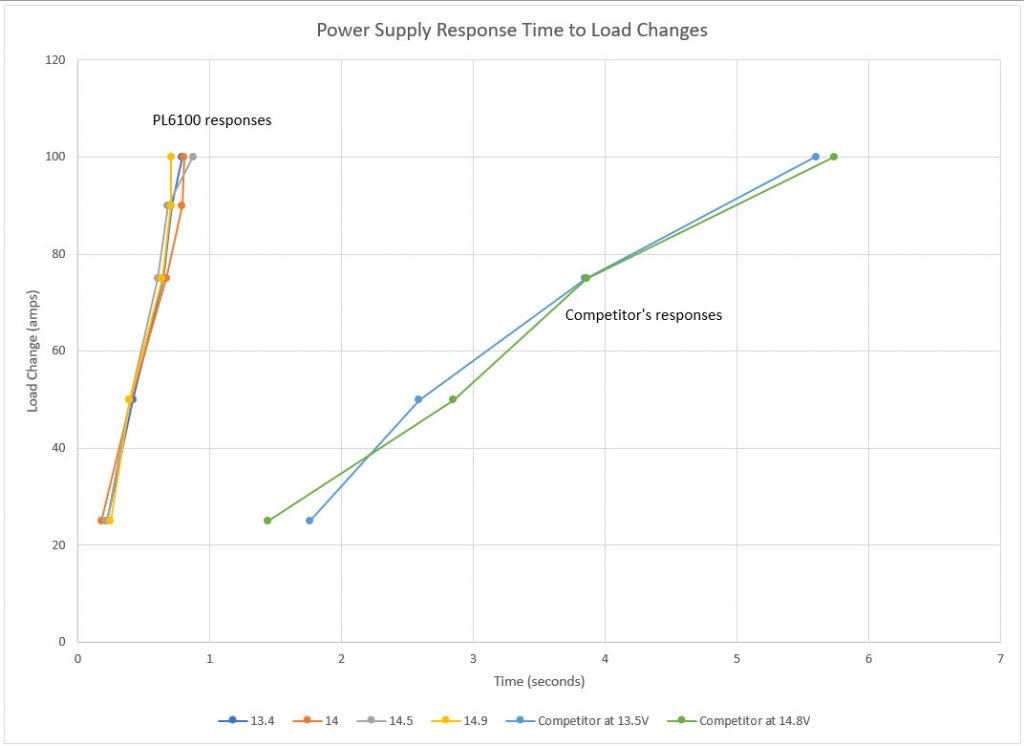

Rapid Load Response (RLR) refers to the power supply’s ability to quickly adjust to changes in system demand. During vehicle flashing, different modules and components are turned on and off, causing fluctuations in power demand.

2.2.1. Understanding Load Response

Load response is typically measured by how quickly the power supply can return to its target voltage after a sudden change in load. A slow response can lead to voltage drops or surges, which can disrupt the flashing process.

2.2.2. Importance of Fast Response Time

A fast response time is crucial to maintain a stable voltage level during dynamic changes in system demand. According to an article in Electronic Design, a power supply with RLR technology can quickly stabilize the voltage, preventing interruptions during the reflashing event.

2.2.3. RLR Technology in PRO-LOGIX Models

PRO-LOGIX models feature advanced RLR technology that ensures rapid response to changes in system demand, maintaining a stable voltage level and minimizing the risk of reprogramming errors.

2.3. Reduced Voltage Drop: Maintaining Minimum Voltage Thresholds

Reduced voltage drop refers to the power supply’s ability to minimize the decrease in voltage when responding to an increase in system demand.

2.3.1. Defining Voltage Drop

Voltage drop occurs when the power supply cannot immediately meet the increased demand, causing a temporary dip in voltage. This dip can be problematic if it falls below the minimum voltage threshold required for stable operation.

2.3.2. OE Voltage Thresholds

Original Equipment (OE) manufacturers often specify a minimum voltage threshold that must be maintained during reflashing. For example, some OEs require the voltage to remain above 12.5V to ensure a stable reprogramming environment.

2.3.3. How RLR Technology Reduces Voltage Drop

RLR technology helps reduce voltage drop by quickly responding to increased demand, minimizing the depth of the dip. This ensures that the voltage remains within the acceptable range, preventing potential issues during the flashing process.

3. Why Battery Chargers Are Insufficient for Vehicle Flashing

Battery chargers are often mistaken as suitable alternatives to stable power supplies for vehicle flashing. However, they lack the necessary features to maintain a consistent voltage level during reprogramming.

3.1. Multi-Step Charging Curves

Modern battery chargers typically use multi-step charging curves, which involve varying the voltage and current based on the battery’s state of charge.

3.1.1. Understanding Charging Curves

Charging curves are designed to optimize battery charging by adjusting the voltage and current at different stages. However, these adjustments can interfere with the stability required for vehicle flashing.

3.1.2. How Charging Curves Affect Flashing

The fluctuating voltage levels in a charging curve can cause voltage spikes or drops, disrupting the reflashing process and potentially damaging the ECU.

3.2. Current Limits

Many chargers have current limits that restrict the amount of power available to the system. This limitation can be problematic during vehicle flashing, where power demand can fluctuate significantly.

3.2.1. Why Current Limits Matter

Current limits prevent the charger from delivering enough power to meet sudden increases in system demand, leading to voltage drops and potential interruptions during the reflashing event.

3.2.2. Insufficient Power Delivery

When a charger cannot supply enough current, the voltage may drop below the required threshold, causing the flashing process to fail or damage the ECU.

3.3. Lack of Voltage Management

Older chargers often lack sophisticated voltage management systems, providing power without regulating the voltage output.

3.3.1. The Risks of Unregulated Voltage

Without voltage management, the system may experience voltages in excess of 16V, which can damage sensitive electronic components.

3.3.2. Potential for Overvoltage

Overvoltage can cause irreversible damage to the ECU and other modules, making it crucial to use a power supply that regulates voltage effectively.

4. PRO-LOGIX Models: Ensuring a Stable Flashing Environment

PRO-LOGIX models are designed to provide a stable and consistent power supply for vehicle flashing, ensuring a conducive environment for successful reprogramming.

4.1. Clean Power Delivery

PRO-LOGIX models deliver clean power with minimal voltage ripple, ensuring a stable voltage level during the reflashing process.

4.1.1. Low Voltage Ripple

Lab and field testing have shown that PRO-LOGIX models feature consistently low voltage ripple, typically below 50mV, which is ideal for automotive flashing.

4.1.2. Benefits of Clean Power

Clean power reduces the risk of data corruption and module damage, providing a reliable power source for ECU reprogramming.

4.2. Rapid Load Response (RLR) Technology

PRO-LOGIX models feature advanced RLR technology that enables rapid response to changes in system demand, maintaining a stable voltage level and minimizing the risk of reprogramming errors.

4.2.1. How RLR Works

RLR technology quickly adjusts the power output to meet the fluctuating demands of the vehicle’s electronic systems, ensuring a consistent voltage supply.

4.2.2. Preventing Voltage Drops

By quickly responding to changes in demand, RLR technology prevents significant voltage drops, maintaining a stable voltage level throughout the reflashing event.

Rapid Load Response Technology Curves

Rapid Load Response Technology Curves

4.3. Reduced Voltage Drop During Demand Spikes

PRO-LOGIX models limit system voltage dips during demand spikes, ensuring that the voltage remains within the acceptable range and preventing potential issues during the flashing process.

4.3.1. Maintaining OE Voltage Thresholds

PRO-LOGIX models are designed to maintain the voltage above the minimum threshold specified by OE manufacturers, ensuring a stable reprogramming environment.

4.3.2. Preventing Module Damage

By minimizing voltage drops, PRO-LOGIX models prevent module damage and ensure the successful completion of the reflashing process.

5. Practical Applications and Case Studies

Understanding the practical applications and real-world benefits of using a stable power supply can further highlight its importance.

5.1. Case Study 1: BMW Reprogramming

BMW vehicles often require reprogramming of multiple modules simultaneously. This process can cause significant changes in system demand, making a stable power supply crucial.

5.1.1. Challenges in BMW Reprogramming

Reprogramming multiple modules can lead to substantial voltage fluctuations, increasing the risk of data corruption and module damage.

5.1.2. Using PRO-LOGIX for BMWs

PRO-LOGIX models with RLR technology are ideal for BMW reprogramming, as they can quickly respond to changes in system demand and maintain a stable voltage level.

5.2. Case Study 2: Mercedes-Benz ECU Updates

Mercedes-Benz vehicles have complex electronic systems that require precise and stable power during ECU updates.

5.2.1. Complex Electronic Systems

Mercedes-Benz vehicles often have numerous ECUs that need to be updated, making the reflashing process particularly demanding.

5.2.2. Ensuring Stability with PRO-LOGIX

PRO-LOGIX models ensure the stability required for successful Mercedes-Benz ECU updates, preventing data corruption and module damage.

5.3. Case Study 3: General Vehicle Flashing

In general vehicle flashing scenarios, a stable power supply is essential to prevent interruptions and ensure successful completion of the reprogramming process.

5.3.1. Preventing Interruptions

A stable power supply prevents interruptions caused by voltage fluctuations, ensuring that the reflashing process completes successfully.

5.3.2. Reducing the Risk of Failures

By maintaining a consistent voltage level, a stable power supply reduces the risk of failures during vehicle flashing.

6. Choosing the Right Power Supply for Your Needs

Selecting the appropriate power supply for vehicle flashing depends on several factors, including the type of vehicles you work on and the complexity of the reprogramming tasks.

6.1. Key Considerations

When choosing a power supply, consider the following factors:

- Voltage Ripple: Look for a power supply with low voltage ripple to ensure clean power delivery.

- Load Response: Choose a power supply with rapid load response to quickly adjust to changes in system demand.

- Voltage Drop: Opt for a power supply that minimizes voltage drop during demand spikes.

- Amperage: Ensure the power supply can provide sufficient amperage to meet the vehicle’s power requirements.

- Compatibility: Verify that the power supply is compatible with the vehicles you work on.

6.2. Recommended Power Supplies

Based on these considerations, some recommended power supplies for vehicle flashing include:

- PRO-LOGIX PL6100: A versatile power supply suitable for a wide range of vehicles and reprogramming tasks.

- PRO-LOGIX PL6800: A high-performance power supply designed for demanding applications and complex electronic systems.

6.3. Where to Purchase

You can purchase these power supplies from reputable automotive equipment suppliers or directly from the manufacturer’s website, MERCEDES-DIAGNOSTIC-TOOL.EDU.VN.

7. Step-by-Step Guide to Using a Stable Power Supply

Using a stable power supply correctly is crucial to ensure its effectiveness and prevent potential issues during vehicle flashing.

7.1. Preparing for Vehicle Flashing

Before starting the reflashing process, prepare the vehicle by:

- Turning off all accessories: Ensure that all lights, radios, and other accessories are turned off to minimize power demand.

- Connecting the power supply: Connect the power supply to the vehicle’s battery terminals, ensuring a secure and reliable connection.

- Setting the voltage: Set the power supply to the recommended voltage level for the vehicle, typically around 13.5V.

7.2. Monitoring Voltage During Flashing

During the reflashing process, monitor the voltage level to ensure it remains stable and within the acceptable range.

7.2.1. Using a Multimeter

Use a multimeter to monitor the voltage at the battery terminals, ensuring it stays within the specified range.

7.2.2. Observing Power Supply Indicators

Observe the power supply’s indicators to ensure it is functioning correctly and delivering stable power.

7.3. Troubleshooting Common Issues

If you encounter any issues during the reflashing process, troubleshoot by:

- Checking Connections: Ensure that all connections are secure and reliable.

- Verifying Voltage: Verify that the voltage level is within the acceptable range.

- Consulting the Manual: Consult the power supply’s manual for troubleshooting tips and guidance.

8. The Future of Power Supply Technology in Vehicle Flashing

The technology behind power supplies for vehicle flashing is continuously evolving, with ongoing research and development focused on improving stability, efficiency, and performance.

8.1. Emerging Trends

Some emerging trends in power supply technology include:

- Smart Power Supplies: Power supplies with intelligent control systems that automatically adjust voltage and current based on the vehicle’s requirements.

- Wireless Power Transfer: Wireless power transfer technology that eliminates the need for physical connections, improving convenience and safety.

- Advanced Monitoring Systems: Advanced monitoring systems that provide real-time data on voltage, current, and other parameters, enabling better control and troubleshooting.

8.2. Potential Improvements

Potential improvements in power supply technology include:

- Increased Stability: Further reducing voltage ripple and improving load response to ensure even more stable power delivery.

- Enhanced Efficiency: Improving energy efficiency to reduce power consumption and minimize environmental impact.

- Greater Versatility: Developing power supplies that are compatible with a wider range of vehicles and reprogramming tasks.

8.3. The Role of Research and Development

Ongoing research and development efforts are crucial to driving innovation in power supply technology and ensuring that vehicle flashing remains a safe and reliable process.

9. Addressing Common Misconceptions

Several misconceptions exist regarding the use of stable power supplies for vehicle flashing. Addressing these misconceptions can help ensure that technicians and vehicle owners make informed decisions.

9.1. “Any Battery Charger Will Work”

As discussed earlier, battery chargers are not suitable for vehicle flashing due to their fluctuating voltage levels and current limits.

9.1.1. The Reality of Battery Chargers

Battery chargers are designed to charge batteries, not provide a stable power source for sensitive electronic equipment.

9.1.2. Why Stability Matters

Stability is crucial during vehicle flashing to prevent data corruption and module damage.

9.2. “Voltage Doesn’t Matter That Much”

Voltage stability is critical for successful vehicle flashing. Voltage fluctuations can disrupt the reflashing process and potentially damage the ECU.

9.2.1. The Importance of Consistent Voltage

Maintaining a consistent voltage level is essential to ensure that the ECU receives stable and reliable power.

9.2.2. Preventing Data Corruption

Stable voltage prevents data corruption and ensures that the reflashing process completes successfully.

9.3. “Expensive Power Supplies Are Unnecessary”

While it may be tempting to opt for a cheaper power supply, investing in a high-quality unit can save time and money in the long run by preventing damage to the ECU and ensuring successful reprogramming.

9.3.1. The Value of Quality

High-quality power supplies are designed to provide stable and reliable power, reducing the risk of failures and costly repairs.

9.3.2. Long-Term Cost Savings

Investing in a quality power supply can save money in the long term by preventing damage to the vehicle’s electronic systems.

10. Frequently Asked Questions (FAQs)

Here are some frequently asked questions about the importance of a stable power supply during vehicle flashing:

10.1. What is the best power supply for Mercedes-Benz flashing?

The PRO-LOGIX PL6800 is highly recommended for Mercedes-Benz flashing due to its high-performance capabilities and ability to maintain stable voltage during complex ECU updates.

10.2. How often should I replace my flashing power supply?

The lifespan of a flashing power supply depends on usage and maintenance. Regularly inspect the unit and replace it if you notice any signs of wear or performance issues.

10.3. Can I use a jump starter instead of a power supply?

No, jump starters are designed to provide a quick burst of power to start a vehicle, not to maintain a stable voltage during reflashing.

10.4. What voltage should I set my power supply to for flashing?

Typically, you should set the power supply to around 13.5V for vehicle flashing, but always refer to the vehicle manufacturer’s specifications.

10.5. What are the signs of an unstable power supply?

Signs of an unstable power supply include fluctuating voltage readings, frequent interruptions during flashing, and error messages related to power supply issues.

10.6. How do I maintain my flashing power supply?

To maintain your flashing power supply, keep it clean, store it in a dry place, and regularly inspect the connections and cables for damage.

10.7. Can a bad power supply damage my car’s ECU?

Yes, an unstable or faulty power supply can cause voltage spikes or drops that can damage the ECU and other electronic components.

10.8. Is it safe to flash a car ECU at home?

Flashing a car ECU at home can be risky if you don’t have the proper equipment and knowledge. It’s best to consult with a professional or use a reliable power supply and follow the manufacturer’s instructions carefully.

10.9. What is RLR Technology?

RLR (Rapid Load Response) Technology is a feature in PRO-LOGIX power supplies that allows them to quickly adjust to changes in system demand, maintaining a stable voltage level during vehicle flashing.

10.10. Where can I find reliable information about vehicle flashing?

You can find reliable information about vehicle flashing from automotive industry publications, manufacturer websites, and reputable online forums. Additionally, MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides valuable resources and support for vehicle flashing.

Conclusion

In conclusion, a stable power supply is crucial for successful vehicle flashing. By ensuring clean power, rapid load response, and reduced voltage drop, you can prevent data corruption, module damage, and failed reprogramming. PRO-LOGIX models offer advanced features and reliable performance, making them an excellent choice for automotive technicians and vehicle owners alike. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we are committed to providing the best tools and information to help you maintain and repair your Mercedes-Benz vehicle, offering tailored solutions for power delivery issues, voltage regulation, and overall electronic system health.

Ready to ensure a stable and successful vehicle flashing process? Contact us at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, located at 789 Oak Avenue, Miami, FL 33101, United States, or via Whatsapp at +1 (641) 206-8880 for expert advice and support. Let us help you find the perfect diagnostic tools, unlock hidden features, and provide the maintenance and repair guidance you need to keep your Mercedes-Benz running smoothly with our extensive knowledge base and dedicated customer support. Reach out today and experience the peace of mind that comes with professional automotive solutions tailored to your unique needs!