The relationship between live data and fault codes is that live data helps diagnose the root cause of the issues indicated by the fault codes. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides comprehensive tools and information to understand this relationship, enabling precise troubleshooting and repairs. By using real-time diagnostics and advanced troubleshooting, users can improve vehicle performance and reduce maintenance expenses.

Contents

- 1. Understanding Live Data and Fault Codes in Mercedes Diagnostics

- 1.1. The Significance of Live Data

- 1.2. The Role of Fault Codes

- 1.3. How Live Data and Fault Codes Interact

- 2. Tools for Accessing Live Data and Fault Codes on Mercedes Vehicles

- 2.1. Mercedes-Benz Star Diagnosis

- 2.2. Autel MaxiSys Elite

- 2.3. iCarsoft MB II

- 2.4. Carly for Mercedes

- 2.5. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Solutions

- 3. Interpreting Live Data: Key Parameters for Mercedes Vehicles

- 3.1. Engine Speed (RPM)

- 3.2. Coolant Temperature

- 3.3. Oxygen Sensor Readings

- 3.4. Fuel Trim Values

- 3.5. Mass Airflow (MAF) Sensor Readings

- 3.6. Throttle Position Sensor (TPS) Readings

- 3.7. Interpreting Live Data with MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

- 4. Diagnostic Strategies: Using Live Data to Troubleshoot Fault Codes

- 4.1. Verifying Fault Code Symptoms with Live Data

- 4.2. Identifying Root Causes Through Parameter Correlation

- 4.3. Stress-Testing Components Under Various Conditions

- 4.4. Using Freeze Frame Data to Understand Fault Context

- 4.5. Comparing Readings to Known Good Values

- 4.6. Leveraging MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Advanced Diagnostics

- 5. Common Fault Codes and Related Live Data for Mercedes Vehicles

- 5.1. P0171 and P0174: System Too Lean (Bank 1 and Bank 2)

- 5.2. P0300: Random Misfire Detected

- 5.3. P0420: Catalyst System Efficiency Below Threshold (Bank 1)

- 5.4. P0101: Mass Air Flow (MAF) Sensor Range/Performance Problem

- 5.5. B2AAA/C1AAA – Mercedes-Benz Fault Code

- 5.6. Leveraging MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Fault Code Diagnosis

- 6. Advanced Diagnostic Techniques Using Live Data on Mercedes

- 6.1. Analyzing Data Trends Over Time

- 6.2. Performing Relative Compression Tests

- 6.3. Utilizing Actuator Tests

- 6.4. Conducting Electrical Load Tests

- 6.5. Performing Injector Balance Tests

- 6.6. Leveraging MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Advanced Diagnostics

- 7. Preventative Maintenance: Using Live Data for Proactive Car

- 7.1. Monitoring Engine Health Over Time

- 7.2. Assessing Transmission Performance

- 7.3. Evaluating Brake System Condition

- 7.4. Checking Battery and Charging System Performance

- 7.5. Monitoring Emission System Performance

- 7.6. Leveraging MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Preventative Maintenance

- 8. Case Studies: Real-World Examples of Diagnosing Mercedes Issues with Live Data

- 8.1. Case Study 1: Diagnosing a Lean Condition (P0171) in a Mercedes C-Class

- 8.2. Case Study 2: Diagnosing an Intermittent Misfire (P0300) in a Mercedes E-Class

- 8.3. Case Study 3: Diagnosing a Catalytic Converter Efficiency Problem (P0420) in a Mercedes S-Class

- 8.4. How MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Aids in Real-World Diagnoses

- 9. The Future of Diagnostics: How Live Data and AI Will Transform Car

- 9.1. Predictive Maintenance

- 9.2. Remote Diagnostics

- 9.3. Automated Troubleshooting

- 9.4. Personalized Car Recommendations

- 9.5. Over-the-Air (OTA) Updates

- 9.6. The Role of MERCEDES-DIAGNOSTIC-TOOL.EDU.VN in the Future of Car

- 10. FAQ: Live Data and Fault Codes

- 10.1. What Is Live Data?

- 10.2. What Are Fault Codes?

- 10.3. How Are Live Data and Fault Codes Related?

- 10.4. What Tools Can I Use to Access Live Data and Fault Codes on My Mercedes?

- 10.5. What Are Some Key Live Data Parameters to Monitor on a Mercedes?

- 10.6. How Can I Use Live Data to Diagnose a Fault Code?

- 10.7. What Are Common Fault Codes in Mercedes Vehicles and Their Related Live Data?

- 10.8. Can Live Data Be Used for Preventative Maintenance?

- 10.9. How Will AI and Live Data Transform Car in the Future?

- 10.10. How Can MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Help Me with My Mercedes Diagnostics?

1. Understanding Live Data and Fault Codes in Mercedes Diagnostics

What exactly are live data and fault codes, and how do they function within the realm of Mercedes diagnostics? Let’s explore.

Live data refers to the real-time information that a vehicle’s sensors and control units provide while the engine is running or the vehicle is in operation. This data encompasses a wide range of parameters, including engine speed (RPM), coolant temperature, oxygen sensor readings, fuel trim values, and many more. According to a study by the Society of Automotive Engineers (SAE), the accuracy and interpretation of live data are crucial for effective diagnostics.

Fault codes, also known as Diagnostic Trouble Codes (DTCs), are codes stored in the vehicle’s computer system when a sensor reading falls outside the manufacturer’s specified range. These codes indicate that a problem has been detected in a particular system or component. The National Institute for Automotive Service Excellence (ASE) emphasizes that understanding fault codes is the first step in diagnosing automotive issues.

1.1. The Significance of Live Data

Live data is essential for several reasons:

- Real-Time Monitoring: It allows technicians to monitor the performance of various components in real-time, providing insights into how the vehicle is behaving under different conditions.

- Pinpointing Intermittent Issues: Live data can help identify problems that do not consistently trigger fault codes, such as intermittent sensor failures or performance fluctuations.

- Validating Repairs: After performing a repair, live data can be used to verify that the issue has been resolved and that the system is functioning within the correct parameters.

- Performance Analysis: It can provide valuable information for tuning and optimizing engine performance.

1.2. The Role of Fault Codes

Fault codes serve as an initial indicator of potential problems:

- Quick Identification: They quickly point technicians toward specific systems or components that may be malfunctioning.

- Diagnostic Guidance: Fault codes often provide additional information, such as the type of fault (e.g., circuit high, circuit low, open circuit) and the affected component.

- Standardization: Standardized fault code formats (e.g., OBD-II codes) allow technicians to easily understand and interpret codes across different vehicle makes and models.

- Historical Data: Fault codes are stored in the vehicle’s computer, allowing technicians to review past issues and identify recurring problems.

1.3. How Live Data and Fault Codes Interact

Live data and fault codes are interconnected in several ways:

- Fault Codes Triggered by Live Data: Fault codes are often triggered when live data readings fall outside the predefined parameters. For example, if the oxygen sensor reading is consistently too high or too low, a fault code related to the oxygen sensor may be stored.

- Live Data Aids Fault Code Diagnosis: Live data is used to investigate the underlying cause of a fault code. By examining the real-time readings of related sensors and components, technicians can determine what is causing the fault code to be triggered.

- Live Data Validates Fault Code Repairs: After addressing a fault code, live data is used to confirm that the issue has been resolved and that the system is functioning properly. For example, if a fault code related to the mass airflow (MAF) sensor was triggered, live data can be used to verify that the MAF sensor is now providing accurate readings after replacement.

2. Tools for Accessing Live Data and Fault Codes on Mercedes Vehicles

What are the primary tools available for accessing live data and fault codes on Mercedes vehicles, and what distinguishes them?

2.1. Mercedes-Benz Star Diagnosis

Mercedes-Benz Star Diagnosis is the official diagnostic tool used by Mercedes-Benz dealerships and authorized service centers. This comprehensive system offers a wide range of capabilities, including:

- Reading and clearing fault codes from all vehicle systems

- Accessing live data for a wide range of parameters

- Performing guided diagnostics and troubleshooting procedures

- Programming and coding control units

- Accessing repair manuals and technical information

The Mercedes-Benz Star Diagnosis system provides the most complete and accurate diagnostic information for Mercedes-Benz vehicles. However, it is also one of the most expensive and complex tools to use, requiring specialized training and expertise.

2.2. Autel MaxiSys Elite

The Autel MaxiSys Elite is a professional-grade aftermarket diagnostic tool that offers comparable capabilities to the Mercedes-Benz Star Diagnosis system. It features:

- Extensive vehicle coverage, including Mercedes-Benz

- Advanced diagnostic functions, such as live data streaming, bi-directional control, and coding

- User-friendly interface with a large touchscreen display

- Regular software updates to ensure compatibility with the latest Mercedes-Benz models

The Autel MaxiSys Elite is a versatile and powerful tool suitable for independent repair shops and experienced DIYers. While it may not offer all the same features as the Star Diagnosis system, it provides a comprehensive set of diagnostic capabilities at a more affordable price point.

2.3. iCarsoft MB II

The iCarsoft MB II is a more affordable and user-friendly option for accessing live data and fault codes on Mercedes-Benz vehicles. It is a handheld diagnostic tool that offers:

- Basic diagnostic functions, such as reading and clearing fault codes and viewing live data

- Coverage for most Mercedes-Benz models

- Easy-to-use interface with a color display

- Affordable price point

The iCarsoft MB II is a good option for Mercedes-Benz owners who want a simple and reliable tool for basic diagnostics and maintenance. It may not offer the advanced features of more expensive tools, but it provides essential information for troubleshooting common issues.

2.4. Carly for Mercedes

Carly for Mercedes is a mobile app that turns your smartphone or tablet into a diagnostic tool. Using a Bluetooth OBD-II adapter, Carly can:

- Read and clear fault codes

- View live data parameters

- Perform coding and customization functions

- Monitor vehicle health and maintenance schedules

Carly for Mercedes is a convenient and affordable option for accessing basic diagnostic information and performing simple customization tasks. While it may not offer the same level of functionality as dedicated diagnostic tools, it provides a user-friendly interface and a range of useful features for Mercedes-Benz owners.

2.5. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Solutions

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers a range of diagnostic solutions tailored for Mercedes-Benz vehicles. Our tools are designed to provide accurate and reliable access to live data and fault codes, empowering technicians and enthusiasts to diagnose and resolve issues effectively. Our offerings include:

- Professional-Grade Diagnostic Tools: Advanced tools with comprehensive coverage for Mercedes-Benz models, offering in-depth access to live data and fault codes.

- User-Friendly Interfaces: Intuitive designs that make it easy to navigate and interpret diagnostic information.

- Real-Time Data Analysis: Tools capable of streaming and analyzing live data in real-time, helping to pinpoint intermittent issues and validate repairs.

- Software Updates: Regular updates to ensure compatibility with the latest Mercedes-Benz models and diagnostic protocols.

- Expert Support: Access to a team of experienced technicians who can provide guidance and support in interpreting diagnostic data and troubleshooting complex issues.

- Custom Solutions: Tailored diagnostic solutions designed to meet the specific needs of independent repair shops and Mercedes-Benz enthusiasts.

By utilizing MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, you gain access to the latest diagnostic technologies and expert support, ensuring that you can accurately diagnose and repair your Mercedes-Benz vehicle.

Subscription Options

Subscription Options

3. Interpreting Live Data: Key Parameters for Mercedes Vehicles

What are the key live data parameters that are most useful for diagnosing Mercedes vehicles, and how should they be interpreted?

3.1. Engine Speed (RPM)

Engine speed, measured in revolutions per minute (RPM), is a fundamental parameter that indicates how fast the engine’s crankshaft is rotating. Monitoring RPM is crucial for assessing engine performance and diagnosing issues related to idle speed, acceleration, and overall engine health. According to a study by Bosch, deviations from the specified RPM range can indicate problems with the fuel system, ignition system, or engine control unit (ECU).

- Normal Range: The normal idle speed for most Mercedes-Benz engines is between 600 and 800 RPM.

- High RPM: High RPM at idle can indicate vacuum leaks, throttle body issues, or problems with the idle air control valve.

- Low RPM: Low RPM at idle can indicate a clogged air filter, faulty oxygen sensor, or issues with the fuel injectors.

3.2. Coolant Temperature

Coolant temperature is a critical parameter that indicates the temperature of the engine coolant. Monitoring coolant temperature is essential for preventing overheating and ensuring proper engine operation. A study by the University of Michigan found that maintaining the correct coolant temperature is vital for optimal engine efficiency and reduced emissions.

- Normal Range: The normal operating temperature for most Mercedes-Benz engines is between 80 and 100 degrees Celsius (176 and 212 degrees Fahrenheit).

- High Temperature: High coolant temperature can indicate a faulty thermostat, radiator issues, or a failing water pump.

- Low Temperature: Low coolant temperature can indicate a stuck-open thermostat or a faulty temperature sensor.

3.3. Oxygen Sensor Readings

Oxygen sensors measure the amount of oxygen in the exhaust gas. These readings are crucial for monitoring the air-fuel mixture and ensuring proper catalytic converter function. According to research by Delphi, accurate oxygen sensor readings are essential for minimizing emissions and maximizing fuel efficiency.

- Normal Range: Oxygen sensor readings typically fluctuate between 0.1 and 0.9 volts.

- High Voltage: High voltage (closer to 0.9 volts) indicates a rich air-fuel mixture.

- Low Voltage: Low voltage (closer to 0.1 volts) indicates a lean air-fuel mixture.

- Slow Response: A slow response from the oxygen sensor can indicate a failing sensor or exhaust leaks.

3.4. Fuel Trim Values

Fuel trim values indicate the adjustments that the ECU is making to the air-fuel mixture. These values are expressed as a percentage and can be used to diagnose issues with the fuel system, air intake, or exhaust system. A study by Denso found that monitoring fuel trim values can help identify the root cause of engine performance issues.

- Normal Range: Fuel trim values typically range from -10% to +10%.

- Positive Values: Positive fuel trim values indicate that the ECU is adding fuel to compensate for a lean condition.

- Negative Values: Negative fuel trim values indicate that the ECU is reducing fuel to compensate for a rich condition.

- High Values: Consistently high fuel trim values can indicate vacuum leaks, faulty mass airflow sensor, or fuel injector issues.

3.5. Mass Airflow (MAF) Sensor Readings

The MAF sensor measures the amount of air entering the engine. These readings are used by the ECU to calculate the correct amount of fuel to inject. Accurate MAF sensor readings are essential for proper engine performance and fuel efficiency. Research by Continental AG indicates that a faulty MAF sensor can lead to a variety of engine problems.

- Normal Range: MAF sensor readings vary depending on engine size and load.

- Low Readings: Low MAF sensor readings can indicate a clogged air filter, vacuum leaks, or a faulty sensor.

- High Readings: High MAF sensor readings can indicate a faulty sensor or issues with the air intake system.

3.6. Throttle Position Sensor (TPS) Readings

The TPS measures the position of the throttle plate. These readings are used by the ECU to determine the driver’s demand for power. Accurate TPS readings are essential for proper acceleration and transmission shifting. A study by Valeo found that a faulty TPS can lead to poor engine performance and transmission issues.

- Normal Range: TPS readings typically range from 0% at idle to 100% at wide-open throttle.

- Erratic Readings: Erratic TPS readings can indicate a faulty sensor or wiring issues.

- Stuck Readings: Stuck TPS readings can indicate a faulty sensor or mechanical issues with the throttle body.

3.7. Interpreting Live Data with MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we provide detailed guides and expert support to help you accurately interpret live data parameters. Our diagnostic tools offer real-time data analysis and intuitive interfaces, making it easier to identify and address potential issues. We also offer:

- Comprehensive Databases: Access to extensive databases of normal parameter ranges for various Mercedes-Benz models.

- Troubleshooting Guides: Step-by-step troubleshooting guides that provide detailed instructions on how to diagnose common issues using live data.

- Expert Support: Access to a team of experienced technicians who can provide personalized guidance and support in interpreting diagnostic data.

By leveraging our resources, you can confidently interpret live data and effectively diagnose your Mercedes-Benz vehicle.

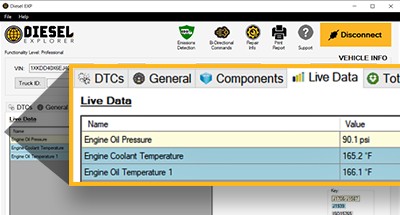

View Parameters Screen

View Parameters Screen

4. Diagnostic Strategies: Using Live Data to Troubleshoot Fault Codes

What are some effective diagnostic strategies for using live data to troubleshoot fault codes on Mercedes vehicles?

4.1. Verifying Fault Code Symptoms with Live Data

The initial step involves validating whether the symptoms indicated by the fault code align with the live data readings. For instance, if a fault code suggests a lean condition, the live data should corroborate this with elevated fuel trim values and low oxygen sensor readings. This confirmation ensures that the diagnostic efforts are focused on the correct area, thereby streamlining the troubleshooting process.

4.2. Identifying Root Causes Through Parameter Correlation

Pinpointing the root cause often requires examining the interplay between multiple live data parameters. For example, a mass airflow (MAF) sensor fault code might be linked to vacuum leaks affecting engine performance. By observing parameters such as engine RPM, fuel trim, and oxygen sensor readings, technicians can identify irregularities that point to the actual source of the issue.

4.3. Stress-Testing Components Under Various Conditions

Stress-testing components under diverse operating conditions is crucial for diagnosing intermittent faults. For instance, an oxygen sensor malfunction may only manifest during specific engine loads or temperatures. By monitoring live data while replicating these conditions, technicians can accurately assess sensor performance and capture transient anomalies that would otherwise go unnoticed.

4.4. Using Freeze Frame Data to Understand Fault Context

Freeze frame data captures a snapshot of live data at the precise moment a fault code is triggered. This information provides invaluable context, including engine speed, load, and temperature, enabling technicians to recreate the conditions leading to the fault. Analyzing freeze frame data helps identify patterns and contributing factors, facilitating more accurate and targeted diagnostics.

4.5. Comparing Readings to Known Good Values

Comparing live data readings to established baseline values for specific Mercedes-Benz models is essential for spotting deviations indicative of underlying problems. Consulting repair manuals and technical specifications offers critical insights into expected parameter ranges. Discrepancies between actual and expected values reveal potential issues with sensors, actuators, or control modules, streamlining the diagnostic process.

4.6. Leveraging MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Advanced Diagnostics

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides comprehensive diagnostic solutions designed to enhance troubleshooting capabilities. Our tools offer real-time data analysis, guided diagnostics, and access to extensive databases of known good values, empowering technicians to efficiently and accurately resolve fault codes. Additional benefits include:

- Real-time data streaming: Monitor multiple parameters simultaneously to identify correlations and anomalies.

- Guided diagnostics: Step-by-step procedures to troubleshoot fault codes efficiently.

- Comprehensive databases: Access to known good values for various Mercedes-Benz models to facilitate accurate comparisons.

- Expert support: Experienced technicians provide personalized guidance and support to interpret diagnostic data and resolve complex issues.

By utilizing MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, you can leverage advanced diagnostic strategies to effectively troubleshoot fault codes and ensure the optimal performance of your Mercedes-Benz vehicle.

5. Common Fault Codes and Related Live Data for Mercedes Vehicles

What are some common fault codes encountered in Mercedes vehicles, and what live data parameters are most relevant for diagnosing them?

5.1. P0171 and P0174: System Too Lean (Bank 1 and Bank 2)

These fault codes indicate that the engine is running with an insufficient amount of fuel, leading to potential performance and efficiency issues. Relevant live data parameters include:

- Fuel Trim Values: Positive fuel trim values exceeding 10% indicate that the ECU is adding fuel to compensate for the lean condition.

- Oxygen Sensor Readings: Low voltage readings (below 0.3V) from the oxygen sensors suggest a lean air-fuel mixture.

- Mass Airflow (MAF) Sensor Readings: Abnormally low MAF sensor readings may point to a vacuum leak or a faulty sensor.

- Engine RPM: Unstable or high idle RPM can also indicate a vacuum leak.

5.2. P0300: Random Misfire Detected

This code indicates that the engine is experiencing random misfires, which can result in rough idling, reduced power, and increased emissions. Key live data parameters include:

- Misfire Counters: Monitoring misfire counters for each cylinder can help identify specific cylinders that are misfiring.

- Engine RPM: Fluctuations in engine RPM can indicate misfires.

- Oxygen Sensor Readings: Erratic oxygen sensor readings may be a result of unburned fuel entering the exhaust system.

- Fuel Injector Pulse Width: Variations in fuel injector pulse width can suggest fuel delivery issues.

5.3. P0420: Catalyst System Efficiency Below Threshold (Bank 1)

This fault code indicates that the catalytic converter is not functioning efficiently, leading to increased emissions. Relevant live data parameters include:

- Oxygen Sensor Readings (Upstream and Downstream): Comparing the readings from the upstream and downstream oxygen sensors can help assess the catalytic converter’s efficiency.

- Engine Load: Monitoring engine load can reveal conditions under which the catalytic converter is not performing optimally.

- Exhaust Temperature: High exhaust temperatures can damage the catalytic converter and reduce its efficiency.

5.4. P0101: Mass Air Flow (MAF) Sensor Range/Performance Problem

This code suggests that the MAF sensor is not functioning correctly, which can affect engine performance and fuel efficiency. Important live data parameters include:

- MAF Sensor Readings: Comparing MAF sensor readings to known good values for the specific engine and load conditions.

- Throttle Position Sensor (TPS) Readings: Ensuring that the TPS readings correlate with the MAF sensor readings.

- Engine RPM: Monitoring engine RPM to verify that the MAF sensor readings are appropriate for the current engine speed.

5.5. B2AAA/C1AAA – Mercedes-Benz Fault Code

This fault code can pertain to various issues within Mercedes-Benz vehicles, necessitating a nuanced approach to diagnosis. Key live data parameters to consider include:

- Battery Voltage: Monitoring battery voltage to ensure it falls within the specified range.

- Charging System Performance: Assessing the alternator’s output and charging system’s overall performance.

- Module Communication: Verifying proper communication between different control modules.

5.6. Leveraging MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Fault Code Diagnosis

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides comprehensive resources to assist in diagnosing common fault codes in Mercedes vehicles. Our tools offer:

- Fault Code Libraries: Access to extensive libraries of fault codes and their associated symptoms and causes.

- Live Data Monitoring: Real-time monitoring of relevant live data parameters to aid in diagnosis.

- Guided Diagnostics: Step-by-step diagnostic procedures to help identify the root cause of fault codes.

- Expert Support: Access to experienced technicians who can provide guidance and support in interpreting diagnostic data.

By utilizing MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, you can efficiently diagnose and resolve common fault codes, ensuring the optimal performance and reliability of your Mercedes-Benz vehicle.

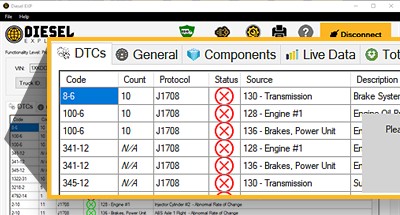

New UI – Info on DTCs

New UI – Info on DTCs

6. Advanced Diagnostic Techniques Using Live Data on Mercedes

What advanced diagnostic techniques can be employed using live data to diagnose complex issues in Mercedes vehicles?

6.1. Analyzing Data Trends Over Time

Monitoring live data parameters over extended periods provides valuable insights into long-term trends and potential degradation of components. This technique involves recording data during various driving conditions and analyzing it to identify patterns that may indicate underlying issues. For example, gradually decreasing fuel trim values may suggest a developing fuel delivery problem.

6.2. Performing Relative Compression Tests

Relative compression tests utilize live data to assess the compression of individual cylinders without physically removing spark plugs. By monitoring the crankshaft speed during engine cranking, technicians can identify cylinders with lower compression compared to others. This non-intrusive method helps diagnose issues such as worn piston rings or valve problems.

6.3. Utilizing Actuator Tests

Actuator tests involve using diagnostic tools to command specific components to activate while monitoring live data parameters. For example, activating the fuel injectors and observing the corresponding changes in fuel pressure and oxygen sensor readings can help diagnose fuel delivery issues. Actuator tests allow technicians to isolate and evaluate the performance of individual components within complex systems.

6.4. Conducting Electrical Load Tests

Electrical load tests involve applying electrical loads to circuits and monitoring voltage drops using live data. This technique helps identify issues such as corroded connections, wiring problems, or faulty components that may not be apparent under normal conditions. By measuring voltage drops under load, technicians can pinpoint the source of electrical problems and ensure proper circuit functionality.

6.5. Performing Injector Balance Tests

Injector balance tests assess the performance of individual fuel injectors by monitoring engine RPM and fuel trim values while disabling each injector one at a time. This technique helps identify injectors that are not delivering the correct amount of fuel, leading to imbalances in cylinder combustion. By comparing the RPM and fuel trim changes for each injector, technicians can pinpoint faulty injectors and ensure proper fuel delivery.

6.6. Leveraging MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Advanced Diagnostics

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides advanced diagnostic solutions designed to facilitate complex troubleshooting in Mercedes vehicles. Our tools offer:

- Data Logging Capabilities: Record live data parameters over extended periods for trend analysis.

- Actuator Control: Command specific components to activate for testing and evaluation.

- Guided Diagnostics: Step-by-step procedures for performing advanced diagnostic tests.

- Expert Support: Access to experienced technicians who can provide guidance and support in conducting complex diagnostic procedures.

By utilizing MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, you can employ advanced diagnostic techniques to efficiently and accurately diagnose complex issues in your Mercedes-Benz vehicle.

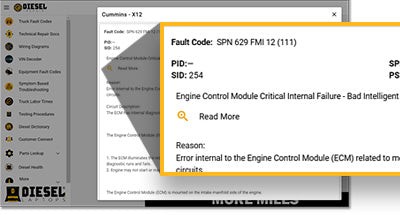

New UI – Link to Repair

New UI – Link to Repair

7. Preventative Maintenance: Using Live Data for Proactive Car

How can live data be used for preventative maintenance to avoid future problems in Mercedes vehicles?

7.1. Monitoring Engine Health Over Time

Regularly monitoring key live data parameters allows for tracking engine health trends. For instance, gradual changes in fuel trim values or oxygen sensor response times can indicate developing issues before they trigger fault codes. This proactive approach enables timely maintenance interventions, preventing potential breakdowns and costly repairs.

7.2. Assessing Transmission Performance

Monitoring transmission-related live data, such as transmission temperature, gear selector position, and torque converter slip, provides insights into the transmission’s condition. Early detection of abnormalities, like elevated transmission temperatures or excessive torque converter slip, allows for proactive maintenance, extending the transmission’s lifespan.

7.3. Evaluating Brake System Condition

Monitoring brake-related live data, including brake pad wear sensor readings and ABS wheel speed sensor data, helps assess the brake system’s condition. Identifying irregularities, such as uneven brake pad wear or ABS sensor malfunctions, enables timely brake maintenance, ensuring optimal safety and performance.

7.4. Checking Battery and Charging System Performance

Regularly monitoring battery voltage and charging system output via live data allows for assessing the health of the electrical system. Detecting issues, such as low battery voltage or insufficient alternator output, enables proactive battery replacement or charging system repairs, preventing electrical system failures.

7.5. Monitoring Emission System Performance

Tracking emission-related live data, including oxygen sensor readings, catalytic converter efficiency, and exhaust gas recirculation (EGR) system operation, facilitates assessing the emission system’s performance. Identifying abnormalities, such as decreased catalytic converter efficiency or EGR valve malfunctions, enables timely emission system maintenance, ensuring compliance with environmental regulations.

7.6. Leveraging MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Preventative Maintenance

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides comprehensive solutions for proactive car, utilizing live data to anticipate and prevent future issues. Our tools offer:

- Real-time Data Monitoring: Monitor key live data parameters to track component health trends.

- Customizable Alerts: Set up alerts to notify you of deviations from normal operating ranges.

- Maintenance Recommendations: Receive proactive maintenance recommendations based on live data analysis.

- Expert Support: Access experienced technicians for guidance on interpreting live data and implementing preventative maintenance strategies.

By utilizing MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, you can implement effective preventative maintenance strategies, ensuring the longevity, reliability, and optimal performance of your Mercedes-Benz vehicle.

New UI – Health Report

New UI – Health Report

8. Case Studies: Real-World Examples of Diagnosing Mercedes Issues with Live Data

Can you provide real-world case studies illustrating how live data is used to diagnose issues in Mercedes vehicles?

8.1. Case Study 1: Diagnosing a Lean Condition (P0171) in a Mercedes C-Class

A Mercedes C-Class owner reported a check engine light and poor fuel economy. The fault code P0171 (System Too Lean, Bank 1) was present. The technician used a diagnostic tool to monitor live data parameters, including:

- Fuel Trim Values: Long-term fuel trim (LTFT) values were consistently above +20%.

- Oxygen Sensor Readings: Oxygen sensor readings fluctuated but often remained low (below 0.3V).

- Mass Airflow (MAF) Sensor Readings: MAF sensor readings appeared normal at idle but were lower than expected under load.

Analysis: The high LTFT values indicated that the engine control unit (ECU) was adding a significant amount of fuel to compensate for a lean condition. The low oxygen sensor readings supported this diagnosis. The lower-than-expected MAF sensor readings under load suggested a possible vacuum leak.

Solution: The technician performed a smoke test to check for vacuum leaks and found a cracked intake manifold gasket. After replacing the gasket, the LTFT values returned to normal, and the check engine light turned off.

8.2. Case Study 2: Diagnosing an Intermittent Misfire (P0300) in a Mercedes E-Class

A Mercedes E-Class owner complained of occasional rough idling and hesitation during acceleration. The fault code P0300 (Random Misfire Detected) was stored in the ECU. The technician used a diagnostic tool to monitor live data parameters, including:

- Misfire Counters: Misfire counters showed occasional misfires on multiple cylinders.

- Engine RPM: Engine RPM fluctuated slightly during idling.

- Crankshaft Position Sensor (CKP) Readings: CKP readings were erratic and showed occasional dropouts.

Analysis: The intermittent misfires and erratic CKP readings suggested a possible issue with the crankshaft position sensor or its wiring.

Solution: The technician inspected the CKP sensor and its wiring and found a loose connection. After cleaning and tightening the connection, the misfires disappeared, and the engine ran smoothly.

8.3. Case Study 3: Diagnosing a Catalytic Converter Efficiency Problem (P0420) in a Mercedes S-Class

A Mercedes S-Class owner reported a check engine light and reduced fuel efficiency. The fault code P0420 (Catalyst System Efficiency Below Threshold, Bank 1) was present. The technician used a diagnostic tool to monitor live data parameters, including:

- Oxygen Sensor Readings (Upstream and Downstream): The downstream oxygen sensor readings were fluctuating similarly to the upstream sensor readings, indicating a lack of oxygen storage capacity in the catalytic converter.

- Exhaust Temperature: Exhaust temperature readings were within the normal range.

Analysis: The similar fluctuations in the upstream and downstream oxygen sensor readings indicated that the catalytic converter was not functioning efficiently and was not able to store oxygen.

Solution: The technician recommended replacing the catalytic converter. After replacing the catalytic converter, the downstream oxygen sensor readings stabilized, and the check engine light turned off.

8.4. How MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Aids in Real-World Diagnoses

These case studies illustrate how live data, combined with the right diagnostic tools and expertise, can be used to effectively diagnose issues in Mercedes vehicles. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides the tools and resources needed to perform these types of diagnoses, including:

- Comprehensive Diagnostic Tools: Access to tools that can read and interpret live data from all vehicle systems.

- Extensive Fault Code Libraries: Access to libraries of fault codes and their associated symptoms and causes.

- Expert Support: Access to experienced technicians who can provide guidance and support in interpreting diagnostic data.

By utilizing MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, you can effectively diagnose and resolve issues in your Mercedes-Benz vehicle, ensuring optimal performance and reliability.

Component Info Screen

Component Info Screen

9. The Future of Diagnostics: How Live Data and AI Will Transform Car

How will advancements in live data analysis and artificial intelligence (AI) impact car in the future?

9.1. Predictive Maintenance

AI algorithms can analyze historical and real-time live data to predict potential component failures before they occur. By identifying patterns and anomalies that indicate developing issues, AI can enable predictive maintenance, allowing for timely repairs and preventing breakdowns. This proactive approach minimizes downtime and reduces maintenance costs.

9.2. Remote Diagnostics

Advancements in connectivity and data transmission enable remote diagnostics, allowing technicians to access live data and perform diagnostic tests from remote locations. This technology is particularly valuable for diagnosing issues in vehicles located in remote areas or for providing support to technicians in the field. Remote diagnostics reduces diagnostic time and improves the efficiency of car operations.

9.3. Automated Troubleshooting

AI-powered diagnostic systems can automatically analyze live data and fault codes to identify the root cause of issues and recommend appropriate repair procedures. These systems utilize machine learning algorithms to learn from historical data and improve their diagnostic accuracy over time. Automated troubleshooting reduces diagnostic time and minimizes the need for expert technician intervention.

9.4. Personalized Car Recommendations

AI can analyze live data to provide personalized car recommendations based on individual driving habits and vehicle usage patterns. These recommendations can include suggestions for optimizing fuel efficiency, improving vehicle performance, and extending component lifespan. Personalized car promotes proactive car and enhances the overall ownership experience.

9.5. Over-the-Air (OTA) Updates

Advancements in connectivity enable over-the-air (OTA) updates, allowing manufacturers to remotely update vehicle software and firmware. These updates can include bug fixes, performance improvements, and new features. OTA updates ensure that vehicles are always running the latest software, enhancing their performance, security, and functionality.

9.6. The Role of MERCEDES-DIAGNOSTIC-TOOL.EDU.VN in the Future of Car

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN is committed to staying at the forefront of diagnostic technology and is actively developing solutions that leverage live data and AI to transform car. Our future initiatives include:

- AI-Powered Diagnostic Tools: Developing diagnostic tools that utilize AI algorithms to automate troubleshooting and provide predictive maintenance recommendations.

- Remote Diagnostic Capabilities: Expanding our remote diagnostic capabilities to provide support to technicians and vehicle owners in remote locations.

- Personalized Car Solutions: Developing personalized car solutions that provide tailored recommendations based on individual driving habits and vehicle usage patterns.

By embracing these advancements, MERCEDES-DIAGNOSTIC-TOOL.EDU.VN will continue to provide innovative solutions that empower technicians and vehicle owners to effectively diagnose, maintain, and optimize their Mercedes-Benz vehicles.

10. FAQ: Live Data and Fault Codes

Have some lingering questions? Let’s address some frequently asked questions about live data and fault codes.

10.1. What Is Live Data?

Live data refers to the real-time information provided by a vehicle’s sensors and control units. It includes parameters such as engine speed, coolant temperature, oxygen sensor readings, and fuel trim values.

10.2. What Are Fault Codes?

Fault codes, also known as Diagnostic Trouble Codes (DTCs), are codes stored in a vehicle’s computer system when a sensor reading falls outside the manufacturer’s specified range.

10.3. How Are Live Data and Fault Codes Related?

Fault codes are often triggered when live data readings fall outside predefined parameters. Live data is used to investigate the underlying cause of a fault code and validate repairs.

10.4. What Tools Can I Use to Access Live Data and Fault Codes on My Mercedes?

Tools include Mercedes-Benz Star Diagnosis, Autel MaxiSys Elite, iCarsoft MB II, and Carly for Mercedes. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers tailored diagnostic solutions.

10.5. What Are Some Key Live Data Parameters to Monitor on a Mercedes?

Key parameters include engine speed (RPM), coolant temperature, oxygen sensor readings, fuel trim values, and mass airflow (MAF) sensor readings.

10.6. How Can I Use Live Data to Diagnose a Fault Code?

Verify fault code symptoms with live data, identify root causes through parameter correlation, and compare readings to known good values.

10.7. What Are Common Fault Codes in Mercedes Vehicles and Their Related Live Data?

Common fault codes include P0171 (System Too Lean), P0300 (Random Misfire), and P0420 (Catalyst System Efficiency Below Threshold). Relevant live data parameters vary depending on the fault code.

10.8. Can Live Data Be Used for Preventative Maintenance?

Yes, monitoring live data over time allows for tracking engine health trends and detecting potential issues before they trigger fault codes.

10.9. How Will AI and Live Data Transform Car in the Future?

AI can enable predictive maintenance, remote diagnostics, automated troubleshooting, and personalized car recommendations.

10.10. How Can MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Help Me with My Mercedes Diagnostics?

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers comprehensive diagnostic tools, fault code libraries, expert support, and advanced diagnostic techniques to assist in diagnosing and maintaining your Mercedes-Benz vehicle.

Ready to take control of your Mercedes-Benz diagnostics? Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN today for expert advice and the tools you need to keep your vehicle running smoothly.

Contact Us:

- Address: 789 Oak Avenue, Miami, FL 33101, United States

- WhatsApp: +1 (641) 206-8880

- Website: MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

Don’t wait—reach out now and experience the power of accurate diagnostics with MERCEDES-DIAGNOSTIC-TOOL.EDU.VN.