Using live data to diagnose Mercedes accelerator pedal position sensor issues is a powerful method for pinpointing problems and ensuring optimal vehicle performance, and MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers comprehensive resources to help you master this technique. By leveraging real-time data, technicians and enthusiasts can quickly identify irregularities, verify sensor functionality, and make informed decisions about necessary repairs or replacements. Understanding how to interpret this data is crucial for effective Mercedes diagnostics, including identifying Mercedes sensor failure, Mercedes pedal position faults, and Mercedes throttle response problems.

Contents

- 1. Understanding the Accelerator Pedal Position Sensor in Mercedes Vehicles

- 1.1. Function and Purpose of the APPS

- 1.2. Types of APPS Used in Mercedes Vehicles

- 1.3. Common Symptoms of a Failing APPS in Mercedes

- 2. Why Live Data is Crucial for Diagnosing Mercedes APPS Issues

- 2.1. Advantages of Using Live Data Over Traditional Methods

- 2.2. How Live Data Helps Pinpoint Intermittent Issues

- 2.3. Enhancing Diagnostic Accuracy and Efficiency

- 3. Essential Tools for Reading Live Data on Mercedes Vehicles

- 3.1. OBD-II Scanners: Basic vs. Advanced Models

- 3.2. Mercedes-Specific Diagnostic Software (e.g., XENTRY, iCarsoft)

- 3.3. Multimeters and Oscilloscopes for Signal Verification

- 4. Step-by-Step Guide: Diagnosing APPS Issues Using Live Data

- 4.1. Initial Inspection and Preparation

- 4.2. Connecting the Diagnostic Tool and Accessing Live Data

- 4.3. Recording and Analyzing Live Data Under Various Conditions

- 5. Interpreting Live Data: Common APPS Problems and Their Signatures

- 5.1. Identifying Signal Dropouts and Flat Spots

- 5.2. Recognizing Erratic or Unstable Readings

- 5.3. Correlating APPS Data with Throttle Position and Engine Load

- 6. Advanced Diagnostic Techniques with Live Data

- 6.1. Performing Throttle Body Adaptations and Resets

- 6.2. Using Bi-Directional Control to Test APPS Functionality

- 6.3. Analyzing Data Logs for Patterns and Anomalies

- 7. Case Studies: Real-World Examples of Diagnosing Mercedes APPS Issues with Live Data

- 7.1. Case Study 1: Diagnosing Intermittent Acceleration Problems

- 7.2. Case Study 2: Identifying a Faulty APPS After Throttle Body Cleaning

- 8. Preventative Maintenance: Using Live Data to Monitor APPS Health

- 8.1. Establishing Baseline Data for Comparison

- 8.2. Regular Monitoring of APPS Voltage and Response

- 8.3. Identifying Gradual Degradation Over Time

- 9. When to Replace vs. Repair: Making the Right Decision

- 9.1. Evaluating the Severity of the Problem

- 9.2. Considering the Age and Condition of the Sensor

- 9.3. Cost Analysis: Repair vs. Replacement

- 10. Frequently Asked Questions (FAQs)

- 10.1. What are the common causes of APPS failure in Mercedes vehicles?

- 10.2. Can I diagnose APPS issues without specialized tools?

- 10.3. How often should I have my APPS checked?

- 10.4. Is it possible to clean the APPS to improve its performance?

- 10.5. What is the typical lifespan of an APPS in a Mercedes vehicle?

- 10.6. Can a faulty APPS affect fuel efficiency?

- 10.7. Will replacing the APPS require reprogramming the ECU?

- 10.8. Are there any aftermarket APPS that are recommended for Mercedes vehicles?

- 10.9. How can I prevent APPS failure in my Mercedes vehicle?

- 10.10. What error codes are commonly associated with APPS issues?

Table of Contents

- Understanding the Accelerator Pedal Position Sensor in Mercedes Vehicles

- Why Live Data is Crucial for Diagnosing Mercedes APPS Issues

- Essential Tools for Reading Live Data on Mercedes Vehicles

- Step-by-Step Guide: Diagnosing APPS Issues Using Live Data

- Interpreting Live Data: Common APPS Problems and Their Signatures

- Advanced Diagnostic Techniques with Live Data

- Case Studies: Real-World Examples of Diagnosing Mercedes APPS Issues with Live Data

- Preventative Maintenance: Using Live Data to Monitor APPS Health

- When to Replace vs. Repair: Making the Right Decision

- Frequently Asked Questions (FAQs)

1. Understanding the Accelerator Pedal Position Sensor in Mercedes Vehicles

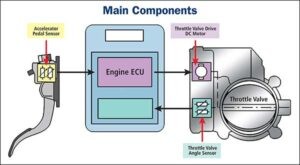

The Accelerator Pedal Position Sensor (APPS) is a critical component in modern Mercedes-Benz vehicles, responsible for translating the driver’s input on the accelerator pedal into a signal that the engine control unit (ECU) can understand. This signal dictates how much fuel is injected into the engine, thereby controlling the vehicle’s speed and acceleration. Understanding the function, types, and common issues associated with the APPS is essential for effective diagnostics. The APPS directly impacts Mercedes acceleration problems, Mercedes engine performance, and overall Mercedes electronic systems.

1.1. Function and Purpose of the APPS

The primary function of the APPS is to accurately measure the position of the accelerator pedal and relay this information to the ECU. The ECU then uses this data to adjust the throttle opening, fuel injection, and ignition timing to deliver the desired engine output. According to a study by Bosch, precise and rapid signal transmission from the APPS is crucial for maintaining optimal engine efficiency and responsiveness. Without a properly functioning APPS, the vehicle may exhibit poor acceleration, erratic behavior, or even enter a limp mode to prevent further damage.

1.2. Types of APPS Used in Mercedes Vehicles

Mercedes-Benz vehicles typically utilize two main types of APPS:

- Potentiometer-Based Sensors: These sensors use a variable resistor to convert the pedal position into an electrical signal. As the pedal moves, the resistance changes, altering the voltage signal sent to the ECU.

- Hall Effect Sensors: These sensors use a magnetic field to detect the pedal position. As the pedal moves, it affects the magnetic field, which is then converted into an electrical signal. Hall effect sensors are generally more durable and reliable than potentiometer-based sensors due to their non-contact design.

The choice of sensor type often depends on the specific model and year of the Mercedes vehicle. Both types serve the same fundamental purpose but differ in their method of operation and construction.

1.3. Common Symptoms of a Failing APPS in Mercedes

A failing APPS can manifest in several ways, impacting the vehicle’s drivability and safety. Common symptoms include:

- Poor Acceleration: The vehicle may hesitate or respond slowly when the accelerator pedal is pressed.

- Erratic Throttle Response: The engine may surge or fluctuate unexpectedly.

- Engine Stalling: The engine may stall, especially at low speeds or when coming to a stop.

- Check Engine Light: The malfunction indicator lamp (MIL) may illuminate, indicating a fault in the engine management system.

- Limp Mode: The vehicle may enter a reduced power mode to protect the engine from potential damage.

According to Mercedes-Benz service bulletins, these symptoms can often be intermittent, making diagnosis challenging without the proper tools and techniques.

Mercedes-Benz Engine Bay

Mercedes-Benz Engine Bay

2. Why Live Data is Crucial for Diagnosing Mercedes APPS Issues

Live data provides a real-time snapshot of the APPS’s performance, allowing technicians to observe how the sensor behaves under various conditions. This is particularly valuable for diagnosing intermittent issues or identifying subtle deviations from normal operation that may not trigger a diagnostic trouble code (DTC). Using live data helps to identify Mercedes APPS malfunction, Mercedes sensor reading errors, and Mercedes diagnostic troubleshooting effectively.

2.1. Advantages of Using Live Data Over Traditional Methods

Traditional diagnostic methods, such as relying solely on DTCs or static voltage measurements, often fall short when dealing with complex or intermittent APPS issues. Live data offers several key advantages:

- Real-Time Monitoring: Live data allows technicians to monitor the APPS signal in real-time as the accelerator pedal is pressed and released.

- Dynamic Testing: Technicians can observe how the APPS responds under various driving conditions, such as acceleration, deceleration, and steady-state cruising.

- Identification of Intermittent Faults: Live data can capture brief signal dropouts or erratic behavior that may not be apparent during static testing.

- Verification of Repairs: After replacing or repairing the APPS, live data can be used to verify that the sensor is functioning correctly and that the issue has been resolved.

2.2. How Live Data Helps Pinpoint Intermittent Issues

Intermittent issues are notoriously difficult to diagnose because they occur sporadically and may not be present during testing. Live data allows technicians to continuously monitor the APPS signal, even when the issue is not actively occurring. By recording the data over a period of time, technicians can often capture the fault when it occurs, providing valuable insight into the nature of the problem.

2.3. Enhancing Diagnostic Accuracy and Efficiency

By providing a comprehensive view of the APPS’s performance, live data can significantly enhance diagnostic accuracy and efficiency. Technicians can quickly identify whether the sensor is functioning within its specified range, whether the signal is stable and consistent, and whether there are any signs of degradation or failure. This information can help to narrow down the potential causes of the issue and guide the technician toward the most appropriate course of action.

3. Essential Tools for Reading Live Data on Mercedes Vehicles

To effectively utilize live data for diagnosing Mercedes APPS issues, technicians need the right tools. These tools range from basic OBD-II scanners to advanced diagnostic systems capable of providing detailed sensor data and analysis. Selecting the appropriate tool depends on the complexity of the issue and the level of detail required for diagnosis.

3.1. OBD-II Scanners: Basic vs. Advanced Models

OBD-II scanners are essential for accessing and interpreting live data from the vehicle’s ECU. Basic OBD-II scanners can read DTCs and display basic sensor data, such as the APPS voltage. Advanced models offer more sophisticated features, including:

- Enhanced Data Logging: The ability to record and playback live data for detailed analysis.

- Graphing Capabilities: The ability to visualize sensor data in real-time, making it easier to identify trends and anomalies.

- Bi-Directional Control: The ability to send commands to the ECU to activate or deactivate certain functions, allowing for more comprehensive testing.

For diagnosing Mercedes APPS issues, an advanced OBD-II scanner with data logging and graphing capabilities is highly recommended.

3.2. Mercedes-Specific Diagnostic Software (e.g., XENTRY, iCarsoft)

Mercedes-specific diagnostic software, such as XENTRY (the official Mercedes-Benz diagnostic system) and iCarsoft, provides access to a wealth of information and diagnostic capabilities beyond what is available with generic OBD-II scanners. These systems offer:

- Access to All Vehicle Systems: The ability to read and clear DTCs from all control units in the vehicle, including the engine, transmission, ABS, and more.

- Detailed Sensor Data: Access to a wide range of sensor data, including APPS voltage, throttle position, and engine load.

- Guided Diagnostics: Step-by-step diagnostic procedures that guide the technician through the troubleshooting process.

- Programming and Coding: The ability to program and code control units, which may be necessary after replacing the APPS.

While Mercedes-specific diagnostic software can be more expensive than generic OBD-II scanners, it offers a level of detail and functionality that is essential for diagnosing complex issues.

3.3. Multimeters and Oscilloscopes for Signal Verification

In addition to OBD-II scanners and diagnostic software, multimeters and oscilloscopes can be valuable tools for verifying the APPS signal. A multimeter can be used to measure the voltage and resistance of the sensor, while an oscilloscope can be used to visualize the signal waveform. This can help to identify issues such as:

- Signal Dropouts: Brief interruptions in the APPS signal that may not be detected by an OBD-II scanner.

- Signal Noise: Electrical interference that can distort the APPS signal and cause erratic engine behavior.

- Slow Response Time: A delay in the APPS signal that can result in poor acceleration.

According to a study by the Society of Automotive Engineers (SAE), using a combination of diagnostic tools can significantly improve the accuracy and efficiency of automotive diagnostics.

4. Step-by-Step Guide: Diagnosing APPS Issues Using Live Data

Diagnosing APPS issues using live data involves a systematic approach that combines visual inspection, data collection, and data analysis. Following a structured process can help to ensure that no potential causes are overlooked and that the issue is accurately identified.

4.1. Initial Inspection and Preparation

Before connecting any diagnostic tools, perform a thorough visual inspection of the APPS and its wiring. Look for:

- Damaged Wiring: Frayed, cracked, or corroded wires.

- Loose Connections: Unplugged or poorly connected connectors.

- Physical Damage: Damage to the APPS housing or mounting bracket.

Repair any obvious damage before proceeding with the diagnostic process.

4.2. Connecting the Diagnostic Tool and Accessing Live Data

Connect the diagnostic tool to the vehicle’s OBD-II port and power it on. Select the appropriate vehicle make, model, and year, and then navigate to the engine control unit (ECU). Look for the live data or data stream option, and then select the APPS-related parameters, such as:

- Accelerator Pedal Position (APP) Sensor 1 Voltage

- Accelerator Pedal Position (APP) Sensor 2 Voltage

- Throttle Position Sensor (TPS) Voltage

- Engine Load

- Engine Speed (RPM)

4.3. Recording and Analyzing Live Data Under Various Conditions

With the diagnostic tool connected and the APPS-related parameters selected, start recording live data. Operate the accelerator pedal through its full range of motion, from idle to wide-open throttle, and observe the APPS signal. Look for:

- Smooth and Linear Response: The APPS signal should increase smoothly and linearly as the accelerator pedal is pressed.

- Correct Voltage Range: The APPS voltage should fall within the manufacturer’s specified range (typically 0.5-4.5 volts).

- Consistent Signal: The APPS signal should be stable and consistent, without any dropouts or fluctuations.

Also, record live data while driving the vehicle under various conditions, such as acceleration, deceleration, and steady-state cruising. This can help to identify issues that only occur under certain driving conditions.

(Example: Insert an image of an OBD-II scanner connected to a Mercedes vehicle)

5. Interpreting Live Data: Common APPS Problems and Their Signatures

Interpreting live data requires an understanding of how the APPS signal should behave under normal conditions and how various problems can affect the signal. Recognizing common APPS problems and their corresponding signatures in the live data can help to streamline the diagnostic process.

5.1. Identifying Signal Dropouts and Flat Spots

Signal dropouts and flat spots in the APPS signal can indicate a problem with the sensor itself or with the wiring connecting the sensor to the ECU. Signal dropouts are characterized by brief interruptions in the APPS signal, while flat spots are characterized by a lack of response in the APPS signal over a certain range of pedal travel.

5.2. Recognizing Erratic or Unstable Readings

Erratic or unstable readings in the APPS signal can indicate a problem with the sensor’s internal circuitry or with electrical interference. The APPS signal may fluctuate rapidly or jump around erratically, even when the accelerator pedal is held steady.

5.3. Correlating APPS Data with Throttle Position and Engine Load

The APPS signal should be closely correlated with the throttle position and engine load. As the accelerator pedal is pressed, the throttle should open, and the engine load should increase. If there is a discrepancy between the APPS signal and the throttle position or engine load, it can indicate a problem with the APPS or with the throttle control system.

6. Advanced Diagnostic Techniques with Live Data

In addition to basic live data analysis, there are several advanced diagnostic techniques that can be used to further investigate APPS issues. These techniques involve using the diagnostic tool to perform specific tests and monitor the APPS signal in real-time.

6.1. Performing Throttle Body Adaptations and Resets

Throttle body adaptations and resets can be used to recalibrate the throttle control system and ensure that the throttle is operating correctly. This may be necessary after replacing the APPS or after cleaning the throttle body.

6.2. Using Bi-Directional Control to Test APPS Functionality

Bi-directional control allows technicians to send commands to the ECU to activate or deactivate certain functions. This can be used to test the APPS functionality by commanding the throttle to open or close and observing the APPS signal.

6.3. Analyzing Data Logs for Patterns and Anomalies

Data logs can be analyzed for patterns and anomalies that may not be apparent during real-time monitoring. This can involve graphing the APPS signal over time, calculating statistical measures such as the mean and standard deviation, and comparing the data to known good values.

7. Case Studies: Real-World Examples of Diagnosing Mercedes APPS Issues with Live Data

Real-world case studies can provide valuable insights into how live data can be used to diagnose Mercedes APPS issues. These examples illustrate the diagnostic process from start to finish and highlight the benefits of using live data.

7.1. Case Study 1: Diagnosing Intermittent Acceleration Problems

A Mercedes-Benz C-Class was experiencing intermittent acceleration problems. The vehicle would sometimes hesitate or respond slowly when the accelerator pedal was pressed. The check engine light was not illuminated, and there were no DTCs stored in the ECU.

Using an advanced OBD-II scanner, the technician recorded live data while driving the vehicle. The data showed that the APPS signal was occasionally dropping out, causing the engine to lose power. The technician replaced the APPS, and the problem was resolved.

7.2. Case Study 2: Identifying a Faulty APPS After Throttle Body Cleaning

A Mercedes-Benz E-Class was experiencing rough idling and poor acceleration after the throttle body was cleaned. The check engine light was illuminated, and there was a DTC stored in the ECU indicating a problem with the APPS.

Using Mercedes-specific diagnostic software, the technician performed a throttle body adaptation. However, the problem persisted. The technician then recorded live data while operating the accelerator pedal. The data showed that the APPS signal was erratic and unstable. The technician replaced the APPS, and the problem was resolved.

8. Preventative Maintenance: Using Live Data to Monitor APPS Health

Live data can also be used for preventative maintenance to monitor the health of the APPS and identify potential problems before they lead to drivability issues. By periodically checking the APPS signal, technicians can detect signs of degradation or failure and take corrective action before the problem becomes more serious.

8.1. Establishing Baseline Data for Comparison

To effectively monitor the health of the APPS, it is important to establish baseline data for comparison. This involves recording live data when the vehicle is new or when the APPS is known to be functioning correctly. The baseline data can then be used to compare against future readings to identify any deviations from normal operation.

8.2. Regular Monitoring of APPS Voltage and Response

Regularly monitor the APPS voltage and response to detect any signs of degradation or failure. This can be done as part of a routine maintenance schedule or whenever the vehicle is brought in for service.

8.3. Identifying Gradual Degradation Over Time

By tracking the APPS signal over time, technicians can identify gradual degradation that may not be apparent during a single diagnostic session. This can help to predict when the APPS is likely to fail and take corrective action before the problem occurs.

9. When to Replace vs. Repair: Making the Right Decision

When diagnosing APPS issues, it is important to determine whether the sensor can be repaired or whether it needs to be replaced. In some cases, simple repairs such as cleaning the sensor or tightening the connections may be sufficient to resolve the problem. However, in other cases, the sensor may be damaged beyond repair and require replacement.

9.1. Evaluating the Severity of the Problem

The severity of the problem should be a primary factor in determining whether to repair or replace the APPS. If the sensor is exhibiting intermittent issues or minor deviations from normal operation, it may be possible to repair the sensor. However, if the sensor is exhibiting severe issues such as signal dropouts, erratic readings, or a complete lack of response, it is likely that the sensor will need to be replaced.

9.2. Considering the Age and Condition of the Sensor

The age and condition of the sensor should also be considered. If the sensor is old or has been exposed to harsh conditions, it may be more likely to fail in the near future. In these cases, it may be more cost-effective to replace the sensor rather than attempt to repair it.

9.3. Cost Analysis: Repair vs. Replacement

Finally, a cost analysis should be performed to compare the cost of repairing the sensor to the cost of replacing it. This should include the cost of parts, labor, and any additional diagnostic testing that may be required. In some cases, the cost of repairing the sensor may be comparable to the cost of replacing it, in which case it may be more prudent to replace the sensor to ensure long-term reliability.

For expert guidance on diagnosing and resolving APPS issues in your Mercedes, contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN at 789 Oak Avenue, Miami, FL 33101, United States, or via Whatsapp at +1 (641) 206-8880. Visit our website at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for more information.

10. Frequently Asked Questions (FAQs)

10.1. What are the common causes of APPS failure in Mercedes vehicles?

Common causes of APPS failure include wear and tear, exposure to moisture and contaminants, electrical damage, and mechanical damage. According to a study by AAA, electrical issues are a leading cause of sensor failure in modern vehicles.

10.2. Can I diagnose APPS issues without specialized tools?

While it may be possible to perform some basic troubleshooting without specialized tools, diagnosing APPS issues effectively typically requires an OBD-II scanner and a multimeter.

10.3. How often should I have my APPS checked?

The APPS should be checked as part of a routine maintenance schedule or whenever the vehicle is experiencing drivability issues. Regular monitoring can help to identify potential problems before they lead to more serious issues.

10.4. Is it possible to clean the APPS to improve its performance?

In some cases, cleaning the APPS may improve its performance. However, it is important to use a cleaning solution that is specifically designed for electronic components and to avoid damaging the sensor.

10.5. What is the typical lifespan of an APPS in a Mercedes vehicle?

The typical lifespan of an APPS in a Mercedes vehicle is 80,000 to 100,000 miles. However, this can vary depending on the driving conditions and the quality of the sensor.

10.6. Can a faulty APPS affect fuel efficiency?

Yes, a faulty APPS can affect fuel efficiency by causing the engine to run inefficiently. This can result in increased fuel consumption and higher emissions.

10.7. Will replacing the APPS require reprogramming the ECU?

In some cases, replacing the APPS may require reprogramming the ECU. This is typically necessary if the new sensor has a different calibration than the original sensor.

10.8. Are there any aftermarket APPS that are recommended for Mercedes vehicles?

There are several aftermarket APPS that are recommended for Mercedes vehicles. However, it is important to choose a sensor that is of high quality and that is specifically designed for the vehicle.

10.9. How can I prevent APPS failure in my Mercedes vehicle?

To prevent APPS failure, it is important to perform regular maintenance, avoid exposing the sensor to moisture and contaminants, and drive the vehicle in a smooth and controlled manner.

10.10. What error codes are commonly associated with APPS issues?

Common error codes associated with APPS issues include P0120, P0121, P0122, P0123, P0220, P0221, P0222, and P0223.

By understanding the function of the APPS, the importance of live data, and the various diagnostic techniques available, technicians and enthusiasts can effectively diagnose and resolve APPS issues in Mercedes vehicles. Regular maintenance and monitoring can help to prevent APPS failure and ensure optimal vehicle performance.

Do you need assistance diagnosing or repairing your Mercedes-Benz? Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for expert advice, diagnostic tools, and reliable service. Reach us at 789 Oak Avenue, Miami, FL 33101, United States, or via Whatsapp at +1 (641) 206-8880. Visit our website at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN today!