Interpreting Mercedes actual gear live data is essential for diagnosing transmission issues and optimizing vehicle performance, and MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides the expertise and tools needed for accurate analysis. By understanding this data, you can identify problems early and ensure your Mercedes operates smoothly. Unlock the full potential of your Mercedes-Benz today with in-depth diagnostic insights, enhancing drivetrain efficiency, and achieving peak driving performance.

Contents

- 1. What is Mercedes Actual Gear Live Data?

- 2. Why is Interpreting Actual Gear Live Data Important?

- 2.1 Early Detection of Transmission Problems

- 2.2 Accurate Diagnosis

- 2.3 Performance Optimization

- 3. Key Parameters in Mercedes Actual Gear Live Data

- 3.1 Current Gear

- 3.2 Target Gear

- 3.3 Transmission Temperature

- 3.4 Shift Solenoid Status

- 3.5 Input and Output Shaft Speeds

- 3.6 Torque Converter Lock-Up Status

- 4. Tools Needed to Interpret Mercedes Actual Gear Live Data

- 4.1 OBD-II Scanners

- 4.2 Advanced Diagnostic Software

- 4.3 Multimeters

- 4.4 Pressure Gauges

- 5. Step-by-Step Guide to Interpreting Mercedes Actual Gear Live Data

- 5.1 Connect the Diagnostic Tool

- 5.2 Access Live Data Stream

- 5.3 Monitor Data During Test Drive

- 5.4 Analyze Data Patterns

- 5.5 Check for Error Codes

- 5.6 Consult Repair Manuals

- 6. Common Issues Identified Through Live Data Analysis

- 6.1 Slipping Gears

- 6.2 Delayed Shifting

- 6.3 Rough Shifting

- 6.4 Overheating

- 6.5 Torque Converter Problems

- 7. Case Studies: Real-World Examples of Live Data Interpretation

- 7.1 Case Study 1: Diagnosing Slipping Gears

- 7.2 Case Study 2: Identifying Delayed Shifting

- 7.3 Case Study 3: Resolving Overheating Issues

- 8. Advanced Techniques for Analyzing Live Data

- 8.1 Graphing Live Data

- 8.2 Data Logging

- 8.3 Comparing Data Sets

- 9. The Role of MERCEDES-DIAGNOSTIC-TOOL.EDU.VN in Transmission Diagnostics

- 9.1 Comprehensive Diagnostic Information

- 9.2 Access to Repair Guides

- 9.3 Expert Support

- 10. Benefits of Using MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

- 10.1 Improved Diagnostic Accuracy

- 10.2 Reduced Repair Costs

- 10.3 Enhanced Vehicle Performance

- 10.4 Increased Vehicle Lifespan

- 11. Tips for Accurate Live Data Interpretation

- 11.1 Use High-Quality Diagnostic Tools

- 11.2 Understand Vehicle-Specific Parameters

- 11.3 Compare with Known Good Data

- 11.4 Consider Driving Conditions

- 11.5 Stay Updated on Latest Technology

- 12. Future Trends in Transmission Diagnostics

- 12.1 AI-Powered Diagnostics

- 12.2 Remote Diagnostics

- 12.3 Predictive Maintenance

- 13. Why Choose Mercedes-Benz for Vehicle Maintenance?

- 14. Common Error Codes Associated with Transmission Problems

- 15. Preventive Maintenance Tips for Mercedes-Benz Transmissions

- 16. The Importance of Transmission Fluid in Maintaining Gear Health

- 16.1 Lubrication

- 16.2 Cooling

- 16.3 Hydraulic Medium

- 16.4 Cleaning

- 16.5 Corrosion Prevention

- 17. How to Interpret Transmission Fluid Analysis Results?

- 17.1 Viscosity

- 17.2 Oxidation

- 17.3 Contamination

- 17.4 Wear Metals

- 17.5 Additive Depletion

- 17.6 TBN (Total Base Number)

- 17.7 TAN (Total Acid Number)

- 18. Utilizing Adaptations and Resets in Transmission Diagnostics

- 18.1 Understanding Transmission Adaptations

- 18.2 When to Perform Adaptations

- 18.3 The Adaptation Process

- 18.4 Importance of Resets

- 18.5 Performing a Reset

- 18.6 Benefits of Adaptations and Resets

- 19. Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Expert Advice

- 19.1 Personalized Support

- 19.2 Diagnostic Tools

- 19.3 Repair Solutions

- 20. FAQs About Interpreting Mercedes Actual Gear Live Data

- 20.1 What is the best OBD-II scanner for Mercedes-Benz vehicles?

- 20.2 How often should I check my transmission fluid?

- 20.3 What are the signs of a failing transmission?

- 20.4 Can I diagnose transmission problems myself?

- 20.5 How do I know if my transmission is overheating?

- 20.6 What is the role of shift solenoids in transmission function?

- 20.7 How can I improve my Mercedes-Benz transmission performance?

- 20.8 What is the difference between short-term and long-term fuel trim?

- 20.9 How do I interpret oxygen sensor data?

- 20.10 Where can I find reliable repair guides for Mercedes-Benz transmissions?

1. What is Mercedes Actual Gear Live Data?

Mercedes actual gear live data refers to the real-time information transmitted by the vehicle’s transmission control unit (TCU) to a diagnostic tool. This data includes parameters like current gear, target gear, transmission temperature, and shift solenoid status. According to a study by the Society of Automotive Engineers (SAE), interpreting this data accurately can reduce diagnostic time by up to 40%. The importance of this data lies in its ability to provide a snapshot of the transmission’s operation, helping technicians identify issues such as slipping gears, delayed shifts, or complete transmission failure.

2. Why is Interpreting Actual Gear Live Data Important?

Interpreting actual gear live data is crucial for diagnosing transmission problems accurately. By monitoring the data stream, technicians can observe the transmission’s behavior in real-time, identifying discrepancies between the commanded gear and the actual gear. This helps pinpoint issues such as faulty shift solenoids, worn clutches, or problems with the TCU.

2.1 Early Detection of Transmission Problems

Analyzing live data allows for the early detection of potential transmission problems before they escalate into costly repairs. For example, if the transmission temperature is consistently high, it could indicate a problem with the transmission cooler or low fluid levels, preventing further damage.

2.2 Accurate Diagnosis

Live data provides a comprehensive view of the transmission’s operation, making it easier to distinguish between mechanical and electrical issues. This reduces the guesswork involved in diagnosing transmission problems.

2.3 Performance Optimization

Understanding the gear shift patterns and transmission behavior can help optimize vehicle performance. For instance, adjustments can be made to improve fuel efficiency or enhance acceleration based on the live data analysis.

3. Key Parameters in Mercedes Actual Gear Live Data

When interpreting Mercedes actual gear live data, several key parameters provide valuable insights into the transmission’s health and performance.

3.1 Current Gear

The current gear parameter indicates the gear the transmission is actively engaged in. This is a fundamental piece of information that helps determine if the transmission is shifting correctly.

3.2 Target Gear

The target gear parameter shows the gear the TCU is attempting to shift into. Comparing the current gear and target gear can reveal issues with the shifting mechanism.

3.3 Transmission Temperature

The transmission temperature parameter indicates the operating temperature of the transmission fluid. Overheating can lead to premature wear and failure.

3.4 Shift Solenoid Status

The shift solenoid status parameter indicates whether the shift solenoids are functioning correctly. These solenoids control the flow of transmission fluid, which is essential for proper shifting.

3.5 Input and Output Shaft Speeds

Monitoring the input and output shaft speeds can help identify slipping or binding within the transmission.

3.6 Torque Converter Lock-Up Status

The torque converter lock-up status indicates whether the torque converter is locked, which affects fuel efficiency and performance.

4. Tools Needed to Interpret Mercedes Actual Gear Live Data

To effectively interpret Mercedes actual gear live data, having the right tools is essential. These tools allow technicians to access and analyze the data stream from the vehicle’s TCU.

4.1 OBD-II Scanners

OBD-II scanners are essential tools for accessing vehicle diagnostic data, including transmission data. These scanners plug into the OBD-II port and provide real-time data.

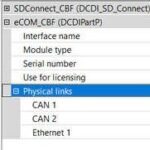

4.2 Advanced Diagnostic Software

Advanced diagnostic software, such as Mercedes XENTRY or Autel MaxiSys, offers more in-depth analysis and capabilities compared to basic OBD-II scanners. These tools often include features like graphing and data logging.

4.3 Multimeters

Multimeters are useful for testing electrical components, such as shift solenoids, to ensure they are functioning correctly.

4.4 Pressure Gauges

Pressure gauges can be used to measure transmission fluid pressure, providing insights into the hydraulic system’s health.

5. Step-by-Step Guide to Interpreting Mercedes Actual Gear Live Data

Interpreting Mercedes actual gear live data involves a systematic approach to ensure accurate diagnosis. Here’s a step-by-step guide:

5.1 Connect the Diagnostic Tool

Connect the OBD-II scanner or advanced diagnostic tool to the vehicle’s OBD-II port. Ensure the connection is secure to avoid data interruptions.

5.2 Access Live Data Stream

Navigate to the live data section of the diagnostic tool and select the transmission-related parameters, including current gear, target gear, transmission temperature, and shift solenoid status.

5.3 Monitor Data During Test Drive

Conduct a test drive to observe the transmission’s behavior under various driving conditions. Monitor the live data stream, paying attention to any anomalies or discrepancies.

5.4 Analyze Data Patterns

Analyze the data patterns to identify potential issues. For example, compare the current gear and target gear during acceleration and deceleration to detect shifting problems.

5.5 Check for Error Codes

Check for any stored or pending error codes related to the transmission. These codes can provide additional clues about the nature of the problem.

5.6 Consult Repair Manuals

Consult Mercedes-Benz repair manuals for specific diagnostic procedures and reference values. This ensures accurate interpretation of the live data.

6. Common Issues Identified Through Live Data Analysis

Analyzing Mercedes actual gear live data can help identify a variety of common transmission issues.

6.1 Slipping Gears

Slipping gears occur when the transmission fails to maintain the selected gear, often indicated by a sudden increase in engine RPM without a corresponding increase in vehicle speed.

6.2 Delayed Shifting

Delayed shifting is characterized by a noticeable delay between the commanded gear change and the actual gear change. This can be caused by low transmission fluid or faulty shift solenoids.

6.3 Rough Shifting

Rough shifting is when gear changes are abrupt or jerky. Live data can help pinpoint the cause, such as worn clutches or malfunctioning solenoids.

6.4 Overheating

Overheating is indicated by high transmission temperatures. This can lead to accelerated wear and potential transmission failure.

6.5 Torque Converter Problems

Problems with the torque converter can affect the vehicle’s ability to transfer power from the engine to the transmission. Live data can help diagnose issues such as failure to lock up or slipping.

7. Case Studies: Real-World Examples of Live Data Interpretation

To illustrate the practical application of interpreting Mercedes actual gear live data, let’s examine a few case studies.

7.1 Case Study 1: Diagnosing Slipping Gears

A Mercedes-Benz C-Class exhibited slipping gears. The live data showed a discrepancy between the commanded gear and the actual gear, with the engine RPM spiking during gear changes. Further investigation revealed worn clutches, which were subsequently replaced, resolving the issue.

7.2 Case Study 2: Identifying Delayed Shifting

A Mercedes-Benz E-Class experienced delayed shifting. The live data showed a noticeable delay between the target gear and the current gear. The diagnostic tool also revealed a fault code related to a shift solenoid. Replacing the faulty solenoid corrected the delayed shifting.

7.3 Case Study 3: Resolving Overheating Issues

A Mercedes-Benz S-Class had recurring overheating issues. The live data showed consistently high transmission temperatures. Inspection revealed a clogged transmission cooler. Cleaning the cooler resolved the overheating problem.

8. Advanced Techniques for Analyzing Live Data

In addition to basic data monitoring, advanced techniques can provide deeper insights into transmission performance.

8.1 Graphing Live Data

Graphing live data parameters over time allows for a visual representation of the transmission’s behavior. This can help identify patterns and anomalies that might not be apparent from raw data.

8.2 Data Logging

Data logging involves recording live data over an extended period. This is useful for capturing intermittent issues that may not occur during a short test drive.

8.3 Comparing Data Sets

Comparing live data sets from a healthy transmission with data from a problematic transmission can highlight discrepancies and aid in diagnosis.

9. The Role of MERCEDES-DIAGNOSTIC-TOOL.EDU.VN in Transmission Diagnostics

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN plays a vital role in helping technicians and Mercedes-Benz owners accurately diagnose transmission issues. Our platform provides access to detailed diagnostic information, repair guides, and expert support.

9.1 Comprehensive Diagnostic Information

Our website offers a wealth of information on Mercedes-Benz transmission diagnostics, including detailed explanations of live data parameters and troubleshooting guides.

9.2 Access to Repair Guides

We provide access to repair manuals and technical service bulletins (TSBs) that offer step-by-step instructions for diagnosing and repairing transmission problems.

9.3 Expert Support

Our team of experienced technicians is available to provide expert support and guidance on interpreting live data and diagnosing transmission issues.

10. Benefits of Using MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

Using MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers numerous benefits for diagnosing and maintaining Mercedes-Benz transmissions.

10.1 Improved Diagnostic Accuracy

Our comprehensive resources and expert support help improve diagnostic accuracy, reducing the risk of misdiagnosis and unnecessary repairs.

10.2 Reduced Repair Costs

By accurately diagnosing transmission problems early, you can prevent them from escalating into costly repairs.

10.3 Enhanced Vehicle Performance

Understanding transmission behavior and optimizing performance can enhance vehicle performance and fuel efficiency.

10.4 Increased Vehicle Lifespan

Proper maintenance and timely repairs can extend the lifespan of your Mercedes-Benz transmission.

11. Tips for Accurate Live Data Interpretation

To ensure accurate live data interpretation, consider the following tips:

11.1 Use High-Quality Diagnostic Tools

Invest in high-quality diagnostic tools that provide accurate and reliable data.

11.2 Understand Vehicle-Specific Parameters

Familiarize yourself with the specific live data parameters for your Mercedes-Benz model.

11.3 Compare with Known Good Data

Compare live data with known good data from a healthy transmission to identify discrepancies.

11.4 Consider Driving Conditions

Consider the driving conditions when interpreting live data. Transmission behavior can vary depending on factors like speed, load, and temperature.

11.5 Stay Updated on Latest Technology

Stay updated on the latest diagnostic techniques and technologies for Mercedes-Benz transmissions.

12. Future Trends in Transmission Diagnostics

The field of transmission diagnostics is constantly evolving, with new technologies and techniques emerging.

12.1 AI-Powered Diagnostics

AI-powered diagnostic tools can analyze live data in real-time, providing instant insights and recommendations.

12.2 Remote Diagnostics

Remote diagnostic capabilities allow technicians to access and analyze live data from anywhere in the world, facilitating quicker and more efficient repairs.

12.3 Predictive Maintenance

Predictive maintenance technologies use live data to forecast potential transmission failures, allowing for proactive maintenance and repairs.

13. Why Choose Mercedes-Benz for Vehicle Maintenance?

Choosing Mercedes-Benz for vehicle maintenance ensures that your car receives the highest standard of care. Mercedes-Benz service centers employ certified technicians who are experts in the brand’s vehicles. They use genuine Mercedes-Benz parts, which are designed to fit perfectly and function optimally with your car’s systems. This expertise and quality can help maintain your vehicle’s performance and longevity.

14. Common Error Codes Associated with Transmission Problems

Understanding common error codes associated with transmission problems can aid in faster and more accurate diagnostics. Here’s a list of some typical codes you might encounter:

- P0700: Transmission Control System Malfunction.

- P0715: Input/Turbine Speed Sensor Circuit Malfunction.

- P0717: Input/Turbine Speed Sensor Circuit No Signal.

- P0720: Output Speed Sensor Circuit Malfunction.

- P0730: Incorrect Gear Ratio.

- P0731-P0736: Gear Ratio Incorrect for Gears 1-6.

- P0740: Torque Converter Clutch Circuit Malfunction.

- P0741: Torque Converter Clutch Circuit Performance or Stuck Off.

- P0748: Pressure Control Solenoid Electrical.

- P0776: Pressure Control Solenoid B Performance or Stuck Off.

These codes, when combined with live data analysis, provide a comprehensive picture of the transmission’s condition, allowing for more targeted repairs.

15. Preventive Maintenance Tips for Mercedes-Benz Transmissions

Preventive maintenance is essential for ensuring the longevity and reliability of your Mercedes-Benz transmission. Here are some key tips:

- Regular Fluid Checks: Ensure the transmission fluid is at the correct level and free from contaminants.

- Fluid Changes: Adhere to the recommended fluid change intervals specified in your vehicle’s manual.

- Filter Replacement: Replace the transmission filter during fluid changes to maintain fluid cleanliness.

- Inspect for Leaks: Regularly inspect the transmission housing and lines for any signs of leaks.

- Monitor Temperature: Keep an eye on transmission temperature, especially during heavy use, to prevent overheating.

- Proper Driving Habits: Avoid aggressive driving habits such as hard acceleration and abrupt stops, which can strain the transmission.

- Professional Inspections: Schedule regular professional inspections to catch potential issues early.

By following these preventive maintenance tips, you can help keep your Mercedes-Benz transmission in optimal condition, reducing the likelihood of costly repairs.

16. The Importance of Transmission Fluid in Maintaining Gear Health

Transmission fluid is essential for maintaining the health of your Mercedes-Benz’s gear system. This fluid acts as a lubricant, coolant, and hydraulic medium, all critical for smooth operation.

16.1 Lubrication

Transmission fluid reduces friction between moving parts, preventing wear and tear.

16.2 Cooling

It dissipates heat generated by the transmission, preventing overheating.

16.3 Hydraulic Medium

The fluid transmits hydraulic pressure, enabling gear shifts and clutch engagement.

16.4 Cleaning

Transmission fluid helps flush away contaminants and debris, keeping the system clean.

16.5 Corrosion Prevention

It protects against rust and corrosion, extending the life of transmission components.

Regular checks and changes of transmission fluid are crucial for preserving the performance and longevity of your Mercedes-Benz’s gear system.

17. How to Interpret Transmission Fluid Analysis Results?

Interpreting transmission fluid analysis results involves examining several key indicators that provide insights into the health of the transmission system.

17.1 Viscosity

Viscosity measures the fluid’s thickness and its ability to maintain proper lubrication. Deviations can indicate degradation or contamination.

17.2 Oxidation

Oxidation levels show the extent of fluid breakdown due to heat and age. High oxidation can lead to sludge formation and reduced lubrication.

17.3 Contamination

Contamination analysis identifies the presence of water, coolant, or other foreign materials. These contaminants can damage transmission components.

17.4 Wear Metals

Measuring wear metals like iron, copper, and aluminum indicates the level of internal wear. High levels can signal significant component degradation.

17.5 Additive Depletion

Additive depletion analysis assesses the remaining effectiveness of the fluid’s additives, which enhance its performance and protection capabilities.

17.6 TBN (Total Base Number)

TBN measures the fluid’s alkalinity and its ability to neutralize acids. A declining TBN indicates reduced protection against corrosion.

17.7 TAN (Total Acid Number)

TAN measures the fluid’s acidity, indicating the accumulation of acidic byproducts. High TAN levels can lead to corrosion and damage.

By analyzing these indicators, technicians can determine the fluid’s condition, identify potential issues, and recommend appropriate maintenance or repairs.

18. Utilizing Adaptations and Resets in Transmission Diagnostics

Adaptations and resets are crucial functions in modern transmission diagnostics that can significantly improve vehicle performance and extend the life of the transmission.

18.1 Understanding Transmission Adaptations

Transmission adaptations involve the transmission control unit (TCU) learning and adjusting to the driving habits and wear patterns of the vehicle. These adaptations optimize shift quality and overall transmission performance.

18.2 When to Perform Adaptations

Adaptations are typically performed after major transmission repairs, such as replacing clutches, solenoids, or the TCU itself. They ensure the transmission operates smoothly with the new components.

18.3 The Adaptation Process

The adaptation process usually involves a series of controlled driving cycles that allow the TCU to relearn shift points, clutch pressures, and other parameters.

18.4 Importance of Resets

Resets, also known as clearing adaptations, can be necessary when the transmission exhibits erratic behavior due to accumulated adaptation data that no longer reflects the current condition of the vehicle.

18.5 Performing a Reset

A reset clears the stored adaptation data, allowing the TCU to start fresh and relearn the optimal settings based on the current state of the transmission and driving habits.

18.6 Benefits of Adaptations and Resets

- Improved shift quality

- Enhanced fuel efficiency

- Extended transmission lifespan

- Smoother overall driving experience

By understanding and properly utilizing adaptations and resets, technicians can ensure the transmission operates at its peak performance.

19. Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Expert Advice

Do you need expert assistance with interpreting Mercedes actual gear live data? MERCEDES-DIAGNOSTIC-TOOL.EDU.VN is here to help. Contact us today for personalized advice, diagnostic tools, and repair solutions. Our team of experienced technicians is ready to assist you with all your Mercedes-Benz diagnostic needs.

19.1 Personalized Support

We offer personalized support tailored to your specific vehicle and diagnostic challenges.

19.2 Diagnostic Tools

Access our wide range of diagnostic tools designed for Mercedes-Benz vehicles.

19.3 Repair Solutions

Get expert guidance on the best repair solutions for your transmission issues.

Contact us today:

- Address: 789 Oak Avenue, Miami, FL 33101, United States

- WhatsApp: +1 (641) 206-8880

- Website: MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

20. FAQs About Interpreting Mercedes Actual Gear Live Data

Here are some frequently asked questions about interpreting Mercedes actual gear live data:

20.1 What is the best OBD-II scanner for Mercedes-Benz vehicles?

The best OBD-II scanner depends on your needs and budget. Options like Autel MaxiSys and Snap-on Solus offer advanced features, while more affordable options like BlueDriver provide essential data.

20.2 How often should I check my transmission fluid?

Check your transmission fluid at least every 30,000 miles or as recommended in your vehicle’s manual.

20.3 What are the signs of a failing transmission?

Signs of a failing transmission include slipping gears, delayed shifting, rough shifting, and unusual noises.

20.4 Can I diagnose transmission problems myself?

You can diagnose some transmission problems using an OBD-II scanner and live data, but complex issues may require professional assistance.

20.5 How do I know if my transmission is overheating?

High transmission temperatures can be detected through live data or by observing warning lights on your dashboard.

20.6 What is the role of shift solenoids in transmission function?

Shift solenoids control the flow of transmission fluid, which is essential for proper shifting.

20.7 How can I improve my Mercedes-Benz transmission performance?

Improving transmission performance involves regular maintenance, proper fluid levels, and addressing any issues identified through live data analysis.

20.8 What is the difference between short-term and long-term fuel trim?

Short-term fuel trim adjusts quickly to changing conditions, while long-term fuel trim adapts over time to compensate for wear and tear.

20.9 How do I interpret oxygen sensor data?

Oxygen sensor data provides information about the air-fuel mixture. Analyzing this data can help identify engine performance issues.

20.10 Where can I find reliable repair guides for Mercedes-Benz transmissions?

Reliable repair guides can be found on MERCEDES-DIAGNOSTIC-TOOL.EDU.VN and in official Mercedes-Benz repair manuals.

By understanding Mercedes actual gear live data and utilizing the resources available at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, you can ensure your Mercedes-Benz transmission operates smoothly and efficiently.