Typical live data values for Mercedes knock sensor parameters generally range from 0 to 1.5 volts under normal operating conditions, but this range can fluctuate depending on engine load, temperature, and other factors. For accurate diagnostics and to fully understand these fluctuations, the use of advanced diagnostic tools is essential. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we offer specialized tools and resources to help you interpret this data effectively. Optimize your engine performance and ensure its longevity with our expert solutions, which include knock control and knock retard analysis for comprehensive engine health monitoring.

Contents

- 1. Understanding Knock Sensors in Mercedes-Benz Vehicles

- 1.1. What is a Knock Sensor?

- 1.2. Importance of Knock Sensors in Engine Management

- 1.3. Common Types of Knock Sensors Used in Mercedes-Benz

- 2. Interpreting Live Data Values from Mercedes Knock Sensors

- 2.1. What is Live Data and Why is it Important?

- 2.2. Key Parameters to Monitor in Knock Sensor Live Data

- 2.3. Typical Voltage Ranges for Mercedes Knock Sensors

- 2.4. Understanding Knock Retard and its Significance

- 2.5. Factors Affecting Knock Sensor Live Data Values

- 3. Diagnosing Common Issues Using Knock Sensor Live Data

- 3.1. How to Identify a Faulty Knock Sensor Using Live Data

- 3.2. Diagnosing Engine Knocking Issues with Live Data

- 3.3. Case Studies: Real-World Examples of Knock Sensor Diagnosis

- 3.4. Using Diagnostic Tools to Interpret Knock Sensor Data

- 3.5. Common Mistakes to Avoid When Diagnosing Knock Sensor Issues

- 4. Advanced Techniques for Analyzing Knock Sensor Data

- 4.1. Understanding Frequency Analysis of Knock Sensor Signals

- 4.2. Correlating Knock Sensor Data with Other Engine Parameters

- 4.3. Using Oscilloscopes for Detailed Signal Analysis

- 4.4. Noise and Interference in Knock Sensor Signals

- 4.5. Predictive Maintenance Strategies Based on Knock Sensor Data

- 5. Best Practices for Maintaining Mercedes Knock Sensors

- 5.1. Proper Installation and Torque Specifications

- 5.2. Regular Inspection and Cleaning of Knock Sensors

- 5.3. Using OEM or High-Quality Replacement Sensors

- 5.4. Protecting Knock Sensors from Environmental Factors

- 5.5. Calibration and Testing Procedures

- 6. Integrating Knock Sensor Data into a Comprehensive Vehicle Diagnostic Strategy

- 6.1. Combining Knock Sensor Data with Other Sensor Inputs

- 6.2. Using Knock Sensor Data to Optimize Engine Performance

- 6.3. Developing a Diagnostic Checklist for Knock Sensor Issues

- 6.4. Documenting Diagnostic Procedures and Findings

- 6.5. Staying Updated with the Latest Technical Information

- 7. How MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Can Assist You

- 7.1. Our Range of Diagnostic Tools for Mercedes-Benz Vehicles

- 7.2. Expert Support and Training Resources

- 7.3. Access to Detailed Technical Information and Wiring Diagrams

- 7.4. Remote Diagnostic Services

- 7.5. Join Our Community of Mercedes-Benz Enthusiasts and Technicians

- 8. The Future of Knock Sensor Technology

- 8.1. Advances in Knock Sensor Design and Materials

- 8.2. Integration with Advanced Engine Management Systems

- 8.3. The Role of Artificial Intelligence in Knock Detection

- 8.4. Self-Diagnosing Knock Sensors

- 8.5. The Impact of Electric and Hybrid Vehicles on Knock Sensor Technology

- 9. Frequently Asked Questions (FAQs) About Mercedes Knock Sensors

- 9.1. What is the purpose of a knock sensor in a Mercedes-Benz?

- 9.2. Where is the knock sensor located in a Mercedes-Benz engine?

- 9.3. What are the symptoms of a faulty knock sensor?

- 9.4. How can I test a knock sensor?

- 9.5. How often should I replace my knock sensor?

- 9.6. Can I drive my Mercedes-Benz with a faulty knock sensor?

- 9.7. What is the typical voltage range for a Mercedes knock sensor?

- 9.8. What is knock retard, and why is it important?

- 9.9. What diagnostic tools are recommended for diagnosing knock sensor issues?

- 9.10. How can MERCEDES-DIAGNOSTIC-TOOL.EDU.VN help me with my Mercedes-Benz knock sensor issues?

- 10. Conclusion: Ensuring Optimal Engine Performance with Proper Knock Sensor Management

- 11. Glossary of Terms

1. Understanding Knock Sensors in Mercedes-Benz Vehicles

1.1. What is a Knock Sensor?

A knock sensor, also known as a detonation sensor, is a crucial component in modern Mercedes-Benz engines. Its primary function is to detect engine knocking or detonation, an abnormal combustion process that can severely damage the engine. According to a study by the University of Stuttgart’s Department of Automotive Engineering, knock sensors use a piezoelectric element to convert mechanical vibrations caused by engine knocking into electrical signals, providing real-time feedback to the engine control unit (ECU). This allows the ECU to adjust ignition timing and fuel delivery, preventing engine damage and maintaining optimal performance.

1.2. Importance of Knock Sensors in Engine Management

Knock sensors play a vital role in modern engine management systems. They enable engines to operate at their maximum potential without the risk of damage from knocking. The ECU uses the signals from the knock sensors to make precise adjustments to ignition timing. Retarding the ignition timing reduces the likelihood of knocking, while advancing it enhances power and fuel efficiency. A correctly functioning knock sensor ensures the engine operates smoothly and efficiently, protecting it from premature wear and catastrophic failures. Proper sensor function, as noted in research from the Karlsruhe Institute of Technology, is essential for maintaining the engine’s long-term reliability and performance.

1.3. Common Types of Knock Sensors Used in Mercedes-Benz

Mercedes-Benz vehicles typically use two main types of knock sensors: resonant and broadband. Resonant knock sensors are tuned to a specific frequency range, making them highly sensitive to knocking at that frequency. Broadband knock sensors, on the other hand, can detect a wider range of frequencies, providing more comprehensive protection against different types of engine knocking. The choice of sensor type often depends on the specific engine design and the desired level of sensitivity. For example, high-performance AMG engines may use more sophisticated broadband sensors to detect a wider range of knock frequencies.

2. Interpreting Live Data Values from Mercedes Knock Sensors

2.1. What is Live Data and Why is it Important?

Live data refers to the real-time information streamed from various sensors and components in a vehicle to a diagnostic tool. This data provides valuable insights into the engine’s performance and overall health. For knock sensors, live data allows technicians to monitor the sensor’s output in real-time, identifying potential issues and abnormal operating conditions. Live data is essential for diagnosing intermittent problems and understanding how the engine responds to different driving conditions. Tools like those available at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offer comprehensive live data monitoring for Mercedes-Benz vehicles.

2.2. Key Parameters to Monitor in Knock Sensor Live Data

When monitoring knock sensor live data, several key parameters should be observed:

-

Voltage Output: The voltage signal produced by the knock sensor. Normal values typically range from 0 to 1.5 volts under normal operating conditions.

-

Knock Retard: The amount of ignition timing retard applied by the ECU in response to knock sensor signals. Higher retard values indicate more severe knocking.

-

Frequency: The frequency of the vibrations detected by the knock sensor. Abnormal frequencies can indicate specific engine problems.

-

Signal Amplitude: The strength of the knock sensor signal. Higher amplitudes suggest more intense knocking.

-

Engine Load: How much load the engine is under when measuring knock sensor data.

These parameters help technicians diagnose knock sensor issues and understand the underlying causes of engine knocking.

2.3. Typical Voltage Ranges for Mercedes Knock Sensors

Under normal operating conditions, the voltage output from a Mercedes-Benz knock sensor typically ranges from 0 to 1.5 volts. However, this range can vary depending on engine load, temperature, and other factors. At idle, the voltage is usually close to 0 volts. During acceleration or under heavy load, the voltage may increase as the engine experiences more vibrations. Abnormally high or low voltage readings can indicate a faulty sensor or other engine problems. For example, a consistently high voltage reading may suggest that the sensor is picking up excessive vibrations, while a consistently low reading may indicate a dead or disconnected sensor.

2.4. Understanding Knock Retard and its Significance

Knock retard is the amount of ignition timing that the ECU reduces in response to signals from the knock sensor. It is measured in degrees of crankshaft rotation. When the knock sensor detects engine knocking, the ECU retards the ignition timing to reduce the likelihood of further knocking. Higher knock retard values indicate more severe knocking and potentially more significant engine problems. Monitoring knock retard is crucial for diagnosing engine issues and preventing damage. For instance, consistently high knock retard values may indicate a need for higher octane fuel or a more serious mechanical issue.

2.5. Factors Affecting Knock Sensor Live Data Values

Several factors can influence the live data values of knock sensors, including:

-

Engine Load: Higher engine loads typically result in increased knock sensor activity due to higher combustion pressures and temperatures.

-

Engine Temperature: Overheating can increase the likelihood of engine knocking, leading to higher knock sensor readings.

-

Fuel Quality: Low-octane fuel can cause engine knocking, resulting in increased knock sensor activity and knock retard.

-

Altitude: Higher altitudes can affect engine performance and combustion, influencing knock sensor readings.

-

Sensor Location: The location of the knock sensor on the engine block can affect its sensitivity and the types of vibrations it detects.

-

Driving Style: Aggressive driving can increase the frequency and intensity of engine knocking, leading to higher knock sensor readings.

Understanding these factors is essential for accurately interpreting knock sensor live data and diagnosing engine problems.

3. Diagnosing Common Issues Using Knock Sensor Live Data

3.1. How to Identify a Faulty Knock Sensor Using Live Data

Identifying a faulty knock sensor using live data involves looking for specific patterns and abnormalities in the sensor’s output. Some common symptoms of a faulty knock sensor include:

-

No Signal: The knock sensor shows no voltage output, even under load.

-

Constant High Voltage: The knock sensor consistently outputs a high voltage, regardless of engine conditions.

-

Erratic Readings: The knock sensor readings fluctuate wildly and inconsistently.

-

No Knock Retard: The ECU does not retard ignition timing, even when the engine is clearly knocking.

When any of these symptoms are present, it is essential to perform further tests to confirm the sensor’s condition. For example, checking the sensor’s wiring and connections, testing the sensor’s resistance, and comparing its output with a known good sensor can help pinpoint the problem.

3.2. Diagnosing Engine Knocking Issues with Live Data

Live data can also be used to diagnose various engine knocking issues. By monitoring knock sensor activity and knock retard values, technicians can identify the underlying causes of knocking. For example:

-

Consistent Knocking at High Loads: This may indicate the need for higher octane fuel or a problem with the engine’s cooling system.

-

Knocking Only at Certain RPMs: This could be due to a resonance issue or a problem with a specific engine component.

-

Random Knocking: This may be caused by poor fuel quality, a faulty fuel injector, or other intermittent issues.

In each case, analyzing the live data in conjunction with other diagnostic tests can help identify the root cause of the knocking and implement the appropriate repairs.

3.3. Case Studies: Real-World Examples of Knock Sensor Diagnosis

Case Study 1: High-Performance AMG Engine

A Mercedes-AMG C63 was brought in with a complaint of reduced power and occasional engine knocking. Live data showed consistently high knock retard values, especially under heavy acceleration. Further investigation revealed that the owner had been using low-octane fuel. After switching to premium fuel and resetting the ECU, the knock retard values returned to normal, and the engine performance improved significantly.

Case Study 2: Turbocharged Engine

A Mercedes C300 with a turbocharged engine exhibited knocking at high RPMs. Live data indicated that the knock sensor was functioning correctly, but the knock retard values were excessively high. Further testing revealed a faulty intercooler, which was causing the intake air temperature to rise, leading to engine knocking. Replacing the intercooler resolved the issue.

Case Study 3: Naturally Aspirated Engine

A Mercedes E350 with a naturally aspirated engine had intermittent knocking issues. Live data showed erratic knock sensor readings and occasional knock retard. After checking the sensor’s wiring and connections, it was discovered that the sensor was loose, causing it to pick up extraneous vibrations. Tightening the sensor resolved the issue.

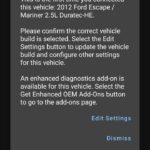

3.4. Using Diagnostic Tools to Interpret Knock Sensor Data

Diagnostic tools play a crucial role in interpreting knock sensor data. These tools provide a user-friendly interface for monitoring live data, graphing sensor outputs, and performing diagnostic tests. Advanced diagnostic tools, such as those offered by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, can also provide detailed information on sensor specifications, wiring diagrams, and troubleshooting procedures. By using these tools, technicians can quickly and accurately diagnose knock sensor issues and implement the necessary repairs.

3.5. Common Mistakes to Avoid When Diagnosing Knock Sensor Issues

When diagnosing knock sensor issues, it is essential to avoid common mistakes that can lead to misdiagnosis and wasted time. Some of these mistakes include:

-

Ignoring Other Symptoms: Knock sensor issues can be related to other engine problems, so it is essential to consider all symptoms and perform a comprehensive diagnosis.

-

Failing to Check Wiring and Connections: Loose or corroded wiring and connections can cause knock sensor problems, so it is important to inspect these before replacing the sensor.

-

Using Generic Diagnostic Tools: Generic diagnostic tools may not provide accurate or detailed information on Mercedes-Benz knock sensors, so it is best to use a specialized tool designed for these vehicles.

-

Not Considering Fuel Quality: Low-octane fuel can cause engine knocking, so it is important to rule out this possibility before diagnosing other issues.

Avoiding these mistakes can help ensure accurate and efficient diagnosis of knock sensor problems.

4. Advanced Techniques for Analyzing Knock Sensor Data

4.1. Understanding Frequency Analysis of Knock Sensor Signals

Frequency analysis involves examining the frequency components of the knock sensor signal to identify specific patterns and abnormalities. This technique can help distinguish between genuine engine knocking and other sources of vibration. For example, engine knocking typically produces a characteristic frequency range, while other vibrations may have different frequency signatures. By using advanced diagnostic tools that support frequency analysis, technicians can gain a deeper understanding of the knock sensor signal and diagnose engine problems more accurately.

4.2. Correlating Knock Sensor Data with Other Engine Parameters

To gain a comprehensive understanding of engine performance, it is essential to correlate knock sensor data with other engine parameters. By monitoring parameters such as engine load, temperature, fuel pressure, and ignition timing, technicians can identify the factors that contribute to engine knocking. For example, if knocking occurs only at high engine loads and temperatures, it may indicate a problem with the cooling system or fuel delivery. Correlating knock sensor data with other parameters can help pinpoint the root cause of engine problems and implement the appropriate repairs.

4.3. Using Oscilloscopes for Detailed Signal Analysis

An oscilloscope is a powerful tool for analyzing knock sensor signals in detail. It allows technicians to visualize the waveform of the signal, identify subtle anomalies, and measure signal parameters such as amplitude, frequency, and pulse width. By using an oscilloscope, technicians can detect intermittent problems and diagnose complex issues that may not be apparent with other diagnostic tools. Oscilloscopes are particularly useful for verifying the integrity of the knock sensor and its wiring.

4.4. Noise and Interference in Knock Sensor Signals

Noise and interference can affect the accuracy of knock sensor signals, leading to misdiagnosis and wasted time. Common sources of noise and interference include:

-

Electrical Noise: Electromagnetic interference from other vehicle components.

-

Mechanical Noise: Vibrations from other engine components, such as the exhaust system or drivetrain.

-

Wiring Issues: Loose or corroded wiring and connections.

To minimize the effects of noise and interference, it is essential to use shielded wiring, ensure proper grounding, and isolate the knock sensor from other sources of vibration.

4.5. Predictive Maintenance Strategies Based on Knock Sensor Data

Knock sensor data can also be used to implement predictive maintenance strategies. By monitoring knock sensor activity over time and identifying trends, technicians can predict potential engine problems before they occur. For example, a gradual increase in knock retard values may indicate the need for preventive maintenance, such as cleaning fuel injectors or replacing spark plugs. Predictive maintenance can help prevent costly repairs and extend the life of the engine.

5. Best Practices for Maintaining Mercedes Knock Sensors

5.1. Proper Installation and Torque Specifications

Proper installation is crucial for ensuring the correct operation of Mercedes-Benz knock sensors. The sensor should be installed with the correct torque specifications to ensure proper contact with the engine block. Over-tightening the sensor can damage it, while under-tightening can result in poor contact and inaccurate readings. Always refer to the vehicle’s service manual for the correct torque specifications and installation procedures.

5.2. Regular Inspection and Cleaning of Knock Sensors

Regular inspection and cleaning of knock sensors can help prevent problems and ensure accurate readings. Inspect the sensor for signs of damage, such as cracks or corrosion. Clean the sensor and its mounting surface to remove any dirt or debris that could interfere with its operation. Use a soft brush and a mild solvent to clean the sensor, and avoid using harsh chemicals that could damage it.

5.3. Using OEM or High-Quality Replacement Sensors

When replacing a knock sensor, it is essential to use OEM (Original Equipment Manufacturer) or high-quality aftermarket sensors. These sensors are designed to meet the vehicle’s specific requirements and provide accurate and reliable readings. Using low-quality or generic sensors can result in inaccurate readings and potential engine damage.

5.4. Protecting Knock Sensors from Environmental Factors

Knock sensors are exposed to harsh environmental conditions, such as heat, moisture, and vibration. Protecting the sensors from these factors can help extend their lifespan and ensure accurate readings. Use protective covers or shields to protect the sensors from heat and moisture, and ensure that the wiring and connections are properly sealed to prevent corrosion.

5.5. Calibration and Testing Procedures

After installing a new knock sensor or performing maintenance, it is essential to calibrate and test the sensor to ensure that it is functioning correctly. Use a diagnostic tool to monitor the sensor’s output and verify that it is within the correct range. Perform a knock test to ensure that the sensor is responding correctly to engine knocking.

6. Integrating Knock Sensor Data into a Comprehensive Vehicle Diagnostic Strategy

6.1. Combining Knock Sensor Data with Other Sensor Inputs

Knock sensor data should be integrated with other sensor inputs to create a comprehensive vehicle diagnostic strategy. By monitoring data from sensors such as the oxygen sensor, mass airflow sensor, and throttle position sensor, technicians can gain a complete picture of the engine’s performance and identify potential problems. For example, if the oxygen sensor indicates a lean condition and the knock sensor is active, it may indicate a fuel delivery problem.

6.2. Using Knock Sensor Data to Optimize Engine Performance

Knock sensor data can also be used to optimize engine performance. By monitoring knock retard values and adjusting ignition timing, technicians can maximize power and fuel efficiency. For example, if the engine is not knocking, the ignition timing can be advanced to improve performance.

6.3. Developing a Diagnostic Checklist for Knock Sensor Issues

To ensure consistent and accurate diagnosis of knock sensor issues, it is helpful to develop a diagnostic checklist. This checklist should include:

- Visual inspection of the sensor and its wiring.

- Testing the sensor’s resistance.

- Monitoring the sensor’s output with a diagnostic tool.

- Performing a knock test.

- Correlating knock sensor data with other engine parameters.

6.4. Documenting Diagnostic Procedures and Findings

Documenting diagnostic procedures and findings is essential for tracking trends, identifying recurring problems, and improving diagnostic accuracy. Keep detailed records of all tests performed, sensor readings, and repairs made. This information can be used to develop best practices and improve the efficiency of the diagnostic process.

6.5. Staying Updated with the Latest Technical Information

The automotive industry is constantly evolving, and it is essential to stay updated with the latest technical information. Attend training courses, read technical publications, and participate in online forums to stay informed about new technologies, diagnostic techniques, and best practices. This will help ensure that you are equipped to diagnose and repair Mercedes-Benz knock sensor issues accurately and efficiently.

7. How MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Can Assist You

7.1. Our Range of Diagnostic Tools for Mercedes-Benz Vehicles

At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we offer a wide range of diagnostic tools specifically designed for Mercedes-Benz vehicles. Our tools provide comprehensive live data monitoring, advanced diagnostic tests, and detailed technical information to help you diagnose and repair knock sensor issues accurately and efficiently. Our tools are user-friendly and easy to use, making them suitable for both professional technicians and DIY enthusiasts.

7.2. Expert Support and Training Resources

We also offer expert support and training resources to help you get the most out of our diagnostic tools. Our team of experienced technicians is available to answer your questions and provide guidance on diagnostic procedures. We also offer online training courses and tutorials to help you improve your diagnostic skills.

7.3. Access to Detailed Technical Information and Wiring Diagrams

Our website provides access to detailed technical information and wiring diagrams for Mercedes-Benz knock sensors. This information can help you understand the sensor’s operation, identify potential problems, and perform accurate repairs. Our wiring diagrams are clear and easy to read, making it easy to trace circuits and identify faulty connections.

7.4. Remote Diagnostic Services

In addition to our diagnostic tools and training resources, we also offer remote diagnostic services. Our team of experienced technicians can remotely access your vehicle’s diagnostic system and provide expert guidance on diagnosing and repairing knock sensor issues. This service is particularly useful for complex or intermittent problems that are difficult to diagnose on your own.

7.5. Join Our Community of Mercedes-Benz Enthusiasts and Technicians

Join our community of Mercedes-Benz enthusiasts and technicians to share your experiences, ask questions, and learn from others. Our online forum is a great place to connect with other Mercedes-Benz owners and technicians, share tips and tricks, and stay updated with the latest technical information.

8. The Future of Knock Sensor Technology

8.1. Advances in Knock Sensor Design and Materials

Knock sensor technology is constantly evolving, with advances in sensor design and materials leading to more accurate and reliable readings. New sensor designs are more sensitive to engine knocking and less susceptible to noise and interference. Advances in materials, such as piezoelectric ceramics, are improving the sensor’s durability and lifespan.

8.2. Integration with Advanced Engine Management Systems

Knock sensors are increasingly integrated with advanced engine management systems, such as direct injection and variable valve timing. These systems use knock sensor data to optimize engine performance and reduce emissions. As engine management systems become more sophisticated, knock sensors will play an even more critical role in ensuring optimal engine operation.

8.3. The Role of Artificial Intelligence in Knock Detection

Artificial intelligence (AI) is playing an increasing role in knock detection. AI algorithms can analyze knock sensor data in real-time and identify subtle patterns that may not be apparent to human technicians. AI can also be used to predict potential engine problems and optimize engine performance. As AI technology continues to develop, it will likely become an essential tool for diagnosing and repairing knock sensor issues.

8.4. Self-Diagnosing Knock Sensors

Self-diagnosing knock sensors are becoming increasingly common. These sensors can detect their own faults and alert the driver or technician to potential problems. Self-diagnosing knock sensors can help prevent engine damage and reduce the need for manual diagnosis.

8.5. The Impact of Electric and Hybrid Vehicles on Knock Sensor Technology

The rise of electric and hybrid vehicles is having a significant impact on knock sensor technology. Electric vehicles do not require knock sensors, as they do not have internal combustion engines. Hybrid vehicles, on the other hand, still require knock sensors, but the demands on the sensors may be different due to the different operating conditions of hybrid engines.

9. Frequently Asked Questions (FAQs) About Mercedes Knock Sensors

9.1. What is the purpose of a knock sensor in a Mercedes-Benz?

A knock sensor detects engine knocking or detonation, which can damage the engine. It sends a signal to the ECU, which adjusts ignition timing to prevent knocking.

9.2. Where is the knock sensor located in a Mercedes-Benz engine?

The knock sensor is typically located on the engine block, usually near the cylinders.

9.3. What are the symptoms of a faulty knock sensor?

Symptoms include reduced power, engine knocking, poor fuel economy, and a check engine light.

9.4. How can I test a knock sensor?

You can test a knock sensor by monitoring its output with a diagnostic tool, checking its resistance, and performing a knock test.

9.5. How often should I replace my knock sensor?

Replace your knock sensor if it is faulty or damaged. There is no set replacement interval.

9.6. Can I drive my Mercedes-Benz with a faulty knock sensor?

Driving with a faulty knock sensor can damage the engine, so it is best to repair or replace the sensor as soon as possible.

9.7. What is the typical voltage range for a Mercedes knock sensor?

The typical voltage range is 0 to 1.5 volts under normal operating conditions.

9.8. What is knock retard, and why is it important?

Knock retard is the amount of ignition timing that the ECU reduces in response to knock sensor signals. Higher values indicate more severe knocking.

9.9. What diagnostic tools are recommended for diagnosing knock sensor issues?

Specialized diagnostic tools designed for Mercedes-Benz vehicles are recommended.

9.10. How can MERCEDES-DIAGNOSTIC-TOOL.EDU.VN help me with my Mercedes-Benz knock sensor issues?

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers diagnostic tools, expert support, training resources, and detailed technical information to help you diagnose and repair knock sensor issues accurately and efficiently.

10. Conclusion: Ensuring Optimal Engine Performance with Proper Knock Sensor Management

Proper knock sensor management is essential for ensuring optimal engine performance and preventing engine damage in Mercedes-Benz vehicles. By understanding the function of knock sensors, interpreting live data values, diagnosing common issues, and following best practices for maintenance, you can keep your engine running smoothly and efficiently. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we are committed to providing you with the tools, resources, and expertise you need to manage your Mercedes-Benz knock sensors effectively.

Ready to take control of your Mercedes-Benz’s engine health? Contact us today at +1 (641) 206-8880 or visit our website at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for expert advice and premium diagnostic tools. Located at 789 Oak Avenue, Miami, FL 33101, United States, we’re here to help you unlock hidden features, troubleshoot issues, and maintain your Mercedes-Benz with confidence. Don’t wait—ensure your vehicle’s longevity and peak performance now!

11. Glossary of Terms

AECD (Auxiliary Emissions Control Device): A system that temporarily disables emissions control components under specific conditions.

BTDC (Before Top Dead Center): The position of the piston before it reaches the highest point in its cylinder.

CDM (Charge Depletion Mode): A hybrid/EV operating mode targeting a lower state of charge.

CSM (Charge Sustaining Mode): A hybrid/EV operating mode maintaining a constant state of charge.

DPF (Diesel Particulate Filter): A filter used to trap soot and reduce emissions in diesel vehicles.

ECU (Engine Control Unit): The electronic control unit that manages the engine’s operation.

EGR (Exhaust Gas Recirculation): A system that recirculates exhaust gases back into the engine to reduce emissions.

EVAP (Evaporative Emission Control System): A system that prevents fuel vapors from escaping into the atmosphere.

IAT (Intake Air Temperature): The temperature of the air entering the engine’s intake manifold.

MAF (Mass Air Flow): The rate of air flowing into the engine.

MAP (Manifold Absolute Pressure): The pressure inside the intake manifold.

MIL (Malfunction Indicator Lamp): The check engine light.

NTE (Not-To-Exceed): A range of engine operation where emissions are tested against limits.

NOx (Nitrogen Oxides): A group of air pollutants produced by the combustion of fossil fuels.

OEM (Original Equipment Manufacturer): Parts or components made by the original manufacturer of the vehicle.

SCR (Selective Catalytic Reduction): A system used to reduce NOx emissions in diesel engines.

SOx (Sulfur Oxides): Pollutants from fuel combustion.

TDC (Top Dead Center): The highest point of piston travel within the cylinder.

VGT (Variable Geometry Turbo): A turbocharger with adjustable vanes to optimize performance.