Which PIDs Are Most Useful For Mercedes Chassis Diagnostics? Parameter IDs (PIDs) that offer crucial insights into your Mercedes-Benz chassis health and performance can be identified using MERCEDES-DIAGNOSTIC-TOOL.EDU.VN. By focusing on these PIDs, you can optimize vehicle diagnostics, address issues efficiently, and ensure a smoother driving experience. Leverage these data points for preventive maintenance and performance tuning, enhancing your understanding and care for your Mercedes. For in-depth chassis analysis, explore resources on steering angle sensors, suspension control, and ABS/ESP system diagnostics.

Contents

- 1. Understanding Parameter IDs (PIDs) in Mercedes Diagnostics

- 1.1. What are PIDs?

- 1.2. Importance of PIDs in Vehicle Diagnostics

- 1.3. Standardized vs. Manufacturer-Specific PIDs

- 1.4. How PIDs are Used in Mercedes Diagnostics

- 1.5. Accessing Enhanced Diagnostics with OBDLink® MX+ Adapter

- 1.6. Downloading Enhanced Diagnostics for Mercedes-Benz

- 2. Key PIDs for Mercedes Chassis Diagnostics

- 2.1. Suspension System PIDs

- 2.2. Steering System PIDs

- 2.3. Braking System PIDs

- 2.4. Chassis Control Module PIDs

- 3. Diagnostic Tools and Software for Reading Mercedes PIDs

- 3.1. OBD-II Scanners

- 3.2. Advanced Diagnostic Tools

- 3.3. Software Solutions

- 3.4. OBDLink® App and Adapter

- 3.5. Selecting the Right Tool for Your Needs

- 3.6. Step-by-Step Guide to Using the OBDLink® App

- 4. Interpreting PID Data for Accurate Chassis Diagnostics

- 4.1. Understanding PID Value Ranges

- 4.2. Identifying Common Issues Through PID Analysis

- 4.3. Using Freeze Frame Data

- 4.4. Bi-Directional Control and System Tests

- 4.5. Case Studies: Interpreting PID Data in Real-World Scenarios

- 4.6. Leveraging MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Expert Guidance

- 5. Common Mistakes to Avoid When Reading Mercedes PIDs

- 5.1. Ignoring Manufacturer Specifications

- 5.2. Neglecting Baseline Data

- 5.3. Overlooking Freeze Frame Data

- 5.4. Failing to Use Bi-Directional Control

- 5.5. Misinterpreting PID Relationships

- 5.6. Ignoring Electrical Issues

- 5.7. Not Verifying Sensor Accuracy

- 5.8. Overlooking Software and Firmware Updates

- 5.9. Failing to Document Diagnostic Procedures

- 5.10. Neglecting Professional Training

- 5.11. Seeking Expert Assistance from MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

- 6. Advanced Techniques for Chassis Diagnostics Using PIDs

- 6.1. Data Logging for Intermittent Issues

- 6.2. Graphing PID Values for Visual Analysis

- 6.3. Advanced PID Analysis Techniques

1. Understanding Parameter IDs (PIDs) in Mercedes Diagnostics

Parameter IDs (PIDs) are essential data points used in vehicle diagnostics to monitor and assess the performance and health of various systems. For Mercedes-Benz vehicles, understanding PIDs is crucial for accurate and effective chassis diagnostics. This section provides an in-depth look at PIDs, their significance, and how they are used in Mercedes diagnostics.

1.1. What are PIDs?

Parameter Identification Numbers (PIDs) are codes used to request data from a vehicle’s On-Board Diagnostic (OBD) system. These codes allow diagnostic tools to access real-time data about various vehicle parameters, such as engine speed, coolant temperature, and sensor readings. According to the Society of Automotive Engineers (SAE), standardized PIDs ensure that diagnostic tools can communicate with any OBD-II compliant vehicle.

1.2. Importance of PIDs in Vehicle Diagnostics

PIDs play a vital role in vehicle diagnostics by providing mechanics and car owners with a window into the internal operations of a vehicle’s systems. Here’s why PIDs are so important:

- Real-Time Data: PIDs provide real-time data, which is essential for diagnosing intermittent issues and monitoring system performance under various driving conditions.

- Comprehensive System Monitoring: PIDs cover a wide range of systems, including the engine, transmission, ABS, and chassis, allowing for a comprehensive assessment of the vehicle’s overall health.

- Accurate Issue Identification: By analyzing PID values, technicians can pinpoint the exact cause of a problem, reducing guesswork and saving time and money.

1.3. Standardized vs. Manufacturer-Specific PIDs

While some PIDs are standardized across all OBD-II compliant vehicles, others are manufacturer-specific.

- Standardized PIDs: These are defined by the SAE and are consistent across different makes and models. They include basic parameters like engine RPM, vehicle speed, and coolant temperature.

- Manufacturer-Specific PIDs: These PIDs are unique to each manufacturer and provide access to more detailed and specific data. For Mercedes-Benz, manufacturer-specific PIDs are crucial for accessing advanced diagnostic information related to the chassis and other proprietary systems.

According to a study by Bosch, manufacturer-specific PIDs can provide up to 80% more diagnostic information compared to standardized PIDs alone.

1.4. How PIDs are Used in Mercedes Diagnostics

In Mercedes diagnostics, PIDs are used in conjunction with diagnostic tools to read and interpret data from the vehicle’s control units. The process typically involves the following steps:

- Connecting the Diagnostic Tool: The diagnostic tool is connected to the vehicle’s OBD-II port, usually located under the dashboard.

- Reading PIDs: The tool sends requests for specific PIDs to the vehicle’s ECU (Engine Control Unit) and other control modules.

- Interpreting Data: The ECU responds with the corresponding data, which is then displayed on the diagnostic tool. Technicians analyze this data to identify any anomalies or issues.

For instance, if a Mercedes-Benz is experiencing issues with its suspension, a technician might use manufacturer-specific PIDs to monitor the ride height sensors, air suspension pressure, and control valve operation to diagnose the problem accurately.

1.5. Accessing Enhanced Diagnostics with OBDLink® MX+ Adapter

Enhanced diagnostics provide access to additional modules and parameters beyond the SAE OBD-II standard. The OBDLink® MX+ adapter, coupled with diagnostic software, enables users to read and clear codes for systems like ABS (anti-lock braking system), SRS (supplemental restraint system), and TPMS (tire pressure monitoring system). This enhanced capability is particularly valuable for Mercedes-Benz vehicles, where intricate systems require detailed insights for effective troubleshooting.

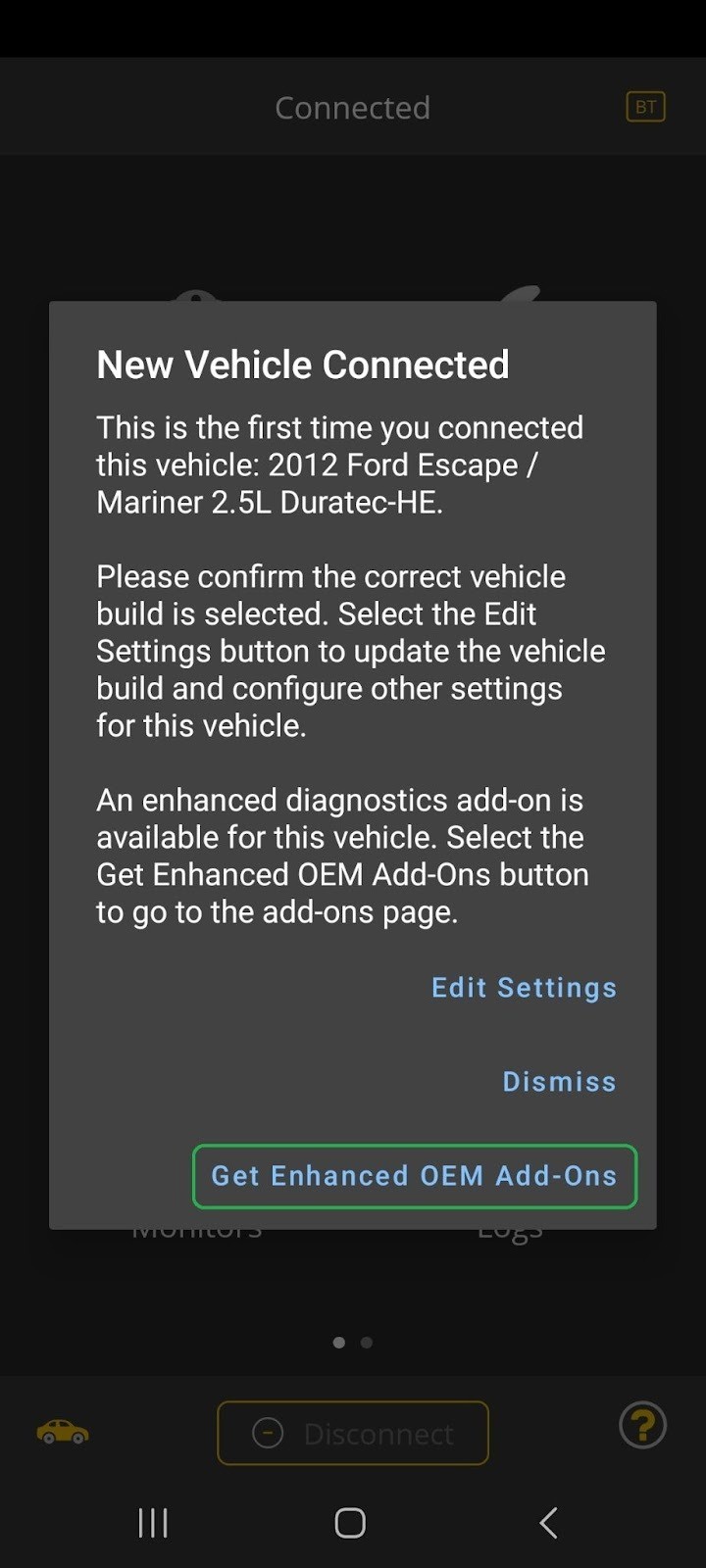

iOS screen showing a New Vehicle Connected message. The Get Enhanced OEM Add-Ons option is highlighted.

iOS screen showing a New Vehicle Connected message. The Get Enhanced OEM Add-Ons option is highlighted.

1.6. Downloading Enhanced Diagnostics for Mercedes-Benz

To access enhanced diagnostics for your Mercedes-Benz, follow these steps using the OBDLink app:

- Connect the Adapter: Start your vehicle and connect your phone/tablet to your OBDLink adapter. Ensure your device is not streaming to any other Bluetooth/BLE devices.

- Get Enhanced OEM Add-Ons:

- If it’s your first time connecting, a dialog box will appear with options to edit your vehicle settings and download enhanced OEM add-ons. Tap Get Enhanced OEM Add-Ons.

- If you don’t see this option, your vehicle may not be supported for enhanced diagnostics.

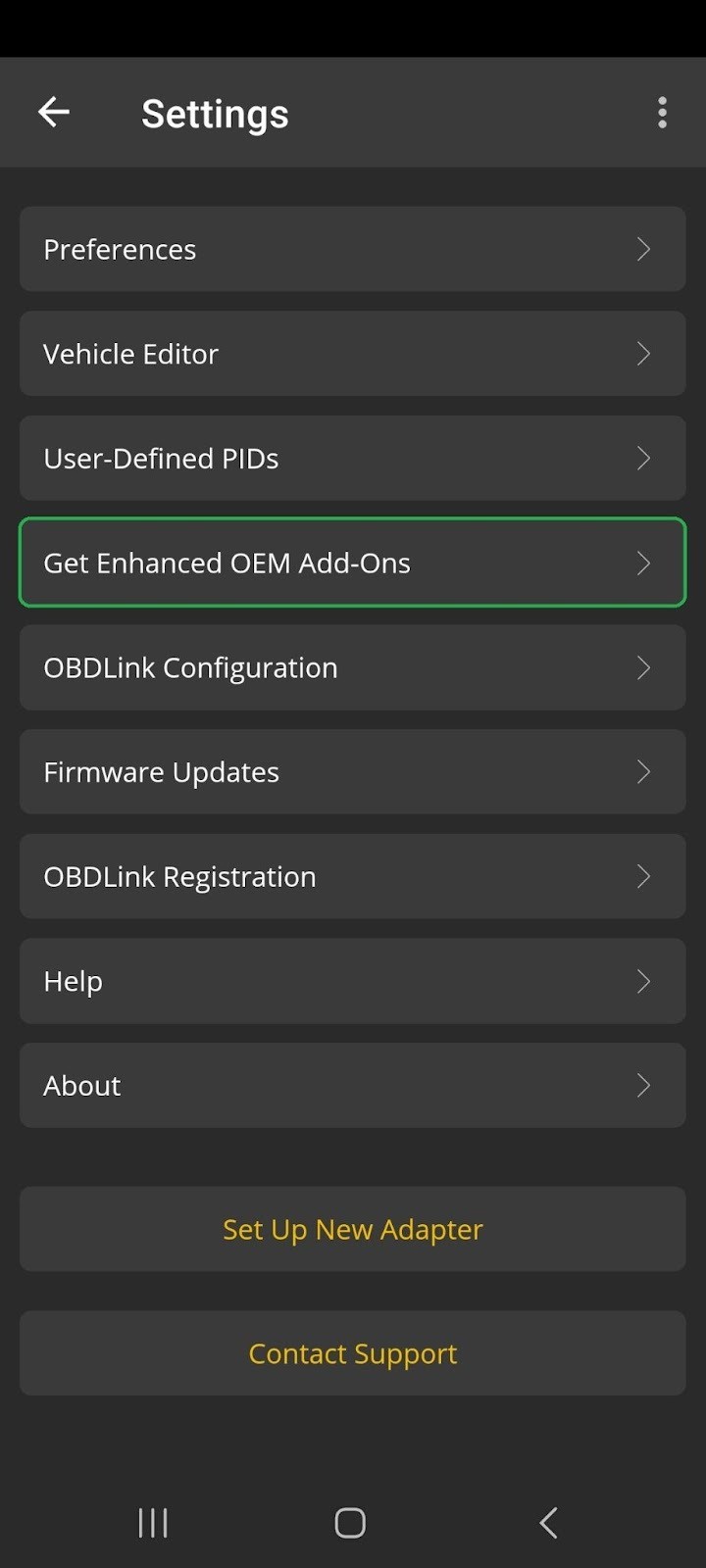

- If this isn’t your first time connecting, navigate to Settings > Get Enhanced OEM Add-Ons.

- Select Your Manufacturer: Browse the list and tap your vehicle manufacturer (Mercedes-Benz).

- Select Model Year: Browse the list and tap your vehicle’s model year.

- Choose Diagnostics: Tap Choose to select the diagnostics for your vehicle.

- Get Free Add-On: If prompted, tap GET FREE ADD-ON to utilize all features of your OBDLink adapter.

- Download Diagnostics: Tap Get to download the diagnostics for your vehicle. This may take a few minutes.

- Complete Installation: Once the download is complete, you’ll see a confirmation that the diagnostics are installed.

Android screenshot of the Settings menu. The Get Enhanced OEM Add-Ons option is highlighted.

Android screenshot of the Settings menu. The Get Enhanced OEM Add-Ons option is highlighted.

By following these steps, you can ensure your OBDLink adapter is fully equipped to provide detailed diagnostic information for your Mercedes-Benz, allowing for more accurate and effective troubleshooting.

2. Key PIDs for Mercedes Chassis Diagnostics

When diagnosing Mercedes-Benz chassis issues, specific Parameter IDs (PIDs) provide critical insights into the system’s health and performance. Focusing on these key PIDs allows technicians and car owners to accurately identify problems and implement effective solutions. Here are some of the most useful PIDs for Mercedes chassis diagnostics.

2.1. Suspension System PIDs

The suspension system is crucial for vehicle stability, ride comfort, and handling. Monitoring the following PIDs can help diagnose suspension-related issues:

- Ride Height Sensors (RHS):

- Description: These sensors measure the distance between the vehicle’s body and the wheels, providing data on ride height at each corner.

- Importance: Monitoring RHS PIDs can help identify issues with air suspension systems, such as sagging or uneven ride height, which can affect handling and comfort.

- Example: Monitoring the front left and front right ride height sensor values can reveal if one side of the vehicle is lower than the other, indicating a potential air strut leak or sensor malfunction.

- Air Suspension Pressure (ASP):

- Description: This PID indicates the pressure within the air suspension system.

- Importance: Monitoring ASP is vital for diagnosing leaks or compressor issues. Low pressure can cause the suspension to collapse, while high pressure can lead to system damage.

- Example: A sudden drop in air suspension pressure while driving can indicate a leak in the air lines or struts, requiring immediate attention.

- Damper Valve Position (DVP):

- Description: This PID reflects the position of the damper valves, which control the flow of fluid within the shock absorbers.

- Importance: Monitoring DVP can help diagnose issues with the adaptive damping system, ensuring optimal ride control and stability.

- Example: If the damper valve position remains constant regardless of driving conditions, it may indicate a faulty valve or control module.

- Acceleration Sensors (AS):

- Description: These sensors measure the vertical acceleration of the vehicle’s body, providing data on ride smoothness and road conditions.

- Importance: Monitoring AS PIDs can help identify issues with the suspension’s ability to absorb bumps and vibrations, affecting ride comfort.

- Example: High acceleration values on a smooth road can indicate worn shock absorbers or suspension components.

2.2. Steering System PIDs

The steering system ensures precise vehicle control and responsiveness. Monitoring the following PIDs can help diagnose steering-related issues:

- Steering Angle Sensor (SAS):

- Description: This sensor measures the angle of the steering wheel relative to the vehicle’s centerline.

- Importance: Monitoring SAS PIDs is crucial for diagnosing issues with the Electronic Stability Program (ESP) and other safety systems that rely on accurate steering angle data.

- Example: An incorrect or erratic SAS reading can cause the ESP system to activate unnecessarily or fail to activate in critical situations.

- Steering Torque Sensor (STS):

- Description: This sensor measures the amount of torque applied to the steering wheel by the driver.

- Importance: Monitoring STS PIDs can help diagnose issues with the power steering system and identify problems with steering effort and responsiveness.

- Example: A consistently high STS value can indicate a failing power steering pump or a blockage in the steering system.

- Power Steering Pressure (PSP):

- Description: This PID indicates the hydraulic pressure within the power steering system.

- Importance: Monitoring PSP is vital for diagnosing power steering pump failures or leaks. Low pressure can result in reduced steering assist, while high pressure can damage the system.

- Example: A gradual decrease in power steering pressure can indicate a worn power steering pump or a leak in the hydraulic lines.

2.3. Braking System PIDs

The braking system is critical for vehicle safety, and monitoring the following PIDs can help diagnose braking-related issues:

- Wheel Speed Sensors (WSS):

- Description: These sensors measure the rotational speed of each wheel.

- Importance: Monitoring WSS PIDs is essential for diagnosing issues with the Anti-lock Braking System (ABS), Traction Control System (TCS), and ESP.

- Example: Inconsistent wheel speed readings can trigger ABS or TCS activation, even on dry pavement, indicating a faulty wheel speed sensor.

- Brake Pressure Sensor (BPS):

- Description: This sensor measures the hydraulic pressure within the brake lines.

- Importance: Monitoring BPS PIDs can help diagnose issues with the brake master cylinder, brake booster, and individual brake calipers.

- Example: Low brake pressure readings can indicate a leak in the brake lines or a failing master cylinder.

- ABS Valve Position (AVP):

- Description: This PID reflects the position of the ABS valves, which control the brake pressure to each wheel during ABS activation.

- Importance: Monitoring AVP can help diagnose issues with the ABS module and ensure proper brake modulation during emergency stops.

- Example: If an ABS valve remains open or closed when it should be modulating, it can lead to uneven braking and loss of control.

2.4. Chassis Control Module PIDs

The chassis control module (CCM) oversees various chassis-related functions. Monitoring the following PIDs can help diagnose issues with the CCM and its interactions with other systems:

- CCM System Voltage (CSV):

- Description: This PID indicates the voltage supplied to the chassis control module.

- Importance: Monitoring CSV is vital for diagnosing electrical issues that can affect the CCM’s operation. Low voltage can cause the CCM to malfunction, leading to various chassis-related problems.

- Example: A sudden drop in CCM system voltage can indicate a failing battery or a loose connection in the electrical system.

- CCM Temperature (CCT):

- Description: This PID indicates the internal temperature of the chassis control module.

- Importance: Monitoring CCT can help identify overheating issues that can cause the CCM to fail. High temperatures can damage the CCM’s internal components, leading to erratic behavior.

- Example: Consistently high CCM temperature readings can indicate a lack of ventilation or a failing cooling fan.

- CCM Error Codes (CEC):

- Description: This PID displays any error codes stored within the chassis control module.

- Importance: Monitoring CEC is essential for diagnosing specific issues with the CCM and its associated systems. Error codes can provide valuable clues about the nature and location of the problem.

- Example: An error code indicating a faulty ride height sensor can help pinpoint the source of a suspension issue.

By focusing on these key PIDs, technicians and car owners can gain valuable insights into the health and performance of the Mercedes-Benz chassis. Regular monitoring and analysis of these data points can help identify potential problems early, preventing costly repairs and ensuring a safe and comfortable driving experience.

3. Diagnostic Tools and Software for Reading Mercedes PIDs

Effectively reading and interpreting Parameter IDs (PIDs) in Mercedes-Benz vehicles requires the right diagnostic tools and software. This section explores various options available, highlighting their features, compatibility, and benefits for Mercedes chassis diagnostics.

3.1. OBD-II Scanners

OBD-II scanners are basic diagnostic tools that can read standard PIDs from any OBD-II compliant vehicle. While they provide essential information, their capabilities are limited compared to more advanced tools.

- Features:

- Reads standard OBD-II PIDs.

- Displays Diagnostic Trouble Codes (DTCs).

- Clears DTCs and resets the check engine light.

- Compatibility:

- Compatible with all Mercedes-Benz vehicles that are OBD-II compliant (typically 1996 and newer).

- Benefits:

- Affordable and easy to use.

- Provides basic diagnostic information.

- Limitations:

- Limited access to manufacturer-specific PIDs.

- Does not support advanced diagnostic functions.

3.2. Advanced Diagnostic Tools

Advanced diagnostic tools offer more comprehensive capabilities, including access to manufacturer-specific PIDs and advanced diagnostic functions. These tools are essential for thorough Mercedes chassis diagnostics.

- Features:

- Reads standard and manufacturer-specific PIDs.

- Performs bi-directional control and system tests.

- Supports advanced functions such as coding and programming.

- Provides detailed diagnostic reports.

- Compatibility:

- Designed to work with Mercedes-Benz vehicles, offering full access to all available PIDs and diagnostic functions.

- Benefits:

- Provides comprehensive diagnostic information.

- Enables advanced troubleshooting and repair.

- Supports coding and programming functions.

- Limitations:

- More expensive than basic OBD-II scanners.

- Requires specialized knowledge and training to use effectively.

3.3. Software Solutions

In addition to diagnostic tools, specialized software solutions enhance the ability to read and interpret Mercedes PIDs. These software options often come with extensive databases and advanced analytical capabilities.

- Mercedes-Benz Diagnostic Software (e.g., XENTRY/DAS):

- Features:

- Full access to all Mercedes-Benz PIDs and diagnostic functions.

- Supports coding, programming, and module initialization.

- Provides detailed diagnostic reports and troubleshooting guides.

- Compatibility:

- Specifically designed for Mercedes-Benz vehicles.

- Benefits:

- Offers the most comprehensive diagnostic capabilities.

- Provides access to the latest software updates and diagnostic information.

- Limitations:

- Expensive and requires a valid license.

- Requires specialized hardware and training.

- Features:

- Third-Party Diagnostic Software (e.g., iCarsoft MB II, Autel MaxiSys):

- Features:

- Reads standard and manufacturer-specific PIDs.

- Performs bi-directional control and system tests.

- Supports some coding and programming functions.

- Provides diagnostic reports and troubleshooting guides.

- Compatibility:

- Compatible with a wide range of Mercedes-Benz models.

- Benefits:

- More affordable than OEM diagnostic software.

- User-friendly interface and easy to use.

- Limitations:

- May not offer full access to all Mercedes-Benz PIDs and diagnostic functions.

- Coding and programming capabilities may be limited.

- Features:

3.4. OBDLink® App and Adapter

The OBDLink® app, when paired with a compatible OBDLink adapter such as the MX+, provides a versatile and cost-effective solution for reading Mercedes PIDs.

- Features:

- Reads standard and enhanced OEM PIDs.

- Displays real-time data and diagnostic trouble codes.

- Generates diagnostic reports.

- Offers add-ons for specific manufacturers like GM, Honda, Acura, Hyundai, and Kia.

- Compatibility:

- Compatible with a wide range of Mercedes-Benz vehicles.

- Works with both iOS and Android devices.

- Benefits:

- Affordable and easy to use.

- Provides enhanced diagnostics for many vehicle types.

- Offers a user-friendly mobile interface.

- Limitations:

- Some advanced functions may require additional add-ons.

- May not offer the same level of detail as OEM diagnostic software.

3.5. Selecting the Right Tool for Your Needs

Choosing the right diagnostic tool and software depends on your specific needs and budget. Consider the following factors:

- Diagnostic Requirements:

- If you only need basic diagnostic information, a simple OBD-II scanner may suffice.

- For comprehensive diagnostics and advanced troubleshooting, invest in an advanced diagnostic tool or software solution.

- Budget:

- Basic OBD-II scanners are the most affordable option.

- Advanced diagnostic tools and software can range from several hundred to several thousand dollars.

- Technical Expertise:

- Basic OBD-II scanners are easy to use and require minimal technical knowledge.

- Advanced diagnostic tools and software require specialized knowledge and training to use effectively.

According to a survey by the Automotive Service Association (ASA), technicians who use advanced diagnostic tools and software are able to diagnose and repair vehicles more efficiently, resulting in increased customer satisfaction and profitability.

3.6. Step-by-Step Guide to Using the OBDLink® App

Here’s a step-by-step guide on how to use the OBDLink® app to read PIDs and diagnose issues in your Mercedes-Benz:

- Download and Install the App: Download the OBDLink app from the App Store (iOS) or Google Play (Android).

- Connect the Adapter: Plug the OBDLink adapter into the OBD-II port of your Mercedes-Benz.

- Pair with Your Device: Start your vehicle and connect your phone/tablet to your OBDLink adapter via Bluetooth.

- Select Vehicle Network: If prompted, select the appropriate vehicle diagnostic network. For everyday use, Generic OBD2 is recommended.

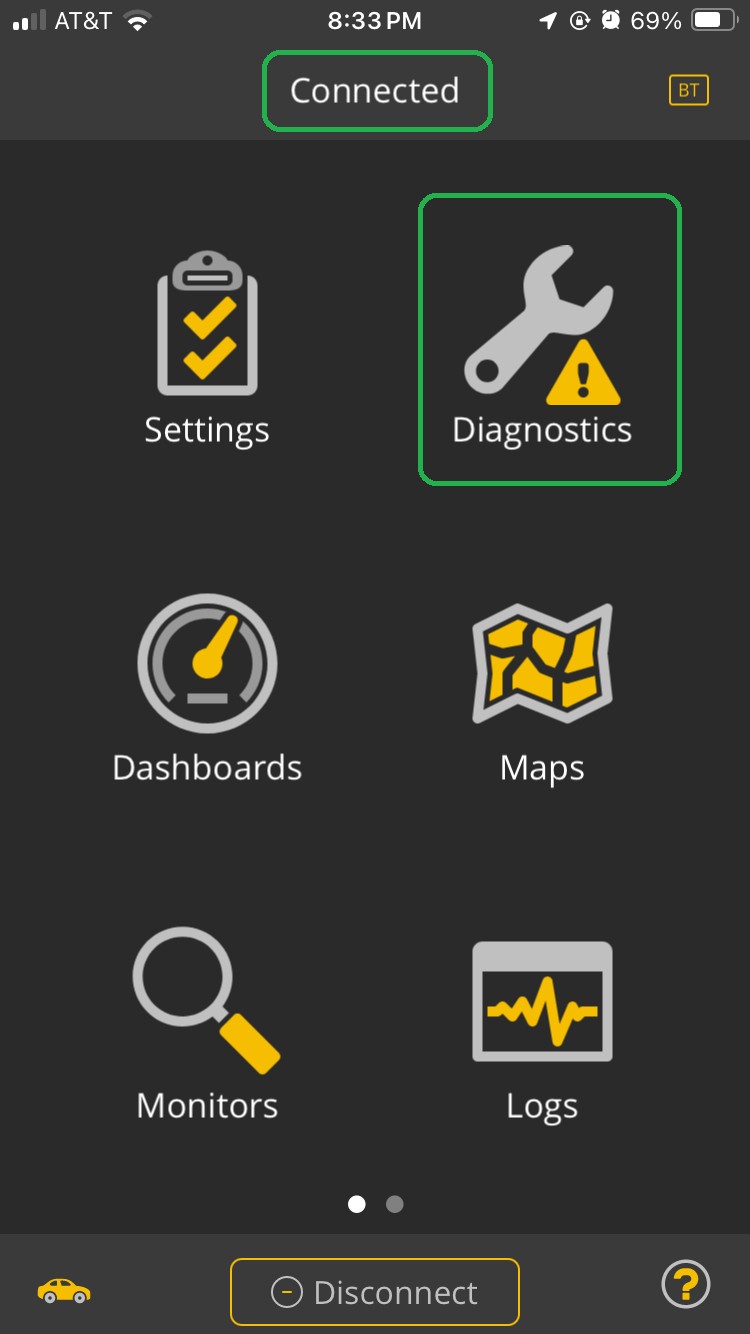

- View Diagnostics: Tap Diagnostics on the main screen.

- Read Trouble Codes: The app will display any Diagnostic Trouble Codes (DTCs). Tap a code for more information.

- View PID Values: Navigate to the PID Values tab to view real-time data from various sensors.

- Generate Reports: Use the Report tab to generate and share diagnostic reports.

iOS home screen. The Connected button and the Diagnostics selection are highlighted.

iOS home screen. The Connected button and the Diagnostics selection are highlighted.

By selecting the right diagnostic tools and software, technicians and car owners can effectively read and interpret Mercedes PIDs, leading to accurate diagnoses and efficient repairs. Regular use of these tools can help maintain the health and performance of your Mercedes-Benz chassis, ensuring a safe and enjoyable driving experience.

4. Interpreting PID Data for Accurate Chassis Diagnostics

Interpreting Parameter ID (PID) data accurately is crucial for effective chassis diagnostics in Mercedes-Benz vehicles. This section provides guidance on how to analyze PID values, identify common issues, and use the data to make informed repair decisions.

4.1. Understanding PID Value Ranges

Each PID has a specific range of acceptable values, and deviations from these ranges can indicate a problem. Understanding these ranges is the first step in interpreting PID data.

- Manufacturer Specifications: Refer to the Mercedes-Benz service manual or technical documentation for the specified value ranges for each PID.

- Baseline Data: Establish a baseline by recording PID values when the vehicle is functioning correctly. This provides a reference point for comparison when diagnosing issues.

- Online Resources: Utilize online forums and diagnostic databases to find typical PID values for specific Mercedes-Benz models and systems.

4.2. Identifying Common Issues Through PID Analysis

By monitoring and analyzing PID data, you can identify a wide range of chassis-related issues in Mercedes-Benz vehicles. Here are some common problems and the corresponding PID values that can help diagnose them:

- Suspension System Issues:

- Air Suspension Leaks: Monitor the Air Suspension Pressure (ASP) PID. A rapid decrease in pressure indicates a leak in the air lines or struts.

- Faulty Ride Height Sensors: Monitor the Ride Height Sensors (RHS) PIDs. Inconsistent or erratic readings can indicate a failing sensor.

- Damper Control Problems: Monitor the Damper Valve Position (DVP) PID. A constant or unresponsive DVP value can indicate a faulty damper control module or valve.

- Steering System Issues:

- Steering Angle Sensor Malfunctions: Monitor the Steering Angle Sensor (SAS) PID. Incorrect or erratic SAS readings can cause issues with the Electronic Stability Program (ESP) and other safety systems.

- Power Steering Pump Failures: Monitor the Power Steering Pressure (PSP) PID. Low PSP values can indicate a failing power steering pump or a leak in the hydraulic lines.

- Steering Torque Sensor Problems: Monitor the Steering Torque Sensor (STS) PID. High STS values can indicate a blockage in the steering system or a failing power steering pump.

- Braking System Issues:

- Wheel Speed Sensor Problems: Monitor the Wheel Speed Sensors (WSS) PIDs. Inconsistent or missing WSS readings can trigger ABS or Traction Control System (TCS) activation.

- Brake Pressure Sensor Failures: Monitor the Brake Pressure Sensor (BPS) PID. Low BPS values can indicate a leak in the brake lines or a failing master cylinder.

- ABS Valve Malfunctions: Monitor the ABS Valve Position (AVP) PID. If an AVP remains open or closed when it should be modulating, it can lead to uneven braking and loss of control.

4.3. Using Freeze Frame Data

Freeze frame data provides a snapshot of PID values at the moment a Diagnostic Trouble Code (DTC) is generated. This information can be invaluable for diagnosing intermittent issues.

- Accessing Freeze Frame Data: Most advanced diagnostic tools and software solutions can access and display freeze frame data.

- Analyzing Freeze Frame Values: Compare the freeze frame PID values to the normal operating ranges to identify any anomalies that may have triggered the DTC.

- Identifying Root Causes: Use the freeze frame data in conjunction with the DTC and other diagnostic information to pinpoint the root cause of the problem.

4.4. Bi-Directional Control and System Tests

Bi-directional control allows you to activate or deactivate specific components and systems to test their functionality. This capability can be extremely useful for diagnosing chassis-related issues.

- Activating Components: Use bi-directional control to activate components such as the air suspension compressor, ABS pump, or damper valves.

- Monitoring PID Values: Monitor the corresponding PID values while activating the components to verify that they are functioning correctly.

- Identifying Faulty Components: If a component fails to activate or the PID values do not respond as expected, it indicates a faulty component or wiring issue.

4.5. Case Studies: Interpreting PID Data in Real-World Scenarios

To further illustrate the importance of interpreting PID data, here are a couple of case studies:

Case Study 1: Air Suspension Issue

- Symptoms: The vehicle is sagging on one side, and the air suspension compressor is running continuously.

- PID Analysis:

- Monitor the Air Suspension Pressure (ASP) PID for each air strut.

- Notice that the ASP value for the affected side is significantly lower than the other side.

- Use bi-directional control to activate the air suspension compressor and monitor the ASP values.

- Observe that the ASP value for the affected side does not increase, indicating a leak.

- Diagnosis: Air leak in the affected air strut or air line.

- Solution: Replace the leaking air strut or repair the damaged air line.

Case Study 2: ABS Malfunction

- Symptoms: The ABS light is illuminated, and the ABS system is activating unnecessarily.

- PID Analysis:

- Monitor the Wheel Speed Sensors (WSS) PIDs for each wheel.

- Notice that one of the WSS PIDs is providing inconsistent or erratic readings.

- Use an oscilloscope to analyze the WSS signal and confirm that it is distorted.

- Diagnosis: Faulty wheel speed sensor.

- Solution: Replace the faulty wheel speed sensor.

4.6. Leveraging MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Expert Guidance

For expert guidance on interpreting PID data and diagnosing Mercedes-Benz chassis issues, turn to MERCEDES-DIAGNOSTIC-TOOL.EDU.VN. Our platform provides:

- Detailed Diagnostic Guides: Step-by-step guides on how to interpret PID data and diagnose common chassis issues.

- Troubleshooting Tips: Expert tips and tricks for resolving complex diagnostic problems.

- Community Forum: A forum where you can connect with other Mercedes-Benz enthusiasts and professionals to share knowledge and ask questions.

- Contact Us: Reach out to us directly via WhatsApp at +1 (641) 206-8880 for personalized assistance and expert advice.

By understanding PID value ranges, analyzing freeze frame data, and utilizing bi-directional control, technicians and car owners can accurately diagnose chassis-related issues in Mercedes-Benz vehicles. Regular use of diagnostic tools and software, combined with expert guidance from MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, can help maintain the health and performance of your Mercedes-Benz chassis, ensuring a safe and enjoyable driving experience.

5. Common Mistakes to Avoid When Reading Mercedes PIDs

Reading Parameter IDs (PIDs) in Mercedes-Benz vehicles can provide valuable diagnostic information, but it’s essential to avoid common mistakes that can lead to inaccurate diagnoses and wasted time. This section outlines frequent errors made when reading PIDs and offers practical tips to ensure accurate and reliable results.

5.1. Ignoring Manufacturer Specifications

One of the most common mistakes is failing to consult the manufacturer’s specifications for PID value ranges. Each Mercedes-Benz model and system has specific parameters, and deviations from these ranges can indicate problems.

- Mistake: Assuming that generic PID values apply to all Mercedes-Benz vehicles.

- Consequence: Misinterpreting PID data and making incorrect diagnoses.

- Tip: Always refer to the Mercedes-Benz service manual or technical documentation for the specified PID value ranges for your vehicle.

5.2. Neglecting Baseline Data

Without a baseline for comparison, it can be challenging to determine whether PID values are within the normal range. Establishing a baseline involves recording PID values when the vehicle is functioning correctly.

- Mistake: Not establishing a baseline for comparison.

- Consequence: Difficulty identifying deviations from normal PID values.

- Tip: Record PID values when the vehicle is functioning correctly to establish a baseline for comparison when diagnosing issues.

5.3. Overlooking Freeze Frame Data

Freeze frame data provides a snapshot of PID values at the moment a Diagnostic Trouble Code (DTC) is generated. Ignoring this data can result in missed clues and inaccurate diagnoses.

- Mistake: Ignoring freeze frame data.

- Consequence: Missing valuable information about the conditions that triggered the DTC.

- Tip: Always analyze freeze frame data in conjunction with the DTC and other diagnostic information to pinpoint the root cause of the problem.

5.4. Failing to Use Bi-Directional Control

Bi-directional control allows you to activate or deactivate specific components and systems to test their functionality. Failing to use this capability can limit your ability to diagnose chassis-related issues effectively.

- Mistake: Not using bi-directional control to test components and systems.

- Consequence: Difficulty isolating faulty components and systems.

- Tip: Use bi-directional control to activate components such as the air suspension compressor, ABS pump, or damper valves and monitor the corresponding PID values.

5.5. Misinterpreting PID Relationships

PID values often have complex relationships with each other, and misinterpreting these relationships can lead to incorrect diagnoses.

- Mistake: Analyzing PID values in isolation without considering their relationships with other PIDs.

- Consequence: Missing important clues about the system’s overall health.

- Tip: Consider the relationships between PID values and how they influence each other when diagnosing issues.

5.6. Ignoring Electrical Issues

Electrical problems can cause erratic or inaccurate PID readings. Ignoring electrical issues can lead to misdiagnoses and wasted time.

- Mistake: Overlooking electrical issues that can affect PID readings.

- Consequence: Misinterpreting PID data and making incorrect diagnoses.

- Tip: Check for electrical issues such as voltage drops, shorts, and open circuits that can affect PID readings.

5.7. Not Verifying Sensor Accuracy

Faulty sensors can provide inaccurate PID readings, leading to misdiagnoses. It’s essential to verify the accuracy of sensors before relying on their PID values.

- Mistake: Assuming that all sensors are accurate and reliable.

- Consequence: Misinterpreting PID data and making incorrect diagnoses.

- Tip: Use a multimeter or oscilloscope to verify the accuracy of sensors before relying on their PID values.

5.8. Overlooking Software and Firmware Updates

Outdated diagnostic tools and software can lead to inaccurate PID readings and missed diagnostic information. It’s essential to keep your tools and software up to date.

- Mistake: Not keeping diagnostic tools and software up to date.

- Consequence: Missing important diagnostic information and making inaccurate diagnoses.

- Tip: Regularly check for software and firmware updates for your diagnostic tools and software and install them as needed.

5.9. Failing to Document Diagnostic Procedures

Proper documentation is essential for accurate and efficient diagnostics. Failing to document your diagnostic procedures can lead to confusion and wasted time.

- Mistake: Not documenting diagnostic procedures and findings.

- Consequence: Difficulty tracking progress and making informed decisions.

- Tip: Document all diagnostic procedures, PID values, and findings to track progress and make informed decisions.

5.10. Neglecting Professional Training

Professional training can provide you with the knowledge and skills needed to accurately read and interpret PIDs. Neglecting professional training can limit your diagnostic capabilities and lead to mistakes.

- Mistake: Not seeking professional training on Mercedes-Benz diagnostics.

- Consequence: Limited diagnostic capabilities and increased risk of making mistakes.

- Tip: Invest in professional training on Mercedes-Benz diagnostics to improve your knowledge and skills.

5.11. Seeking Expert Assistance from MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

For expert assistance on avoiding common mistakes when reading Mercedes PIDs, turn to MERCEDES-DIAGNOSTIC-TOOL.EDU.VN. Our platform offers:

- Comprehensive Diagnostic Guides: Detailed guides on how to accurately read and interpret PIDs.

- Troubleshooting Tips: Expert tips and tricks for avoiding common diagnostic mistakes.

- Community Forum: A forum where you can connect with other Mercedes-Benz enthusiasts and professionals to share knowledge and ask questions.

- Contact Us: Reach out to us directly via WhatsApp at +1 (641) 206-8880 for personalized assistance and expert advice.

- Address: 789 Oak Avenue, Miami, FL 33101, United States.

By avoiding these common mistakes, technicians and car owners can accurately read and interpret PIDs in Mercedes-Benz vehicles, leading to more effective diagnoses and efficient repairs. Regular use of diagnostic tools and software, combined with expert guidance from MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, can help maintain the health and performance of your Mercedes-Benz chassis, ensuring a safe and enjoyable driving experience.

6. Advanced Techniques for Chassis Diagnostics Using PIDs

To elevate chassis diagnostics in Mercedes-Benz vehicles, advanced techniques using Parameter IDs (PIDs) can provide deeper insights into system performance and potential issues. This section explores these advanced techniques, including data logging, graphing, and advanced PID analysis.

6.1. Data Logging for Intermittent Issues

Data logging involves recording PID values over a period of time, allowing you to capture intermittent issues that may not be apparent during a static diagnostic test.

- Setting Up Data Logging: Use a diagnostic tool or software solution that supports data logging. Select the PIDs you want to monitor and set the logging interval.

- Driving Under Various Conditions: Drive the vehicle under various conditions that are likely to trigger the intermittent issue.

- Analyzing the Data: Review the logged data to identify any anomalies or deviations from normal PID values that occurred during the intermittent issue.

- Example: If a Mercedes-Benz is experiencing intermittent suspension problems, log the Ride Height Sensors (RHS), Air Suspension Pressure (ASP), and Damper Valve Position (DVP) PIDs while driving over bumpy roads. Analyze the data to identify any sudden drops in pressure or erratic sensor readings that correlate with the suspension issue.

6.2. Graphing PID Values for Visual Analysis

Graphing PID values provides a visual representation of the data, making it easier to identify trends and anomalies.

- Using Graphing Tools: Utilize diagnostic tools or software solutions that offer graphing capabilities.

- Selecting PIDs to Graph: Select the PIDs you want to graph and set the graphing parameters.

- Analyzing the Graphs: Review the graphs to identify any spikes, dips, or oscillations in the PID values that may indicate a problem.

- Example: Graphing the Wheel Speed Sensors (WSS) PIDs can help identify a faulty wheel speed sensor that is causing ABS activation issues. A graph will visually highlight any erratic or inconsistent readings from the affected sensor.

6.3. Advanced PID Analysis Techniques

Advanced PID analysis techniques involve using mathematical formulas and algorithms to derive additional information from the PID data.

- Calculating PID Derivatives: Calculate the rate of change of PID values to identify sudden changes or trends that may indicate a problem.

- Using PID Ratios: Calculate the ratio between two PID values to identify imbalances or inefficiencies in the system.

- Applying Statistical Analysis: Apply statistical analysis techniques such as moving averages and standard deviations to smooth out the PID data and identify outliers.

- Example: Calculating the derivative of the engine RPM PID can help identify misfires or other engine performance issues. A sudden drop in RPM can indicate a misfire, while a