Are Obd1 And Obd2 Compatible? No, OBD1 and OBD2 are generally not compatible due to significant differences in their communication protocols, connector types, and the data they transmit; however, it’s important to understand the nuances of each system, including exceptions and workarounds to make informed decisions about vehicle diagnostics, and MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers resources to navigate these complexities, providing insights, tools, and support for diagnosing and maintaining Mercedes-Benz vehicles. Exploring vehicle diagnostic protocols, understanding scan tool compatibility, and recognizing adapter solutions will help you in your diagnostic efforts.

Contents

- 1. Understanding OBD1 and OBD2: A Detailed Comparison

- 1.1. What is OBD1?

- 1.2. What is OBD2?

- 1.3. Key Differences Between OBD1 and OBD2

- 1.4. OBD2 Enhanced Capabilities

- 1.5. Benefits of OBD2 Standardization

- 2. Exploring OBD1 Compatibility Challenges

- 2.1. Lack of Standardization in OBD1 Systems

- 2.2. Connector Variations in OBD1

- 2.3. Protocol Differences in OBD1

- 2.4. Diagnostic Code Inconsistencies in OBD1

- 2.5. Limited Data Availability in OBD1

- 2.6. Locating the OBD1 Port

- 2.7. Using Adapters for OBD1 Connections

- 2.8. The Role of Service Manuals in OBD1 Diagnostics

- 3. Addressing OBD1 and OBD2 Incompatibility

- 3.1. Can OBD2 Scanners Read OBD1 Vehicles?

- 3.2. Using OBD1 to OBD2 Adapters: What You Need to Know

- 3.3. Limitations of Using Adapters

- 3.4. The Importance of OBD1-Specific Scan Tools

- 3.5. Identifying OBD1-Compliant Scan Tools

- 3.6. Ensuring Protocol Compatibility

- 3.7. Software Considerations for OBD1 Diagnostics

- 4. A Deep Dive into Mercedes-Benz Diagnostic Tools

- 4.1. Overview of Mercedes-Benz Diagnostic Systems

- 4.2. Key Features of Mercedes-Benz Diagnostic Tools

- 4.3. Types of Diagnostic Tools for Mercedes-Benz Vehicles

- 4.4. Specific Mercedes-Benz Diagnostic Tools

- 4.5. Choosing the Right Diagnostic Tool

- 4.6. Ensuring Compatibility with Your Mercedes-Benz Model

- 4.7. Updating Diagnostic Tool Software

- 5. Navigating Scan Tool Compatibility for Mercedes-Benz

- 5.1. Understanding Mercedes-Benz Diagnostic Protocols

- 5.2. Identifying the Correct Protocol for Your Mercedes-Benz

- 5.3. Scan Tool Features to Look For

- 5.4. OEM vs. Aftermarket Scan Tools for Mercedes-Benz

- 5.5. Top Scan Tool Brands for Mercedes-Benz Vehicles

- 5.6. Updating Scan Tool Software for Mercedes-Benz Models

- 5.7. Using Scan Tools for Specific Diagnostic Tasks

- 6. Practical Solutions for Mercedes-Benz Diagnostics

- 6.1. Common Diagnostic Trouble Codes (DTCs) in Mercedes-Benz Vehicles

- 6.2. Step-by-Step Diagnostic Procedures

- 6.3. Using Wiring Diagrams and Technical Information

- 6.4. Diagnosing Intermittent Problems

- 6.5. Using Real-Time Data to Diagnose Problems

- 6.6. Tips for Effective Mercedes-Benz Diagnostics

- 6.7. Resources for Mercedes-Benz Technicians

- 7. The Future of Vehicle Diagnostics

- 7.1. Advancements in Diagnostic Technology

- 7.2. The Role of Telematics in Vehicle Diagnostics

- 7.3. The Impact of Electric Vehicles (EVs) on Diagnostics

- 7.4. The Importance of Training and Certification

- 7.5. Preparing for the Future of Vehicle Diagnostics

- 8. Frequently Asked Questions (FAQs) About OBD1 and OBD2 Compatibility

- 8.1. What does OBD stand for?

- 8.2. Is my car OBD1 or OBD2?

- 8.3. Can I use an OBD2 scanner on an OBD1 car with an adapter?

- 8.4. What is the difference between OBD1 and OBD2?

- 8.5. What are the benefits of OBD2?

- 8.6. What is a DTC?

- 8.7. Where can I find the OBD port in my car?

- 8.8. What is a scan tool?

- 8.9. How do I update my scan tool software?

- 8.10. What is the future of vehicle diagnostics?

- 9. Call to Action

1. Understanding OBD1 and OBD2: A Detailed Comparison

OBD (On-Board Diagnostics) systems have revolutionized vehicle diagnostics, providing technicians and car owners with valuable insights into a vehicle’s performance and health, but understanding the difference between OBD1 and OBD2 is crucial for anyone working with or maintaining vehicles.

1.1. What is OBD1?

OBD1 was the first generation of on-board diagnostic systems implemented in vehicles. Its primary function was to monitor emissions-related components and systems, alerting drivers to potential issues through a malfunction indicator lamp (MIL), commonly known as the “check engine light.” However, OBD1 systems varied significantly between manufacturers, lacking standardization in diagnostic codes, connector types, and communication protocols. This inconsistency made it challenging for technicians to diagnose and repair vehicles from different manufacturers, requiring specialized tools and knowledge for each make and model.

1.2. What is OBD2?

OBD2 is the second generation of on-board diagnostic systems, introduced in the mid-1990s. Unlike OBD1, OBD2 is characterized by its standardization. Mandated in the United States for all passenger vehicles manufactured after 1996, OBD2 features a standardized diagnostic connector (SAE J1962), a uniform set of diagnostic trouble codes (DTCs), and a standardized communication protocol (SAE J1979). This standardization allows a single scan tool to interface with and diagnose any OBD2-compliant vehicle, greatly simplifying the diagnostic process. OBD2 also provides more comprehensive monitoring of vehicle systems, including emissions-related components, powertrain, and some body and chassis functions.

1.3. Key Differences Between OBD1 and OBD2

Understanding the key differences between OBD1 and OBD2 is essential for anyone working with vehicle diagnostics. These differences span across communication protocols, connector types, diagnostic capabilities, and the level of standardization.

| Feature | OBD1 | OBD2 |

|---|---|---|

| Standardization | Non-standardized | Standardized |

| Connector Type | Varies by manufacturer | Standardized 16-pin connector (SAE J1962) |

| Communication Protocol | Varies by manufacturer | Standardized protocols such as CAN, ISO 9141-2, and SAE J1850 |

| Diagnostic Codes | Manufacturer-specific | Standardized DTCs (SAE J2012) |

| Systems Monitored | Primarily emissions-related components | Comprehensive monitoring of emissions, powertrain, and some body/chassis functions |

| Data Availability | Limited data parameters | Enhanced data parameters and real-time data streaming |

| Tool Compatibility | Requires specialized tools for each manufacturer | Universal scan tools can be used across different makes and models |

1.4. OBD2 Enhanced Capabilities

OBD2 offers enhanced capabilities that surpass those of OBD1, providing more detailed and standardized diagnostic information. These enhancements include:

- Standardized Diagnostic Trouble Codes (DTCs): OBD2 employs a standardized set of DTCs defined by SAE J2012, ensuring that the same code indicates the same problem across different vehicle makes and models. This standardization simplifies the diagnostic process and reduces the need for manufacturer-specific knowledge.

- Comprehensive System Monitoring: OBD2 monitors a wider range of vehicle systems, including not only emissions-related components but also powertrain, fuel system, ignition system, and even some body and chassis functions. This comprehensive monitoring provides a more holistic view of the vehicle’s health.

- Real-Time Data Streaming: OBD2 allows technicians to access real-time data from various sensors and components, providing valuable insights into the vehicle’s performance under different operating conditions. This real-time data streaming enables more accurate and efficient diagnostics.

- Freeze Frame Data: When a DTC is triggered, OBD2 stores “freeze frame” data, which captures the operating conditions of the vehicle at the moment the fault occurred. This information can be invaluable in diagnosing intermittent problems.

- Readiness Monitors: OBD2 includes “readiness monitors” that indicate whether certain emissions-related systems have been tested and are functioning correctly. These monitors are crucial for ensuring compliance with emissions regulations.

1.5. Benefits of OBD2 Standardization

The standardization of OBD2 has brought numerous benefits to the automotive industry, including:

- Simplified Diagnostics: Technicians can use a single scan tool to diagnose a wide range of vehicles, reducing the need for specialized equipment.

- Reduced Training Costs: The standardized diagnostic codes and procedures reduce the amount of training required for technicians.

- Faster Repair Times: The availability of standardized diagnostic information and real-time data allows technicians to diagnose and repair vehicles more quickly and efficiently.

- Improved Emissions Control: The comprehensive monitoring of emissions-related systems helps ensure that vehicles comply with emissions regulations, reducing air pollution.

- Enhanced Consumer Protection: Consumers benefit from more transparent and consistent diagnostic information, empowering them to make informed decisions about vehicle maintenance and repair.

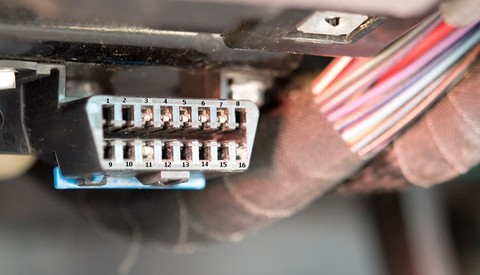

OBD2 Port

OBD2 Port

The OBD2 port is a standardized 16-pin connector, any scan tool will plug directly into this port with no adapter required.

2. Exploring OBD1 Compatibility Challenges

Understanding OBD1 compatibility challenges is essential for working with older vehicles, as these systems lack the standardization found in OBD2. Addressing these challenges often requires specialized tools, knowledge, and techniques.

2.1. Lack of Standardization in OBD1 Systems

The primary challenge with OBD1 systems is the lack of standardization. Unlike OBD2, which features a standardized connector, diagnostic codes, and communication protocols, OBD1 systems vary significantly between manufacturers. This lack of standardization means that a scan tool designed for one make of vehicle may not work with another, requiring technicians to invest in multiple specialized tools.

2.2. Connector Variations in OBD1

OBD1 vehicles feature a wide variety of diagnostic connectors, with each manufacturer often using its own proprietary design. These connectors can range from simple pin connectors to more complex multi-pin interfaces. The lack of a universal connector makes it difficult to connect a generic scan tool to an OBD1 vehicle, often requiring the use of adapter cables.

nissan 14 pin adapter

nissan 14 pin adapter

A 14-pin adapter cable required for older Nissans.

2.3. Protocol Differences in OBD1

OBD1 systems employ a variety of communication protocols, with each manufacturer using its own proprietary protocol. These protocols dictate how the scan tool communicates with the vehicle’s computer, and they vary in terms of data transmission rates, message formats, and error-checking mechanisms. The lack of a universal protocol means that a scan tool designed for one OBD1 protocol may not work with another, requiring specialized software and hardware.

2.4. Diagnostic Code Inconsistencies in OBD1

OBD1 systems use manufacturer-specific diagnostic trouble codes (DTCs) to indicate faults in the vehicle’s systems. These codes vary significantly between manufacturers, with the same code potentially indicating different problems in different vehicles. The lack of standardized DTCs makes it difficult for technicians to interpret the diagnostic information provided by OBD1 systems, often requiring access to manufacturer-specific repair manuals and databases.

2.5. Limited Data Availability in OBD1

OBD1 systems typically provide limited data compared to OBD2 systems. They may only monitor a small number of sensors and components, and they may not provide real-time data streaming or freeze frame data. This limited data availability can make it more difficult to diagnose complex problems in OBD1 vehicles, requiring technicians to rely on their experience and intuition.

2.6. Locating the OBD1 Port

Finding the OBD1 port can be challenging, as its location varies significantly depending on the vehicle’s make and model. In some vehicles, the port is located under the dashboard, while in others, it may be found in the engine compartment or even behind a panel. Consulting the vehicle’s service manual or a reliable online resource is often necessary to locate the OBD1 port.

2.7. Using Adapters for OBD1 Connections

Due to the variety of connector types used in OBD1 systems, adapters are often necessary to connect a scan tool to the vehicle. These adapters typically feature an OBD2 connector on one end and a manufacturer-specific connector on the other end, allowing a generic OBD2 scan tool to interface with the OBD1 vehicle. However, it’s important to ensure that the adapter is compatible with both the scan tool and the vehicle’s OBD1 system.

2.8. The Role of Service Manuals in OBD1 Diagnostics

Service manuals play a crucial role in OBD1 diagnostics, providing detailed information about the vehicle’s systems, diagnostic codes, and repair procedures. These manuals often contain wiring diagrams, sensor specifications, and troubleshooting tips that are essential for diagnosing complex problems in OBD1 vehicles. Access to accurate and up-to-date service manuals is crucial for any technician working with OBD1 systems.

toyota 22 pin obd port

toyota 22 pin obd port

Toyota OBD1 22-pin port located in the engine bay, requiring the Toyota 22-pin OBD1 adapter.

3. Addressing OBD1 and OBD2 Incompatibility

Addressing OBD1 and OBD2 incompatibility requires understanding the limitations and potential workarounds. While direct compatibility is not possible, several strategies can help bridge the gap.

3.1. Can OBD2 Scanners Read OBD1 Vehicles?

OBD2 scanners cannot directly read OBD1 vehicles due to the differences in connectors, communication protocols, and diagnostic codes. An OBD2 scanner is designed to communicate with vehicles that adhere to the standardized OBD2 protocol, which was mandated in the United States for all passenger vehicles manufactured after 1996. OBD1 vehicles, on the other hand, use a variety of proprietary protocols and connectors, making them incompatible with OBD2 scanners.

3.2. Using OBD1 to OBD2 Adapters: What You Need to Know

OBD1 to OBD2 adapters can be used to connect an OBD2 scanner to an OBD1 vehicle, but they do not magically make the two systems compatible. These adapters simply convert the physical connector from the OBD1 standard to the OBD2 standard, allowing the scanner to plug into the vehicle. However, the adapter does not bridge the gap between the different communication protocols and diagnostic codes used by OBD1 and OBD2 systems.

3.3. Limitations of Using Adapters

While OBD1 to OBD2 adapters can be useful in certain situations, it’s important to understand their limitations. These adapters do not convert the data being transmitted between the scanner and the vehicle. The OBD2 scanner will still attempt to communicate using the OBD2 protocol, which the OBD1 vehicle will not understand. As a result, the scanner will not be able to retrieve any diagnostic information from the vehicle.

3.4. The Importance of OBD1-Specific Scan Tools

To properly diagnose and repair OBD1 vehicles, it’s essential to use an OBD1-specific scan tool. These scan tools are designed to communicate with the specific protocols and connectors used by OBD1 vehicles. They also come equipped with the necessary software and databases to interpret the manufacturer-specific diagnostic codes used by OBD1 systems.

3.5. Identifying OBD1-Compliant Scan Tools

Identifying OBD1-compliant scan tools requires careful research and attention to product specifications. Look for scan tools that specifically mention OBD1 compatibility and list the makes and models of vehicles they support. Check the scan tool’s documentation to ensure that it includes the necessary software and adapters for the OBD1 vehicles you intend to diagnose.

3.6. Ensuring Protocol Compatibility

When selecting an OBD1-compliant scan tool, it’s crucial to ensure that it supports the specific communication protocols used by the OBD1 vehicles you intend to diagnose. Some scan tools may only support a limited number of OBD1 protocols, while others may offer broader compatibility. Consult the vehicle’s service manual or a reliable online resource to determine the correct protocol for your vehicle.

3.7. Software Considerations for OBD1 Diagnostics

Software plays a critical role in OBD1 diagnostics, as it is responsible for interpreting the manufacturer-specific diagnostic codes and data transmitted by the vehicle. Ensure that the OBD1-compliant scan tool you select includes the necessary software for the vehicles you intend to diagnose. Some scan tools may require you to purchase additional software or subscriptions to access the full range of diagnostic capabilities.

toyota22pin_adapter

toyota22pin_adapter

The required adapter for this type of port is the Toyota 22-pin OBD1 adapter.

4. A Deep Dive into Mercedes-Benz Diagnostic Tools

Mercedes-Benz vehicles, known for their advanced engineering and sophisticated electronics, require specialized diagnostic tools to ensure accurate and efficient troubleshooting. These tools range from basic code readers to comprehensive diagnostic systems, each designed to address specific needs and capabilities.

4.1. Overview of Mercedes-Benz Diagnostic Systems

Mercedes-Benz diagnostic systems are designed to provide comprehensive access to the vehicle’s electronic control units (ECUs), allowing technicians to read diagnostic trouble codes (DTCs), access real-time data, perform component tests, and program control units. These systems typically consist of a hardware interface, software, and a database of vehicle-specific information.

4.2. Key Features of Mercedes-Benz Diagnostic Tools

Mercedes-Benz diagnostic tools offer a range of features that are essential for diagnosing and repairing these complex vehicles. These features include:

- DTC Reading and Clearing: The ability to read and clear DTCs from all ECUs in the vehicle.

- Real-Time Data Streaming: Access to real-time data from sensors and components, allowing technicians to monitor vehicle performance under different operating conditions.

- Component Testing: The ability to perform component tests to verify the functionality of individual components, such as sensors, actuators, and solenoids.

- Control Unit Programming: The ability to program and calibrate control units, ensuring that they are properly configured for the vehicle.

- Guided Diagnostics: Step-by-step diagnostic procedures that guide technicians through the troubleshooting process.

- Wiring Diagrams and Technical Information: Access to wiring diagrams, technical specifications, and repair procedures.

4.3. Types of Diagnostic Tools for Mercedes-Benz Vehicles

Several types of diagnostic tools are available for Mercedes-Benz vehicles, each offering different levels of functionality and coverage:

- OBD2 Code Readers: Basic code readers that can read and clear DTCs from the engine control unit (ECU). These tools are typically inexpensive and easy to use, but they offer limited functionality beyond basic code reading.

- Multisystem Scanners: Scanners that can read and clear DTCs from multiple ECUs in the vehicle, including the engine, transmission, ABS, and airbag systems. These tools offer more comprehensive coverage than OBD2 code readers, but they may not provide access to all of the features of a full-fledged diagnostic system.

- Mercedes-Benz Dealer-Level Diagnostic Systems: These are the diagnostic systems used by Mercedes-Benz dealerships, offering the most comprehensive coverage and functionality. They provide access to all of the vehicle’s ECUs, as well as advanced features such as control unit programming, guided diagnostics, and access to technical information.

- Aftermarket Diagnostic Systems: These are diagnostic systems developed by third-party manufacturers that offer similar functionality to the dealer-level systems. They can be a cost-effective alternative to the dealer-level systems, but it’s important to choose a reputable brand that offers good coverage and support.

4.4. Specific Mercedes-Benz Diagnostic Tools

Several specific diagnostic tools are popular among Mercedes-Benz technicians and enthusiasts:

- Mercedes-Benz XENTRY: The official dealer-level diagnostic system for Mercedes-Benz vehicles. It provides comprehensive coverage and functionality, including access to all ECUs, control unit programming, and guided diagnostics.

- Autel MaxiSYS: A popular aftermarket diagnostic system that offers good coverage and functionality for Mercedes-Benz vehicles. It supports DTC reading and clearing, real-time data streaming, component testing, and some control unit programming.

- iCarsoft MB II: A more affordable option that offers decent coverage for Mercedes-Benz vehicles. It supports DTC reading and clearing, real-time data streaming, and some component testing.

4.5. Choosing the Right Diagnostic Tool

Choosing the right diagnostic tool for your Mercedes-Benz vehicle depends on your needs and budget. If you are a professional technician working on Mercedes-Benz vehicles on a daily basis, a dealer-level diagnostic system like XENTRY is the best option. If you are a DIY enthusiast or a small repair shop, an aftermarket diagnostic system like Autel MaxiSYS may be a more cost-effective choice.

4.6. Ensuring Compatibility with Your Mercedes-Benz Model

Before purchasing a diagnostic tool, it’s important to ensure that it is compatible with your specific Mercedes-Benz model. Check the tool’s specifications to see if it supports the year, make, and model of your vehicle. Some tools may require additional software or adapters to work with certain vehicles.

4.7. Updating Diagnostic Tool Software

Keeping your diagnostic tool’s software up to date is essential for ensuring accurate and reliable diagnostics. Diagnostic tool manufacturers regularly release software updates that include new vehicle coverage, bug fixes, and enhanced functionality. Check the manufacturer’s website for information on how to update your tool’s software.

5. Navigating Scan Tool Compatibility for Mercedes-Benz

Navigating scan tool compatibility for Mercedes-Benz vehicles requires understanding the specific diagnostic protocols and systems used by these vehicles, as well as the capabilities of different scan tools. Ensuring compatibility is crucial for accurate and efficient diagnostics.

5.1. Understanding Mercedes-Benz Diagnostic Protocols

Mercedes-Benz vehicles use a variety of diagnostic protocols, including:

- OBD2 (On-Board Diagnostics II): The standardized protocol used by all passenger vehicles manufactured after 1996. OBD2 provides access to basic diagnostic information, such as DTCs and real-time data from the engine control unit (ECU).

- CAN (Controller Area Network): A communication protocol used by many modern Mercedes-Benz vehicles to communicate between different ECUs. CAN allows for faster and more reliable data transmission than older protocols.

- KW2000 (Keyword 2000): A communication protocol used by some older Mercedes-Benz vehicles.

- K-Line: A single-wire communication protocol used by some older Mercedes-Benz vehicles.

5.2. Identifying the Correct Protocol for Your Mercedes-Benz

Identifying the correct diagnostic protocol for your Mercedes-Benz vehicle is essential for selecting a compatible scan tool. Consult your vehicle’s service manual or a reliable online resource to determine the correct protocol. You can also try using an OBD2 scan tool to see if it can communicate with your vehicle. If the OBD2 scan tool cannot establish a connection, your vehicle may use a different protocol.

5.3. Scan Tool Features to Look For

When selecting a scan tool for your Mercedes-Benz vehicle, look for the following features:

- OBD2 Compatibility: Ensure that the scan tool is compatible with the OBD2 protocol.

- CAN Support: If your vehicle uses the CAN protocol, ensure that the scan tool supports it.

- Mercedes-Benz Specific Coverage: Look for scan tools that specifically mention Mercedes-Benz coverage. These tools typically include the necessary software and adapters to communicate with Mercedes-Benz vehicles.

- DTC Reading and Clearing: The ability to read and clear DTCs from all ECUs in the vehicle.

- Real-Time Data Streaming: Access to real-time data from sensors and components.

- Component Testing: The ability to perform component tests to verify the functionality of individual components.

- Control Unit Programming: The ability to program and calibrate control units (for advanced users).

5.4. OEM vs. Aftermarket Scan Tools for Mercedes-Benz

When choosing a scan tool for your Mercedes-Benz vehicle, you have two main options: OEM (Original Equipment Manufacturer) scan tools and aftermarket scan tools.

- OEM Scan Tools: These are the diagnostic systems used by Mercedes-Benz dealerships, offering the most comprehensive coverage and functionality. However, they are typically very expensive and may require a subscription to access the software and updates.

- Aftermarket Scan Tools: These are diagnostic systems developed by third-party manufacturers that offer similar functionality to the OEM systems. They can be a cost-effective alternative to the OEM systems, but it’s important to choose a reputable brand that offers good coverage and support.

5.5. Top Scan Tool Brands for Mercedes-Benz Vehicles

Several scan tool brands are popular among Mercedes-Benz technicians and enthusiasts:

- Mercedes-Benz XENTRY: The official dealer-level diagnostic system for Mercedes-Benz vehicles.

- Autel: A popular aftermarket brand that offers a wide range of diagnostic tools for Mercedes-Benz vehicles.

- iCarsoft: A more affordable option that offers decent coverage for Mercedes-Benz vehicles.

- Launch: Another popular aftermarket brand that offers a variety of diagnostic tools for Mercedes-Benz vehicles.

5.6. Updating Scan Tool Software for Mercedes-Benz Models

Keeping your scan tool’s software up to date is essential for ensuring accurate and reliable diagnostics. Diagnostic tool manufacturers regularly release software updates that include new vehicle coverage, bug fixes, and enhanced functionality. Check the manufacturer’s website for information on how to update your tool’s software.

5.7. Using Scan Tools for Specific Diagnostic Tasks

Scan tools can be used for a variety of diagnostic tasks on Mercedes-Benz vehicles, including:

- Reading and Clearing DTCs: Identifying and clearing diagnostic trouble codes.

- Diagnosing Engine Problems: Troubleshooting engine-related issues, such as misfires, poor performance, and emissions problems.

- Diagnosing Transmission Problems: Troubleshooting transmission-related issues, such as slipping, rough shifting, and failure to engage.

- Diagnosing ABS Problems: Troubleshooting ABS-related issues, such as brake failure and warning lights.

- Diagnosing Airbag Problems: Troubleshooting airbag-related issues, such as warning lights and deployment failures.

- Performing Component Tests: Verifying the functionality of individual components, such as sensors, actuators, and solenoids.

- Programming Control Units: Programming and calibrating control units (for advanced users).

6. Practical Solutions for Mercedes-Benz Diagnostics

Effective diagnostics for Mercedes-Benz vehicles require a combination of the right tools, knowledge, and techniques. By understanding common diagnostic challenges and implementing practical solutions, technicians and enthusiasts can ensure accurate and efficient troubleshooting.

6.1. Common Diagnostic Trouble Codes (DTCs) in Mercedes-Benz Vehicles

Understanding common DTCs in Mercedes-Benz vehicles can help technicians quickly identify and address common problems. Some of the most common DTCs include:

- P0171 and P0174: System Too Lean (Bank 1 and Bank 2) – These codes often indicate a vacuum leak, a faulty mass airflow (MAF) sensor, or a problem with the fuel system.

- P0300: Random Misfire Detected – This code indicates that the engine is misfiring, which can be caused by a variety of factors, such as faulty spark plugs, ignition coils, or fuel injectors.

- P0420: Catalyst System Efficiency Below Threshold (Bank 1) – This code indicates that the catalytic converter is not functioning properly, which can lead to emissions problems.

- P0715: Input/Turbine Speed Sensor Circuit Malfunction – This code indicates a problem with the input or turbine speed sensor in the transmission.

- C1000: BAS (Brake Assist System) Control Module – This code indicates a problem with the BAS control module.

6.2. Step-by-Step Diagnostic Procedures

Following a step-by-step diagnostic procedure can help technicians systematically troubleshoot problems and avoid unnecessary repairs. A typical diagnostic procedure includes the following steps:

- Verify the Complaint: Confirm the customer’s complaint and gather as much information as possible about the problem.

- Check for DTCs: Use a scan tool to check for DTCs in all relevant ECUs.

- Research the DTCs: Consult a service manual or a reliable online resource to research the DTCs and understand their possible causes.

- Perform Visual Inspection: Perform a thorough visual inspection of the vehicle, looking for obvious problems such as damaged wiring, loose connections, and leaking fluids.

- Perform Component Testing: Use a scan tool or other diagnostic equipment to perform component tests to verify the functionality of individual components.

- Analyze the Data: Analyze the data gathered from the DTCs, visual inspection, and component testing to identify the most likely cause of the problem.

- Repair the Problem: Repair the problem according to the manufacturer’s recommended procedures.

- Verify the Repair: After completing the repair, verify that the problem has been resolved and that no new DTCs have been set.

6.3. Using Wiring Diagrams and Technical Information

Wiring diagrams and technical information are essential for diagnosing complex problems in Mercedes-Benz vehicles. These resources provide detailed information about the vehicle’s electrical systems, sensor specifications, and repair procedures. Access to accurate and up-to-date wiring diagrams and technical information is crucial for any technician working on Mercedes-Benz vehicles.

6.4. Diagnosing Intermittent Problems

Diagnosing intermittent problems can be particularly challenging, as the problem may not be present when the vehicle is being inspected. In these cases, it’s important to gather as much information as possible about the conditions under which the problem occurs. This information can help you narrow down the possible causes of the problem and identify the components that are most likely to be involved.

6.5. Using Real-Time Data to Diagnose Problems

Real-time data can be a valuable tool for diagnosing problems in Mercedes-Benz vehicles. By monitoring the data from various sensors and components, technicians can gain insights into the vehicle’s performance under different operating conditions. This information can help them identify problems that may not be apparent from DTCs alone.

6.6. Tips for Effective Mercedes-Benz Diagnostics

Here are some tips for effective Mercedes-Benz diagnostics:

- Use the Right Tools: Use the right diagnostic tools for the job, including a scan tool, multimeter, and other specialized equipment.

- Stay Up-to-Date: Stay up-to-date on the latest diagnostic techniques and repair procedures.

- Follow a Systematic Approach: Follow a systematic approach to troubleshooting problems, starting with the basics and working your way up to more complex issues.

- Gather Information: Gather as much information as possible about the problem, including the customer’s complaint, DTCs, and visual inspection findings.

- Analyze the Data: Analyze the data gathered from the various diagnostic tests to identify the most likely cause of the problem.

- Verify the Repair: After completing the repair, verify that the problem has been resolved and that no new DTCs have been set.

6.7. Resources for Mercedes-Benz Technicians

Several resources are available to help Mercedes-Benz technicians improve their diagnostic skills:

- Mercedes-Benz WIS (Workshop Information System): The official online resource for Mercedes-Benz repair information.

- ALLDATA: A subscription-based service that provides access to a wide range of repair information, including wiring diagrams, technical specifications, and repair procedures.

- Mitchell 1: Another subscription-based service that provides access to repair information.

- Online Forums: Online forums can be a valuable resource for sharing information and getting help from other Mercedes-Benz technicians.

- Training Courses: Several training courses are available to help Mercedes-Benz technicians improve their diagnostic skills.

7. The Future of Vehicle Diagnostics

The field of vehicle diagnostics is constantly evolving, driven by advancements in technology and the increasing complexity of modern vehicles. Understanding these trends is crucial for technicians and enthusiasts to stay ahead of the curve.

7.1. Advancements in Diagnostic Technology

Several advancements in diagnostic technology are shaping the future of vehicle diagnostics:

- Wireless Diagnostics: Wireless scan tools and diagnostic systems are becoming increasingly popular, allowing technicians to move freely around the vehicle while performing diagnostic tests.

- Cloud-Based Diagnostics: Cloud-based diagnostic systems provide access to a vast database of repair information, wiring diagrams, and technical specifications. They also allow technicians to collaborate with other technicians and access remote diagnostic support.

- Artificial Intelligence (AI) in Diagnostics: AI is being used to develop diagnostic systems that can automatically analyze data from sensors and components to identify the most likely cause of a problem.

- Augmented Reality (AR) in Diagnostics: AR is being used to develop diagnostic systems that can overlay diagnostic information onto the technician’s view of the vehicle, providing step-by-step instructions and guidance.

- Remote Diagnostics: Remote diagnostics allow technicians to diagnose and repair vehicles from a remote location, using telematics data and remote access to the vehicle’s systems.

7.2. The Role of Telematics in Vehicle Diagnostics

Telematics, the use of wireless communication technologies to transmit data from vehicles, is playing an increasingly important role in vehicle diagnostics. Telematics data can be used to:

- Monitor Vehicle Health: Telematics systems can continuously monitor the vehicle’s systems and alert the driver or a remote diagnostic center to potential problems.

- Predictive Maintenance: Telematics data can be used to predict when maintenance is needed, allowing vehicle owners to schedule maintenance before problems occur.

- Remote Diagnostics: Telematics data can be used to diagnose and repair vehicles from a remote location.

- Over-the-Air (OTA) Updates: Telematics systems can be used to deliver OTA updates to the vehicle’s software, fixing bugs and adding new features.

7.3. The Impact of Electric Vehicles (EVs) on Diagnostics

Electric vehicles (EVs) are presenting new challenges and opportunities for vehicle diagnostics. EVs have fewer mechanical components than traditional gasoline-powered vehicles, but they have more complex electrical systems. This means that technicians need to be trained on the specific diagnostic procedures for EVs, and they need to have the right tools and equipment to work on these vehicles.

7.4. The Importance of Training and Certification

As vehicle technology becomes increasingly complex, training and certification are becoming more important than ever for vehicle technicians. Technicians need to stay up-to-date on the latest diagnostic techniques and repair procedures, and they need to have the skills and knowledge to work on a wide range of vehicles.

7.5. Preparing for the Future of Vehicle Diagnostics

To prepare for the future of vehicle diagnostics, technicians and enthusiasts should:

- Invest in Training: Invest in training courses and certifications to stay up-to-date on the latest diagnostic techniques and repair procedures.

- Stay Informed: Stay informed about the latest advancements in diagnostic technology.

- Develop Skills: Develop skills in electrical diagnostics, computer networking, and software programming.

- Invest in Tools: Invest in the right diagnostic tools and equipment for the vehicles you work on.

- Network with Other Technicians: Network with other technicians and share information and experiences.

8. Frequently Asked Questions (FAQs) About OBD1 and OBD2 Compatibility

Here are some frequently asked questions about OBD1 and OBD2 compatibility:

8.1. What does OBD stand for?

OBD stands for On-Board Diagnostics. It is a system that monitors a vehicle’s performance and alerts the driver to potential problems.

8.2. Is my car OBD1 or OBD2?

Most vehicles manufactured after 1996 are OBD2 compliant. Vehicles manufactured before 1996 are typically OBD1. You can check your vehicle’s service manual or look for the OBD2 connector under the dashboard to confirm.

8.3. Can I use an OBD2 scanner on an OBD1 car with an adapter?

No, an OBD2 scanner cannot directly read an OBD1 car, even with an adapter. The adapter only changes the connector type, not the communication protocol.

8.4. What is the difference between OBD1 and OBD2?

OBD1 is a non-standardized system with manufacturer-specific connectors, communication protocols, and diagnostic codes. OBD2 is a standardized system with a universal connector, communication protocols, and diagnostic codes.

8.5. What are the benefits of OBD2?

OBD2 offers several benefits, including standardized diagnostic codes, comprehensive system monitoring, real-time data streaming, and improved emissions control.

8.6. What is a DTC?

DTC stands for Diagnostic Trouble Code. It is a code that indicates a problem with a vehicle’s system.

8.7. Where can I find the OBD port in my car?

The OBD2 port is typically located under the dashboard, near the steering column. The OBD1 port location varies depending on the vehicle’s make and model.

8.8. What is a scan tool?

A scan tool is a device used to communicate with a vehicle’s computer and retrieve diagnostic information, such as DTCs and real-time data.

8.9. How do I update my scan tool software?

Check the scan tool manufacturer’s website for information on how to update your tool’s software.

8.10. What is the future of vehicle diagnostics?

The future of vehicle diagnostics includes advancements in wireless diagnostics, cloud-based diagnostics, artificial intelligence (AI), augmented reality (AR), and remote diagnostics.

9. Call to Action

Navigating the complexities of OBD1 and OBD2 compatibility, particularly for Mercedes-Benz vehicles, can be challenging. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we understand these challenges and offer expert guidance, tools, and services to help you diagnose, repair, and maintain your Mercedes-Benz. Whether you’re looking for the right diagnostic tool, need assistance with unlocking hidden features, or require step-by-step repair instructions, we’re here to assist.

Contact us today for personalized assistance and unlock the full potential of your Mercedes-Benz:

- Address: 789 Oak Avenue, Miami, FL 33101, United States

- WhatsApp: +1 (641) 206-8880

- Website: MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

Let MERCEDES-DIAGNOSTIC-TOOL.EDU.VN be your trusted partner in Mercedes-Benz diagnostics and maintenance.